Tom's Hardware Verdict

The Creality Ender 5 S1 is faster with more features than the previous versions of the open frame printer.

Pros

- +

Quality prints

- +

All Metal Hotend

- +

Improved Speed

- +

Direct drive

- +

Auto bed leveling

- +

Easy to navigate menu

Cons

- -

Mislabeled nozzle

- -

Print surface easily damaged

- -

Leveling directions are incorrect in the quick start guide

Why you can trust Tom's Hardware

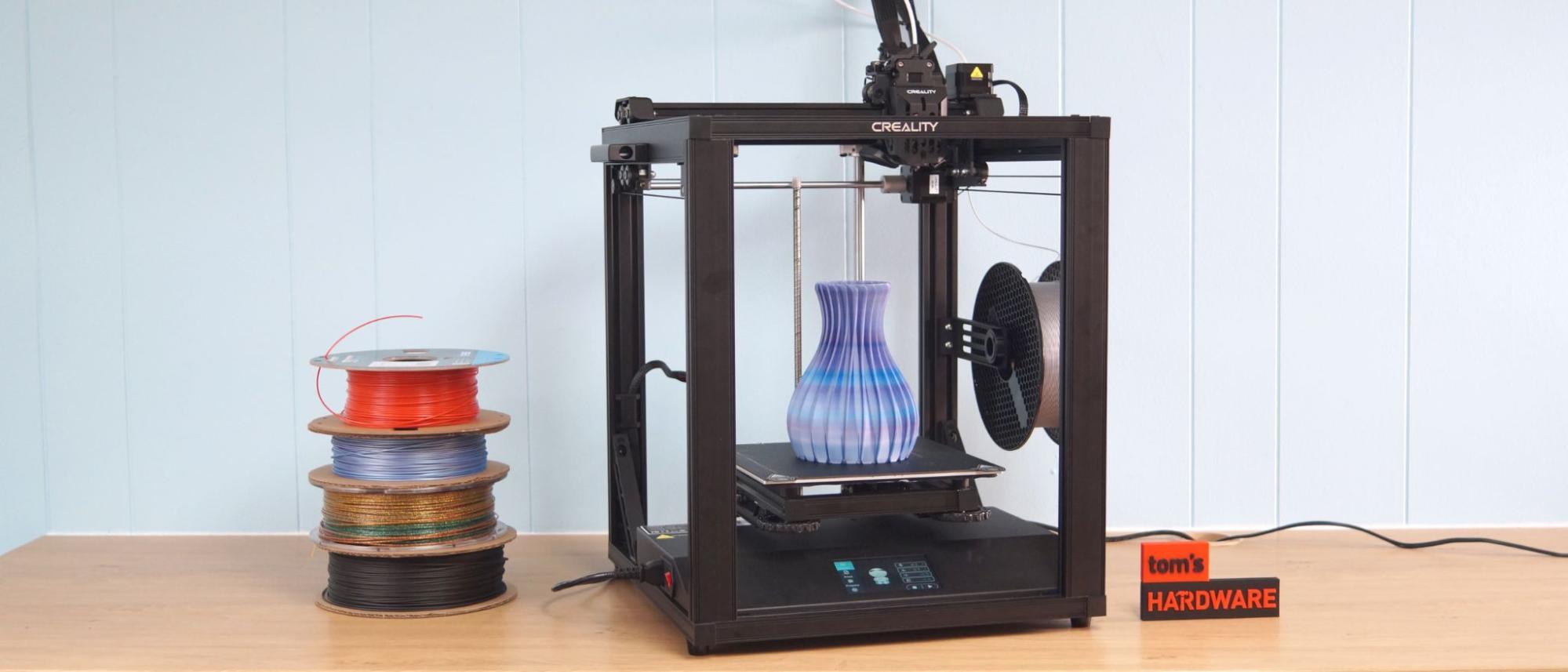

Creality’s Ender 5 S1 is the latest rendition of its sturdy cube printer. Significant improvements have been made to the design, such as adding an all metal hotend, direct drive, auto bed leveling and a beefier, reinforced frame.

Retailing at $559 and ready to compete with the best 3D printers on the market, the Ender 5 S1 has a print volume similar to the less expensive Ender 3 S1 (with a bonus 10mm in height) but is more stable on the Z axis and more compact. This is because the print bed moves up and down, rather than back and forth. It’s not a Core XY machine, where the X and Y axis are driven together by belts, but it IS a lot smoother.

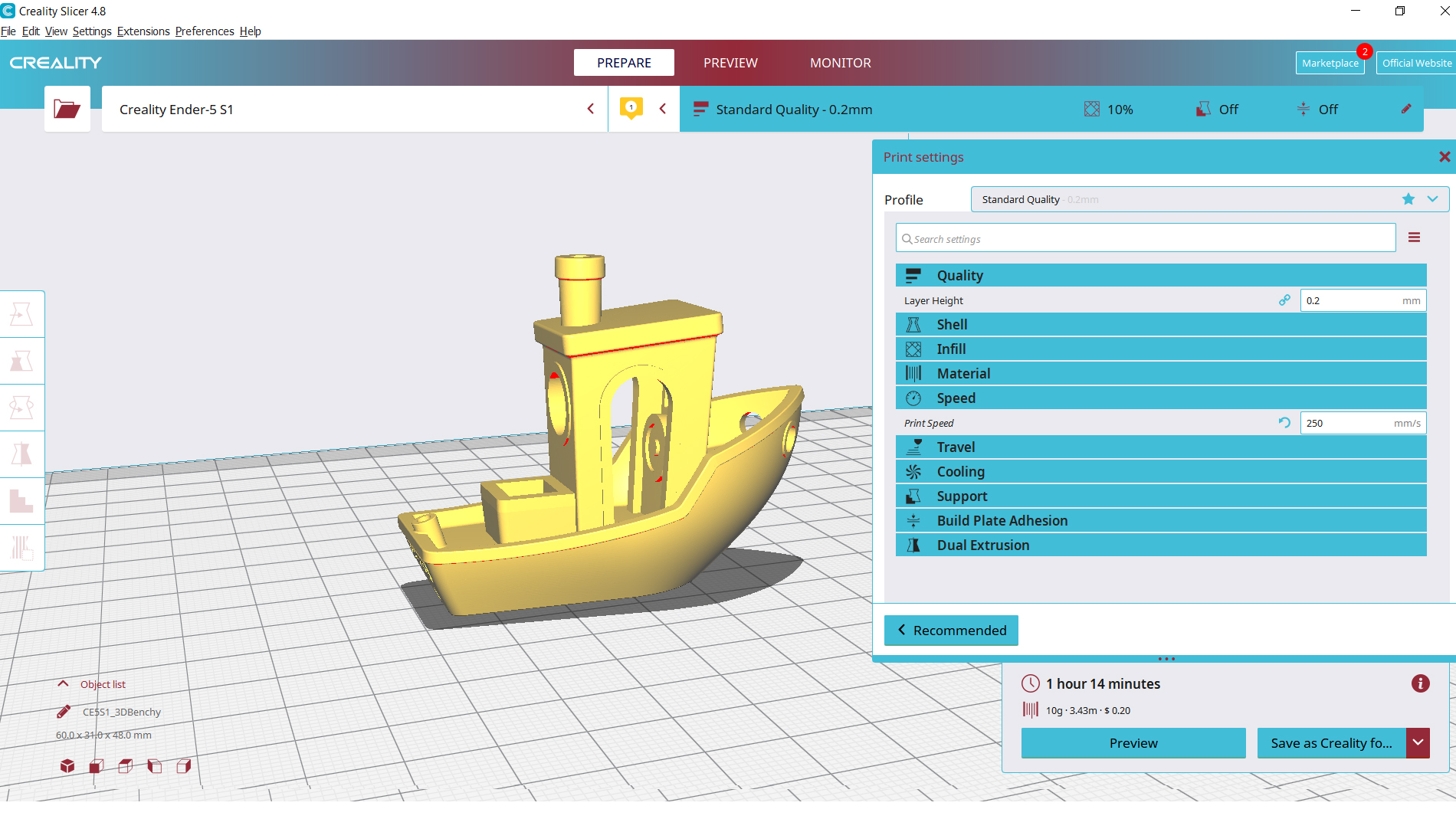

Creality claims the Ender 5 S1 can run at a blazing 250 mm/s, but the profile included with Creality Slicer is a more subdued 120 mm/s. When I changed the setting to 250 mm/s, prints were only a little bit faster. This is largely due to limits in acceleration – no printer can instantaneously hit maximum speeds then maintain them while going around corners.

Despite this, the machine is fairly fast for one still running Marlin. Its acceleration firmware limit is 3000 mm/s – whereas an Ender 3 S1 Pro is held to 500 mm/s. We can’t wait to see how much speed it gains when it is hooked to a Creality Sonic Pad and allowed to run on Klipper in a future review.

The Ender 5 S1 is equipped with a lightweight direct drive with an all metal hotend, something I love seeing on new printers. The melt zone for this hotend was borrowed from the Spider high temperature hotend, which improves the flow rate at the cost of requiring a longer nozzle. This could confuse buyers who accidentally buy the traditional MK8 nozzle used in every other Creality machine and find it doesn’t work with the Ender 5 S1.

Specifications: Creality Ender 5 S1

| Build Volume | 220 x 220 x 280 mm (8.7 x 8.7 x 11 in) |

| Material | PLA/PETG/ABS (up to 300 degrees) |

| Extruder Type | Direct Drive |

| Nozzle | .4mm Spider |

| Build Platform | PC Spring Steel, Heated |

| Bed Leveling | CR Touch Auto Leveling |

| Filament Runout Sensor | Yes |

| Connectivity | SD card, USB Type-C |

| Interface | 4.3 inch color touchscreen |

| Machine Footprint | 425x 460 x 570 mm (16.7 x 18.1 x 22.4 in) |

| Machine Weight | 12.1 kg (26.6 lbs) |

Included in the box: Creality Ender 5 S1

The Creality Ender 5 S1 comes with everything you need to get started: tools to build and maintain the printer, a big nozzle cleaner, side cutters, a scraper and an SD card with USB adapter. You also get a spare nozzle and a 200 gram sample of white PLA.

There’s a paper copy of the quick start guide to help you get set up. The SD card has three test models, the full manual in PDF format and a video to help you assemble it.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The leveling directions in the paper quick start guide I received were incorrect. Please use the PDF for guidance.

Assembling the Creality Ender 5 S1

The Ender 5 S1 is a DIY kit, and needs quite a lot of assembly. I was able to build it in about an hour, but if this is your first kit printer you may need to set aside a bit more time. Though the parts were clearly labeled, the build guide was difficult to follow in spots and I ended up putting a few things on backwards. This caused some delay and frustration.

Watching the included build video is quite helpful and I recommend digging it out of the box and watching it first.

Leveling the Creality Ender 5 S1

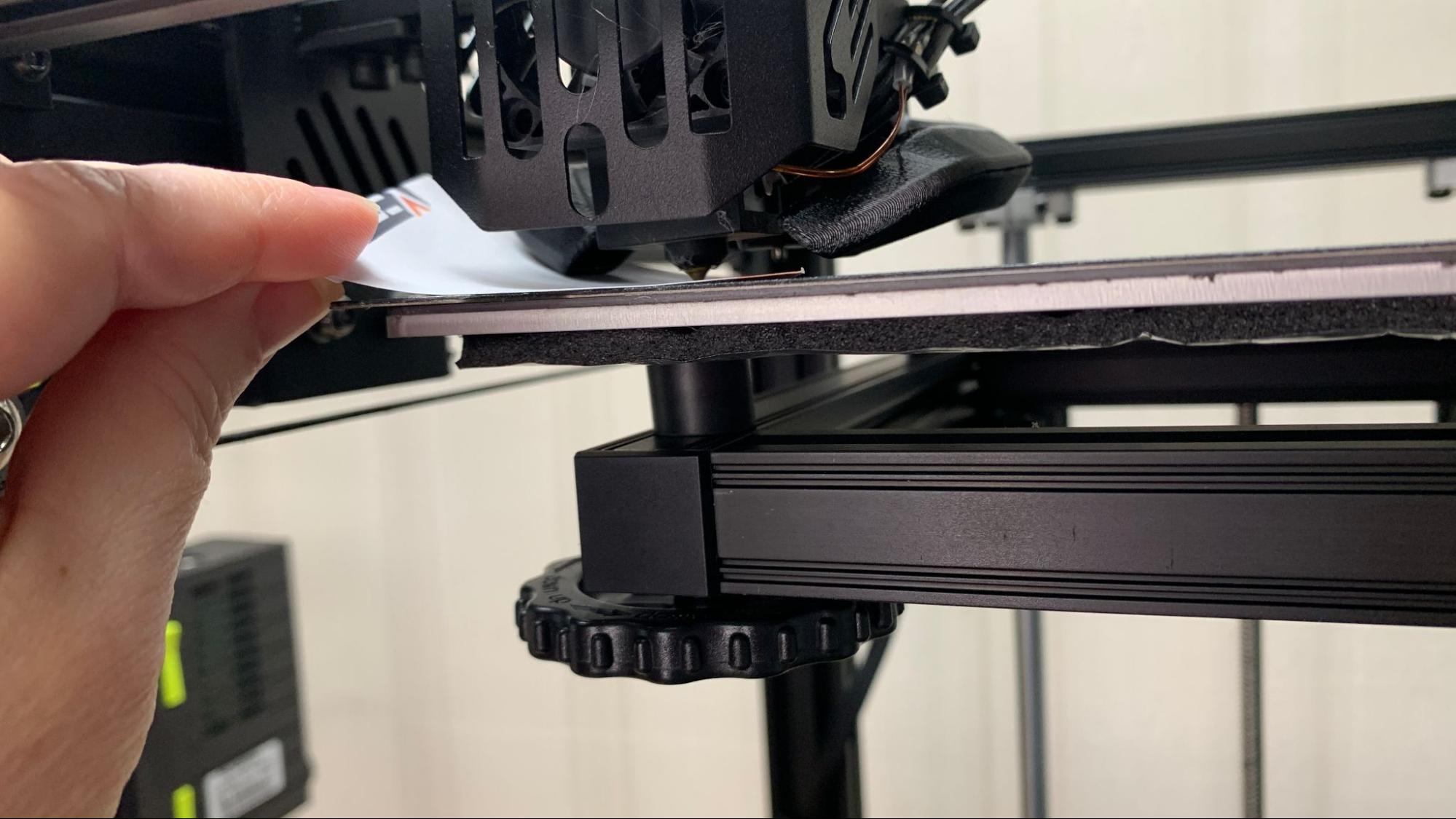

The Ender 5 S1 Pro comes with a CR Touch installed, making leveling more accurate if not simpler. You still need to manually adjust the bed via adjustment screws, then the CR Touch probes the surface and compensates for any deformities in the bed.

The quick start guide has the wrong directions for leveling this machine. I followed these directions and the knobs nearly fell off.

The correct directions are in the PDF manual.

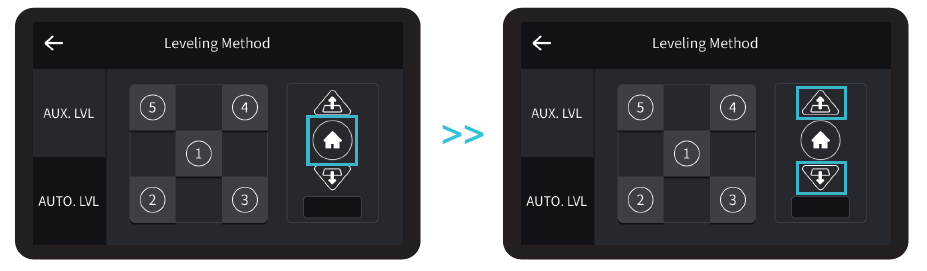

First select Leveling Method from the settings menu. Next, click the home button (a house icon) which brings the bed up to zero. Click the up arrows until the bed is nearly touching the nozzle.

Slide a piece of paper under the nozzle, and click one of the corners (labeled 2 - 5) and manually adjust the bed so that the nozzle scrapes the paper. Do this for each corner.

After manually leveling, click AUTO LVL →Start and the printer will immediately go into its leveling routine. It will tap 16 points across the bed with a metal probe and create a mesh to smooth out any high or low spots on the bed.

You’re not done yet – after the Auto Level you need to check the final Z Offset. Click the Home button again and slide a piece of paper under the nozzle. If you can’t get paper under the nozzle, tap the down button until you can. Now adjust this until the paper scrapes the nozzle.

It's difficult to get the Z height perfect using the paper method, but you can easily make adjustments on the fly during your first print. Observe the first layer going down, and if the nozzle needs to be closer or farther, tap the Z button on the screen and make an adjustment.

Loading Filament in the Creality Ender 5 S1

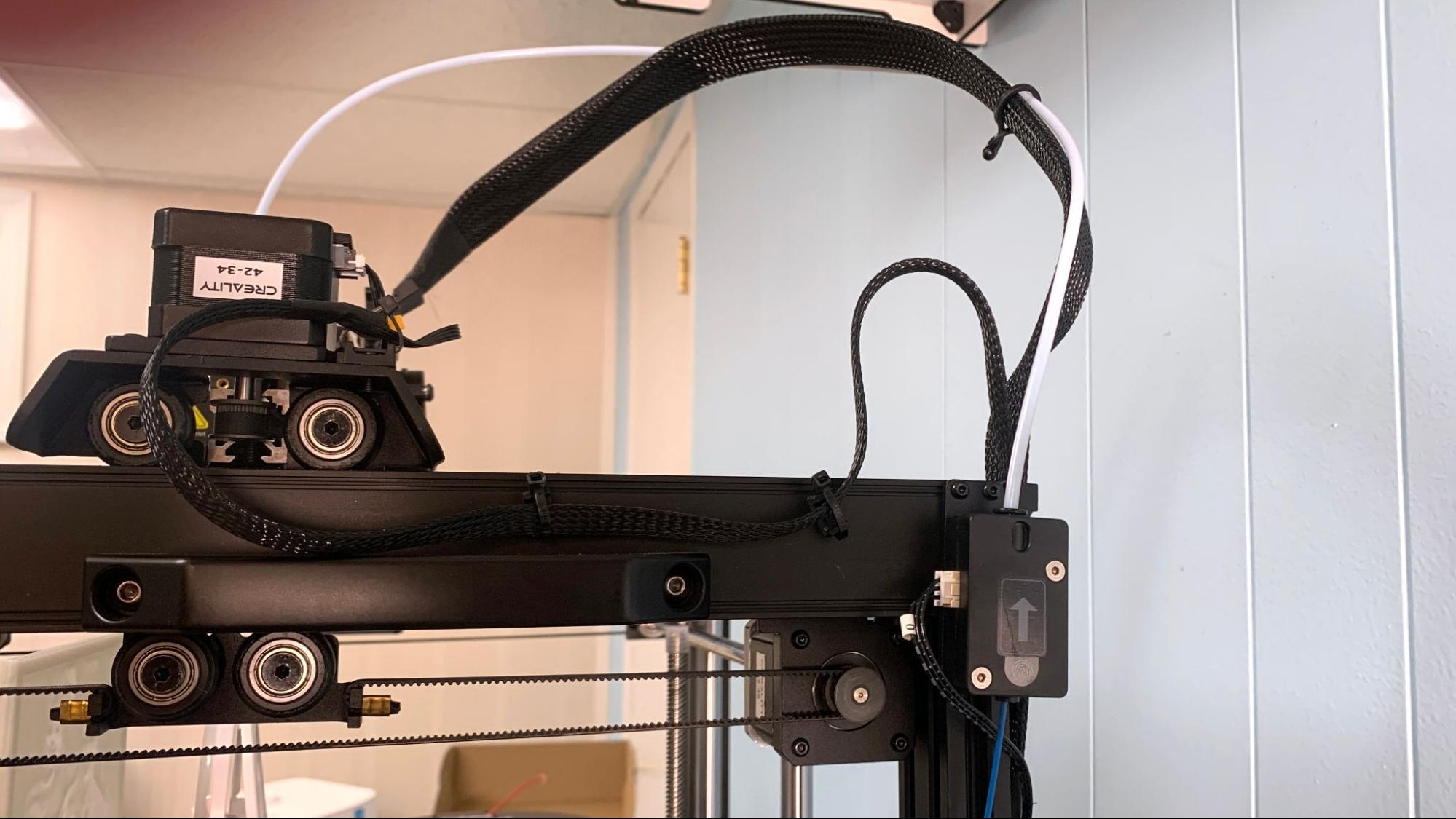

The Ender 5 S1 has a direct drive with a reverse Bowden tube to guide filament up from a side mounted spool holder. To load filament you need to first trim the end of the plastic at a 45-degree angle – a pointy end feeds through the gears better.

Filament is pushed through the run out sensor on the top corner of the frame, then through the Bowden tube and into the direct drive. The tube is not clamped onto the extruder, so you can pull it off in order to see the filament. I find it easier to push back the tension lever and physically push the first few inches of filament into the drive.

Preheat the hotend by pushing Prepare on the main menu, then selecting the PLA or ABS present. You can also enter your own temperature. Once the hotend reaches the proper temperature, switch to the In/out menu (located at the bottom of the screen) and enter a number of millimeters to advance the filament. 50 mm is a good number to start – you may need to run more if you’re switching from a bold to light color.

Design of the Creality Ender 5 S1

The Ender 5 S1 is an open frame 3D printer with a clean, compact design and relatively small footprint. The bed moves up and down rather than back and forth, yielding a smoother print that doesn’t suffer from Z wobble at taller heights.

Cable management is excellent on this updated version – I’ve seen older Ender 5 machines where bare wiring is allowed to run amok carelessly. This printer comes with a handful of custom clips as well as black zip ties to neatly secure the bundled wire to its frame.

The printer’s case and touch screen are combined into one smooth unit at the base of the machine and the spool holder is mounted sideways to the frame. All this keeps the footprint small and mostly square.

Another improvement in design is the addition of bracing – a pair of brackets steady the frame and two more are underneath the build plate.

Creality added hollow silicone bed mounts which fit over the leveling springs. Normally solid silicone mounts are used INSTEAD of springs. The theory is solid silicone mounts are more stable than springs and won’t vibrate loose over time. However, the unit I tested slipped out of level after a few days of printing. The leveling knobs don’t have a tight grip on the screw, which could be allowing them to slowly loosen after many hours of printing. Adding lock nuts or even a light threadlock to the leveling screws could help.

The direct drive installed on this printer is said to be a Sprite, which I reviewed on the Ender 3 S1 Pro. However, this particular tool head has a custom cooling system and a hotend with aspects similar to Creality’s new high temperature Spider hotend.

This is one of those good news/bad news things. The good news is the cooling systems has a larger 5015 fan with wrap-around ducts channeling air to both the left and right sides. More good news is the Spider-like hotend has a titanium alloy heat break and a larger heater block – this allows filament to flow hotter and print faster. All metal hotends also jam less frequently since there’s no PTFE tube touching the metal where it can start to burn and degrade with time.

The bad news is the larger Spider melt zone requires a longer Spider nozzle. Nowhere in either manual does Creality tell you the nozzle is non-standard.

The Spider nozzle lands somewhere between E3D’s Volcano and Creality’s normal MK8 nozzle. It’s been out long enough – this nozzle was first used in the Ender 7 – that third party manufacturers like Microswiss started making upgraded replacement nozzles, so you’ll have choices when shopping for replacements. But you need to know what you’re looking for.

I’m concerned that calling this new tool head a Sprite and not a Spider will lead to someone attempting to stick an ordinary MK8 into their Ender 5 S1 extruder. It will fit – the diameter remains the same, but the shorter length will leave a gap and cause filament to puddle within and form a nasty clog.

The removable build plate is made of coated flexible steel, which is awesome. The surface is a bit of a let down since the soft PC coating is easily damaged. My plate already suffered a few scratches, including a deep gouge resulting from that typo I talked about in the leveling directions. The surface does a good job of holding onto prints, but if your Z height is a bit too close you’ll end up embedding plastic into the surface. No fun.

Thankfully the bed is a standard Ender size and the plate can be easily replaced. I’d recommend swapping it with this double-sided PEI plate from Comgrow that has both smooth and textured surfaces.

If you’re interested in printing a lot of ABS, you should consider adding an enclosure to this machine to protect it from drafts and keep the build area toasty. You can add a simple tent style enclosure for less than $100.

Preparing Files / Software

The Creality Ender 5 S1 comes with a copy of Creality Slicer 4.8.2. This is a custom version of Cura and includes profiles for every printer Creality has ever made. You could use Cura or PrusaSlicer if you like, but as there’s no default profiles available for 3rd party slicers you’ll have to modify the profile for the older Ender 5 Pro.

The first thing I noticed was the default profile is set at 120 mm/s, much lower than the 250 mm/s Creality claims the printer can do. Acceleration is also set to 500 mm/s, when the machine itself has a Max value of 3000 mm/s. Thankfully, Cura cannot override the machine’s settings unless “Enable Acceleration” is checked – if you leave it unselected, Cura only uses that data for estimating print time.

This means Cura’s stock estimates are wildly inaccurate. My 250 mm/s Benchy printed 24 minutes faster than Cura thought it would. You can find the machine’s actual limits on the control panel (under WHAT). When I plugged these numbers into Cura (3000 for acceleration and 15 for jerk) the estimates became closer to reality, but not perfect.

However, the difference between 120 and 250 mm/s may not matter much, because the actual speed difference is tiny. On a Benchy the difference is only 3 minutes. This is because the machine needs to accelerate to the top speed, then slow down before turning a corner. Just like your car, it can’t reach top speeds instantaneously. Even if a print covers the entire bed it will rarely hit the maximum speed.

Printing on the Creality Ender 5 S1

The Ender 5 S1 comes with a generous sample spool of PLA, but you’ll need more before you know it. Check out our guide to the best filaments for 3D printing for examples of our favorite materials when you’re ready to add to your supply.

The first print I ran on the Ender 5 S1 was a pre-sliced rabbit that came preloaded on the SD car. I used the sample spool of white PLA and it printed cleanly without problem.

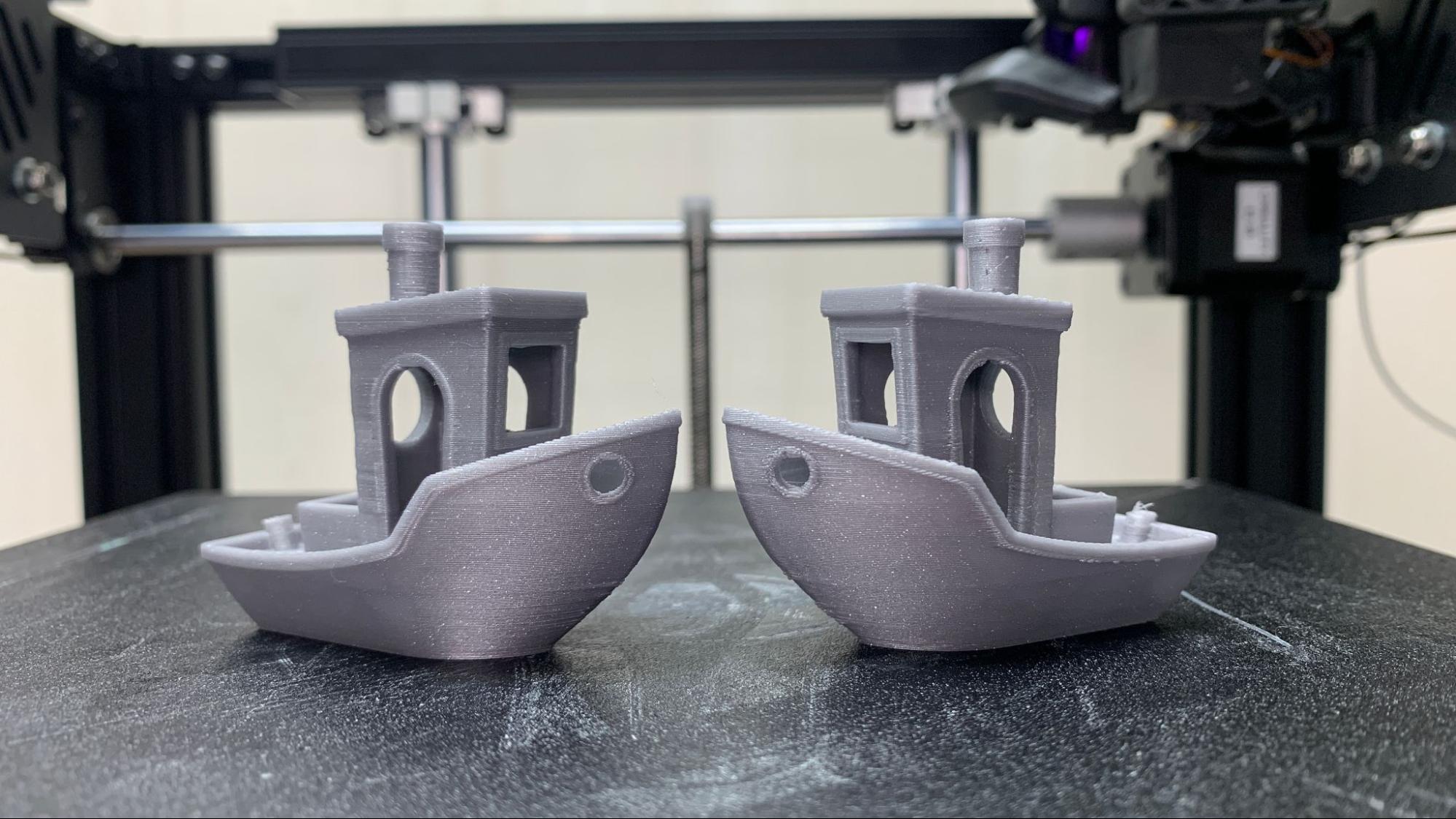

Next came several Benchy’s to test the Ender 5 S1’s quality at speed. The Benchy seen on the left was printed at Creality’s suggested speed of 120 mm/s, which printed in 1 hour and 11 minutes. The one on the right is printed at 250 mm/s, the top speed listed on Creality’s website. It printed in 52 minutes. That’s an HOUR faster than an Ender 3 S1 printing at with standard settings and a recommended speed of 50mm/s.

The difference between the 120 and 250 Benchys are negligible – the faster boat on the right has a little rough spot along the door and some stringing at the stern. Printed in Prusament Galaxy Silver.

One of the best reasons to buy a printer with a bed that doesn’t fling back and forth is the ability to make smooth lithophanes. Lithophanes are thin 3D printed photos that reveal an image when light is placed behind it. The smoother the print, the cleaner your photo. This was printed with the sample PLA at a .16 mm layer height at 120 mm/s and only took 4 hours and 42 minutes. By comparison, my Ender 3 Pro had to be slowed to 40 mm/s to achieve a decent lithophane and took over 10 hours to print the same image – and it’s not this smooth.

PETG was very impressive, and the Ender 5 S1 printed these two print-in-place flexi alligators with no issues or stringing. Both were printed with 3 walls for strength, but 15% lightning infill and .2 layer height for speed. The one on the left was printed at 120 mm/s in 1 hour and 17 minutes. The one on the right was printed at 250 mm/s and printed just a few minutes faster at 1 hour and 13 minutes. This is another case where the printer simply can’t achieve it’s highest speeds due to the complexity of the print. The alligators are printed in Inland Green PETG.

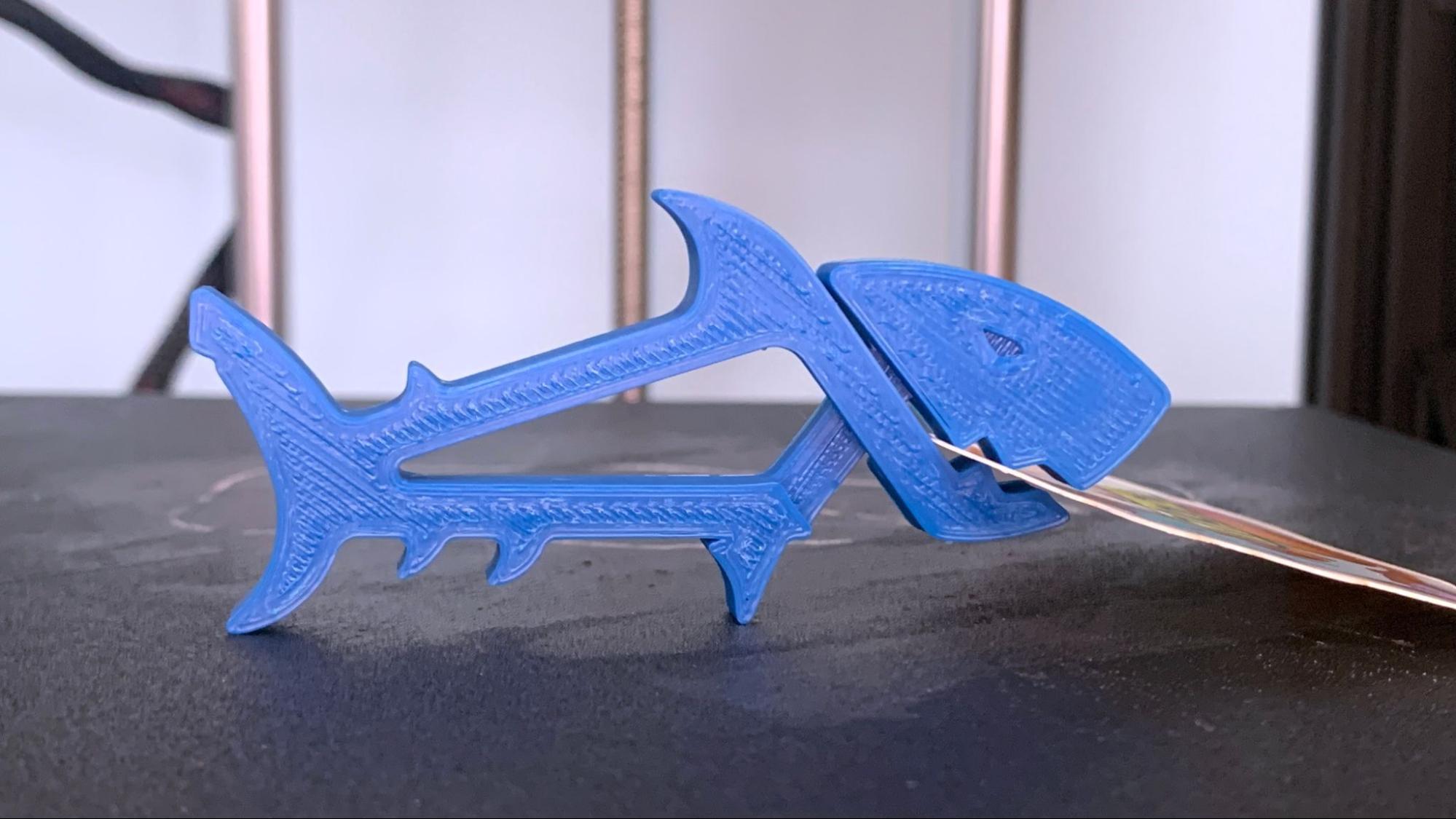

The Ender 5 S1 has an all metal hotend, which means it can run at higher temperatures without risk of damaging a PTFE tube and causing clogs. The open frame is not the best environment for some materials like ABS, but this printer is in a draft free room so I tried it anyway. I was rewarded with a beautiful print that didn’t warp or string. This was printed at 120 mm/s with a .2 mm layer height and took 25 minutes to print. Printed in Inland Blue ABS.

Lastly, we have a TPU Cute Octopus, which I was able to print at regular speed without needing to slow it down. This is one of the best TPU prints I’ve seen in a long time and required no clean up at all. It was printed at 120 mm/s with a .2 mm layer and took 1 hour and 35 minutes to print. An Ender 3 S1 would take at least 4 hours to print this. Printed in Matterhackers Build Series Purple TPU.

Bottom Line

The Ender 5 has seen a lot of improvement between the Pro and S1 editions. It’s now faster, easier to level, less likely to jam and more sturdy to prevent vibrations from marring prints. It would be nice if the Ender 5 S1 also came with a more durable bed surface, but this is a part you can easily upgrade when needed.

Retailing at $559, the Ender 5 S1 is a great 3D printer for makers looking for an Ender sized machine that takes up a little less space while moving quite a bit faster than traditional Cartesian printers. With an all-metal hotend and CR Touch, this is one of our best 3D printers right now.

Creality seems to be capitalizing on the 3D print community’s obsession with speed, and may be overselling the Ender 5 S1’s capabilities a bit. It’s not as fast as the AnkerMake M5, which truly runs at 250 mm/s as is our favorite fastest printer. But this machine can reliably hit 150 mm/s and can certainly run circles around an Ender 3 S1. It’s definitely

My only real issue with the Ender 5 S1 is how Creality did not draw attention to the longer high temperature nozzle they’ve slid into the customized Sprite extruder. Hopefully they can update the manual or website to let people know what replacement will be needed.

MORE: Best 3D Printers

MORE: Best Resin 3D Printers

MORE: Best Filaments for 3D Printing

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

Ahumado Cons-Reply

Mislabeled nozzle

-

Print surface easily damaged

-

Leveling directions are incorrect in the quick start guideMislabeled and incorrect? Four stars? No way. No way