5 GHz Project: CPU Cooling With Liquid Nitrogen

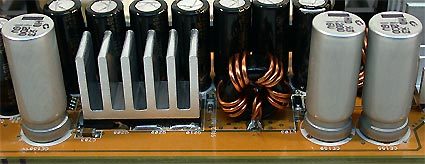

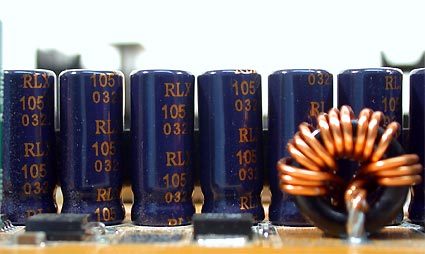

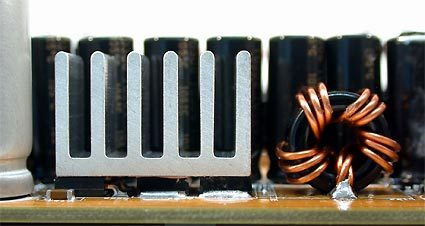

100 Amperes On The Switching Regulator: Modifications To The Asus P4C800-E

According to VRM [voltage regulator module] specifications, the voltage regulator on a modern motherboard is designed for a maximum current of almost 90 amperes. That means that sufficient safety reserves are available for normal operation - even when running the Pentium 4 3.2 EE (based on the Prestonia core in Intel’s Xeon) with heat dissipation of 94 watts.

At a core voltage of 1.525 volts that means a healthy 62 amperes. In our extreme overclocking attempt to over 5 GHz, heat dissipation briefly rises to up to 180 watts - at a CPU core voltage of 1.88 volts. In plain language that means that the voltage regulator is subjected to 96 amperes. To illustrate the enormous voltages bearing down on the regulator on an extremely overloaded motherboard, consider that the mains supply in a single-family home is usually designed for just under 80 amperes - at 230 volts, mind you.

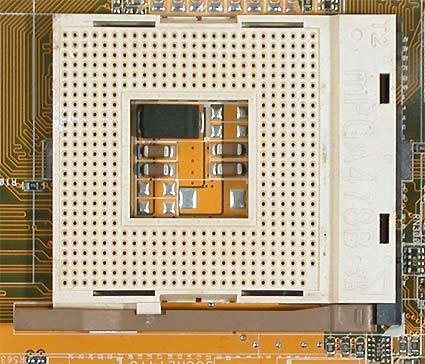

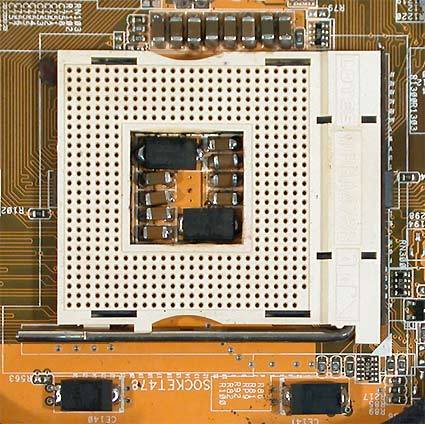

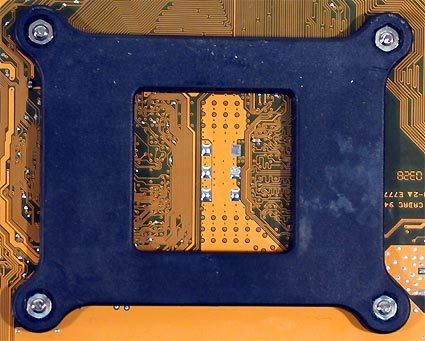

Asus made other changes to the CPU socket. The following images show the differences between a regular P4C800-E and our converted motherboard for extreme tweaking.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: 100 Amperes On The Switching Regulator: Modifications To The Asus P4C800-E

Prev Page Insulation To Counter Condensation Build-up Next Page Preconditioning: Dual Cooling Of Northbridge And CPU-

Now, with that big of a heatsink how do you plan to close the tower? How do you plan to renew the liquid nitrogen without blowing up your PCReply

-

you will notice that this was done outside... so not very safe I bet. Also you would never be able to keep switching the system on and off as the ice would damage the pcReply

-

NEOhm I couldn't help but think that there was a lot more they could have done to insulate the rest of the system from the CPU's immediate area .... I'm sure this system must have gone onto a crashing spree once all that ice built up and started short-circuiting all those electronics around the CPU's base .... for one example, they could have gone as far as to coating that area with silicone, i would think; or in the vary least, covering that area more to protect from the super cooled 'steam' flowing over the top of the copper tube and down onto the motherboard.Reply

Secondly, the over-use of thermal pastes ... from my understanding, application of thermal paste between a chip and a heatsink is supposed to be EXTREMELY THIN and evenly spread; any excess paste REDUCES thermal performance and just splotching it on can easily introduce air bubbles which would cause 'hot-spots' wherever a bubble lies.

If your going to draw attention to yourself by breaking some world records, it would be probably a good idea to do everything you can to make everything as perfect as can be ... for example, cleaning up the copper soldiering residues to 'good enough' levels isn't Good Enough!, go all the way and use scouring pads, polish and some attention to detail and people will respect you the more for your efforts and clean presentation. A key to success in life = Strive for excellence in whatever you do! Don't settle for second-best. -

Zorg I know it's late, but you guys are clowns.Reply

They did it and then took it apart and threw it in a box. Sorry it won't fit in a case and it wasn't shiny enough for you nitpickers.

Let me know how cool yours is when you get done.

If you're going to post garbage then don't post at all.