EVGA SuperNOVA 550 GS PSU Review

EVGA teamed up with Seasonic to release an affordable, mid-capacity, 80 PLUS Gold, fully modular PSU, the SuperNOVA 550 GS, which costs just $90.

Why you can trust Tom's Hardware

A Look Inside And Component Analysis

Parts Description

Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station and a Hakko 808 desoldering gun.

| Primary Side | |

|---|---|

| OEM | Seasonic |

| Transient Filter | 6x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor & Relay |

| Bridge Rectifier(s) | 1x GBU10V08 (800V, 10A @ 85 C) |

| APFC MOSFETs | 2x Infineon IPD65R225C7(700V, 11A @ 100 C, 0.225mΩ) |

| APFC Boost Diode | 1x Vishay 8EWX06FN (600V, 8A @ 175 C) |

| Hold-Up Cap(s) | 1x Rubycon (420V, 470uF, 3000h @ 105 C, MXG) |

| Main Switchers | 2x Infineon IPD50R280CE (550V, 8.2A @ 100 C, 0.28mΩ) |

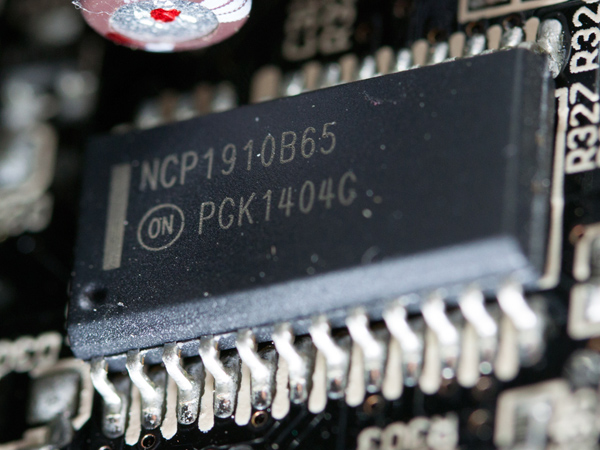

| Combo APFC & Resonant Controller | On Semiconductor NCP1910 |

| Topology | Primary side: Half-Bridge & LLC Resonant ConverterSecondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

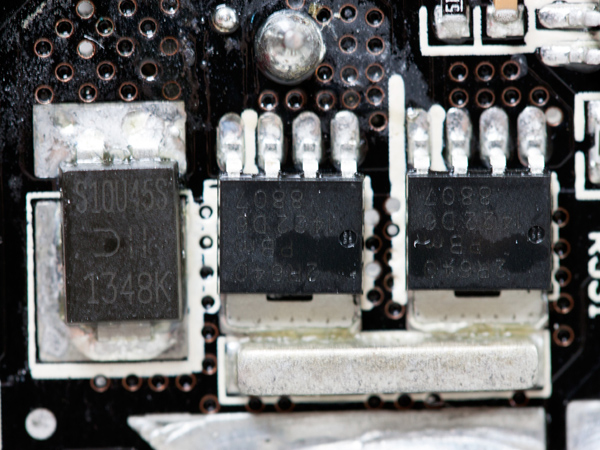

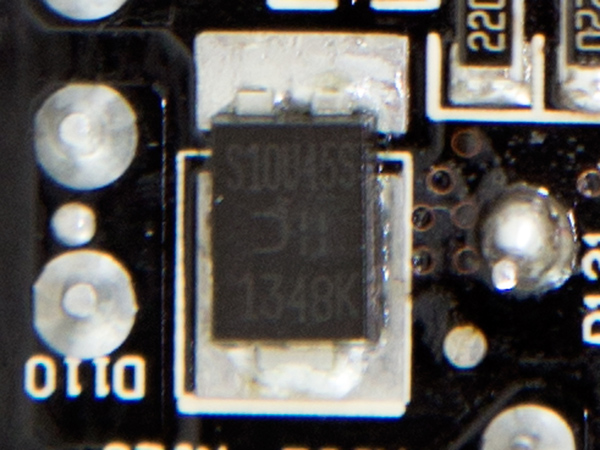

| +12V Regulators | 4x NXP PSMN2R6-40YS MOSFETs (40V, 100A @ 100 C, 3.7mΩ)2x SBR10U45S SBRs (45V, 10A @ 110 C, 0.54V Forward Voltage Drop @ 125 C) |

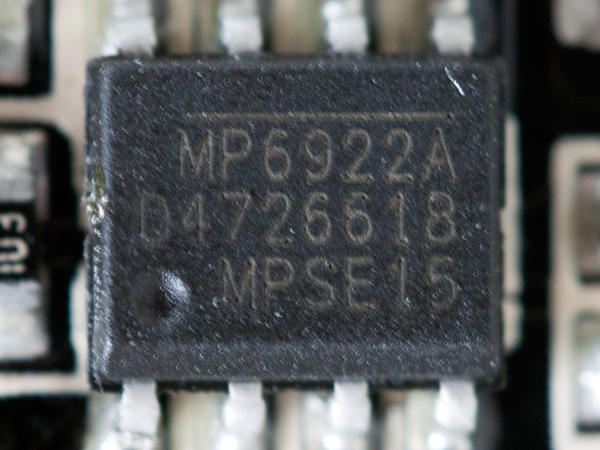

| +12V Synchronous Rectifier | Monolithic Power Systems MP6922A |

| 5V & 3.3V | DC-DC Converters |

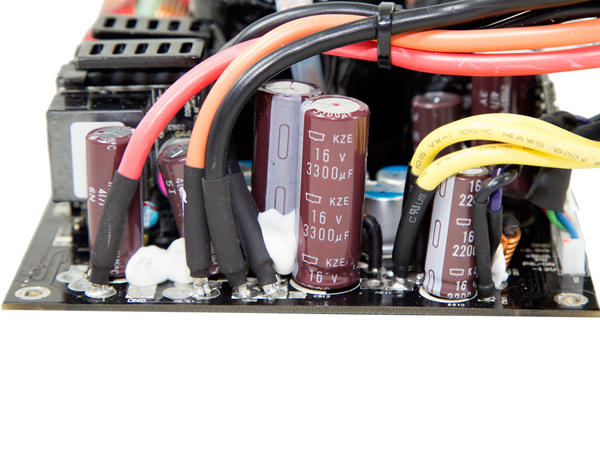

| Filtering Capacitors | Electrolytics: Nippon Chemi-Con (KY 5000h @ 105 C, KZE 5000h @ 105 C)Polymers: Nippon Chemi-Con, EneSol, NIC |

| Supervisor IC | HY-510N (OVP, UVP, SCP) |

| Fan Model | Jet Motor T1202512LLN (120mm, 12V, 0.2A) |

| 5VSB Circuit | |

| Rectifying Diode | 1x SBR10U45S |

| Standby PWM Controller | Fairchild FSQ0365 |

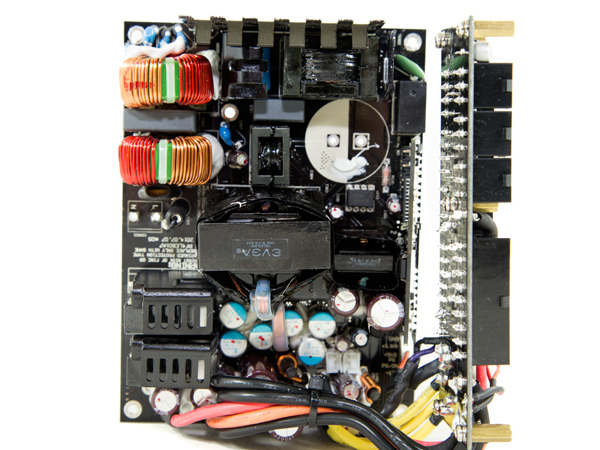

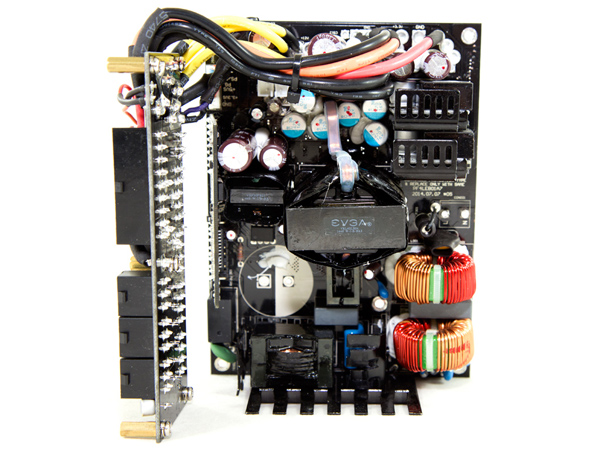

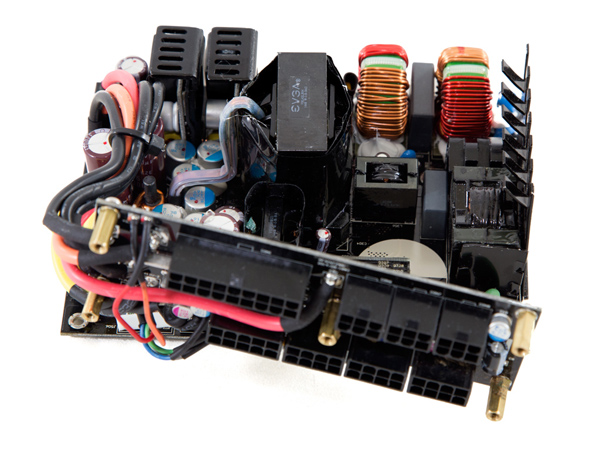

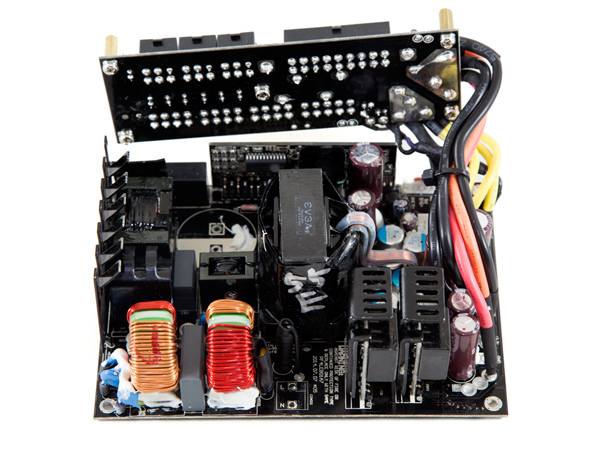

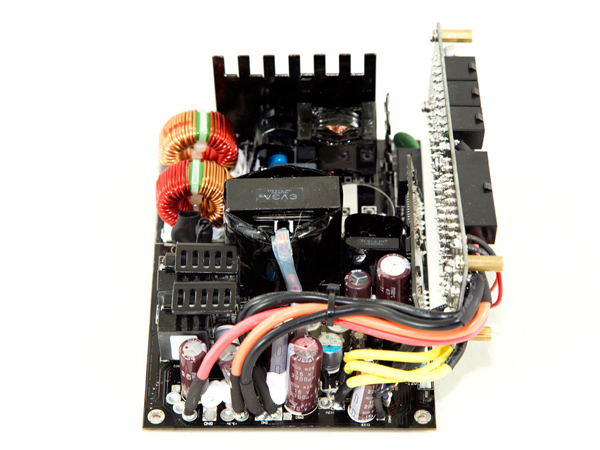

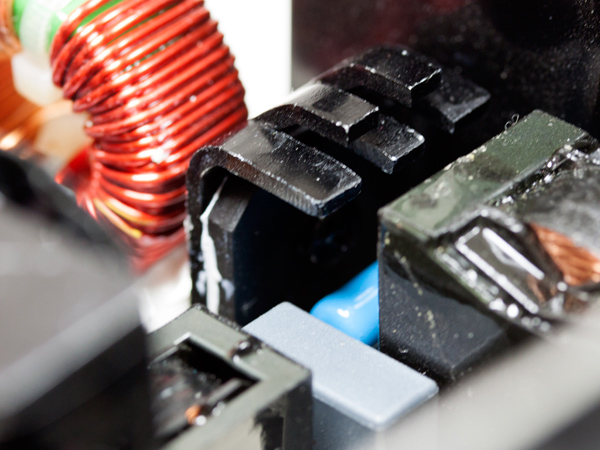

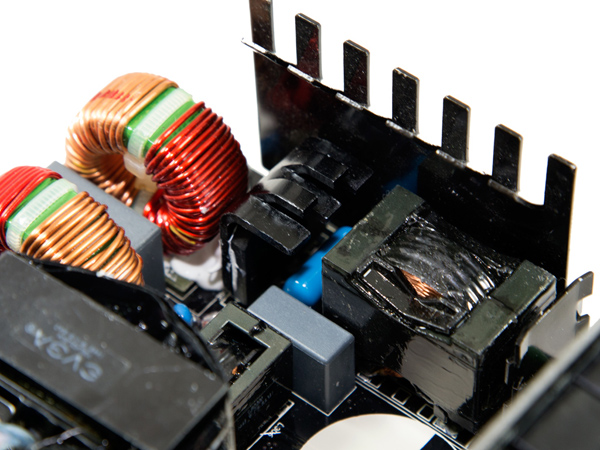

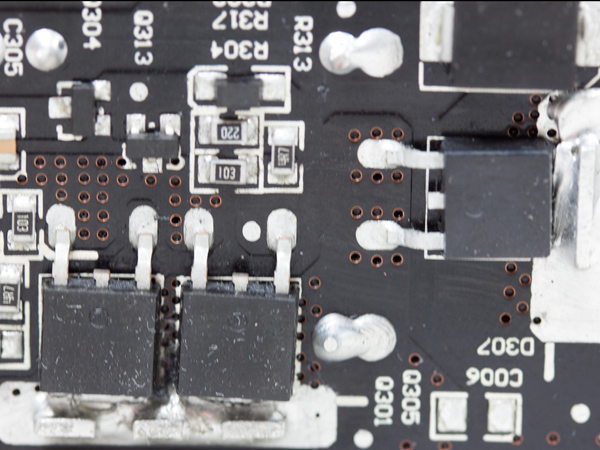

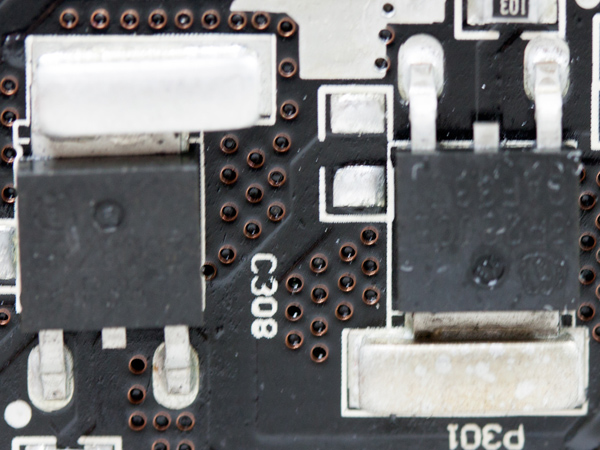

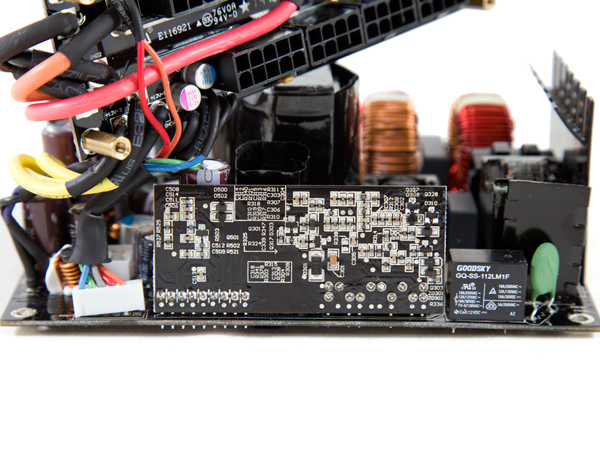

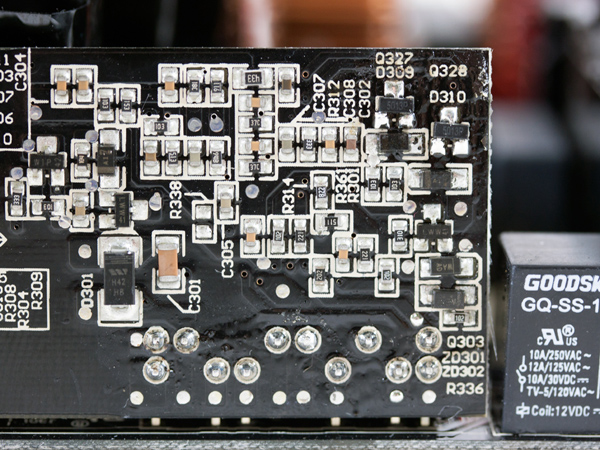

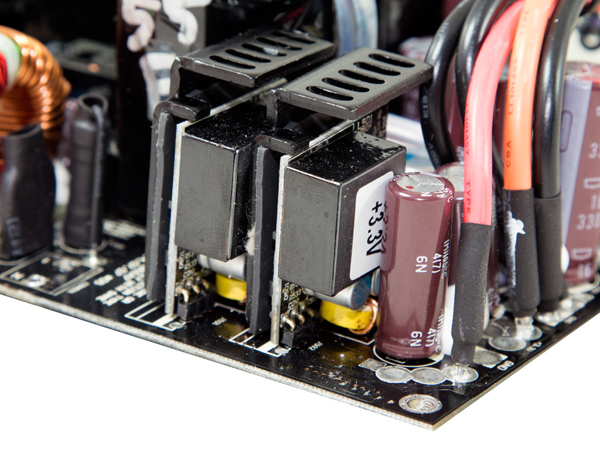

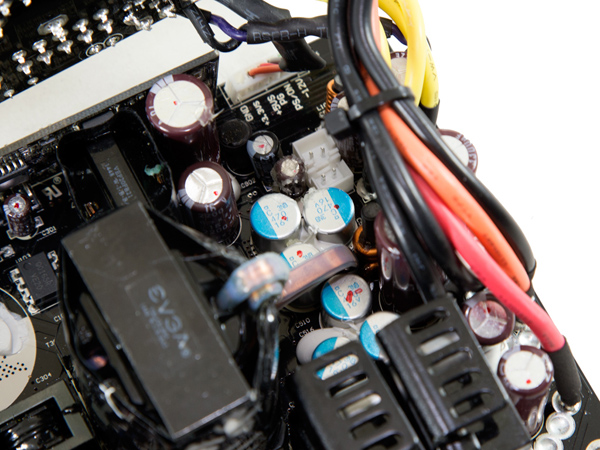

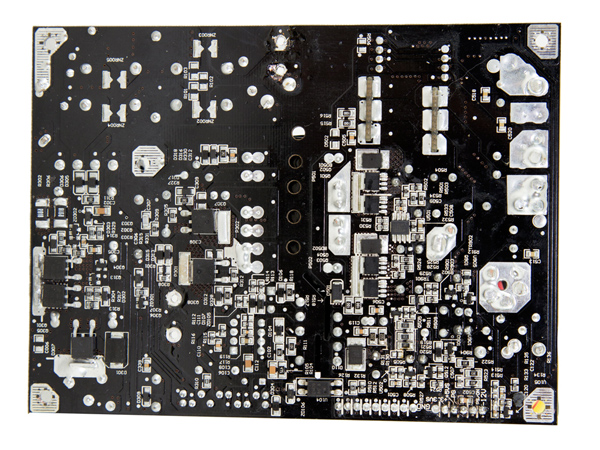

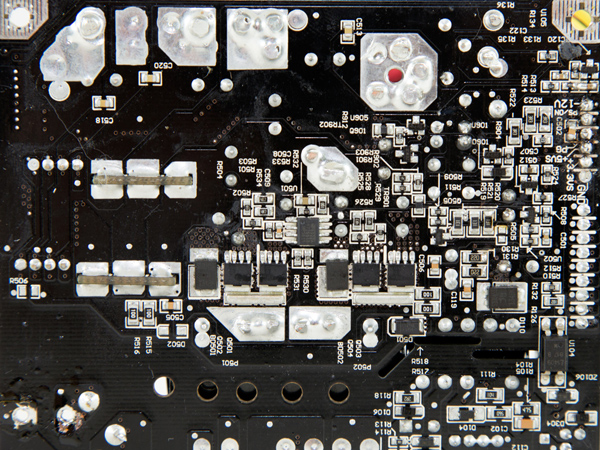

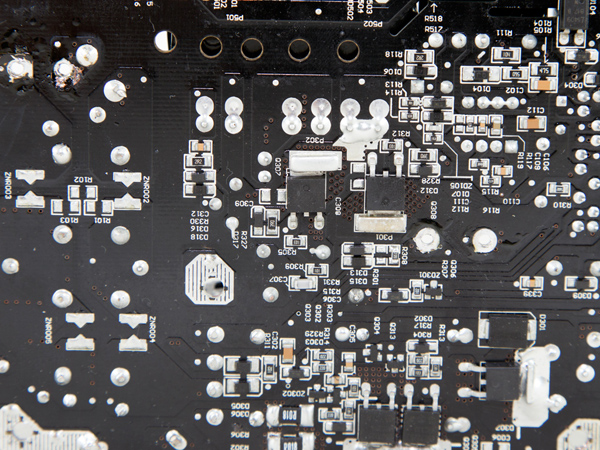

This PSU utilizes a Seasonic platform that we haven't encountered before. The first thing we noticed is that all switching MOSFETs except for the ones used in the DC-DC converters are installed on the solder side of the main PCB. This allows for the installation of only one large heat sink with nothing bolted onto it. This heat sink helps dissipate thermal energy from the installed MOSFETs below it. We don't know what led Seasonic to use only surface-mount MOSFETs in this PSU, but the company must have had its reasons. And, according to our test results, this PSU achieves high efficiency levels under light and normal loads. On the primary side, a half-bridge topology is utilized along with an LLC resonant converter, while on the secondary side, a synchronous design is used with two DC-DC converters regulating the minor rails.

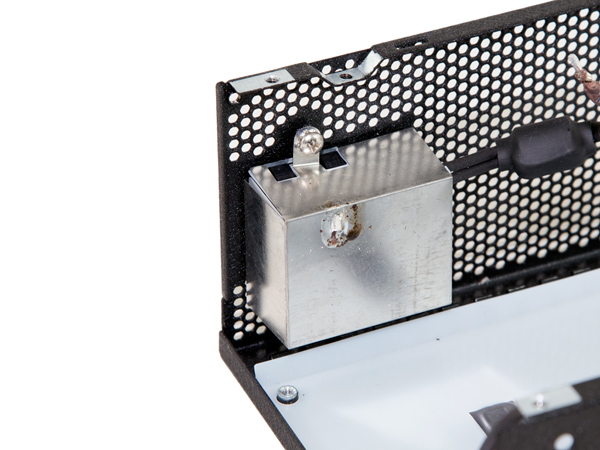

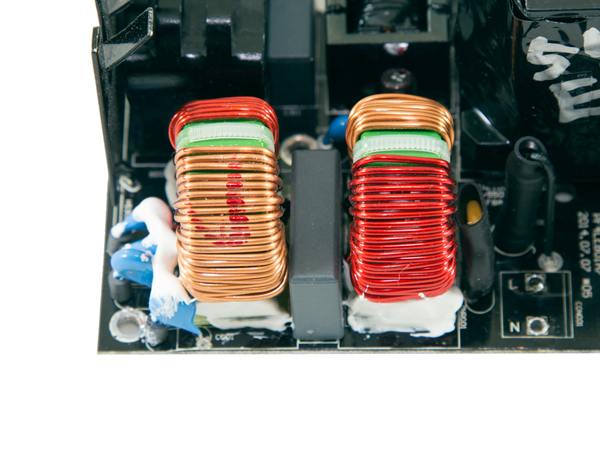

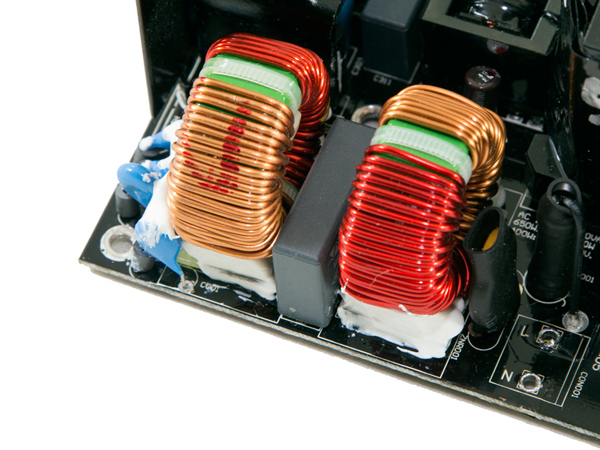

The first part of the EMI filter is right behind the AC receptacle and is shielded. It includes two Y caps and a single X cap. The remaining parts of this filter are on the main PCB, consisting of two pairs of Y caps, one X cap, two CM chokes and an MOV. The EMI filter is more than complete in this unit.

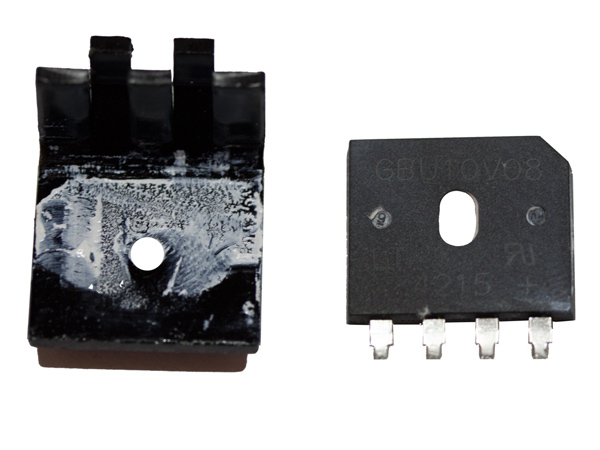

The single bridge rectifier (model number GBU10V08) is bolted on a dedicated heat sink. It can rectify up to 10A of current, so it easily meets this PSU's demands. After the aforementioned bridge rectifier, we find the PFC input capacitor, which filters high-frequency ripple.

In the APFC converter, two Infineon IPD65R225C7 FETs are used along with a Vishay 8EWX06FN boost diode, both soldered on the solder side of the PCB. A large heat sink along with a much smaller heat sink are installed on the component side of the PCB. The bulk cap is provided by Rubycon (420V, 470uF, 3000h at 105 degrees C, MXG) and seems to have enough capacity to offer sufficient hold-up time. Taking into account the bulk cap's specifications and assuming a 60-degree Celsius operating temperature, its expected lifetime is 75,000 hours or 8.5 years of continuous operation. It's more likely that the cooling fan will fail before this bulk capacitor, especially since a 60C internal PSU temperature reflects an extreme case. Next to the bulk cap, the NTC thermistor is installed for protection against large inrush currents, along with an electromagnetic relay that bypasses the thermistor once the start-up phase finishes.

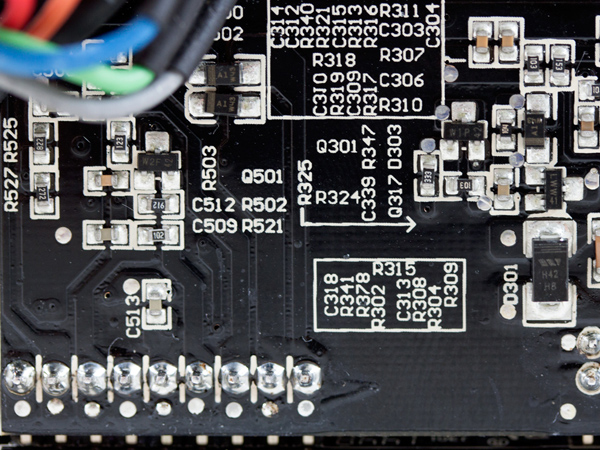

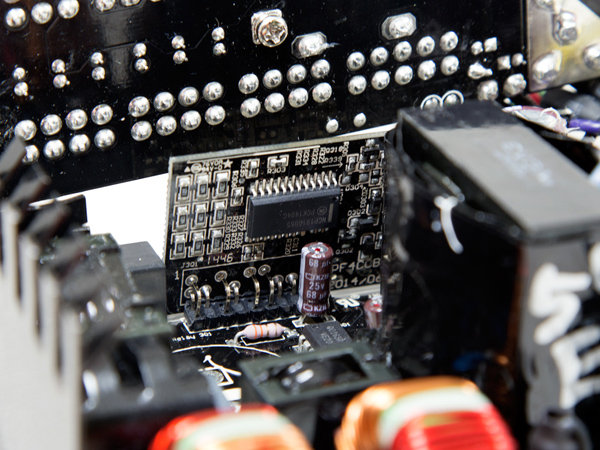

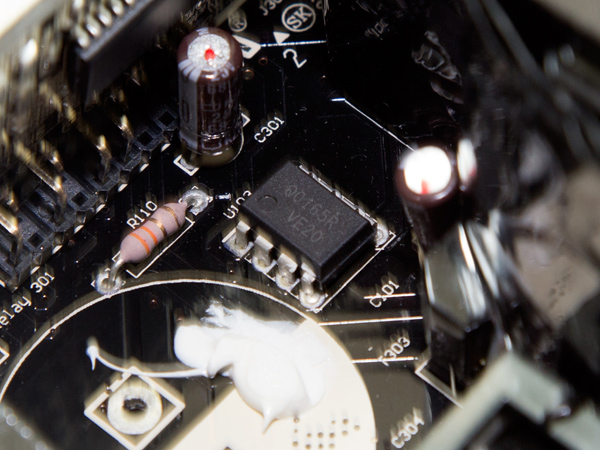

The main switchers, arranged into a half-bridge topology, include two Infineon IPD50R280CE FETs. These FETs dissipate heat through the PSU's chassis, since there isn't a heat sink installed on top of them. Instead, we find an LLC resonant tank. The combo APFC/resonant controller (model number NCP1910 IC) provided by ON Semiconductor is installed on a daughter board. On the same board, we also find a HY-510N supervisor IC, which offers only basic protection features (OVP, UVP, SCP). The over-power protection, which is an essential feature (especially when over-current protection isn't present), is handled by the NCP1910 IC.

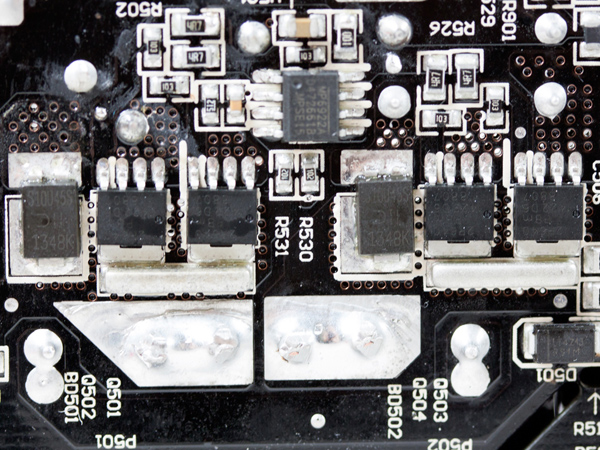

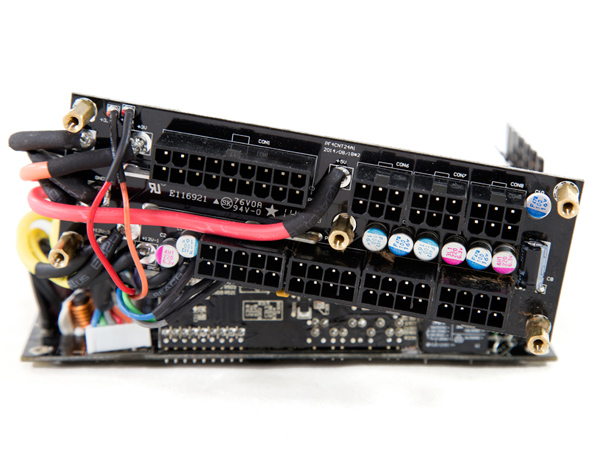

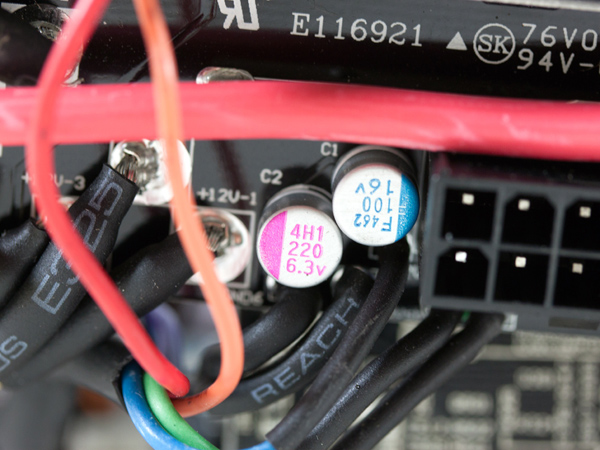

On the secondary side of the PCB, four NXP PSMN2R6-40YS FETs are used for the generation of the +12V rail along with two SBR10U45S SBRs that increase efficiency. They replace the body diodes of these FETs, which have larger voltage drops. The minor rails regulate two DC-DC converters, which are installed on two small heat sinks. The view of the components used on the DC-DC converters was blocked, and we didn't want to fully desolder both boards in order to identify them. Finally, ripple filtering on the secondary side of the main PCB is done by a mix of polymer and electrolytic caps manufactured by Chemi-Con. We also found a small Rubycon electrolytic cap.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The standby PWM controller is a Fairchild FSQ0365, while the Schottky Barrier Rectifier (SBR) that generates the 5VSB rail is an SBR10U45S. The SBR is installed on the solder side of the main PCB.

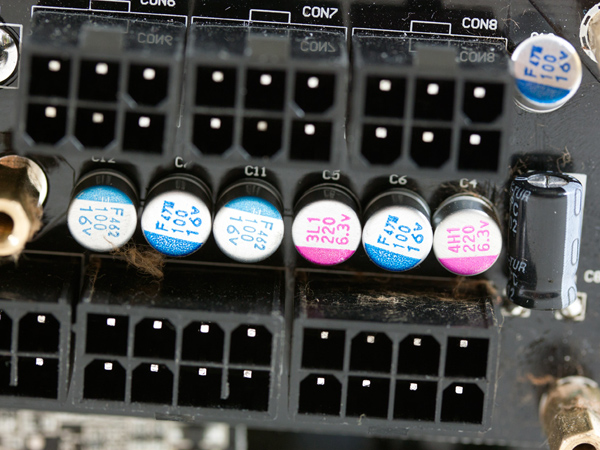

On the front of the modular PCB, a mix of Chemi-Con, Enesol and NIC polymer caps, along with a single, small electrolytic cap, are used to filter the rails. We're not impressed by the build quality on the back side of the modular PCB, though. We are used to higher standards from Seasonic. In this PSU, we noticed several flaws like the leaning daughter board that holds the APFC/resonant controller and the awkward installation of the header that provides voltage signals to the modular board.

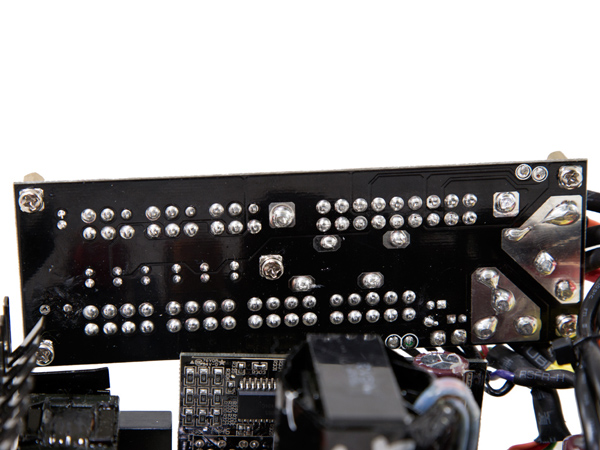

Fortunately, soldering quality at the rear side of the main PCB is pretty good, although not among Seasonic's best. This isn't one of the company's high-end platforms of course, so we can't expect perfection.

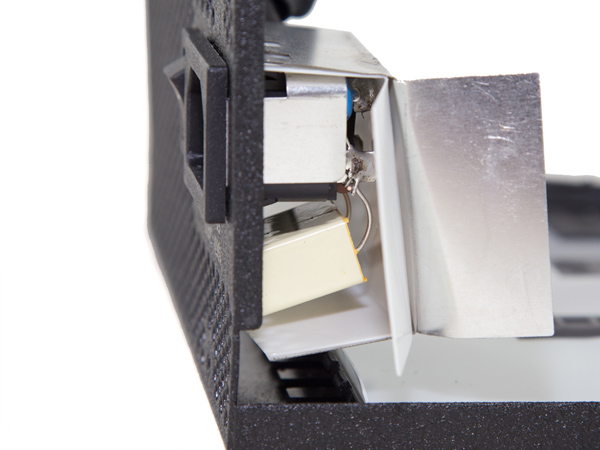

The cooling fan uses a Teflon-coated bearing that, along with an air pressure effect, provides better characteristics and a longer lifetime compared to sleeve-bearing fans. According to EVGA, this type of bearing offers low noise output and should last longer than 80,000 hours at 40 degrees C ambient. Since it doesn't use oil, it isn't prone to leakage. On top of that, it is more suitable for horizontal installation, which is the main problem for sleeve-bearing fans that don't have gaskets to secure the oil inside the bearing's compartment.

Current page: A Look Inside And Component Analysis

Prev Page Packaging, Contents, Exterior And Cabling Next Page Load Regulation, Hold-Up Time And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

Aris_Mp my last reviews were of smaller capacity units and I will try to bring even more of them.Reply -

Luay Coorection, EVGA did release a gold rated 1050W and 850W Seasonic PSU also branded as GS, and a platinum 1000W PS. There's also a 650W version of the PSU reviewed here which takes the total to five Seasonic OEMs branded by EVGA.Reply -

Larry Litmanen ReplyThere are less rippletastic options at that price point.

For the most part when it comes to PC parts you get what you pay for. Unless you spot a great sale, a 550W fully modular, 80 Gold PSU from a company like EVGA with a 5 year warranty. EVGA is super easy to deal with should you need to replace a unit. All that for $90? If this PSU was a 650W unit with same features and for the same price it would have been perfect.

-

atheus Reply

You mean the price would have been perfect? Confusing idea to change the wattage rather than just change the price. I take that to mean instead of a certain price/performance you would rather have a 650 watt PSU than a 550.There are less rippletastic options at that price point.

For the most part when it comes to PC parts you get what you pay for. Unless you spot a great sale, a 550W fully modular, 80 Gold PSU from a company like EVGA with a 5 year warranty. EVGA is super easy to deal with should you need to replace a unit. All that for $90? If this PSU was a 650W unit with same features and for the same price it would have been perfect.

I see 650 watt PSU's as only for SLI systems, which are fairly niche. With 550 you can handle any single GPU, and in the case of Maxwell GPU's <= 980 you could even SLI them so long as you aren't doing some obscene overclocking or running a dozen fans and pumps and a datacenter worth of HDD's. So for my go-to wattage for a standard high performance single GPU build is 550. For medium performance 450 is even better. -

logainofhades Unless you really feel the need for a gold rated PSU, I would probably save some cash and stick with a Seasonic 520w or 620w M12II. Even the 750w B2 series is cheaper.Reply -

Aris_Mp ReplyCoorection, EVGA did release a gold rated 1050W and 850W Seasonic PSU also branded as GS, and a platinum 1000W PS. There's also a 650W version of the PSU reviewed here which takes the total to five Seasonic OEMs branded by EVGA.

This is exactly what I write inside the review. Four GS PSUs and one PS.

"So far, the new PS series includes only a single unit with 1kW of max power; EVGA's GS line, on the other hand, has four PSUs with 550, 650, 850 and 1050W capacities."

I also have the 650 GS in my lab, but this isn't for Tom's.