EVGA 850 B3 PSU Review

Why you can trust Tom's Hardware

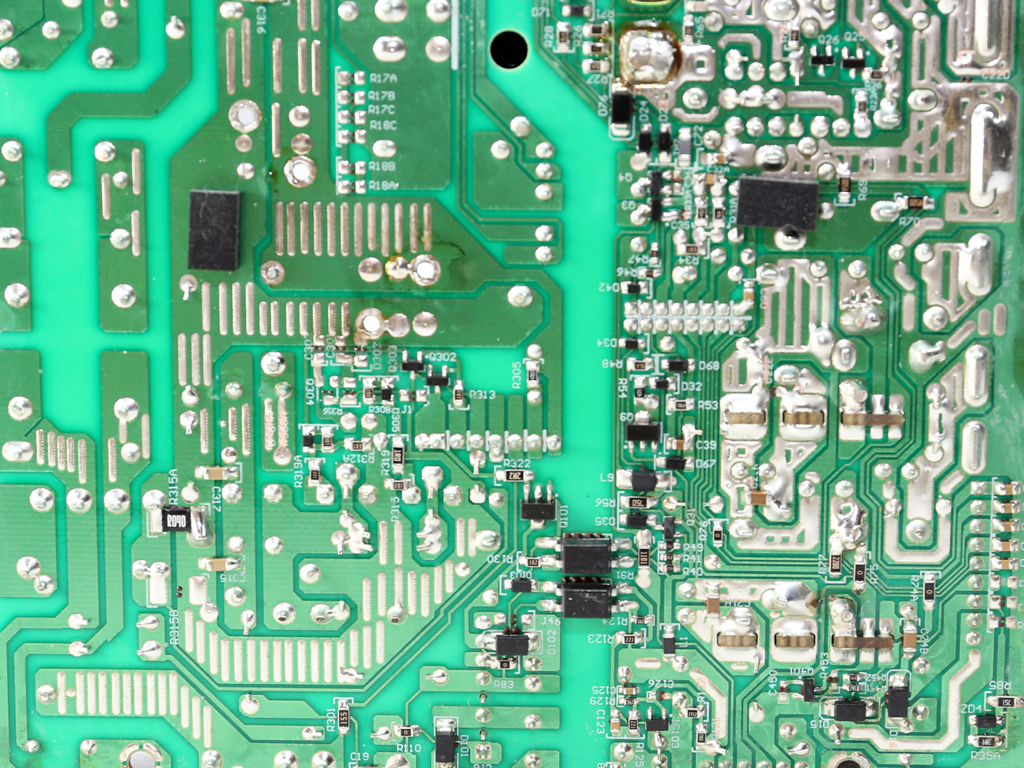

Teardown & Component Analysis

The following video shows how sparks fly when the 850 B3's bulk caps short out during testing. We should note here that the PSU was already dead once we did this, refusing to start, so we thought to show you how dangerous the bulk caps can be even when the PSU isn't connected to the mains.

Parts Description

Before proceeding with this page we strongly encourage you to a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss. Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station and a Hakko FR-300 desoldering gun. Finally, for the identification of tiny parts we use an Andonstar HDMI digital microscope.

| General Data | |

|---|---|

| Manufacturer (OEM) | Super Flower |

| Platform Model | Leadex Bronze |

| Primary Side | |

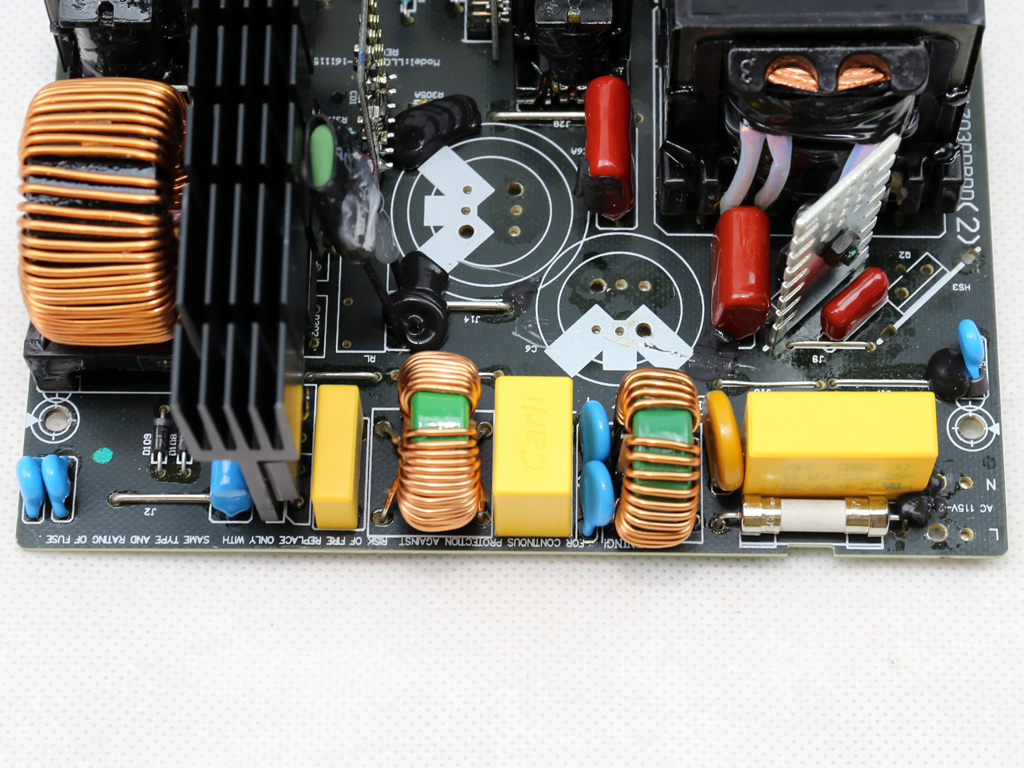

| Transient Filter | 5x Y caps, 3x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor |

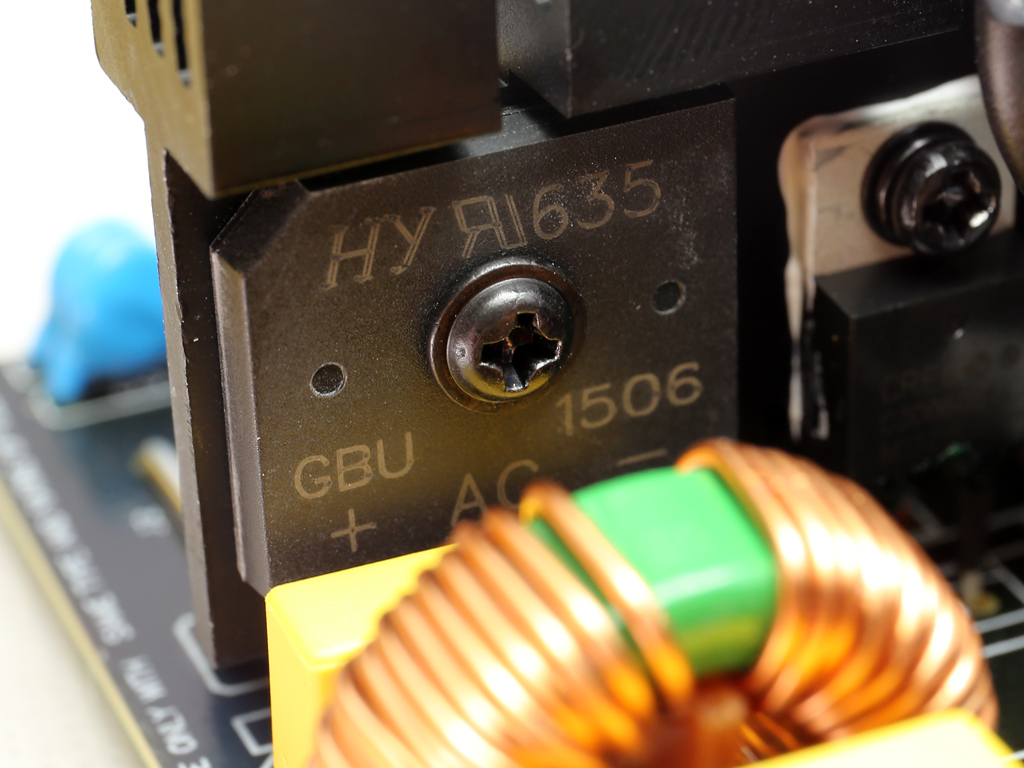

| Bridge Rectifier(s) | 1x GBU1506 (600V, 15A @ 100°C) |

| APFC MOSFETs | 2x A&O AOTF29S50 (500V, 18A @ 100°C, 0.15Ω) |

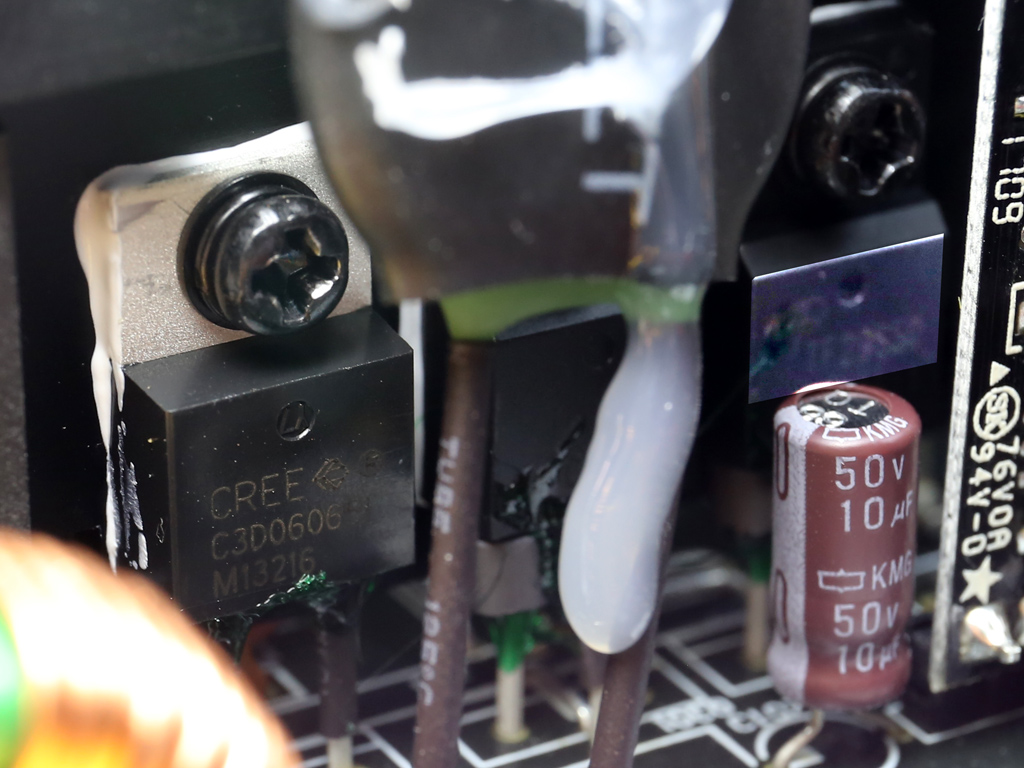

| APFC Boost Diode | 1x CREE C3D06065A (650V, 6A @ 150°C) |

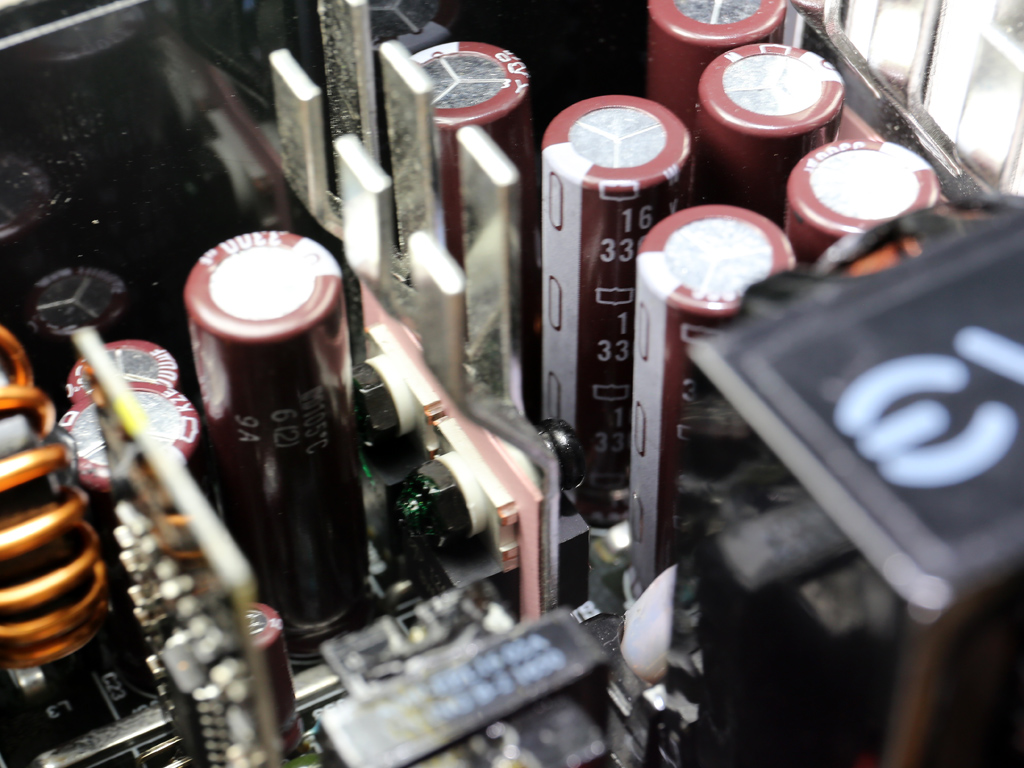

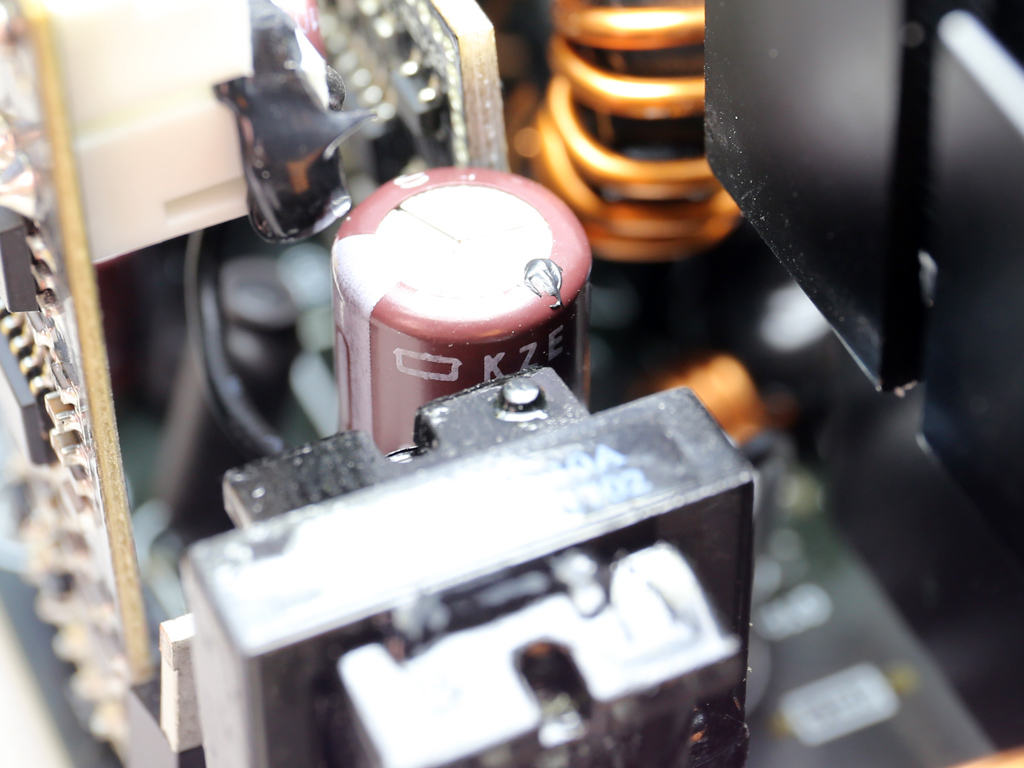

| Hold-up Cap(s) | 2x Nippon Chemi-Con (400V, 270uF each or 540uF combined, 95°C, CE) |

| Main Switchers | 2x Infineon IPA50R199CP (550V, 11A @ 100°C, 0.199Ω) |

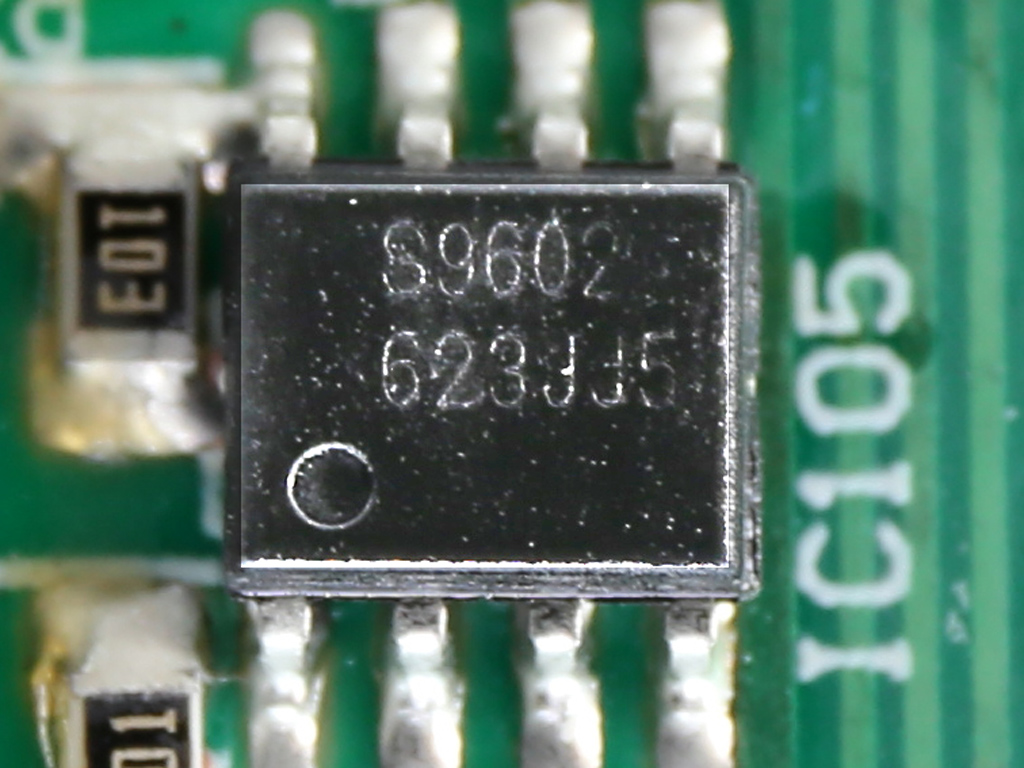

| APFC Controller | SF29603 & S9602 & ICE3PCS02G |

| Resonant Controller | SF29605 |

| Topology | Primary side: Half-Bridge & LLC Resonant Controller Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

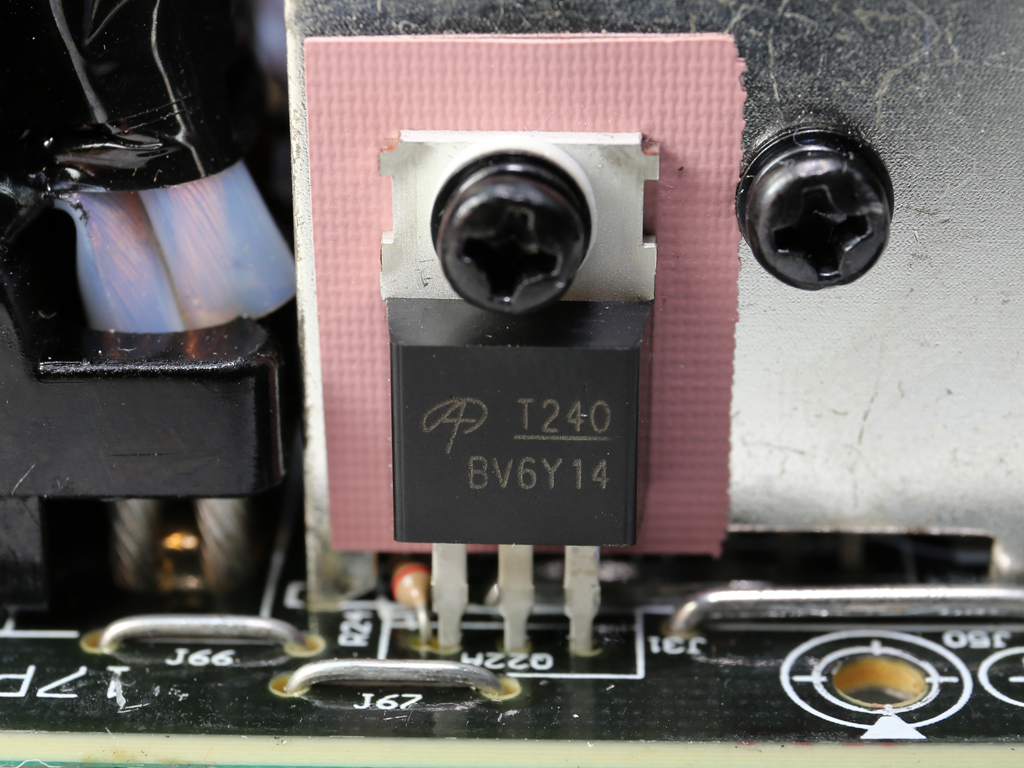

| +12V MOSFETs | 6x A&O AOT240L (40V, 82A @ 100°C, 4.7mΩm @ 125°C) |

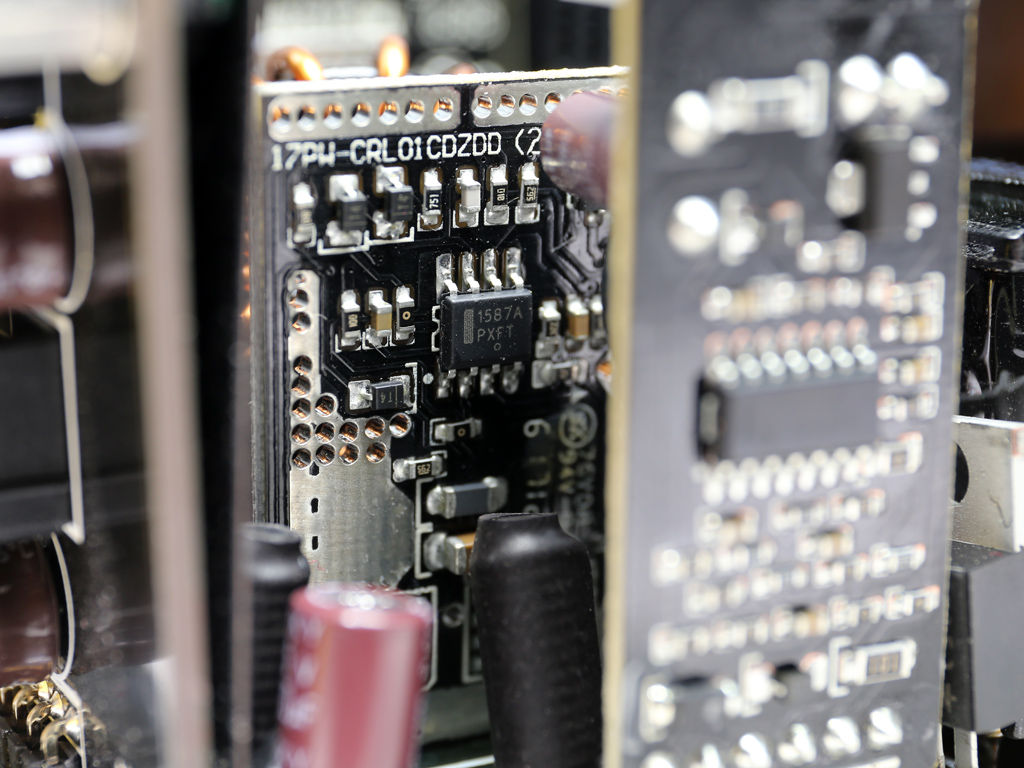

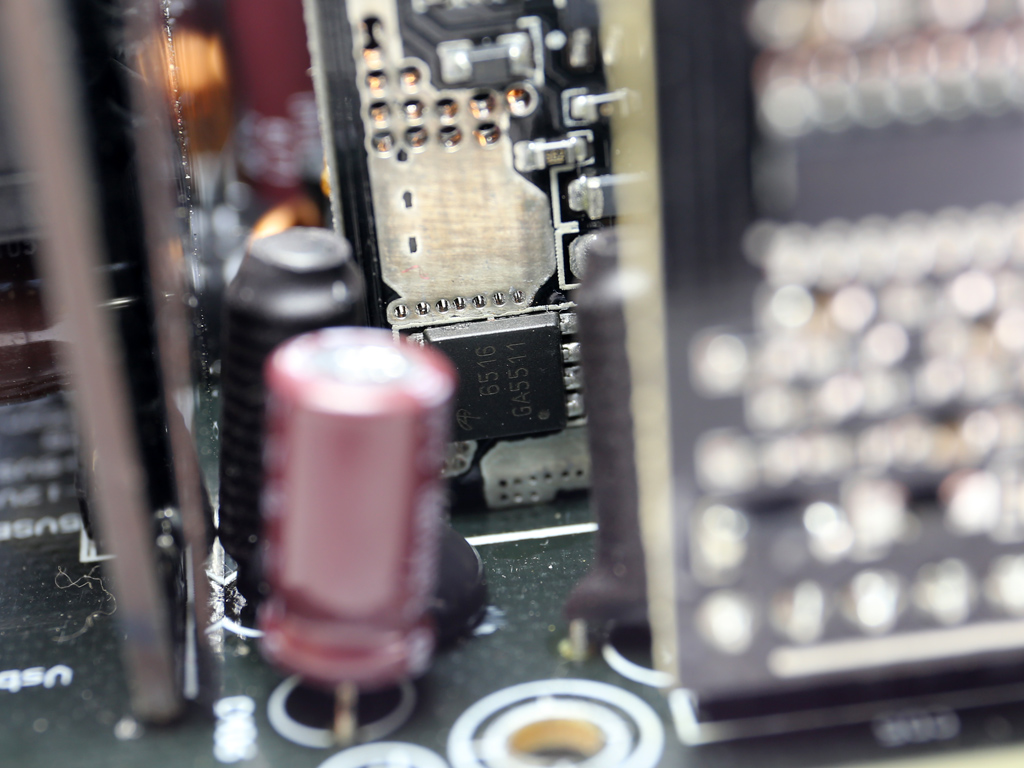

| 5V & 3.3V | DC-DC Converters: 8x A&O AON6516 (30V, 25A @ 100°C, 8mΩ) PWM Controller: 2x On Semiconductor NCP1587A |

| Filtering Capacitors | Electrolytics: Chemi-Con 7x W, 3x KZE, 3x KY, 2x KMG, 7x KRG (modular board) Polymers: 8x Chemi-Con |

| Supervisor IC | SF29603 & LM339A |

| Fan Model | S1282412H (120mm, 12V, 0.35A, Sleeve Bearing) |

| 5VSB Circuit | |

| Rectifier | Mospec S10C60C |

| Standby PWM Controller | 29604 |

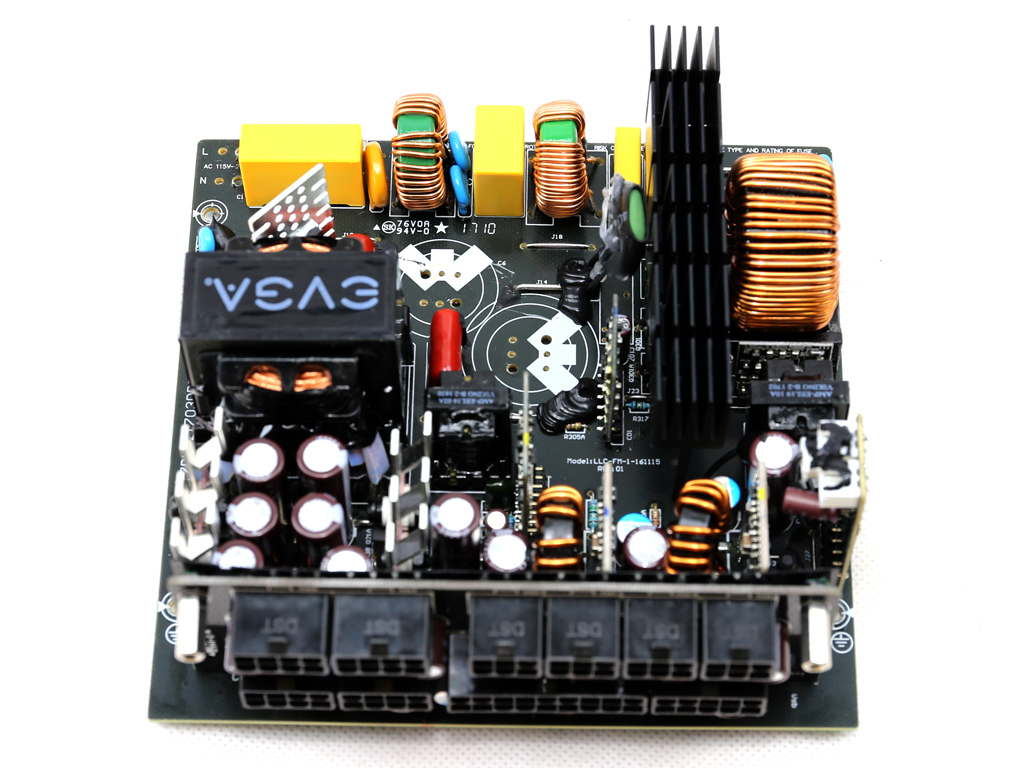

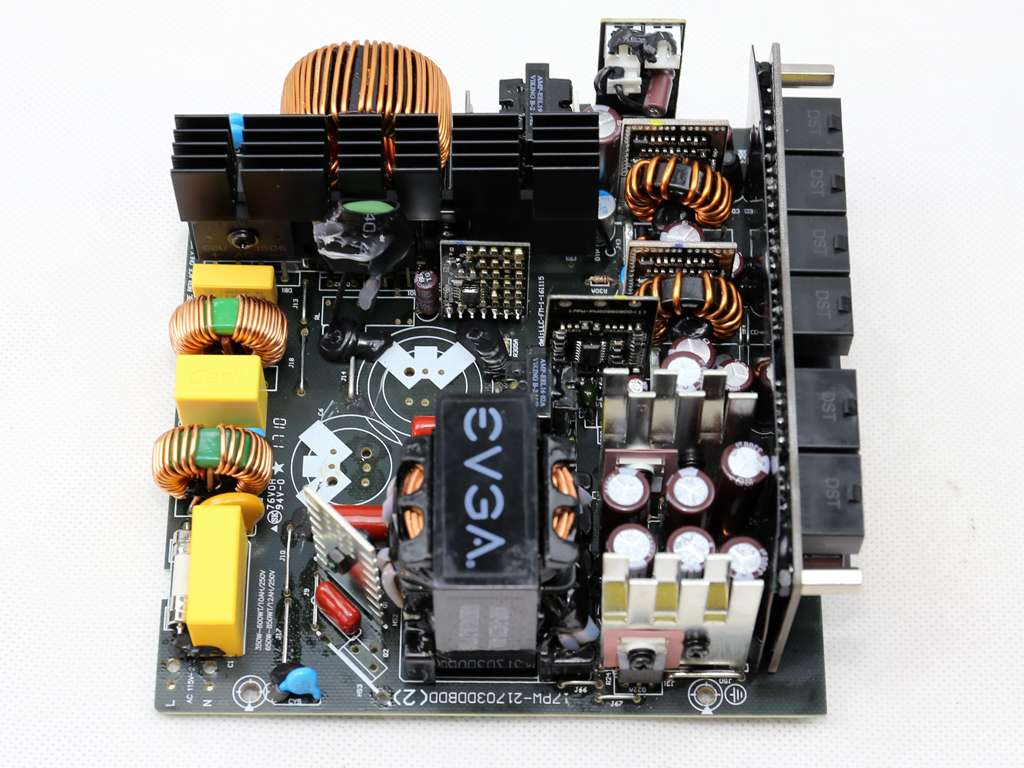

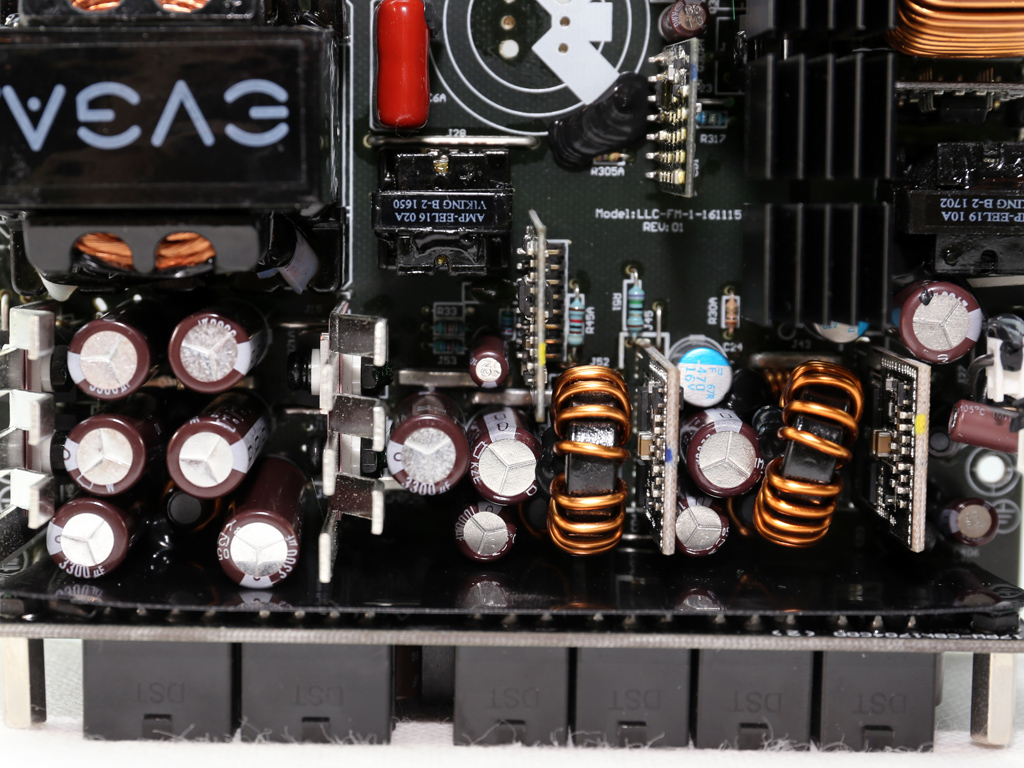

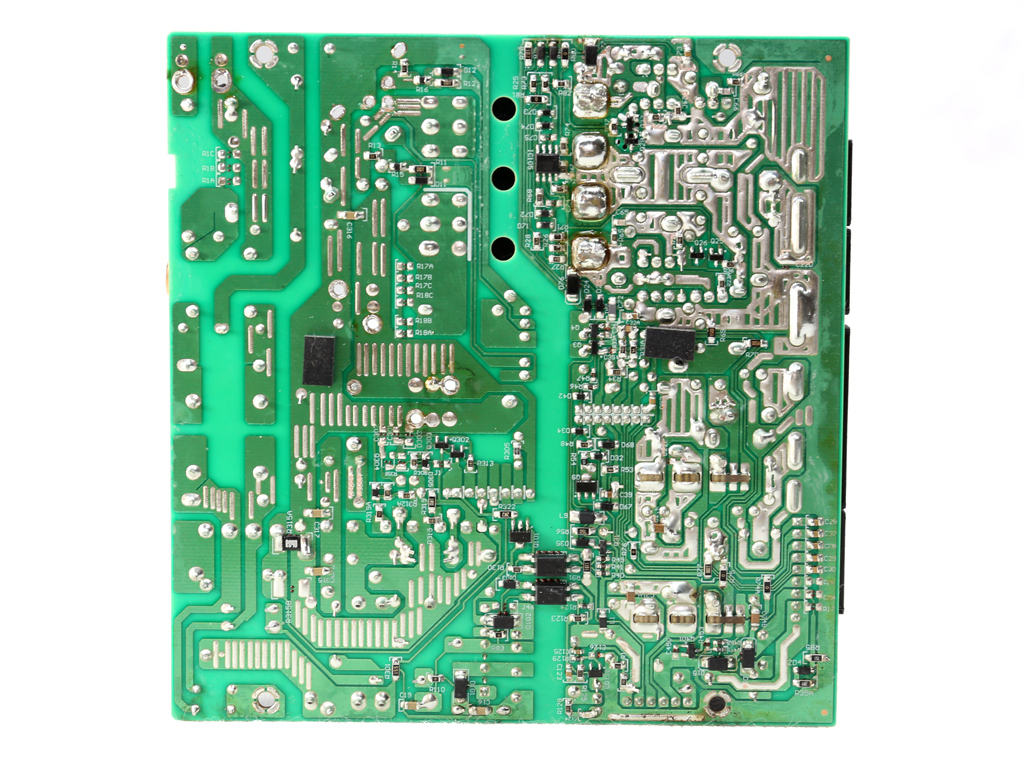

Like the other B3 models, EVGA's 850 B3 is made by Super Flower. It utilizes a budget-oriented Leadex platform with much lower efficiency than what we've come to expect from high-end Leadex-based designs. Although this is a mid-level PSU, EVGA went with Japanese capacitors on its main PCB, along with several polymer caps that also come from a Japanese manufacturer. Really, the implementation is too modern for such a low-efficiency unit. Combining a half-bridge topology and an LLC resonant converter usually results in anywhere from an 80 PLUS Gold to Titanium certification. Obviously, this is not your ordinary entry-level PSU, an observation supported by the semi-passive mode. It's uncommon to see that feature on a PSU known to suffer high thermal loads due to low efficiency.

Compared to the 450 B3 that we reviewed previously, this platform looks almost identical. The only major difference is a change from Teapo to Chemi-Con capacitors. As of this writing, you'll pay twice as much for the 850 B3 than EVGA's 450 B3, so major component changes are required to justify such a significant price difference. It's all the more disappointing, then, that a sleeve-bearing fan remains. EVGA should use a better fan in its 750W and 850W B3 PSUs.

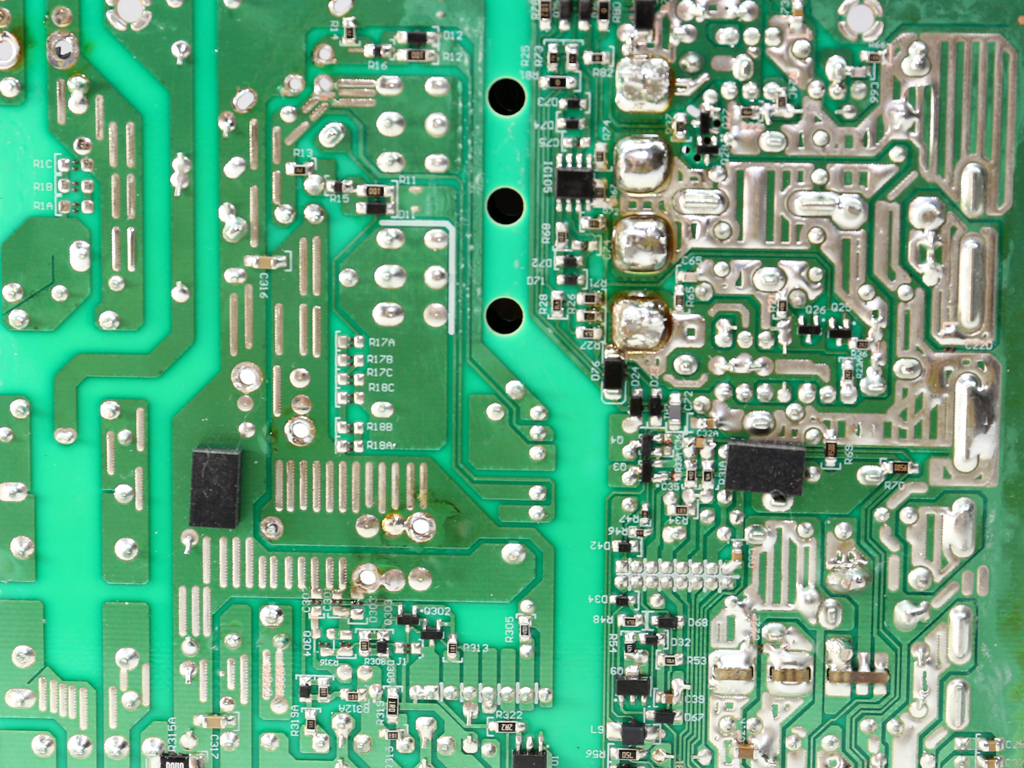

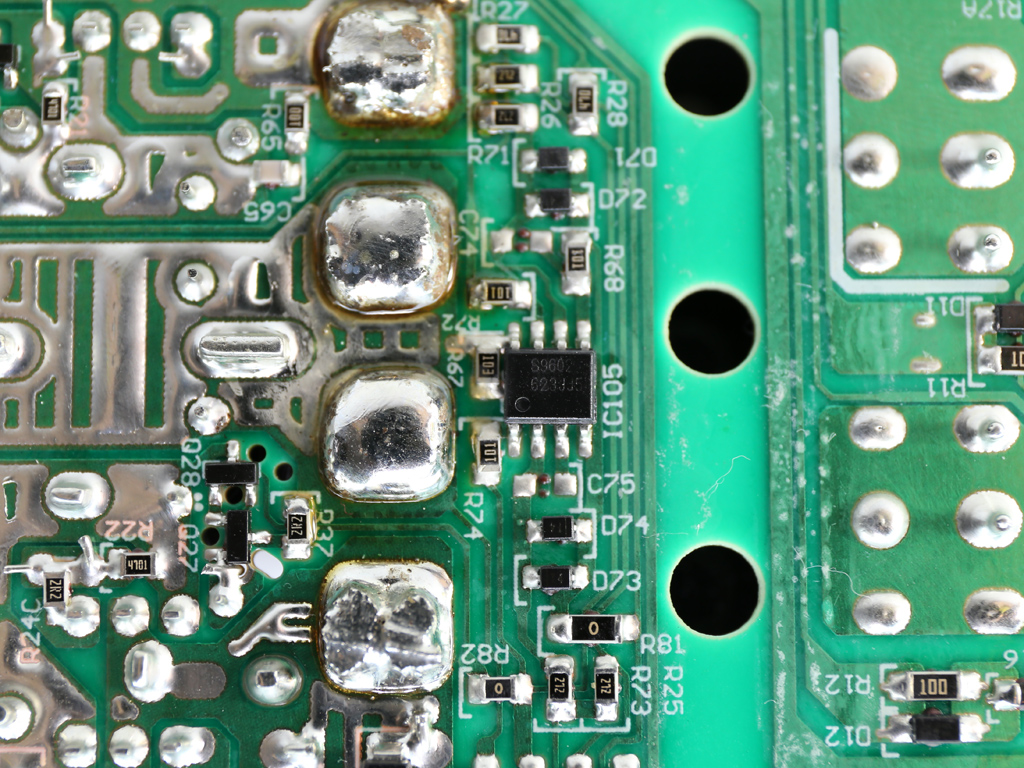

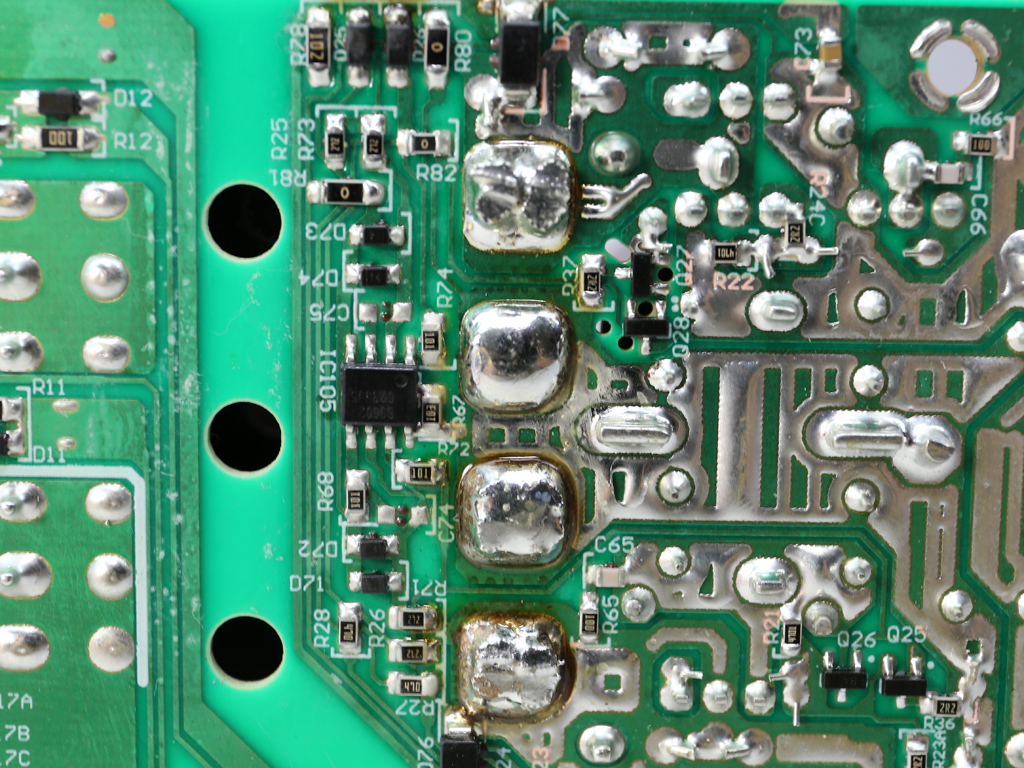

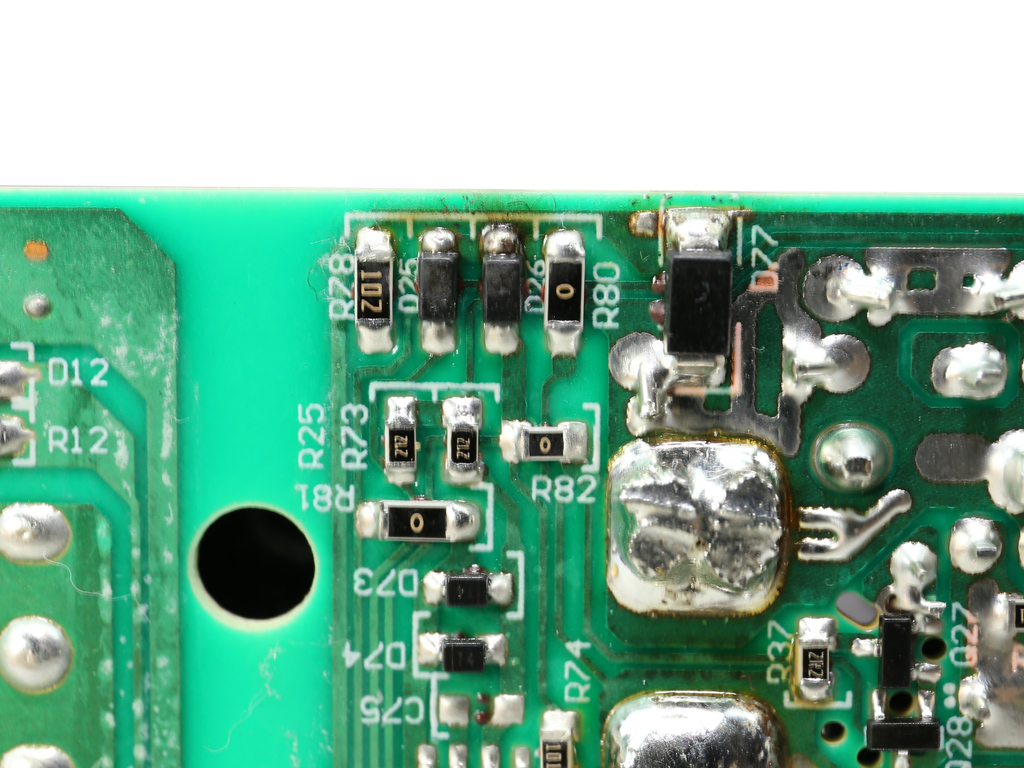

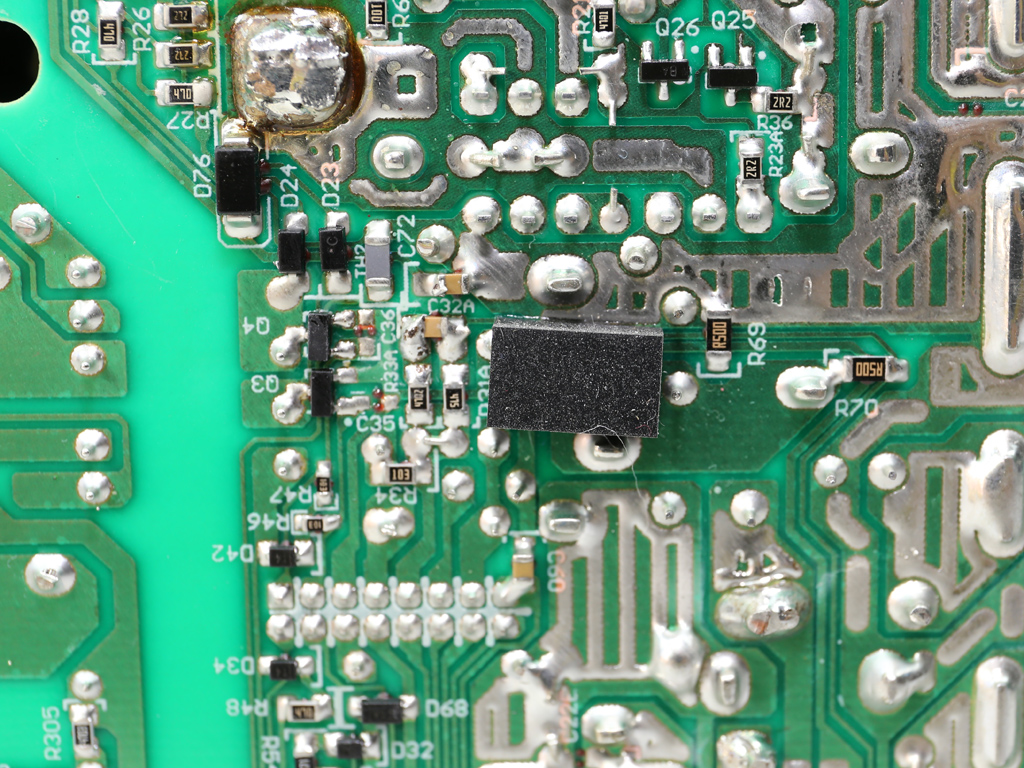

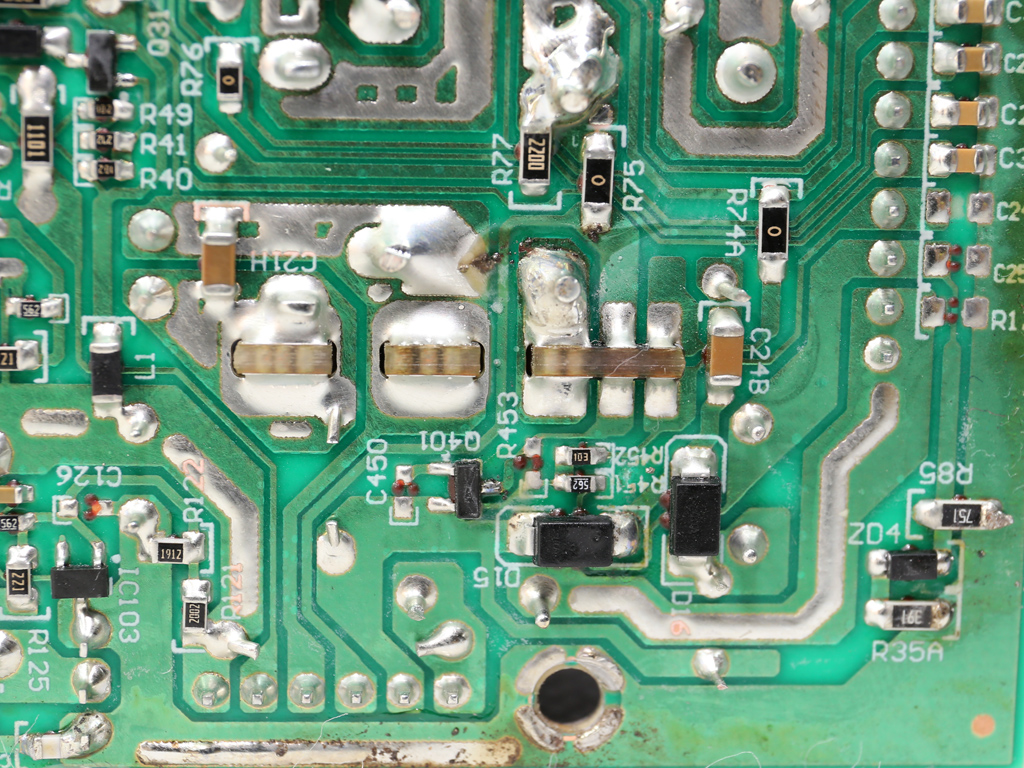

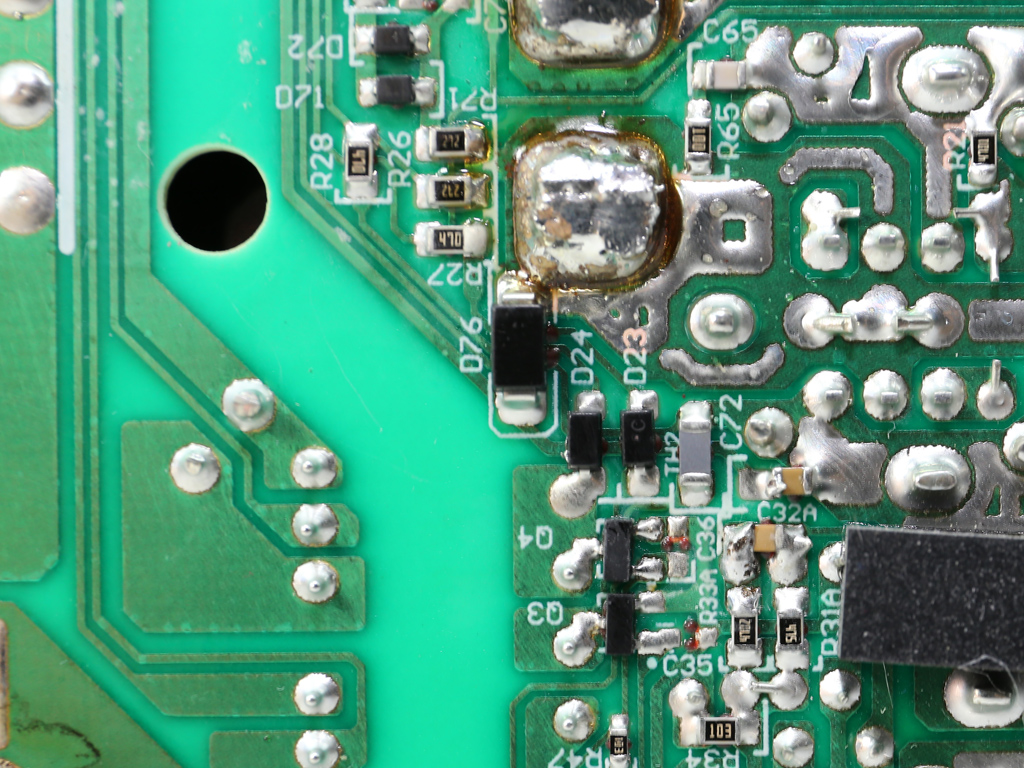

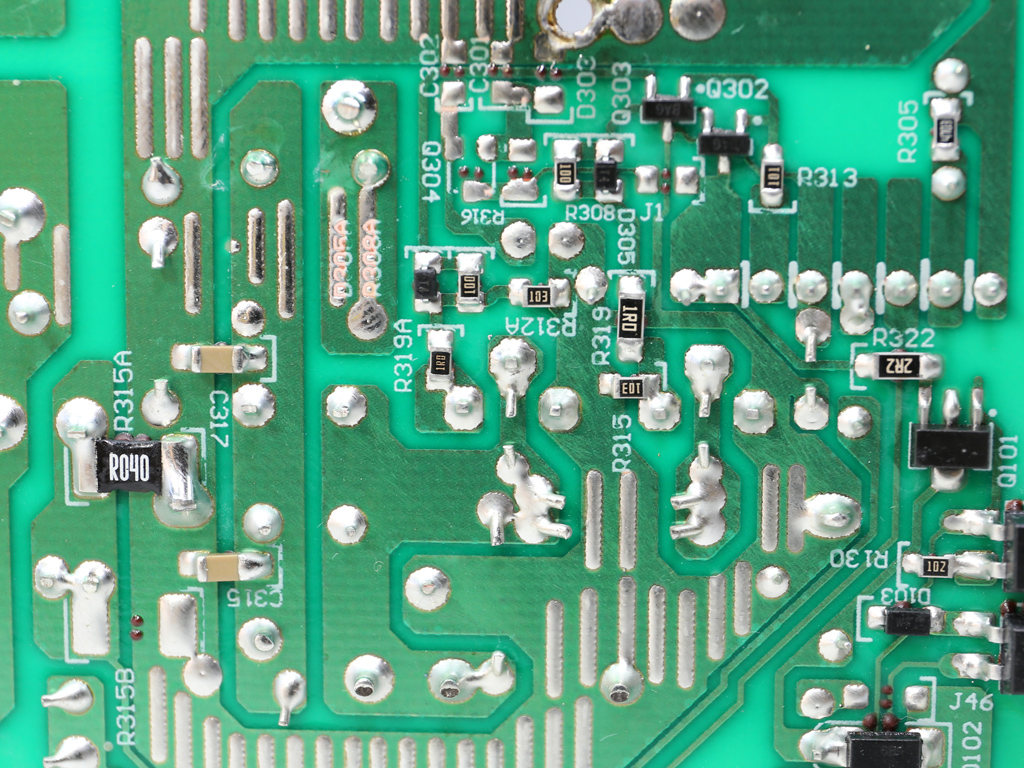

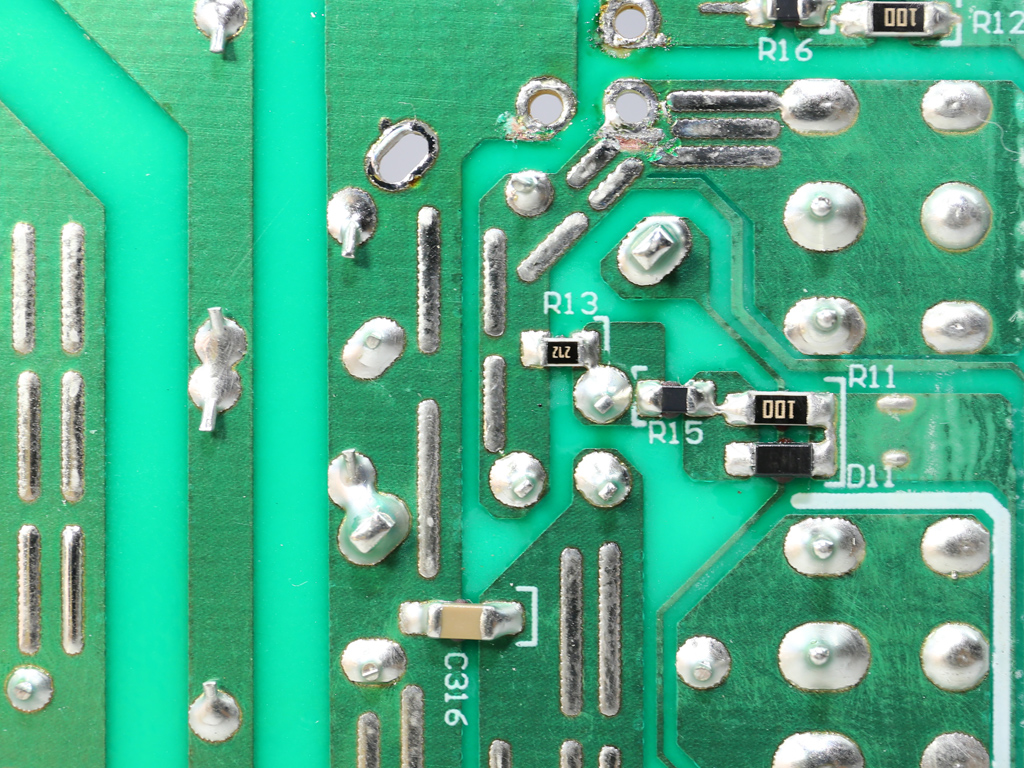

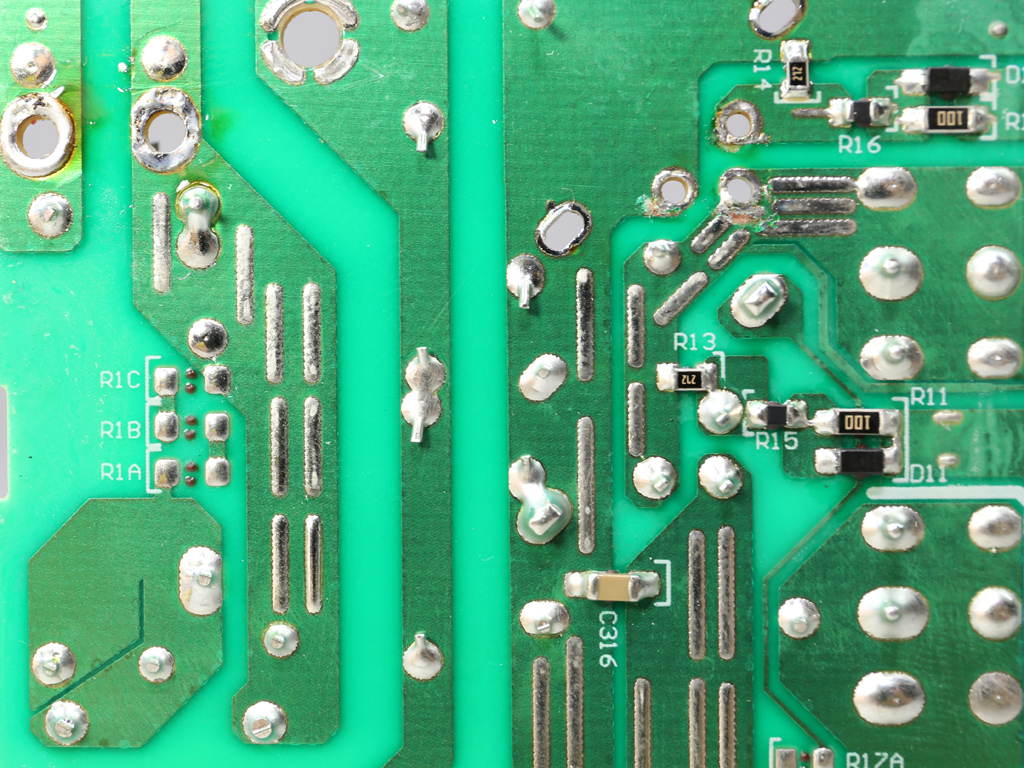

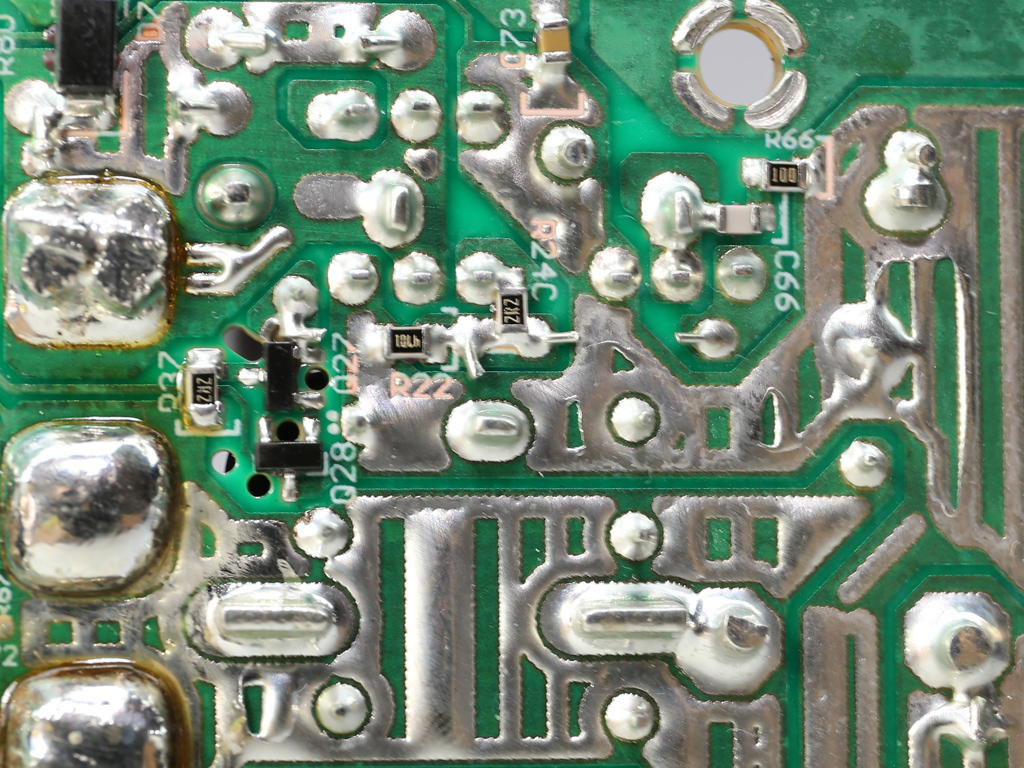

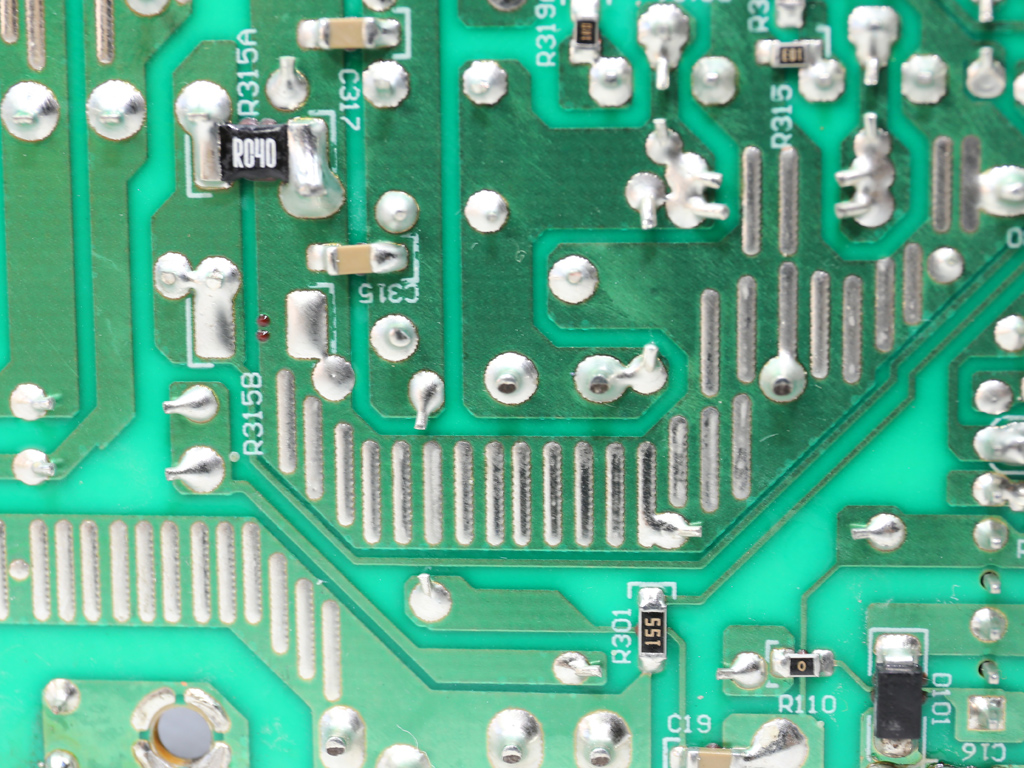

Spoiler alert: this PSU died after our OPP test; it simply doesn't start any more. So, we removed some parts in order to figure out why. Although we couldn't identify a specific fault, poor build quality is apparent throughout. Despite using good components, the assembly (especially on the main PCB's solder side) is anything but acceptable. There were no fireworks this time around, and the 5VSB rail still works. It's obvious, then, that some protection feature is keeping our sample from firing up, meaning the problem is somewhere on the secondary side. We'll repair some of the bad solder joints, cut the potentially problematic leads, and put the 850 B3 back together. Though we hope for the best, we aren't holding our breath.

Even when the PSU isn't plugged in, its bulk caps still store energy. In other words, be extra careful. They're completely capable of delivering a shock if you touch them without draining them first. The best way to do this is through a small circuit with a resistor, which applies a load to the cap, converting the capacitor's energy to heat on the resistor. A high-wattage (50W or more) >10Ω resistor should do the trick. Connect the resistor's terminal to two thick wires and then connect those wires to the cap's terminals. The small spark you may see is nothing compared to what happens if you use an insulated screwdriver to short the cap's terminals (as we did in the video at the start of the page).

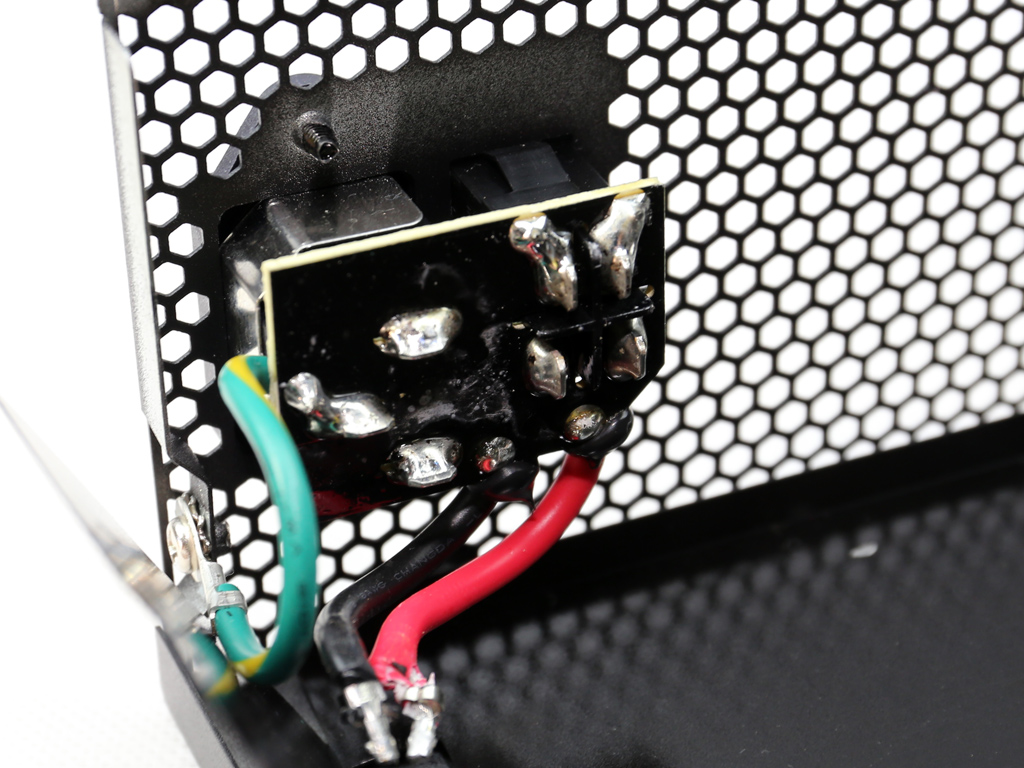

As we'd expect from a Super Flower platform, the PCB right behind the AC receptacle doesn't host any EMI-filtering components. The entire filter is on the main PCB, and it consists of five Y caps, three X caps, two CM chokes, and an MOV.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

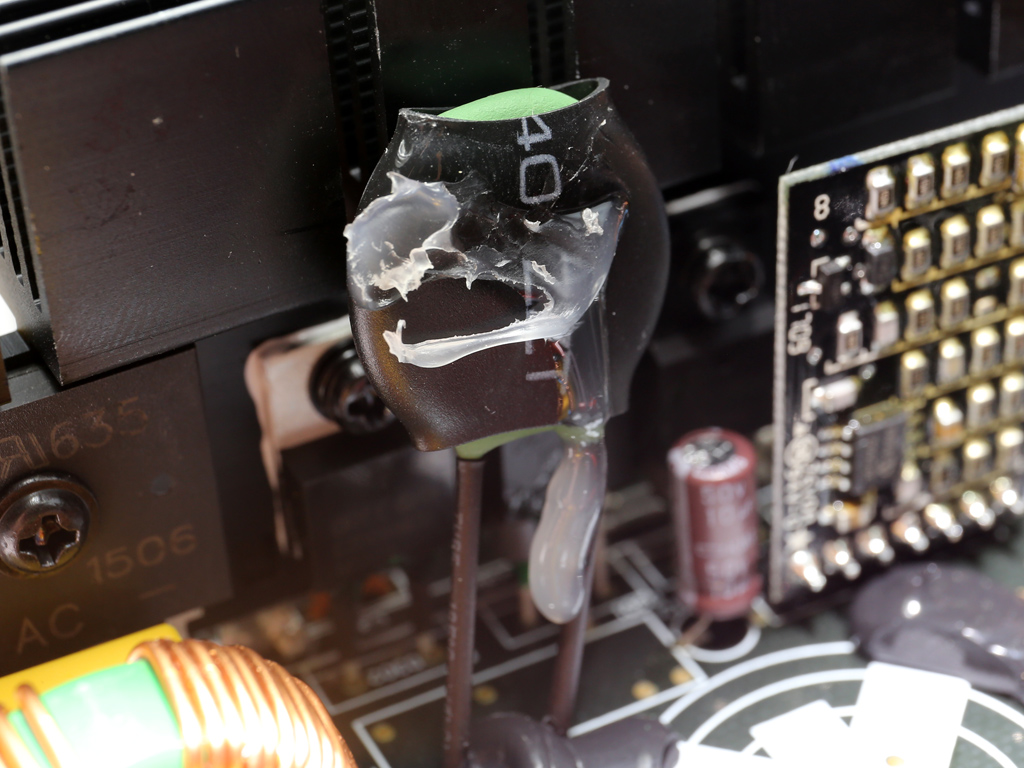

Pictured above is a large NTC thermistor for restricting the inrush currents. It isn't supported by a bypass relay, even though that'd improve efficiency and allow the thermistor to cool down quickly. The glue on the thermistor comes from our testing; it was used to secure the probes we install inside the PSU during testing.

The single bridge rectifier, a GBU1506, is installed on the APFC's heat sink.

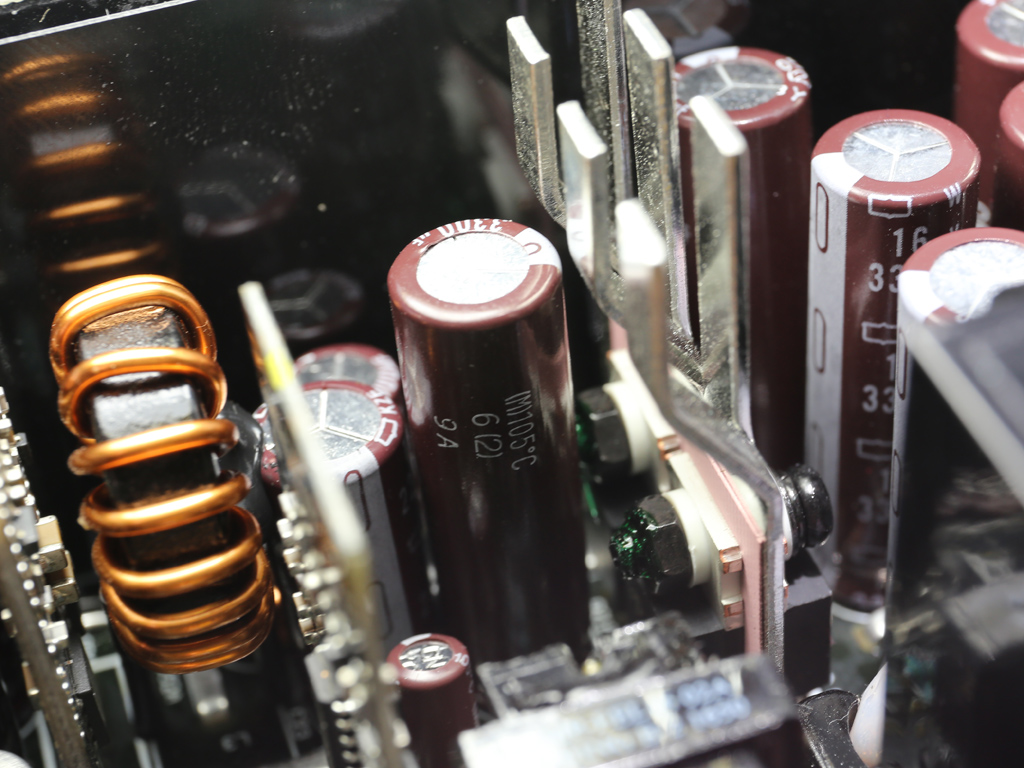

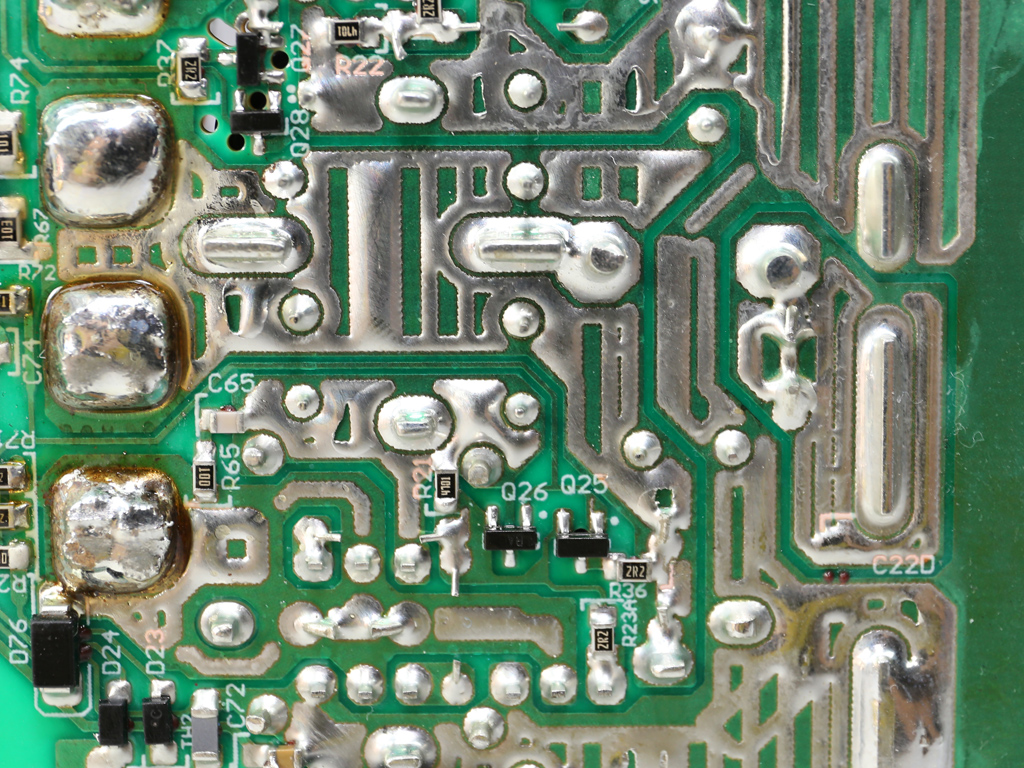

Two A&O AOTF29S50 FETs are used in the APFC converter, along with a single CREE C3D06065A boost diode. The bulk caps are provided by Chemi-Con and they have 95°C rating. Their combined capacity looks low, but the PSU is still able to achieve a long hold-up time (likely because of an optimized design).

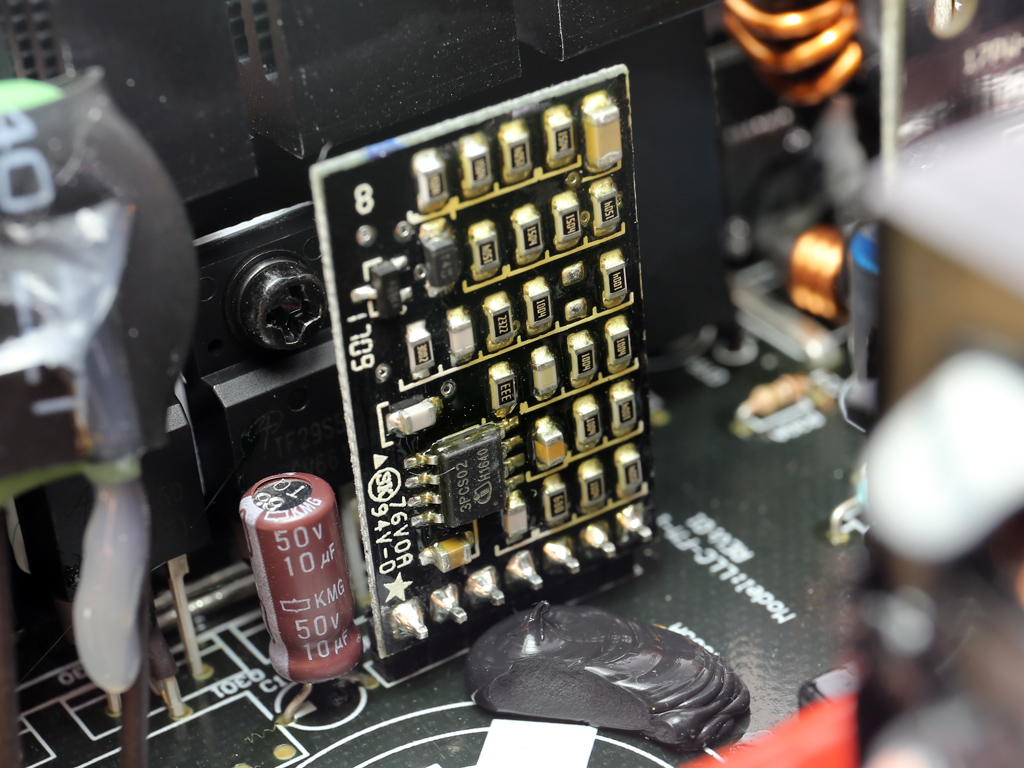

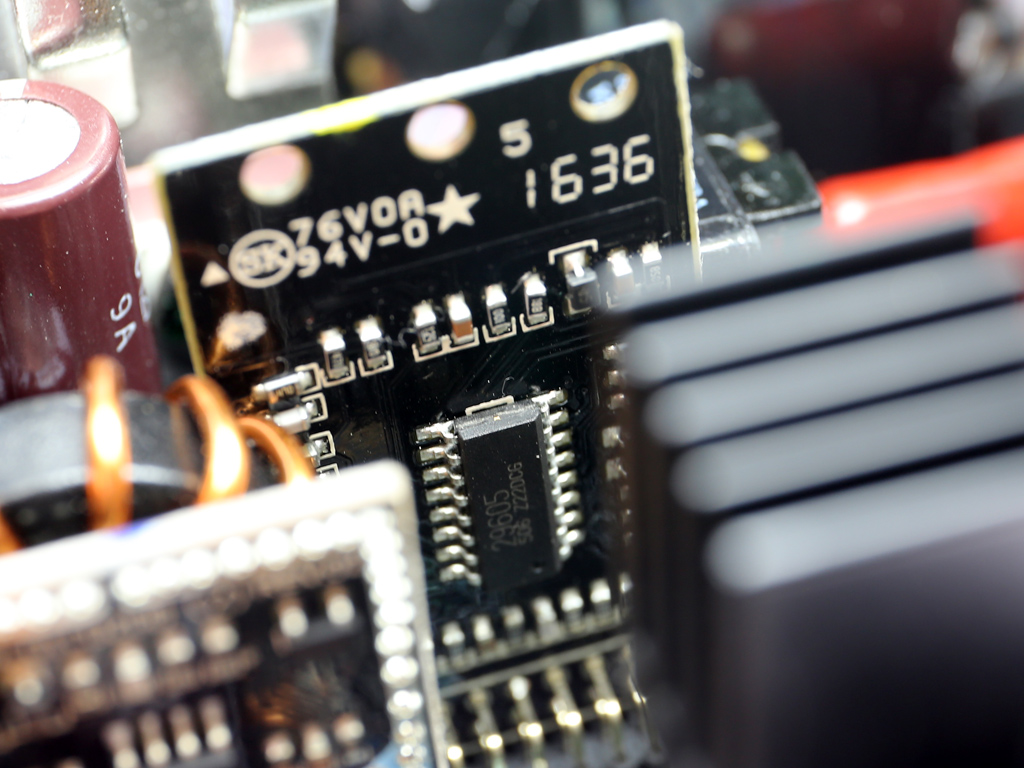

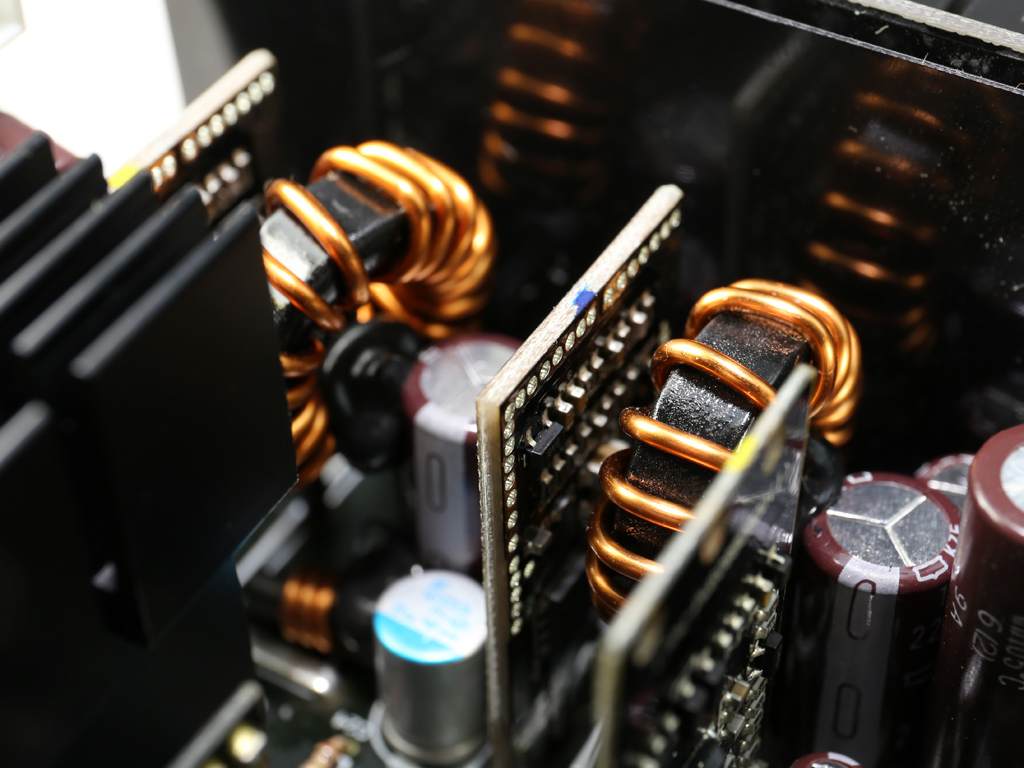

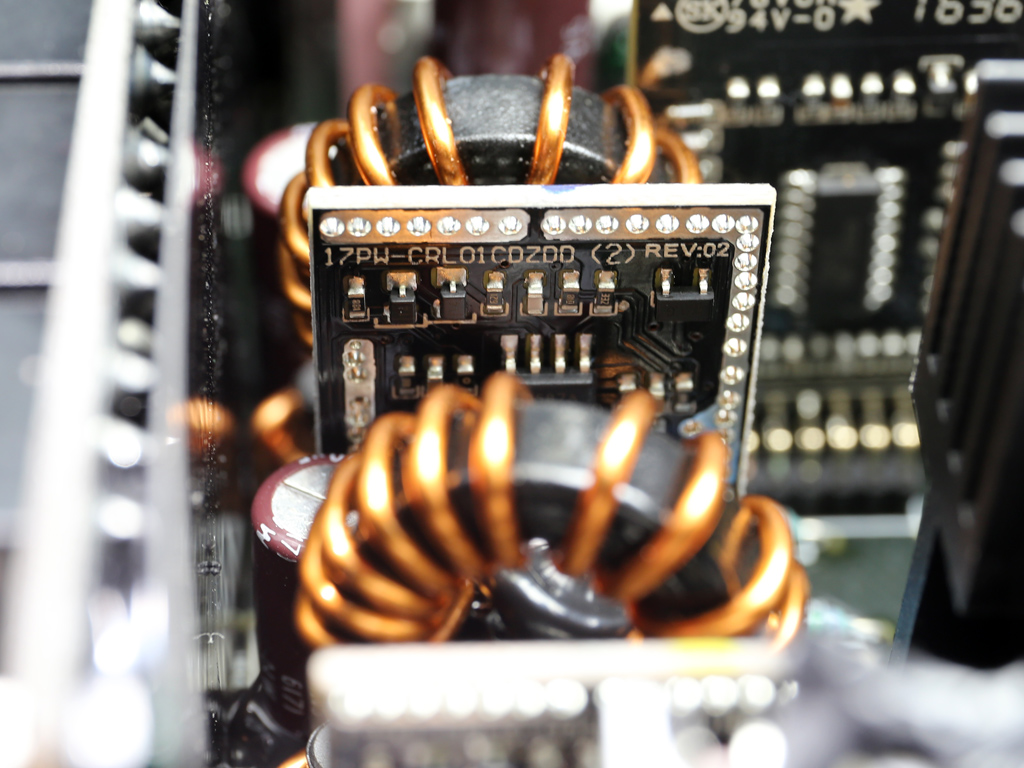

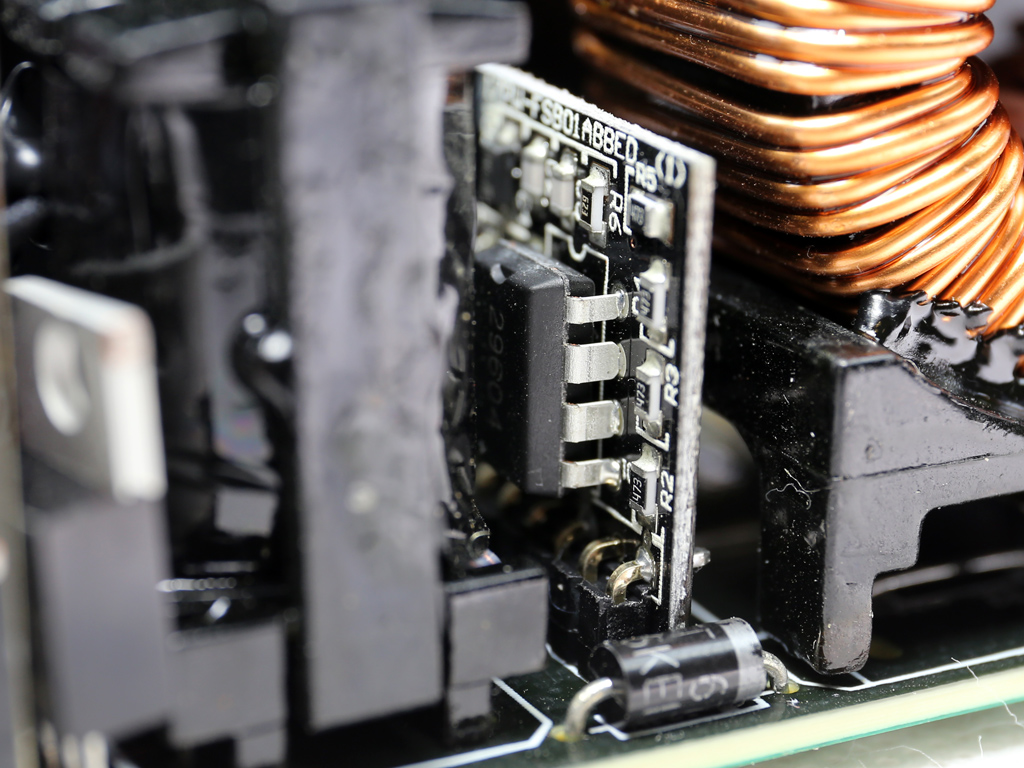

A small daughterboard hosts the APFC controllers (SF29603 and ICE3PCS02G). We also spot a S9602 on the solder side of the main PCB, which is also a controller IC for active CCM power factor correction converters.

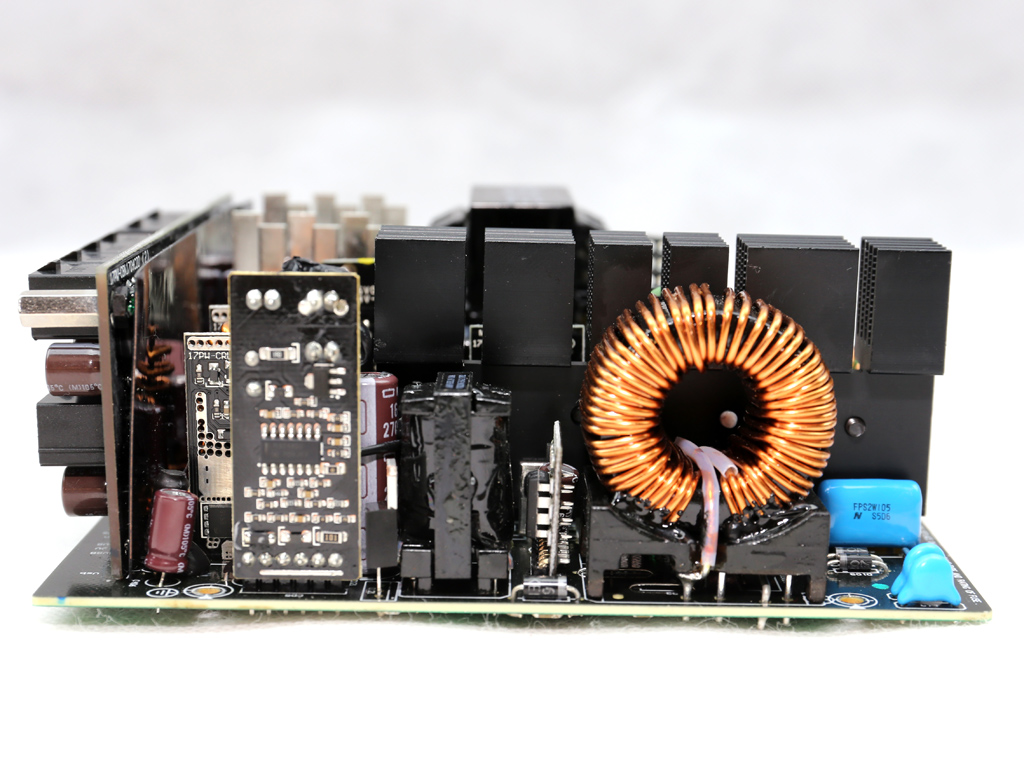

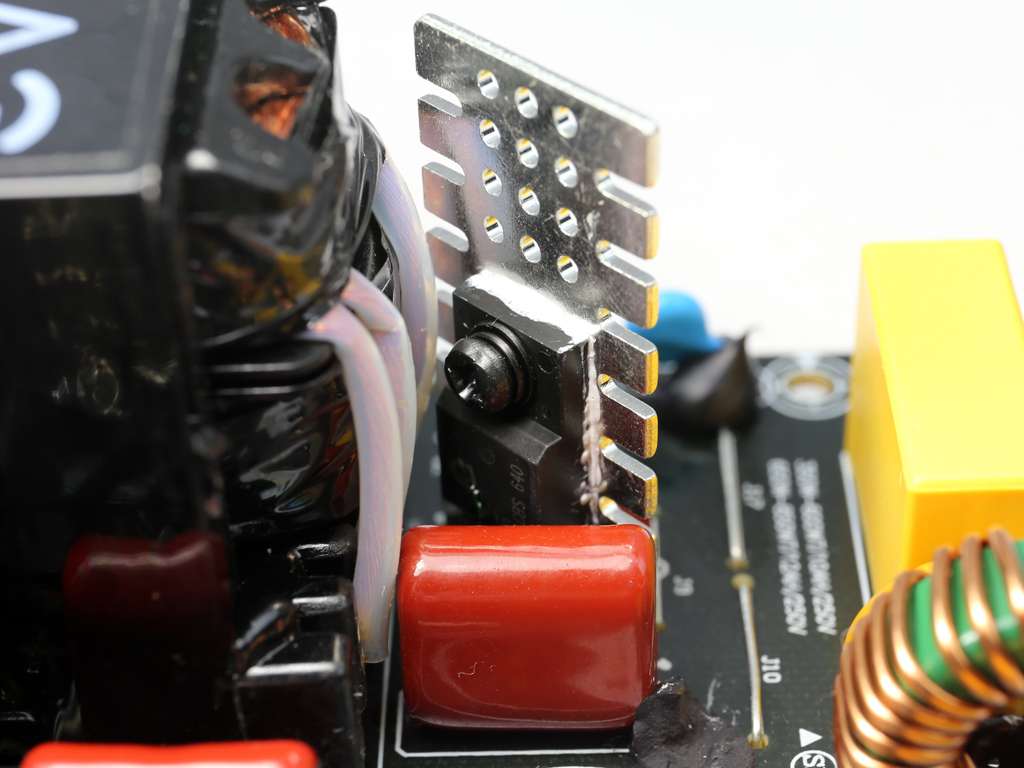

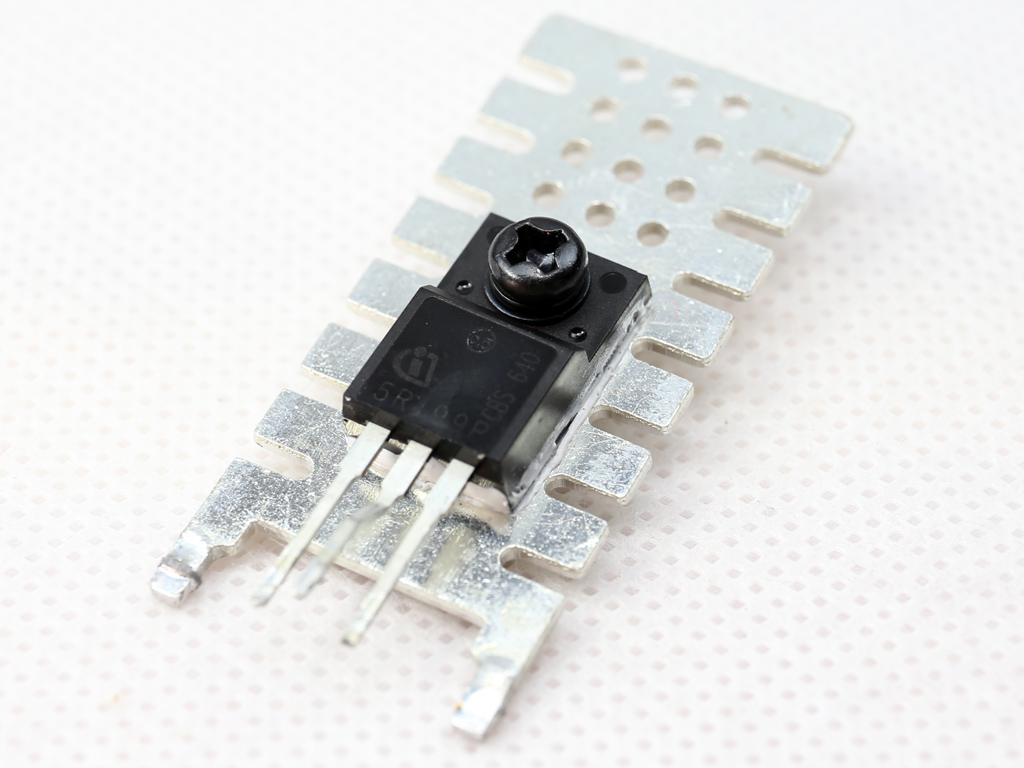

The primary FETs, two Infineon IPA50R199CPs, are bolted onto an equal number of small heat sinks.

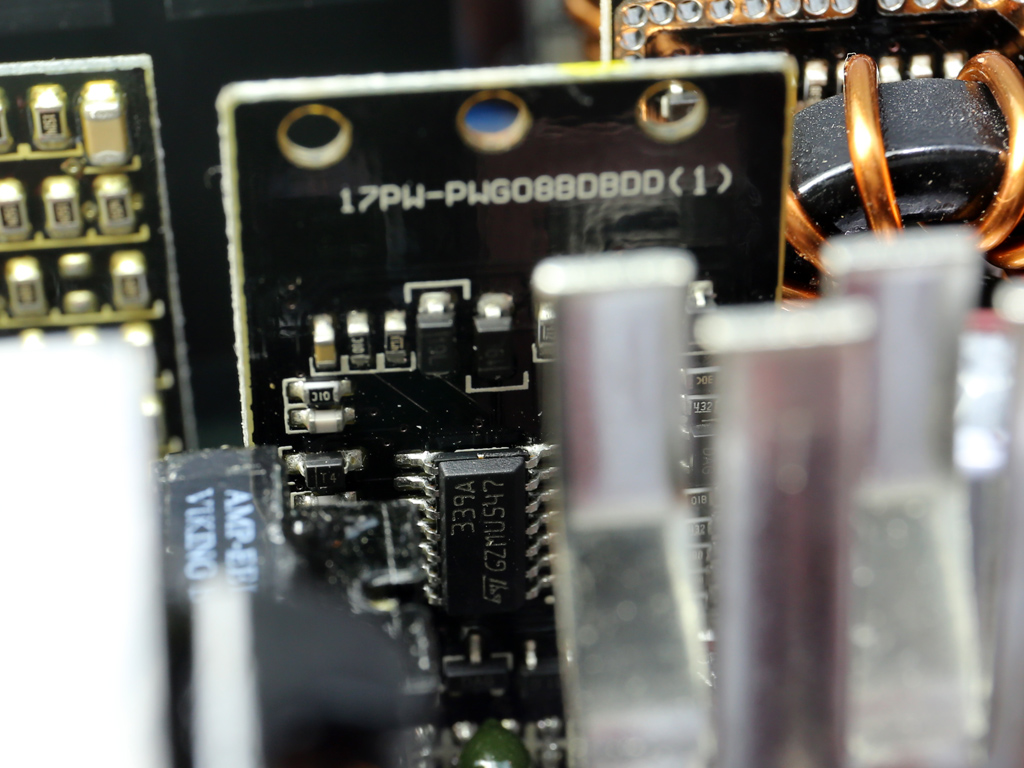

The resonant controller is an SF29605 IC that likely handles the unit's protection features. On the same board that hosts the SF29605, there is also an LM339Avoltage comparator that supports the main supervisor IC.

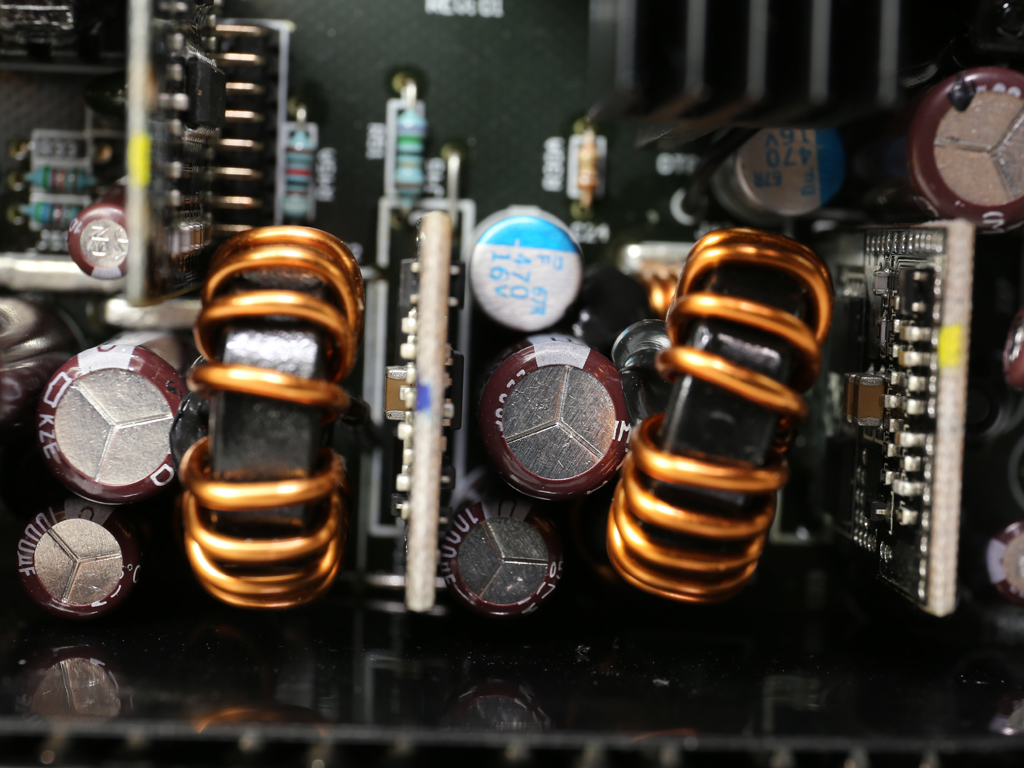

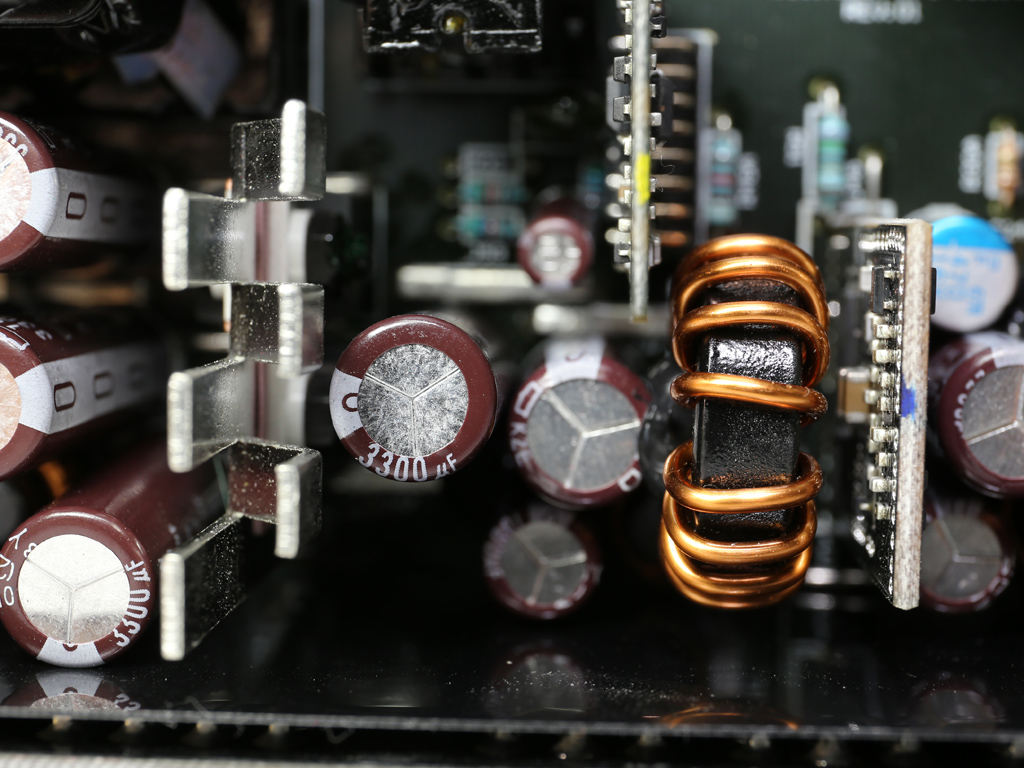

On the secondary side, a couple of small heat sinks hold six A&O AOT240L FETs, responsible for regulating the +12V rail.

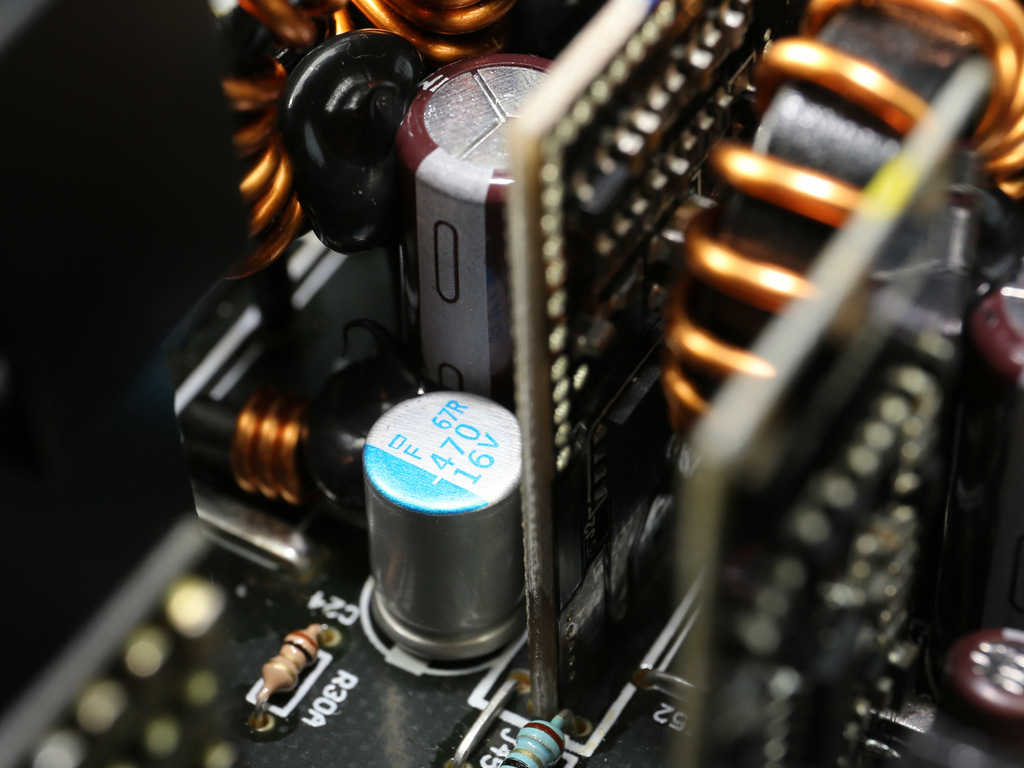

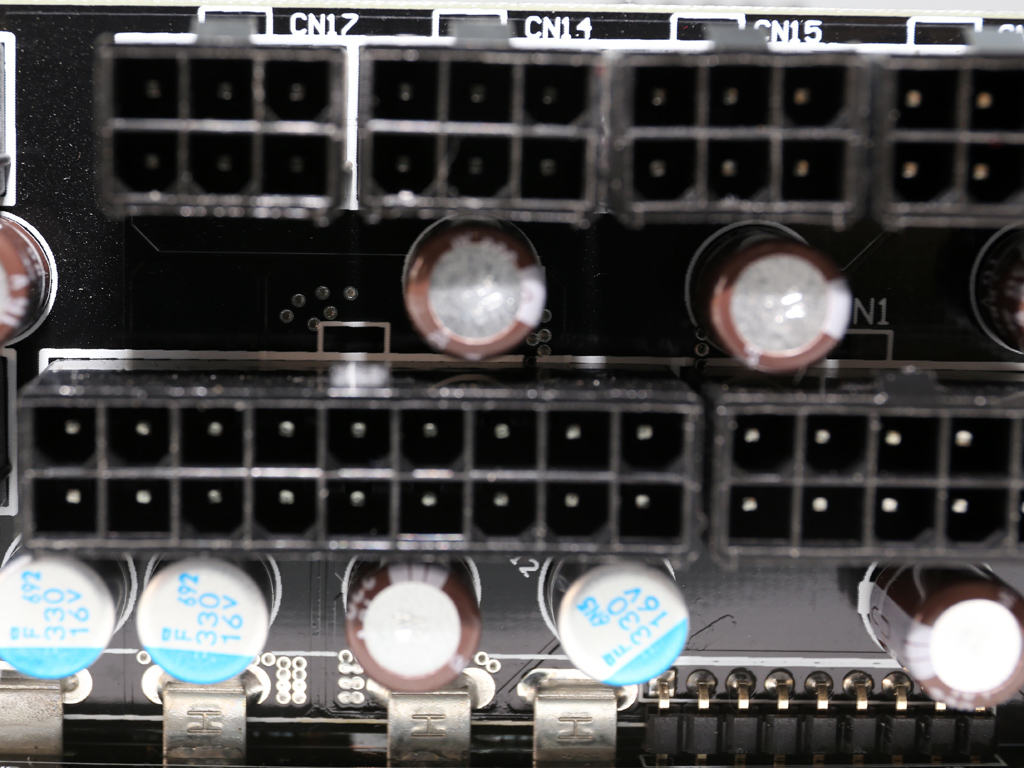

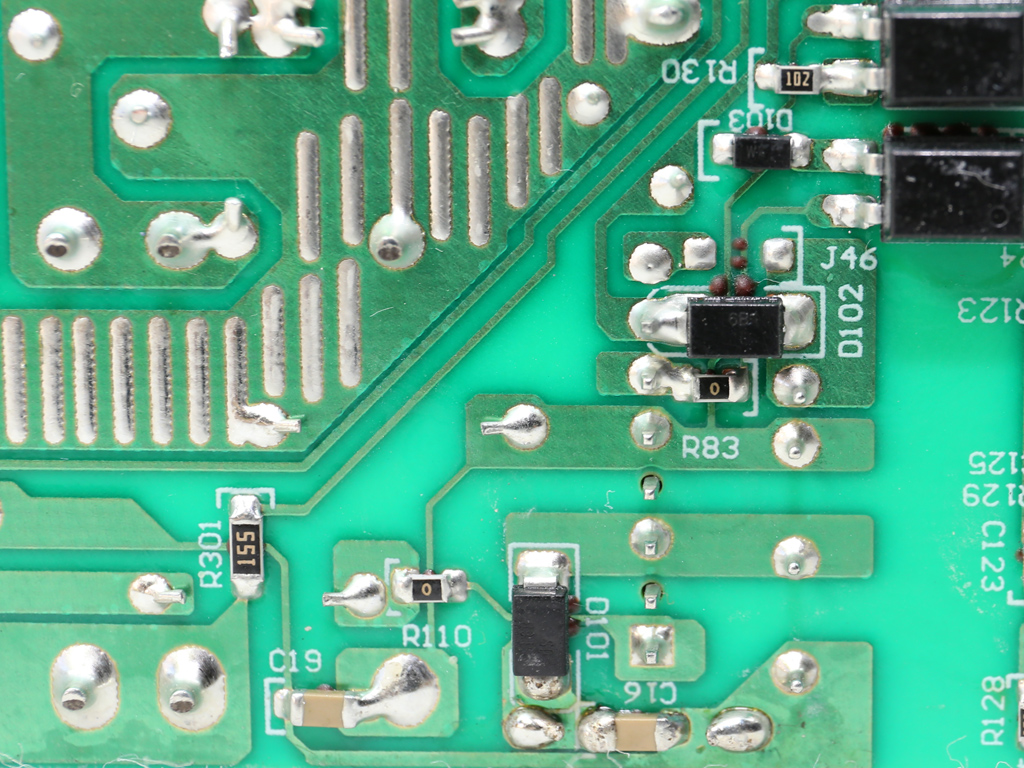

A couple of DC-DC converters generate the minor rails through the +12V rail. Each converter uses a NCP1587A PWM controller and four AON6516 FETs.

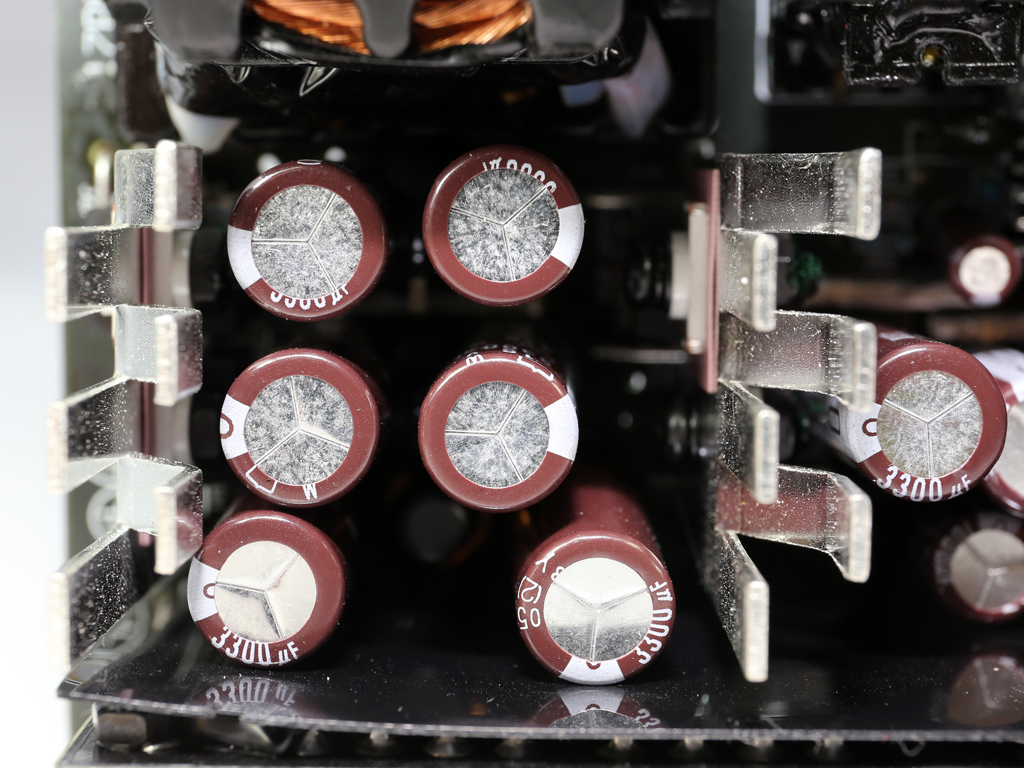

All filtering caps (electrolytic and polymer) on the secondary side are provided by Chemi-Con. This is a major upgrade compared to the (much more affordable) 450 B3, which uses Teapo caps.

The 5VSB circuit is generated through a Mospec S10C60C SBR. The PWM controller is a propriety 29604 IC.

Several Chemi-Con KRG electrolytic and polymer caps form an extra layer of ripple filtering on the front side of the modular PCB. The KRG caps have a low lifetime (1000h @ 105°C). However, they don't have to endure much stress.

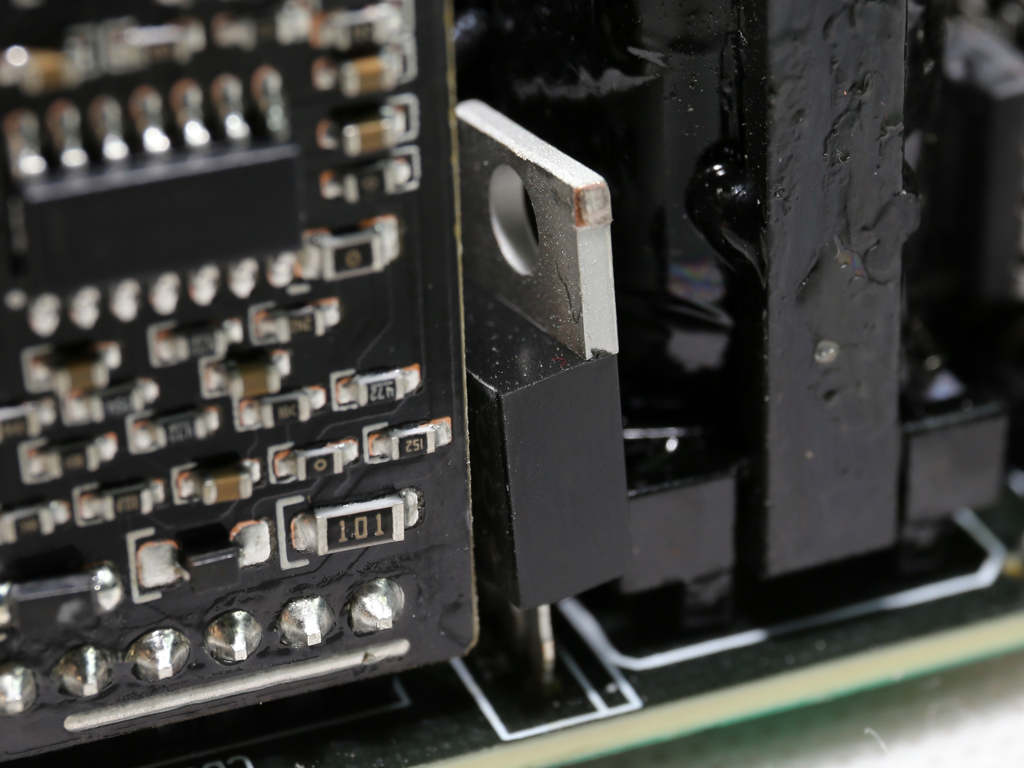

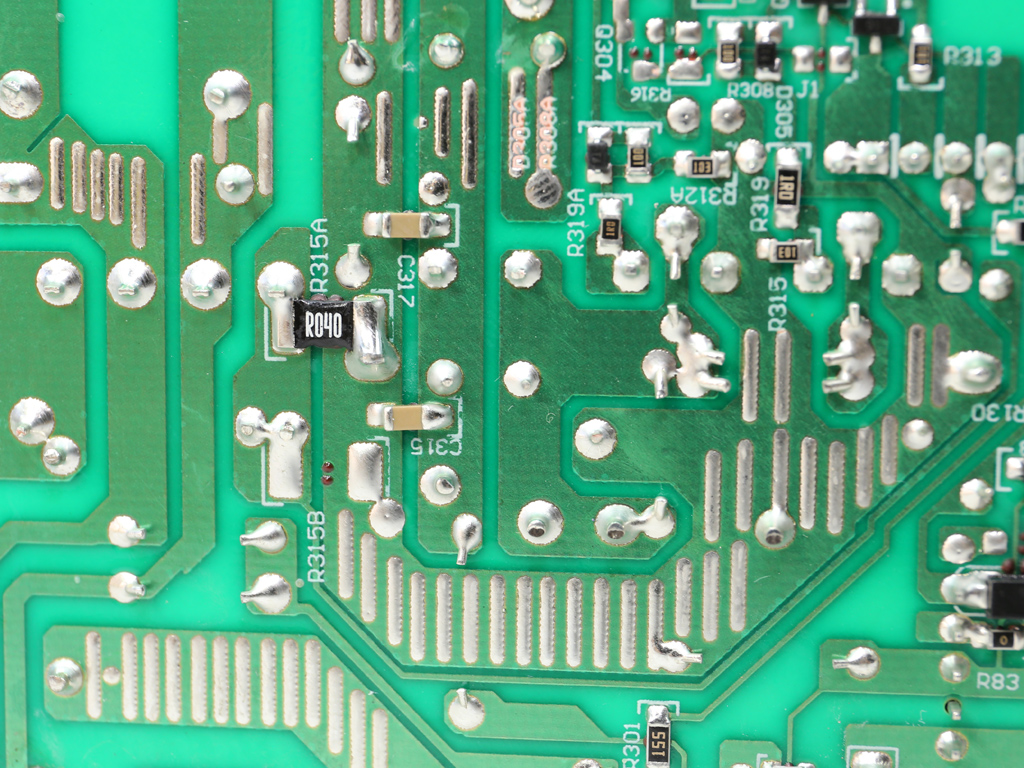

Again, the build quality we observe is mediocre. We spot many sloppy soldering joints and some long component leads that nearly come in contact with nearby PCB traces. Apparently, Super Flower or its subcontractor (RSY) didn't pay much attention to the B3 family's manufacturing process. Such lousy assembly quality reminds us of the early days of Super Flower, when this company's platforms had terrible soldering (but still somehow performed well).

The fan's model is S1282412H. It measures 130mm across and uses a sleeve bearing. We expected a better fan in a $100 PSU. Its controller is the same as what we find in other Leadex platforms, and it is installed on a vertical PCB that'll snap off if you aren't careful.

MORE: Best Power Supplies

MORE: How We Test Power Supplies

MORE: All Power Supply Content

Current page: Teardown & Component Analysis

Prev Page Packaging, Contents, Exterior & Cabling Next Page Load Regulation, Hold-Up Time & Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

orionfotl There's a typo in the Final Analysis: "Although we're glad the 850 B3 didn't blow up like the 450W model, this is our second (so fat) B3-series power supply to die on the bench."Reply

So fat.

Shame on the PSU. -

Realist9 Part of what I got from this review and the associated charts is that my next psu will likely be a Corsair unit.Reply -

dstarr3 It seems like the general wisdom is still "Don't buy a PSU unless it has a 7- to 10-year warranty." The best products from the best OEMs always come with those warranties lately.Reply -

Aris_Mp If you ask me the warranty isn't an indication from the moments it is 5 years long. On the other hand when a company avoids sending some specific PSUs for review, then the whole thing looks suspicious.Reply -

dstarr3 Reply20217010 said:If you ask me the warranty isn't an indication from the moments it is 5 years long. On the other hand when a company avoids sending some specific PSUs for review, then the whole thing looks suspicious.

I don't necessary mean that longer warranty = better product. I just mean that there are some OEMs that are better than the rest, and their best PSUs are the best on the market, and all those best PSUs happen to have 7- to 10-year warranties on them. So if you see that warranty on a PSU right now, you can reasonably assume that it is one of the best models from one of the best OEMs. -

Olle P I don't totally agree with the "Pros" and "Cons":Reply

* Six 8-pin PCIe-connectors are supposed to be capable of delivering up to 900W. This PSU can't handle that.

* The efficiency is as advertised. That's neither a "Con" nor a "Pro". (In fact I'm impressed with the efficiency at 20W load. Expected worse.)

* Sleeve bearing is what makes the fan relatively quiet, so it's not a "Con" per se. Had it been a ball bearing fan you'd written "High noise level" as a "Con" instead. -

Aris_Mp Efficiency is a con in general. It is lowReply

If the fan had DBB and an optimal fan profile then it wouldn't be a con. A sleeve bearing fan in a 100 buck PSU doesn't look good and those type of bearings are suited for horizontal installation so they should normally be avoided in PSUs. -

al3xand3r Hi Aris, congratulations for the wonderful review and all of your work.Reply

I've seen all of your reviews, but one thing I do not understand compared to other review sites and that's related to the advanced transient tests. For example, the be quiet! Pure Power 10 600W PSU, in Advanced Transient Test at +12V, 20% - 20ms has a voltage drop of 0.211V. At 50% load 20 ms is a voltage drop of 0.222 volts. Instead, at ardOCP, the same PSU records a 0.520 volt voltage drop at 20% load - 10 ms and 0.540 volts at 50% load – 10ms. And that's a huge difference. And I do not think this difference is because of the reduced time from 20ms to 10ms because at 1ms wich is tougher the drops it's not as high. What is wrong with ardOCP methodology?

Is it possible that a quality PSU like this to have a voltage drop in load so high (0.52 Volts)? And that's just an example. At all the PSU’s I've seen on both sites are differences like this. Same as when you were doing only 50ms or 200ms. Is there any explanation for these figures that do not coincide?

Thank you