APC BX1000 Click-of-Death Repair

Capacitors: Can’t Live With ‘Em, Can’t Live Without ‘Em

And there's another repair in the books where the failure point was a $0.10 capacitor. I looked at waveforms around all other electrolytic capacitors on the board and did not find any showing significant noise across their terminals, which lends some credibility to my hypothesis that the single capacitor failure may have been an isolated material, manufacturing, or handling defect. Then again, the other capacitors aren’t being fed from a charge pump at 2kHz. The main charging supply rail capacitor is powered from a 300kHz flyback circuit, the 12V rail is powered from the battery/charging rail by a linear regulator, and although I didn’t find it, the micro-controller must be powered by the 12V rail through a linear regulator as well. I must admit I did not really hunt for the 5V as all I needed was to measure it and verify that it looked good. If a supply rail looks good near its load, it will usually be at least as good closer to its source.

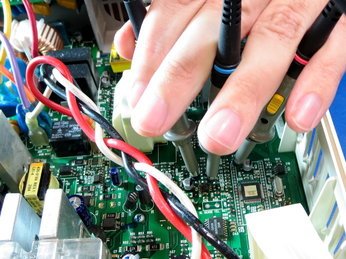

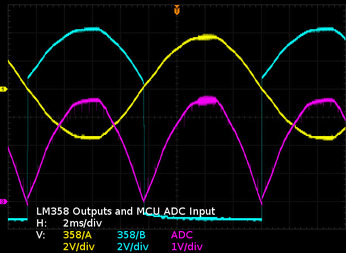

While scratching my head about how the negative output spikes appeared to cause the micro-controller to reset, I decided to have a look at what sort of waveform the micro-controller receives from the LM358 by simultaneously probing both of the LM358’s outputs and the micro-controller ADC input. Holding three probes with one hand so I have the other free to take pictures/pause the oscilloscope can be challenging. When I probed the ADC pin prior to replacing the cap, the input signal looked similar to the chopped up LM358 output. Because of that, I did not bother saving it. After the repair though, everything made a lot more sense: the second LM358 channel is used in conjunction with the diodes around it to simulate an ideal diode bridge and present a 0-5V rectified input to the micro-controller. This eliminates the need for the micro to have an ADC capable of dealing with negative voltages. Unipolar chip pins rarely appreciate being pulled more than 500-700mV below ground as this may cause their transistors and diodes to uncontrollably conduct when they aren’t supposed to. Depending on the chip and circuit design, this can lead to issues ranging from random malfunctions to catastrophic failure.

There you have it: if you happen to own a circa-2005 APC BX/RS/XS 1000/1300/1500 UPS with a chronic clicking behavior, you now know that C41 (or whatever the negative supply bypass capacitor near the op-amp handling line voltage sensing might be labeled) should be high on your suspect list. I know I opened this story by saying that I was highly optimistic for a simple definitive fix, but I still imagined I was going to find more than one failed capacitor involved.

What am I going to do with my newly-restored BX1000 when I already have more battery backup than I know what to do with? I have at least two ideas, but they will have to wait until I have more test equipment and parts to experiment with. If there is something in particular you would like to see me do, though, let me know in the comments!

MORE: APC BR1000G Tear-Down

MORE: APC BN650M1-CA Tear-Down

MORE: APC BGE90M-CA Tear-Down

Follow us on Facebook, Google+, RSS, Twitter and YouTube.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Capacitors: Can’t Live With ‘Em, Can’t Live Without ‘Em

Prev Page What Is A Charge Pump?-

Zaxx420 'Now on to the next one: why did the capacitor fail in the first place?'Reply

That's one aspect that sooo many folks never consider or can't be bothered to investigate. Just like a fuse that keeps blowing...there is something that's causing it to blow...even if it lasts a while before blowing. Even worse is when they decide to bridge it with a piece of wire or wrap the blown (glass) fuse with aluminum foil. Now I'm guilty as well but ONLY long enuff to get myself out of a jam...like being stranded on the side of the road or something. Just never do it with a high current load or if it's blowing the instant you turn it on...and never with a sensitive/expensive critical component like the ignition ECU of your self semi-restored muscle car project...don't ask. -

Daniel Sauvageau Reply

The repair is already done and I'm not set up for recording - don't even own a video camera or webcam. Even if I did own one, I'm no good with talking and working at the same time. Also, if I posted repairs on YouTube, I wouldn't be able to post them on THG since THG is paying me for exclusive publication.18828366 said:When you do fix it, can you YouTube it?

Too much credit :) This is basic troubleshooting, anyone going through electronics tech training should be able to do as before graduation.18830162 said:You are so smart.

-

jcamilo70 I have a 2005 RS1200 that died on me, making clicking sound constantly, and only turning on directly into battery mode.Reply

Where did you manage to get the replacement pieces? Where could I find the micro-controller for this unit or how should I identify its part number in order to look for it? -

Daniel Sauvageau Reply

The only part I needed to replace here was that single capacitor. Where did I get the capacitor from? It was just one of many leftover parts I've accumulated either from ordering more parts than necessary for past repairs/projects, or parts I had ordered for potential future projects to pad orders for free S&H. I may have over $2000 worth of parts in my spare parts and samples boxes.18830308 said:I have a 2005 RS1200 that died on me, making clicking sound constantly, and only turning on directly into battery mode.

Where did you manage to get the replacement pieces? Where could I find the micro-controller for this unit or how should I identify its part number in order to look for it?

For the micro-controller, I didn't touch it. Even if I had wanted to replace it, they can only be ordered blank from parts distributors (or pre-programmed with your own firmware for large enough orders or distributors that offer such a service for an additional fee) and those would be no good without the correct firmware to put on them. If the controller died, it is game over unless you can find a donor UPS based on the same PCB. -

powernod This example showed us the importance of high quality caps to be used in such critical components such as a UPS/PSU. A single cap-failure (*from the many a UPS uses) and caused total malfunction of the UPS !!Reply

P.S. This review has also shown us the importance/need for UPSs reviews. Since PSUs are being thoroughly reviewed for many years, i don't understand why UPSs shouldn't be reviewed as well!! A PSU's proper operation is in consequence with the proper operation of the hardware that "feeds" a PSU (*UPS)

P.S.2 : Great article by the way!!