Tom's Hardware Verdict

The FSP Hydro PTM Pro 1200W achieves satisfactory performance, but there is room for improvement.

Pros

- +

Full power at 47 degrees Celsius

- +

High build quality

- +

Quiet operation

- +

Highly efficient 5VSB rail

- +

Loads of connectors

- +

Fully modular

Cons

- -

Two EPS on the same cable

- -

Couldn't deliver 110% power

- -

High Vampire Power with 230V input

- -

Low efficiency with 2% load

- -

High OCP on the minor rails

- -

Large dimensions

Why you can trust Tom's Hardware

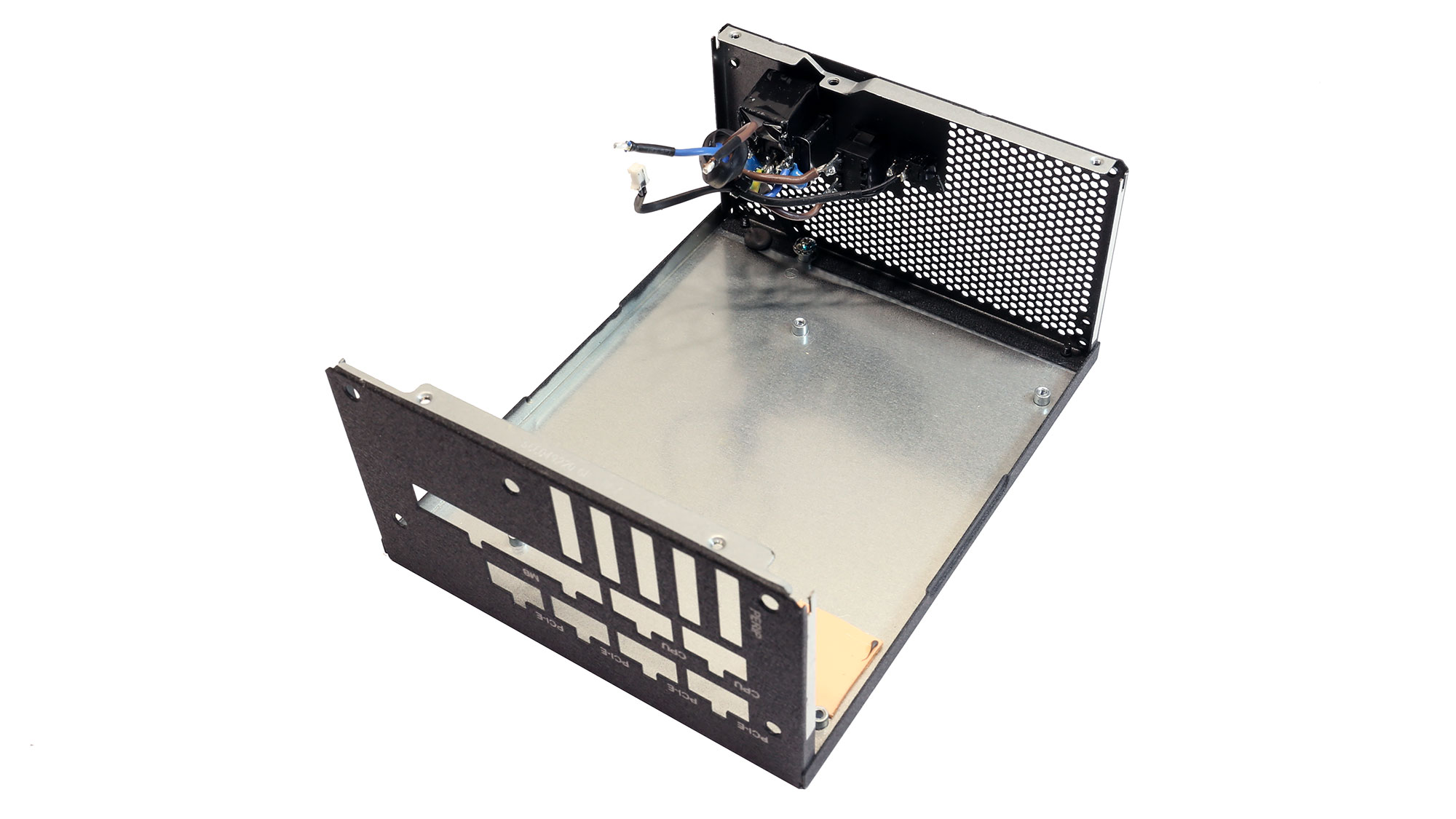

The FSP Hydro PTM Pro with 1200W capacity is a powerful PSU, able to keep up with the energy needs of the new generation, energy-hungry GPUs. It falls a little behind in terms of overall performance compared to the high-end offerings from Asus, Corsair, Thermaltake, and Seasonic, so that it won't be added to our best PSU picks article. Nonetheless, its build quality is high, and a hefty warranty supports it.

The FSP Hydro PTM Pro consists of four members with capacities ranging from 650W to 1200W. One major feature is that they all meet the new IEC62368 safety requirements. Another interesting feature is the Off-Wet technology "conformal coating," which protects the power supply and its internal components from dust and humidity. According to FSP, the Hydro PTM PRO series is tested to work properly even in 95% relative humidity. This is an interesting feature for users wanting PSU for harsh environments.

Product Photos

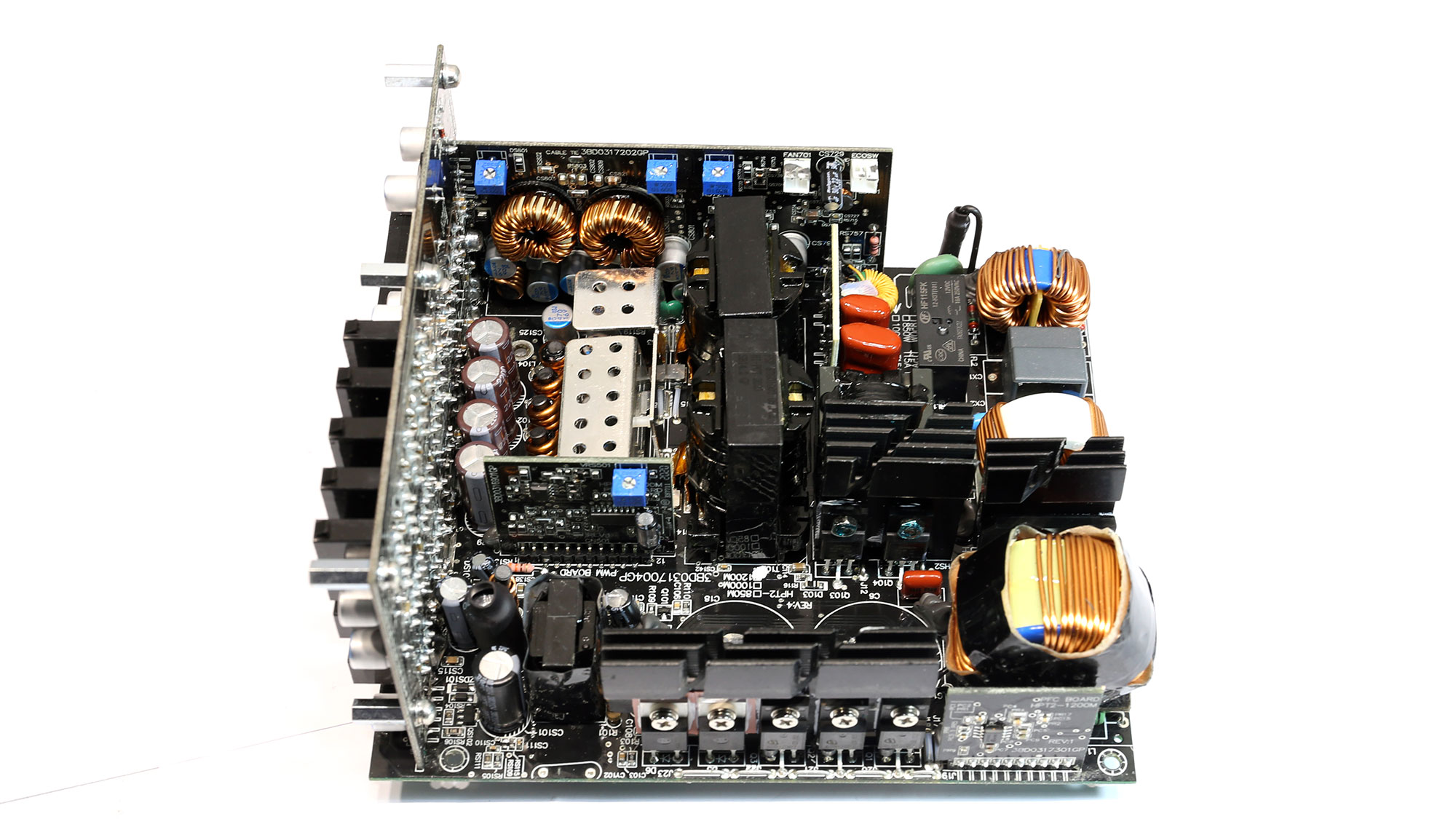

We will evaluate the flagship Hydro PTM Pro model with 1200W max power in this review. This unit uses a full-bridge topology, which is ideal for powerful power supplies. Given the ten-year warranty, we expect this platform to fare well in the long run and not cause any issues. Nonetheless, we will fully break the PSU to check its build quality and the quality of the parts that FSP used. A product review is not complete without a full break-down and a detailed part analysis.

To keep noise output as low as possible, especially with light and moderate loads, FSP equipped this unit with a semi-passive operation. They call it ECO mode, and it can be deactivated through a switch located at the PSU's front side. So users wanting the PSU's fan to operate all around the clock have this option.

Product Photos

Specifications

|

Manufacturer (OEM) |

FSP |

|

Max. DC Output |

1200W |

|

Efficiency |

80 PLUS Platinum, ETA-A (88-91%) |

|

Noise |

LAMBDA-A- (25-30 dB[A]) |

|

Modular |

✓ (Fully) |

|

Intel C6/C7 Power State Support |

✓ |

|

Operating Temperature (Continuous Full Load) |

0 - 50°C |

|

Over Voltage Protection |

✓ |

|

Under Voltage Protection |

✓ |

|

Over Power Protection |

✓ |

|

Over Current (+12V) Protection |

✓ |

|

Over Temperature Protection |

✓ |

|

Short Circuit Protection |

✓ |

|

Surge Protection |

✓ |

|

Inrush Current Protection |

✓ |

|

Fan Failure Protection |

✗ |

|

No Load Operation |

✓ |

|

Cooling |

135mm Fluid Dynamic Bearing Fan (MGA13512XF-A25) |

|

Semi-Passive Operation |

✓ (selectable) |

|

Dimensions (W x H x D) |

150 x 85 x 190mm |

|

Weight |

2 kg (4.41 lb) |

|

Form Factor |

ATX12V v2.4, EPS 2.92 |

|

Warranty |

10 Years |

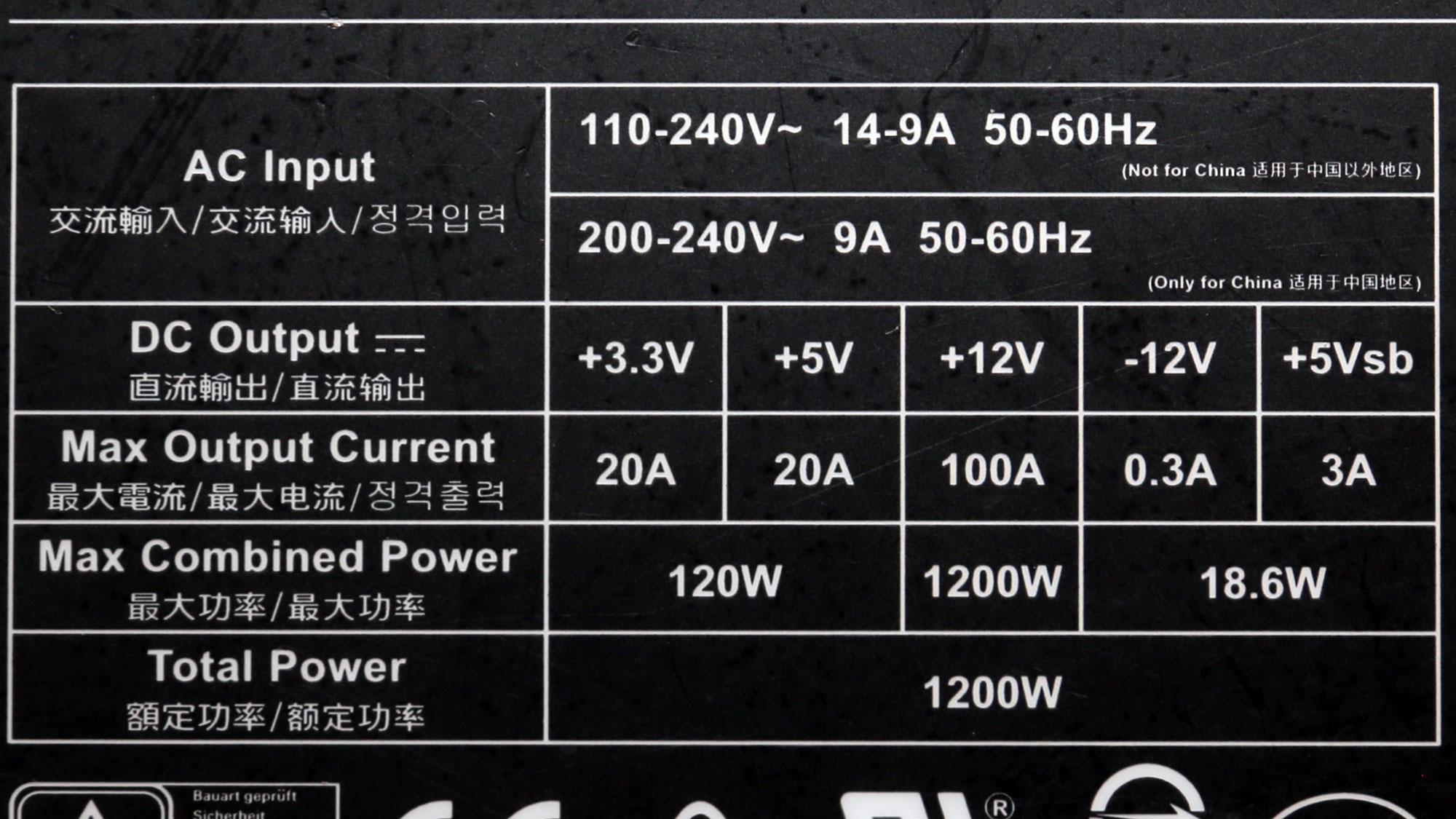

Power Specifications

| Rail | 3.3V | 5V | 12V | 5VSB | -12V | |

|---|---|---|---|---|---|---|

| Max. Power | Amps | 20 | 20 | 100 | 3 | 0.3 |

| Watts | 120 | 1200 | 15 | 3.6 | ||

| Total Max. Power (W) | 1200 |

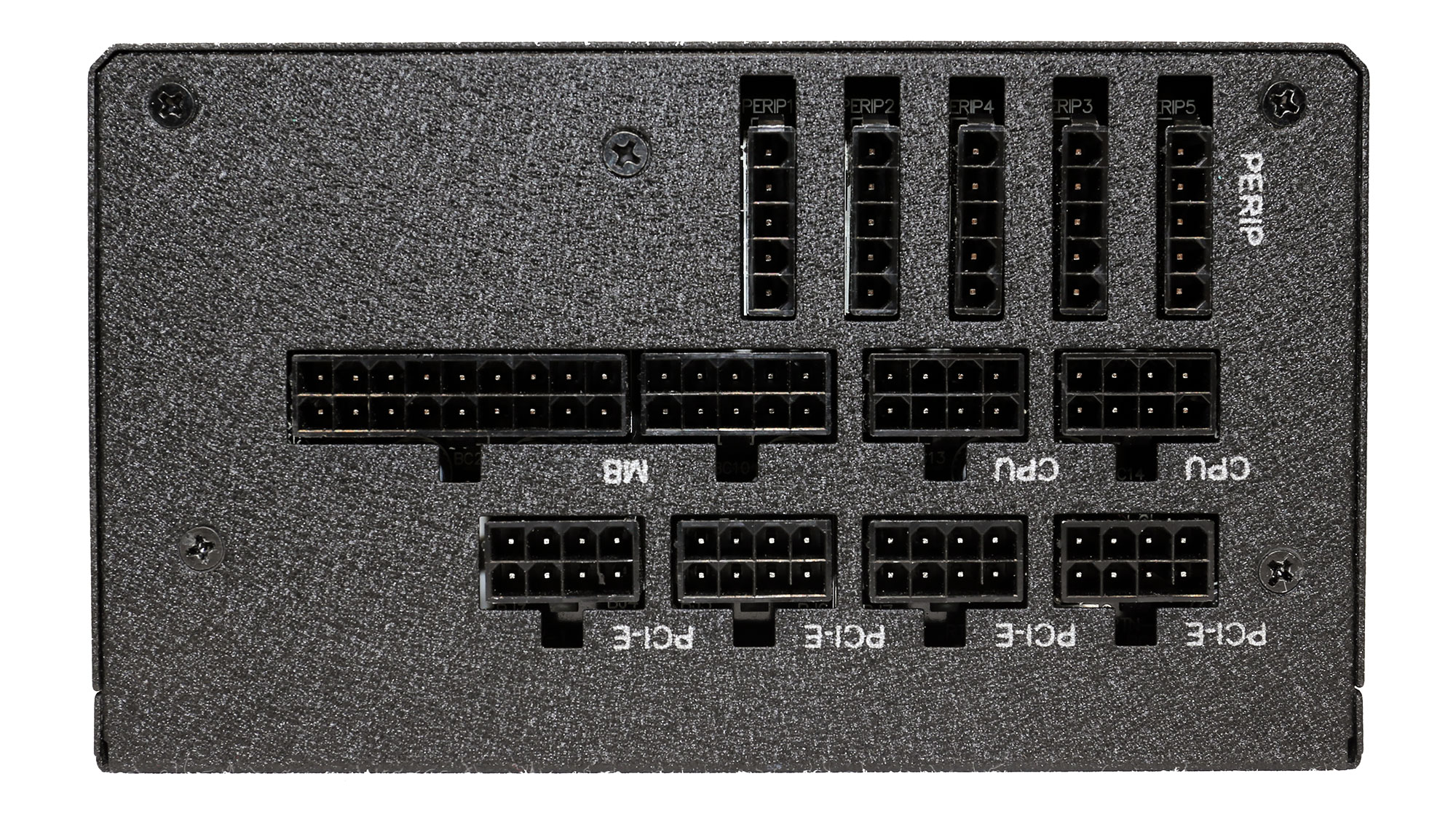

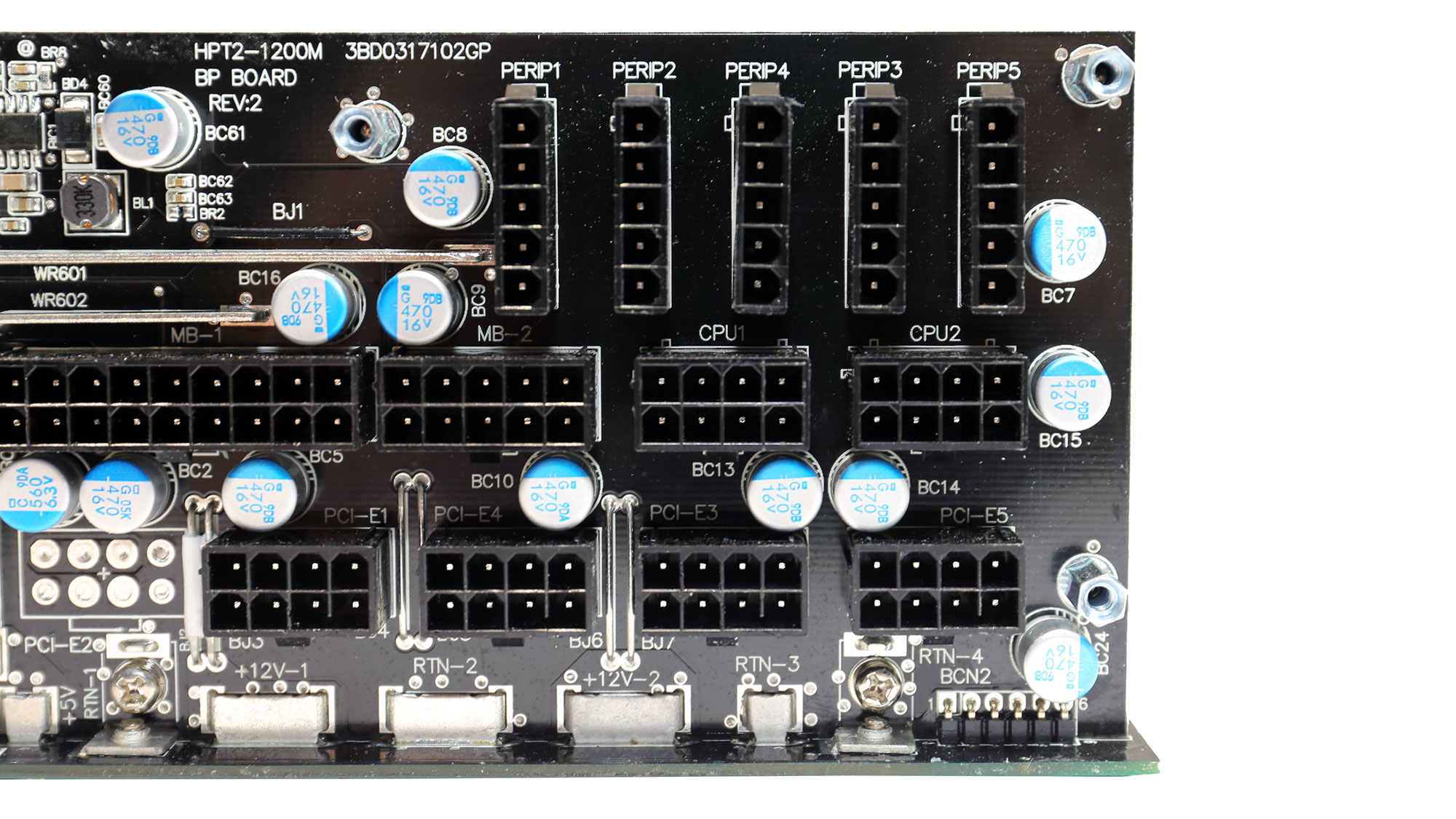

Cables & Connectors

| Modular Cables | Cable Count | Connector Count (Total) | Gauge | In Cable Capacitors |

|---|---|---|---|---|

| ATX connector 20+4 pin (600mm) | 1 | 1 | 16-22AWG | No |

| 4+4 pin EPS12V (700mm) | 1 | 1 | 16AWG | No |

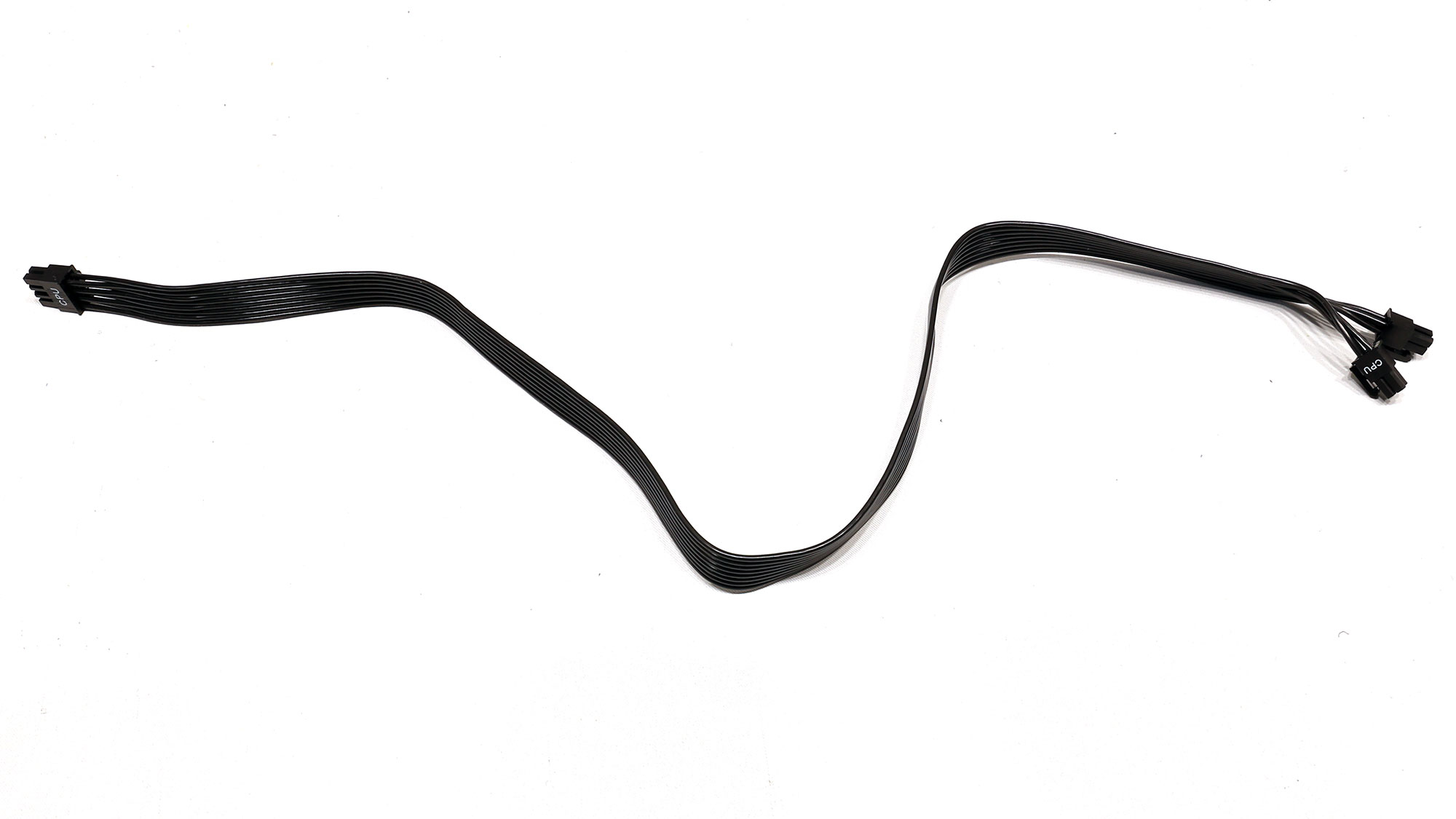

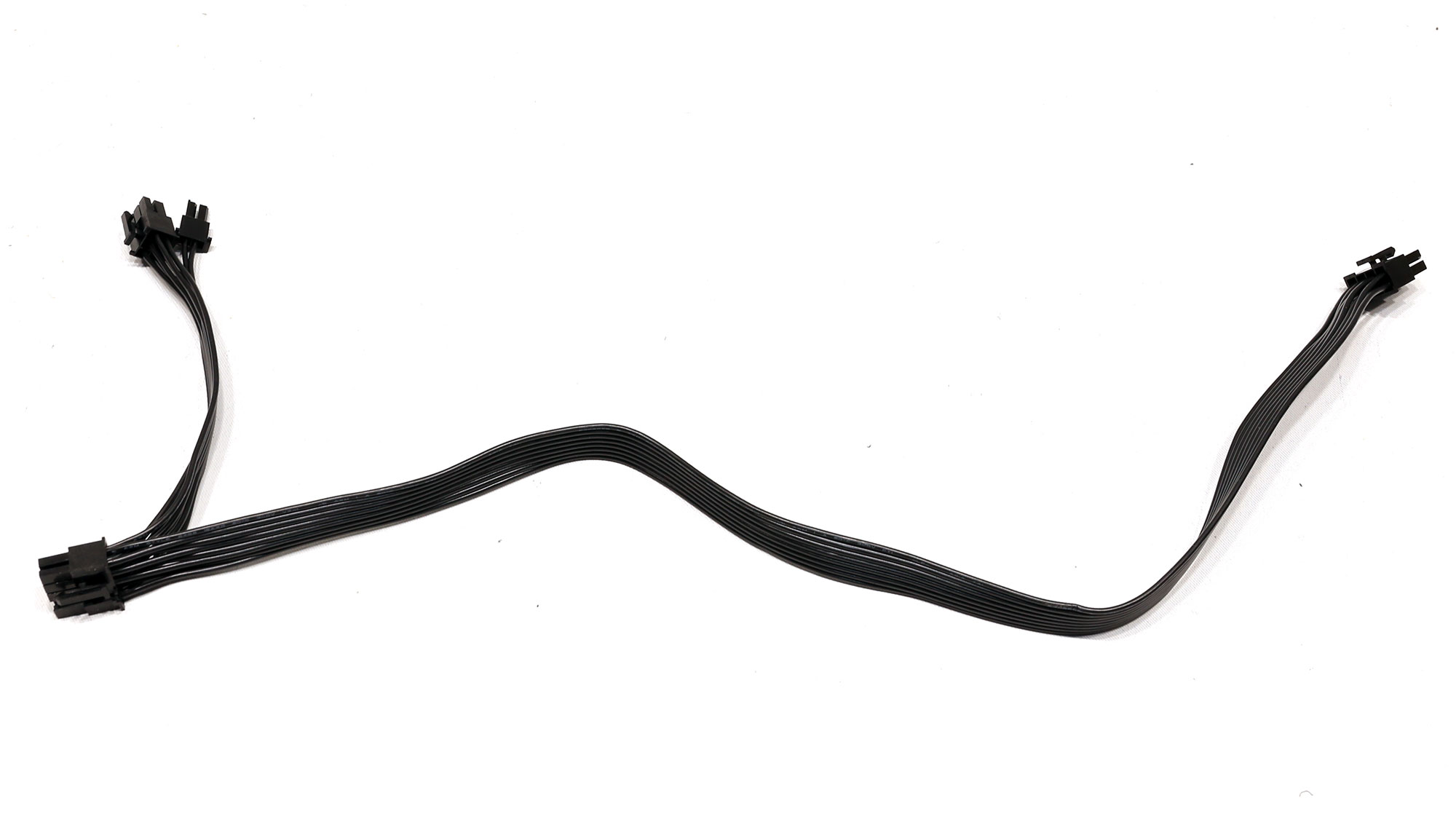

| 8 pin EPS12V (700mm) / 4+4 pin EPS12V (150mm) | 1 | 2 | 18AWG | No |

| 6+2 pin PCIe (650mm+150mm) | 2 | 4 | 18AWG | No |

| 6+2 pin PCIe (500mm+150mm) | 2 | 4 | 18AWG | No |

| SATA (510mm+160mm+160mm+160mm) | 2 | 8 | 18AWG | No |

| SATA (510mm+160) / 4-pin Molex (+160mm+160mm) | 2 | 4 / 4 | 18AWG | No |

| SATA (510mm+160) / 4-pin Molex (+160mm) / FDD (+160mm) | 1 | 2 / 1 / 1 | 18-22AWG | No |

| AC Power Cord (1440mm) - C13 coupler | 1 | 1 | 16AWG | - |

The PSU comes with not two but three EPS connectors! Apparently, FSP knows something that we don't (mainboards with three EPS sockets?) The problem here is that a pair of these connectors are installed on a single cable, and to make matters even worse, this cable uses the standard 18AWG gauges instead of thicker ones. This means that if you push both EPS connectors hard, you will most likely melt either the gauges or the connector on the PSU's side. If you want to offer three EPS connectors, you should do it properly, and this is through dedicated cables—each EPS connector on its own cable.

There are no dedicated PCIe cables, and you should be careful not to use a single PCIe cable with two corresponding connectors on a power-hungry graphics card (e.g., Nvidia RTX 3080 or RTX 3090). Else you could damage both the PSU and the graphics card.

The amount of provided connectors is huge, and it is also nice to see an adequate distance between the peripheral connectors.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Cable Photos

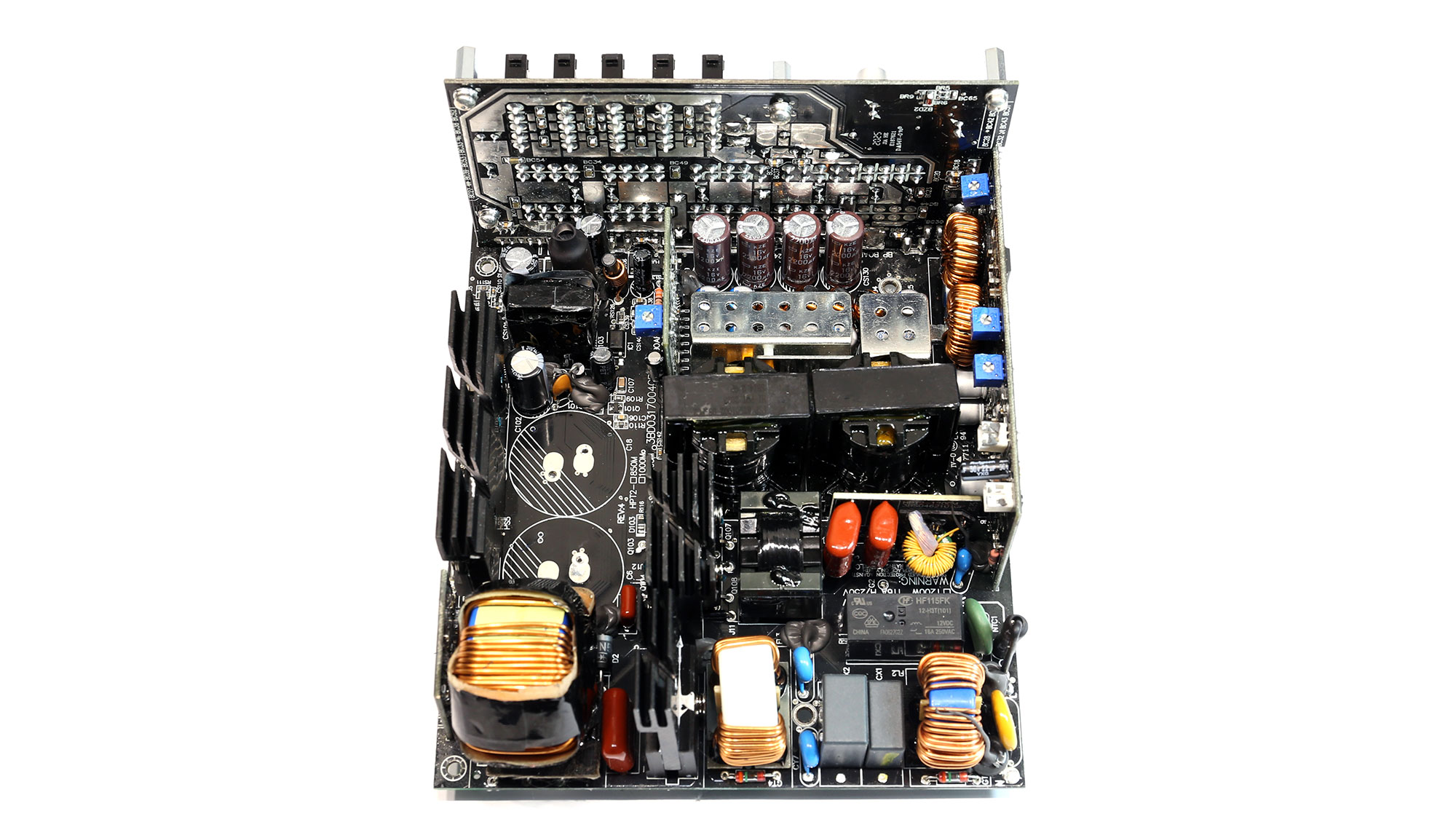

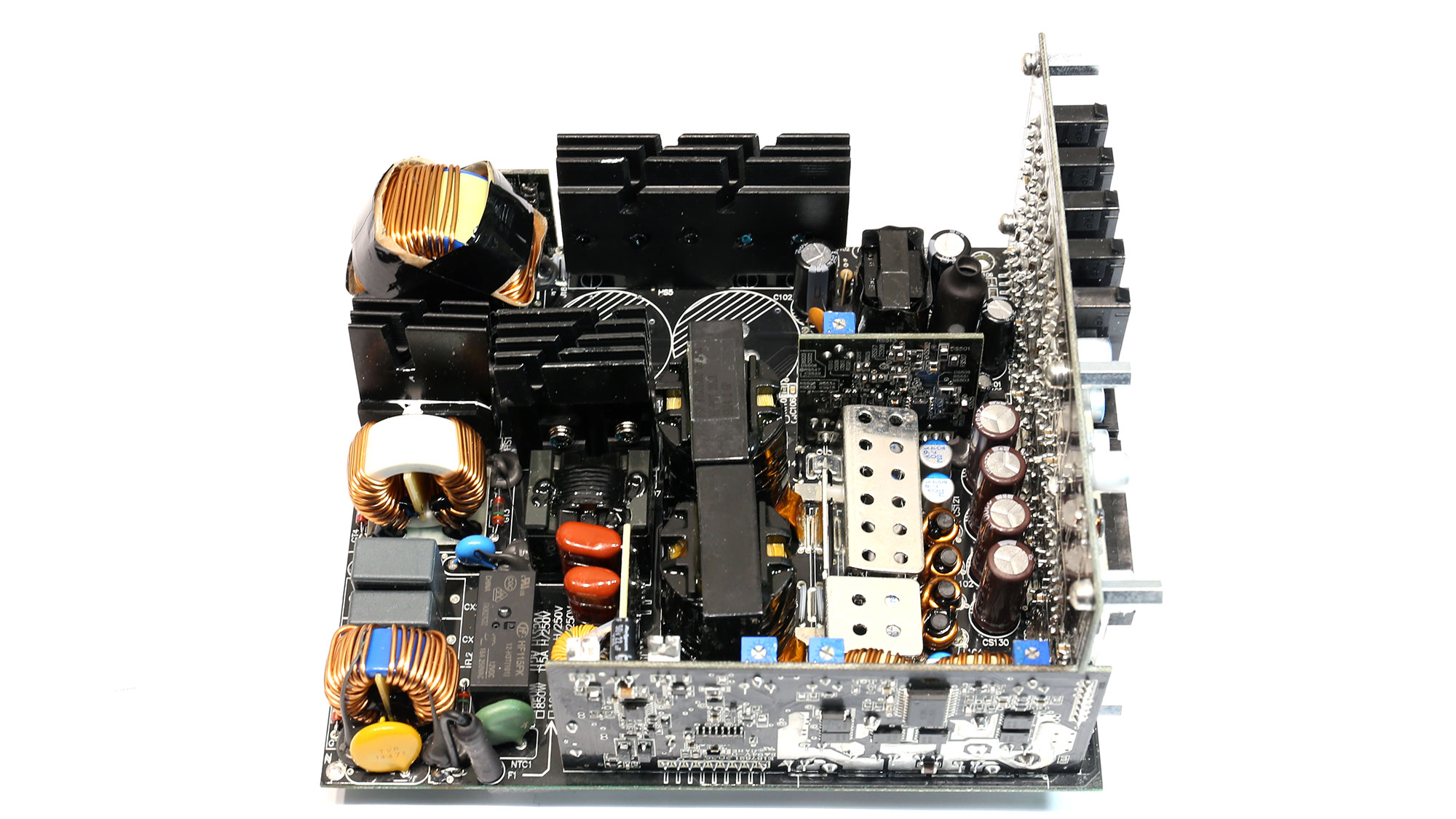

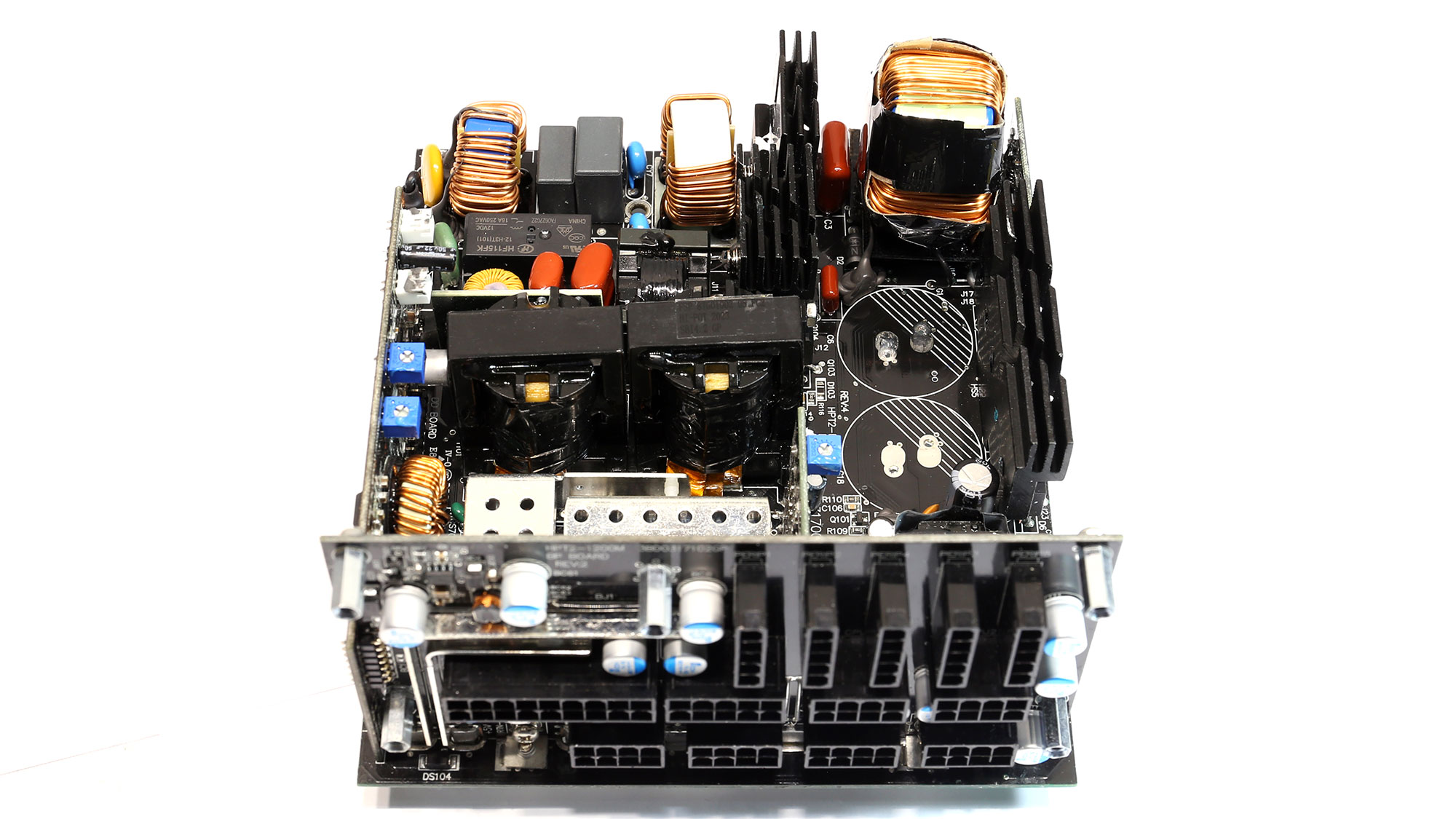

Component Analysis

We strongly encourage you to have a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss.

| General Data | - |

| Manufacturer (OEM) | FSP |

| PCB Type | Double Sided |

| Primary Side | - |

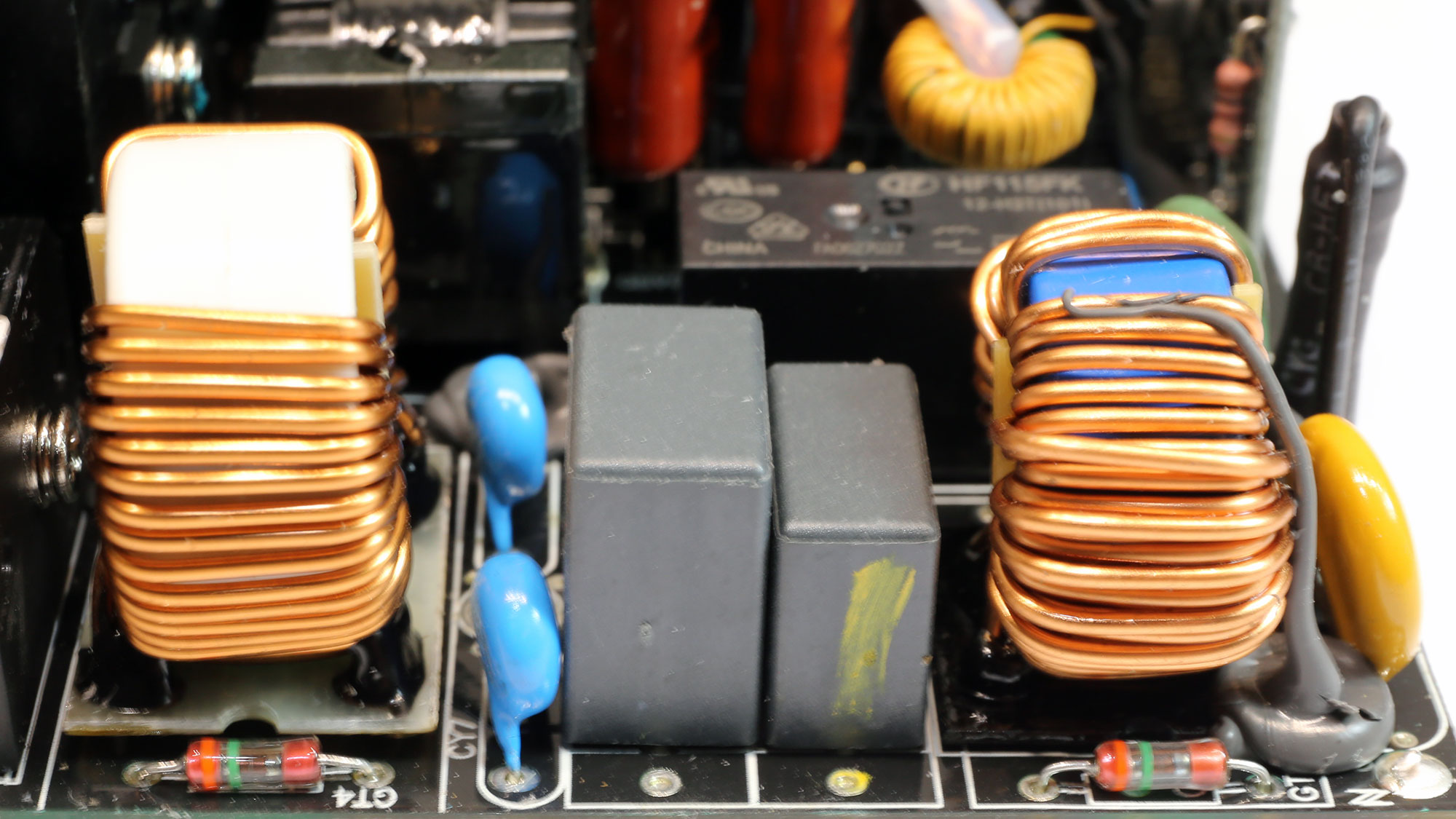

| Transient Filter | 4x Y caps, 3x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor SCK-056 (5 Ohm) & Relay |

| Bridge Rectifier(s) | 2x HY GBJ2506P (600V, 25A @ 100°C) |

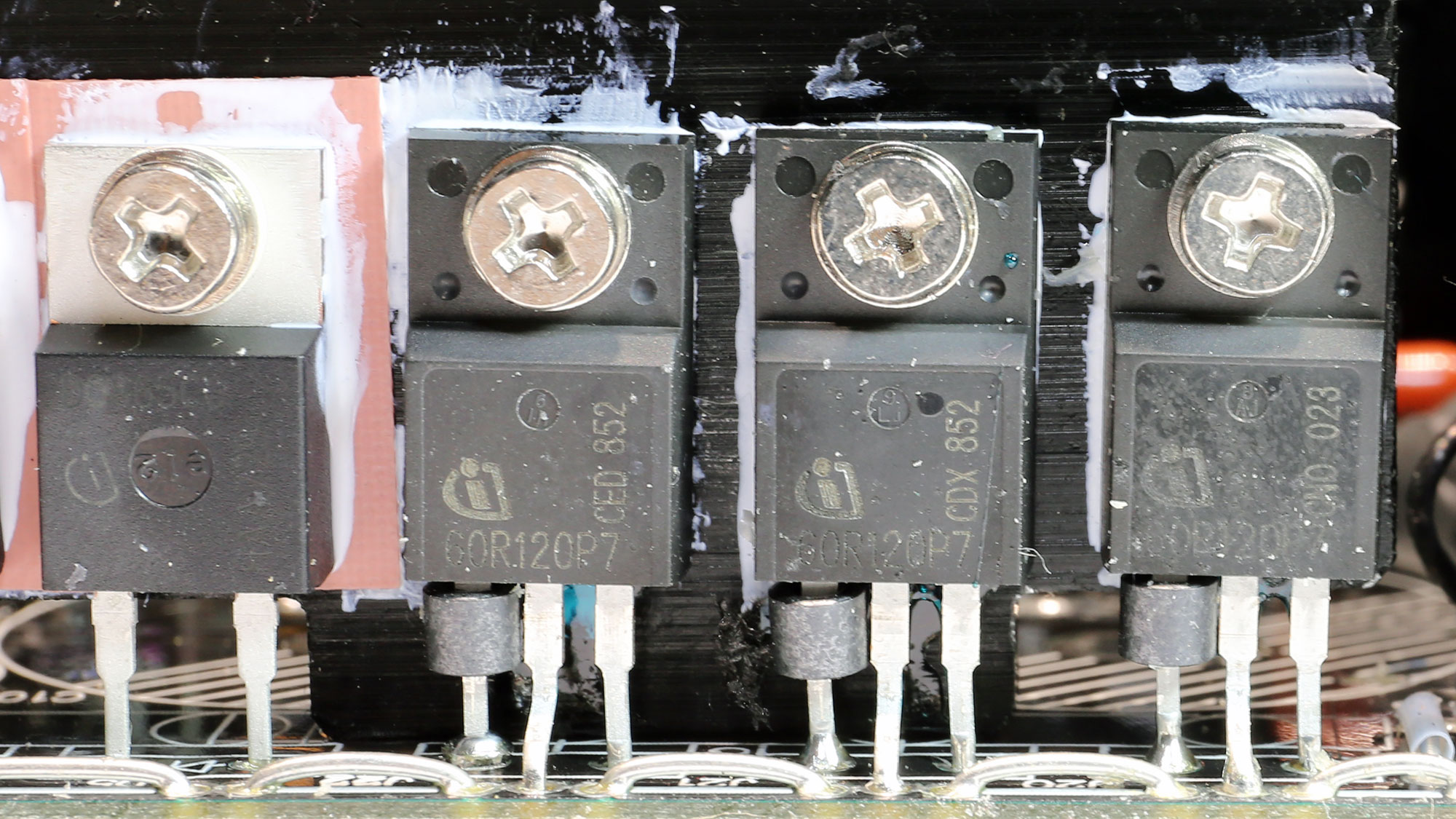

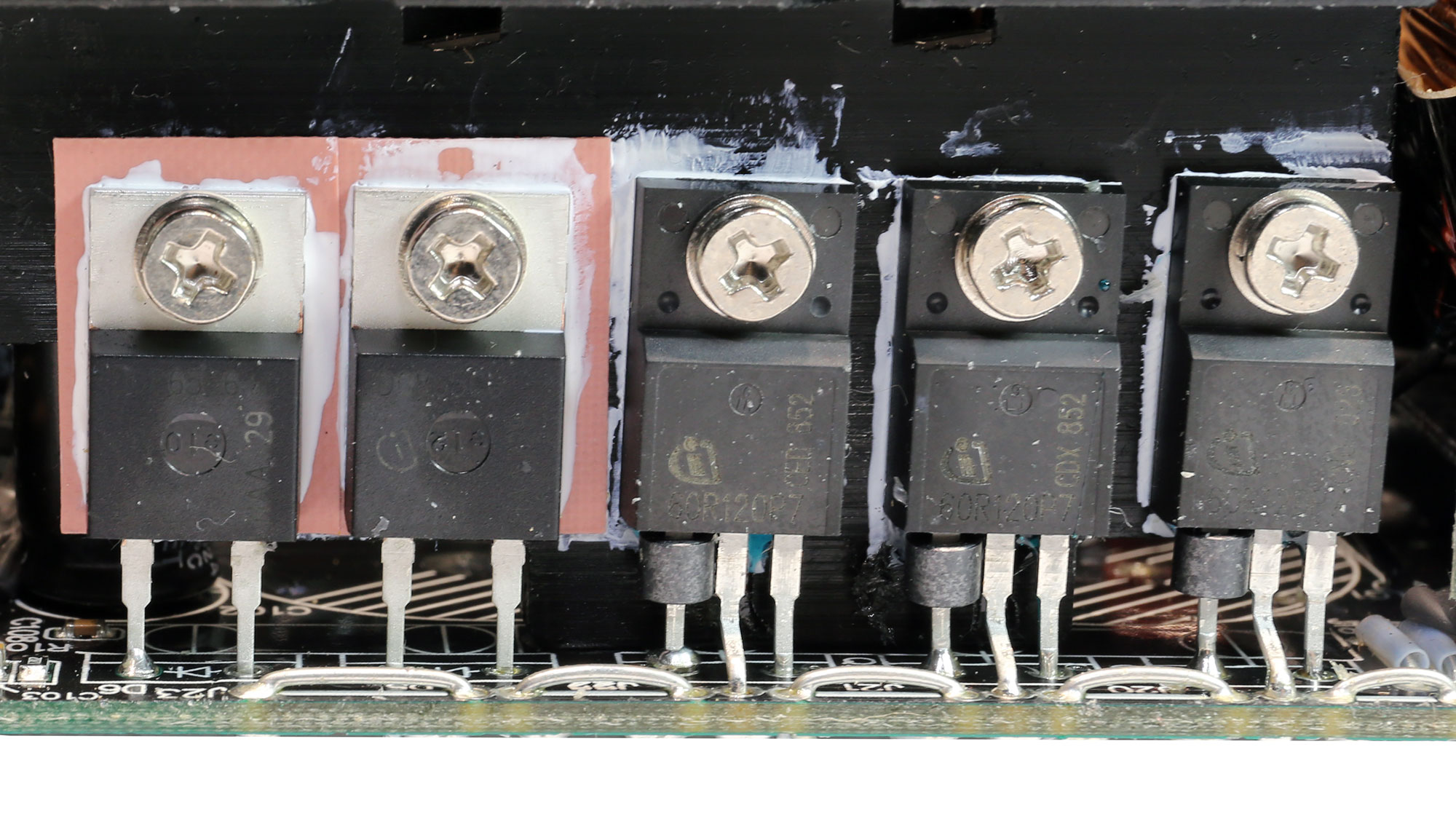

| APFC MOSFETs | 3x Infineon IPA60R120P7 (650V, 16A @ 100°C, Rds(on): 0.12Ohm) |

| APFC Boost Diode | 2x Infineon IDH08G65C6 (650V, 8A @ 145°C) |

| Bulk Cap(s) | 2x Hitachi (450V, 560uF each or 1.120uF combined, 2,000h @ 105°C, HU) |

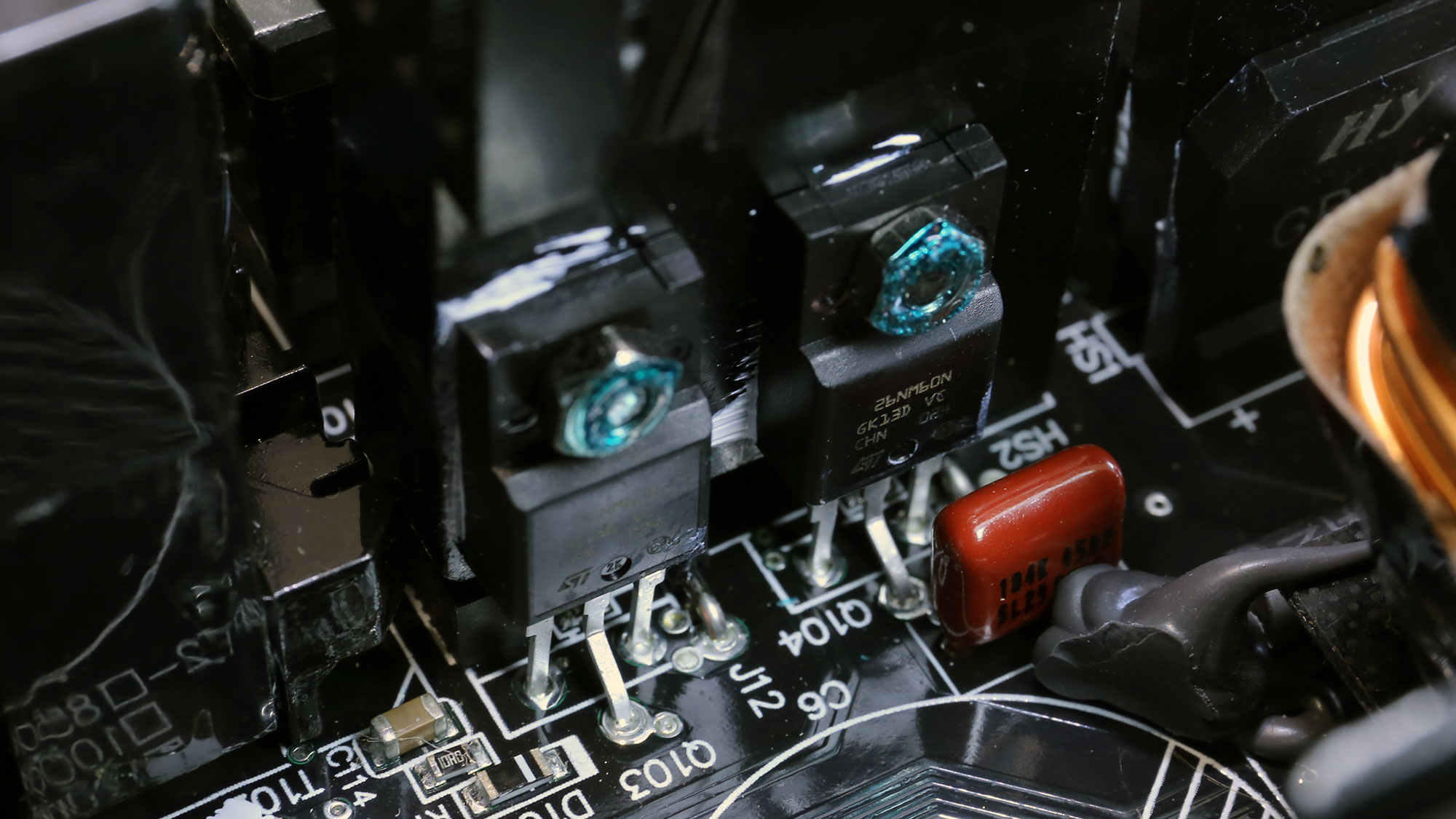

| Main Switchers | 4x STMicroelectronics STF26NM60N (600V, 12.6A @ 100°C, Rds(on): 0.165Ohm) |

|

IC Driver | 2x Silicon Labs Si8233BD |

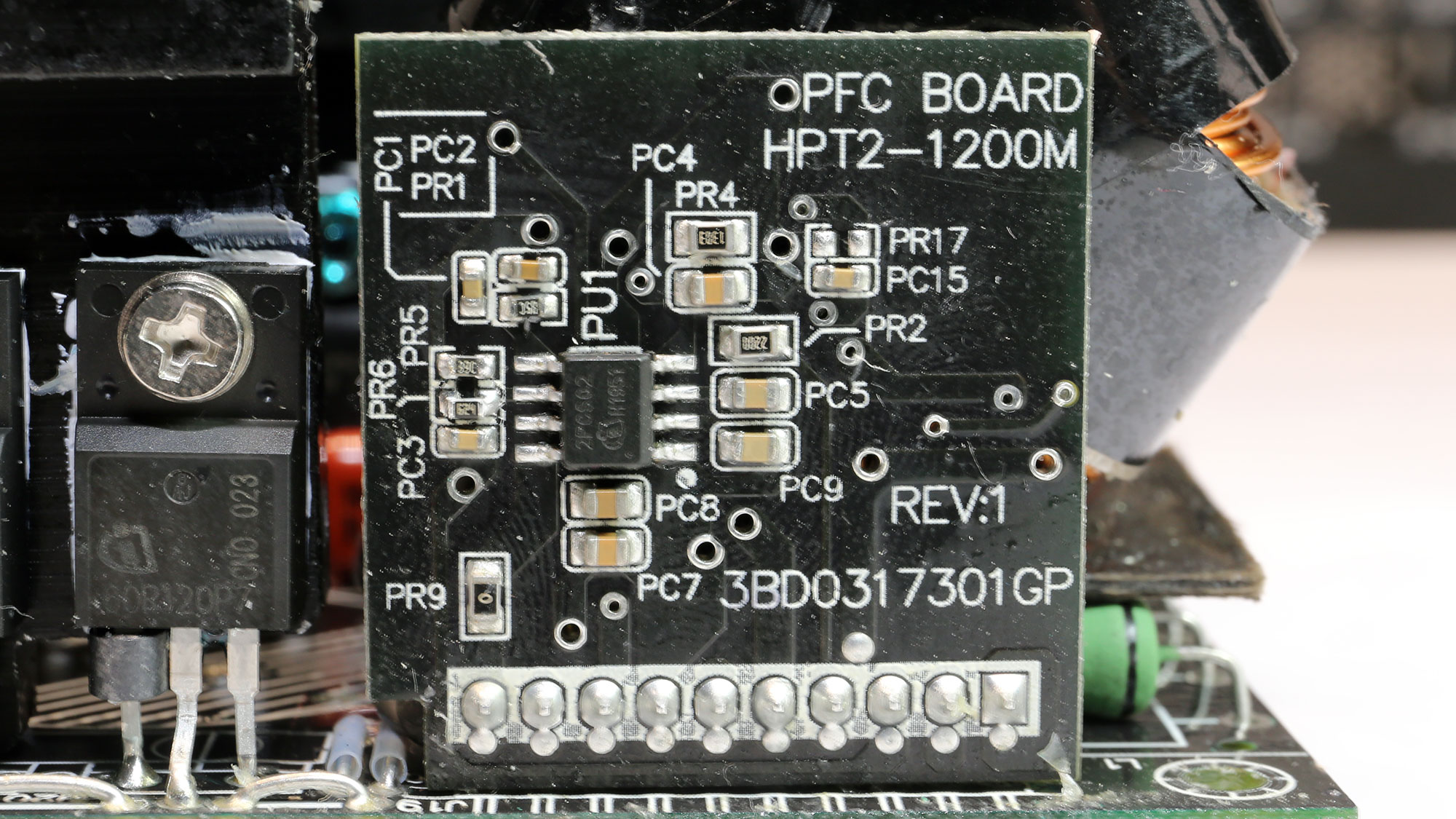

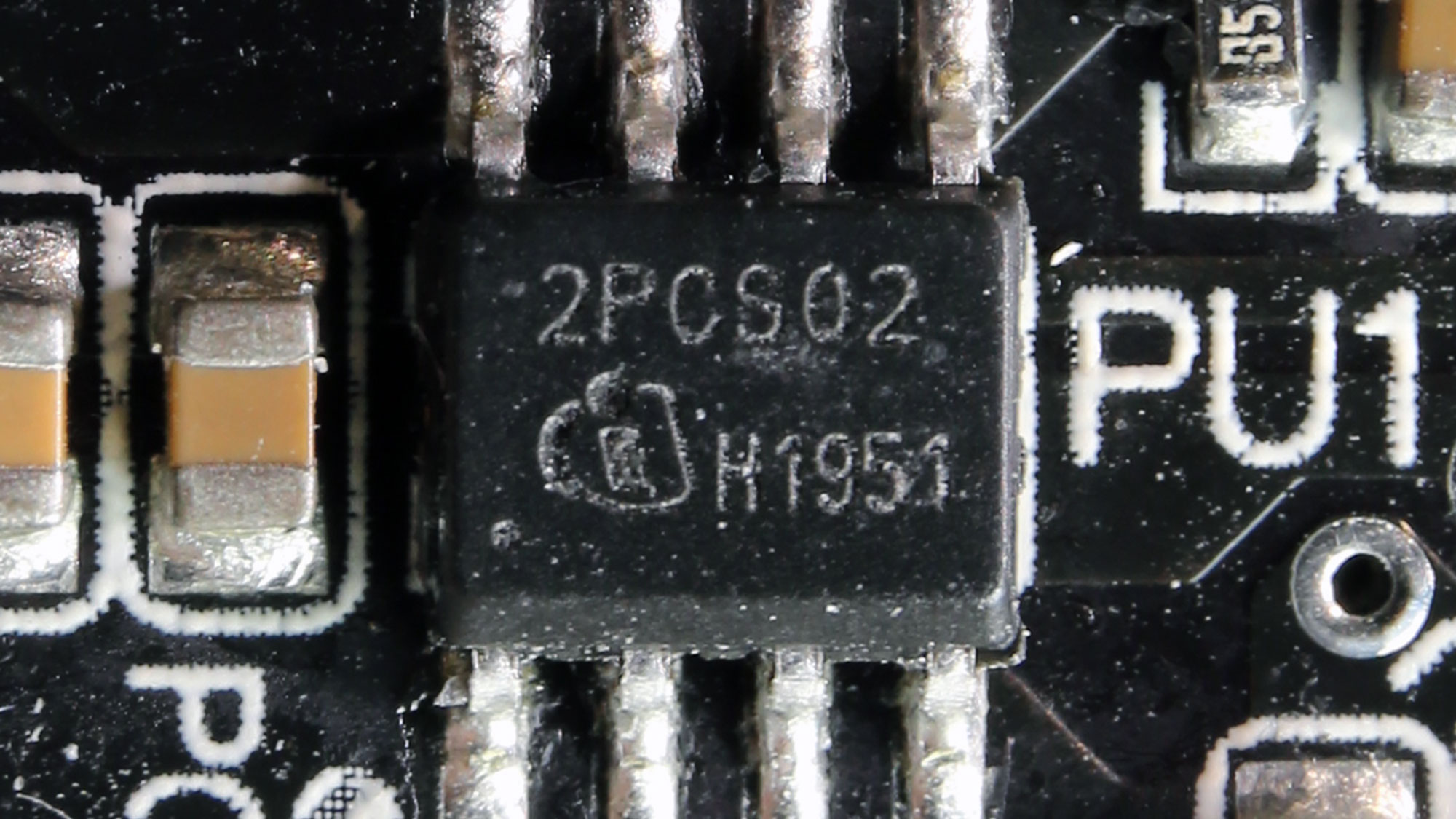

| APFC Controller | Infineon ICE2PCS02G |

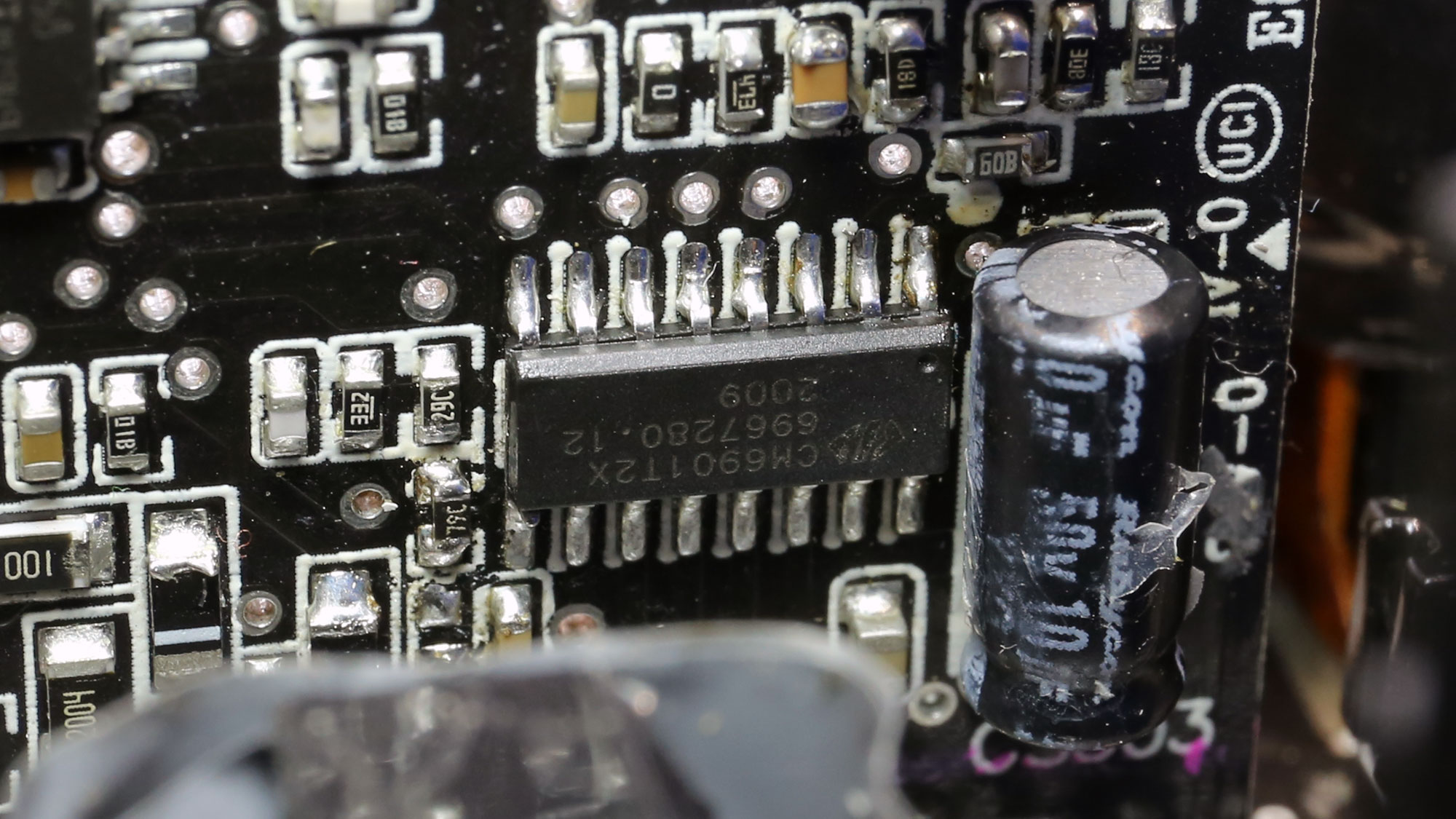

| Resonant Controller | Champion CM6901T2X |

| Topology | Primary side: APFC, Full-Bridge & LLC converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | - |

| +12V MOSFETs | 8x |

| 5V & 3.3V | DC-DC Converters: 6x Infineon BSC0901NS (30V, 94A @ 100°C, Rds(on): 1.9mOhm) PWM Controllers: ANPEC APW7159C |

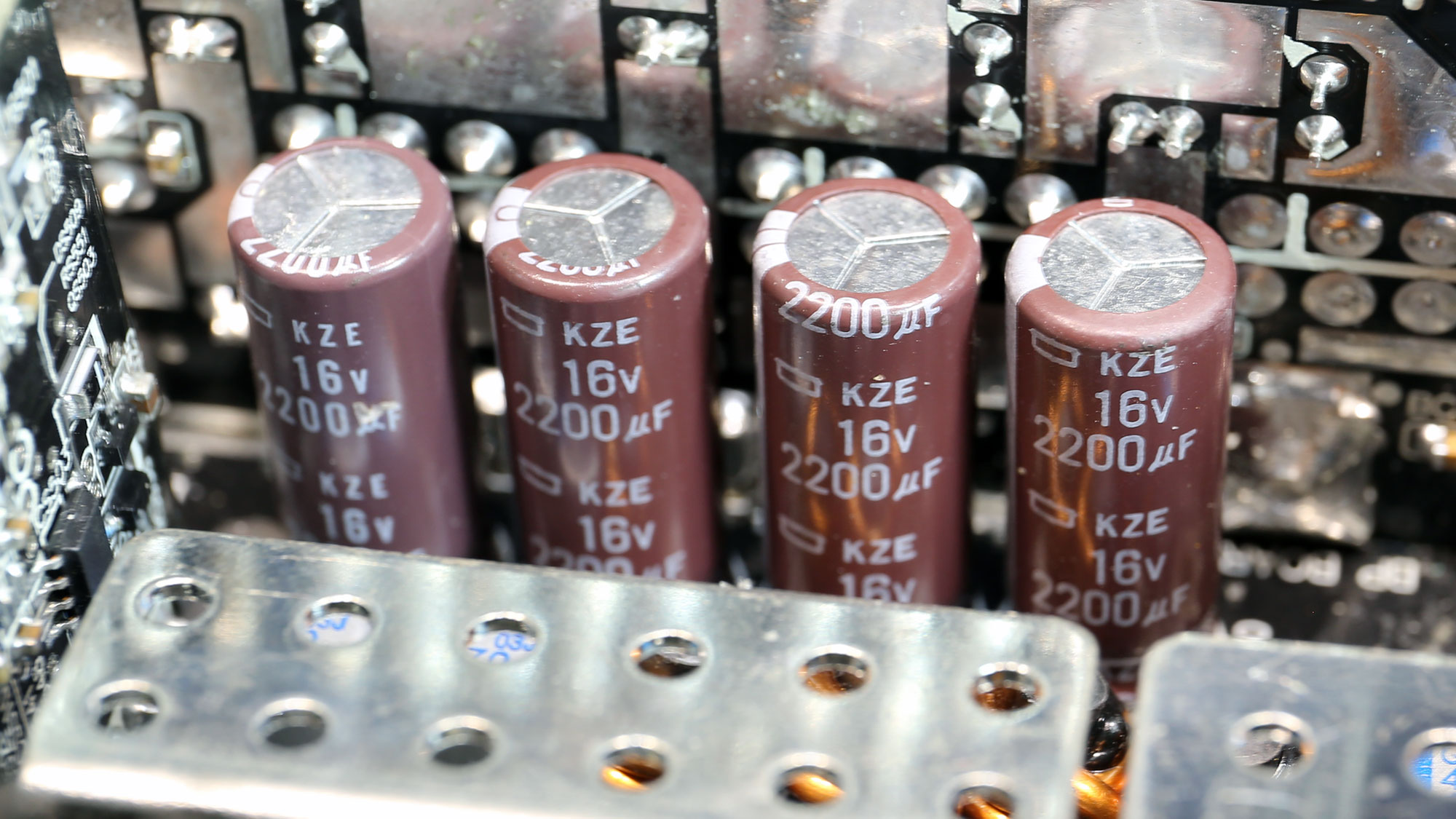

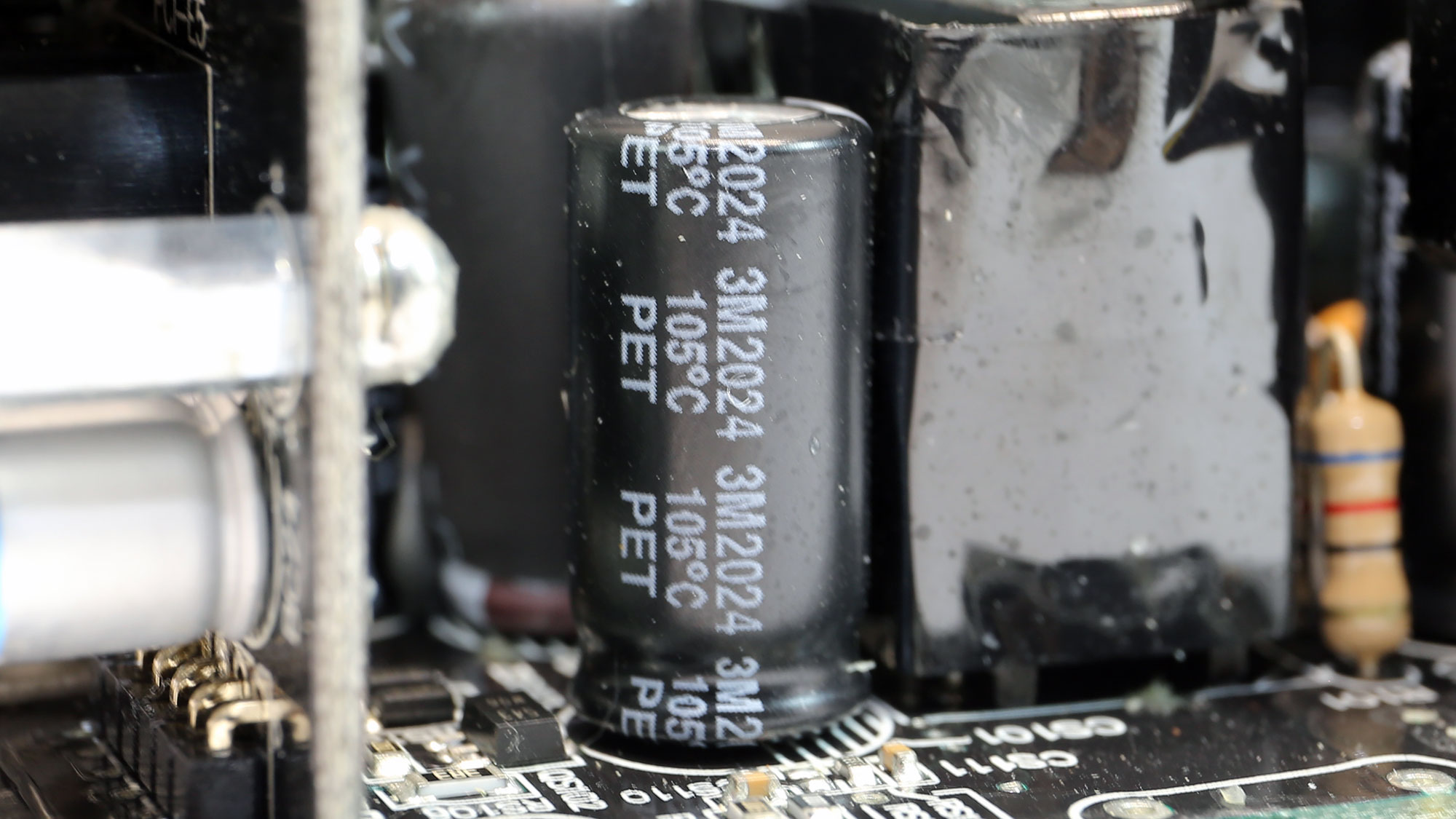

| Filtering Capacitors | Electrolytic: 4x Nippon Chemi-Con (1-5,000h @ 105°C, KZE), 2x Rubycon (4-10,000h @ 105°C, YXF), 1x Rubycon (6-10,000h @ 105°C, ZLH), 1x Rubycon (4-10,000h @ 105°C, YXH), 2x Rubycon (3-6,000h @ 105°C, YXG) Polymer: 31x United Chemi-Con |

| Supervisor IC | SITI PS223H (OCP, OTP, OVP, UVP, SCP, PG) |

| Fan Controller | APW9010 |

| Fan Model | Protechnic Electric MGA13512XF-A25 (135mm, 12V, 0.38A, Fluid Dynamic Bearing Fan) |

| 5VSB Circuit | - |

| Rectifier | 1x International Rectifier IRF1018ESPbF FET (60V, 56A @ 100°C, Rds(on): 8.4mOhm) |

| Standby PWM Controller | Power Integrations INN2603K |

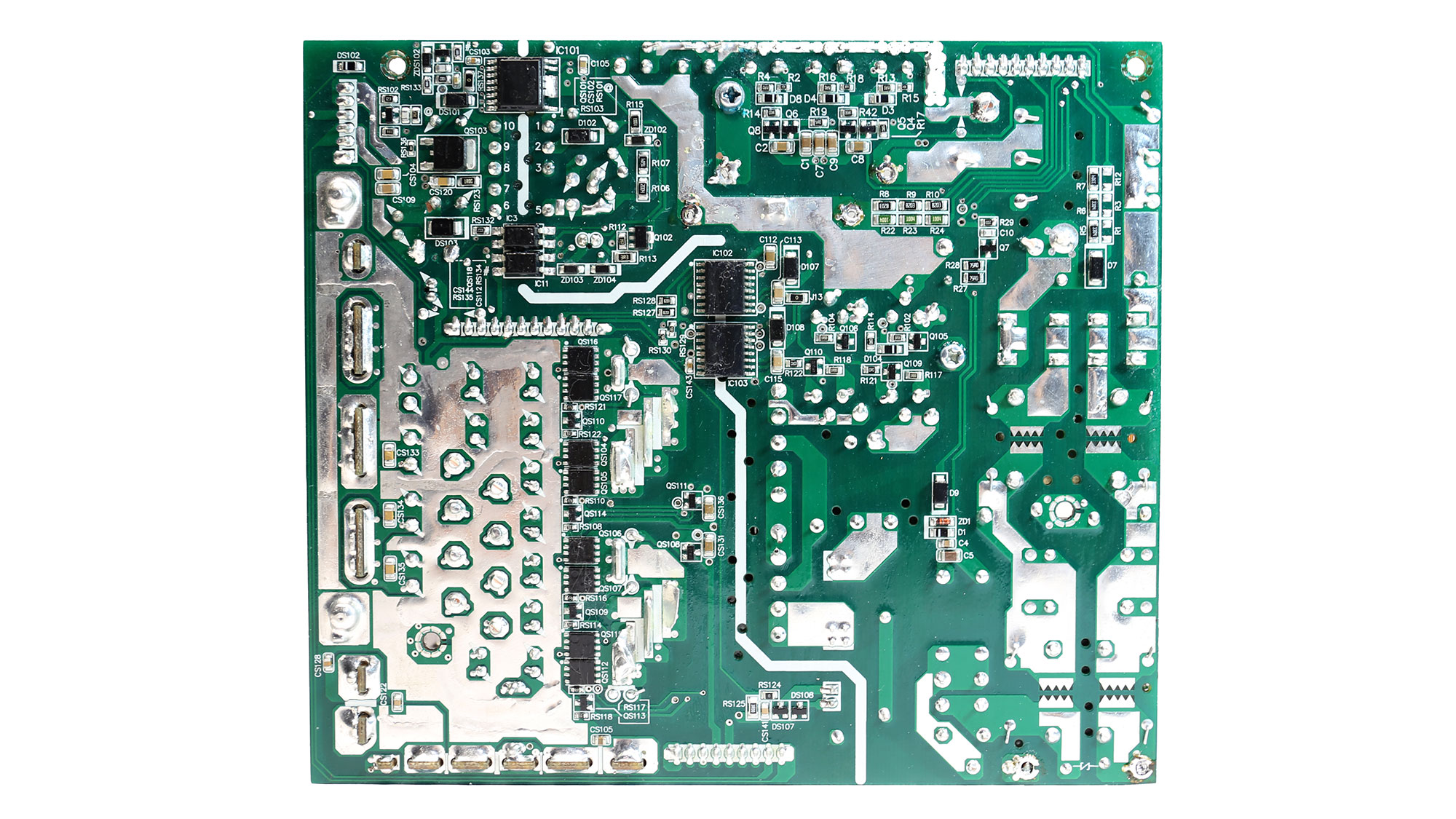

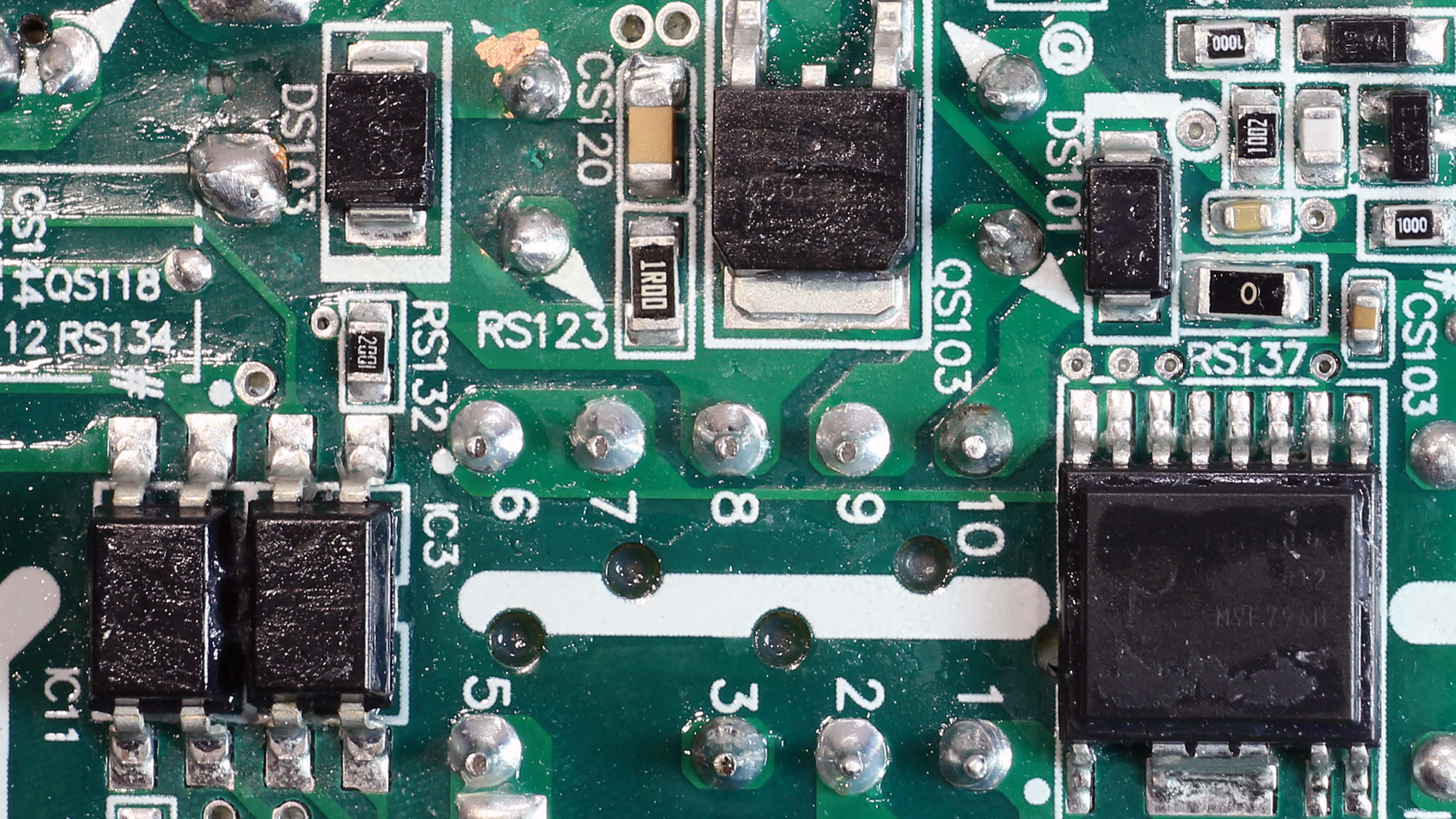

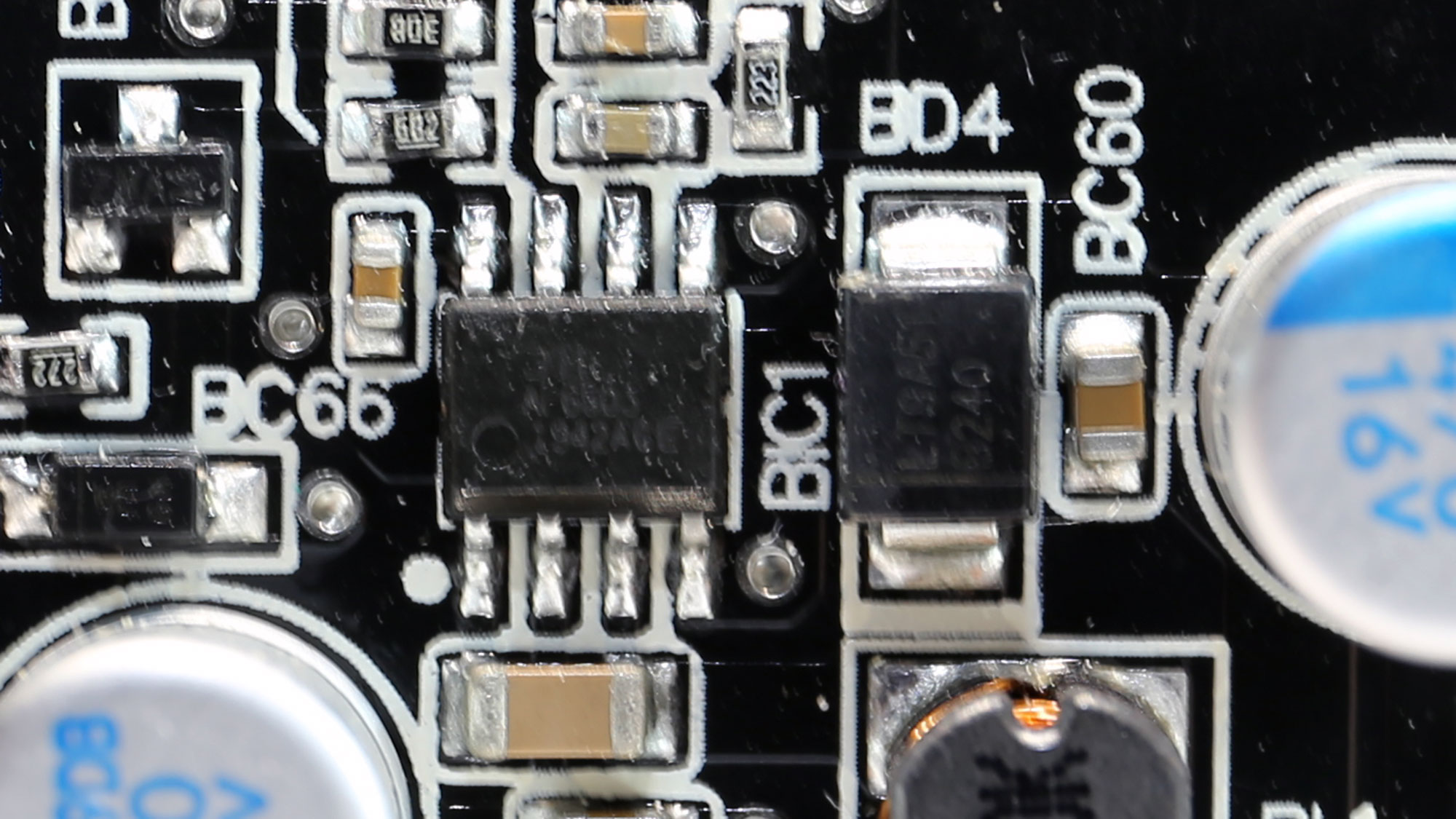

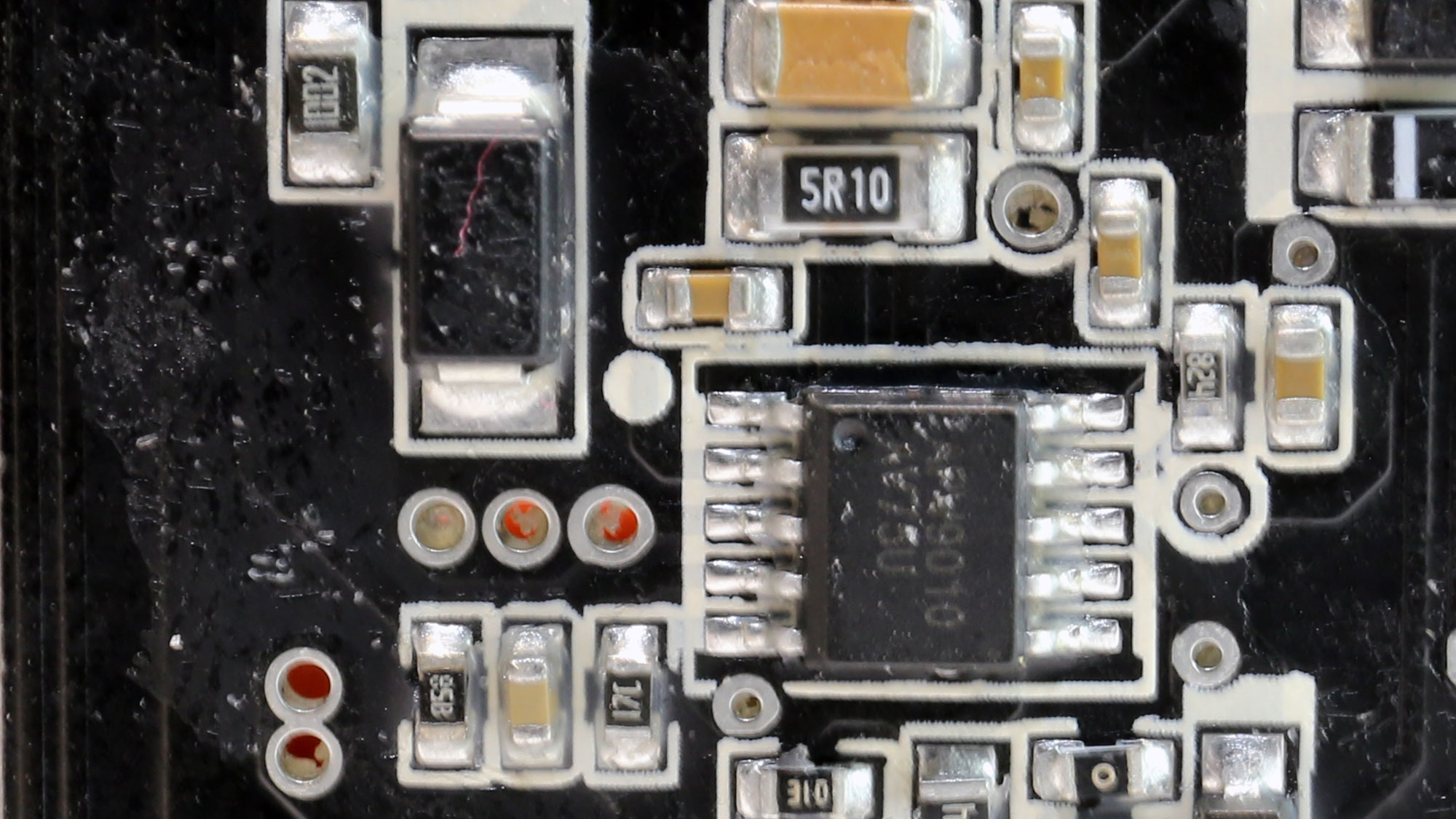

Overall Photos

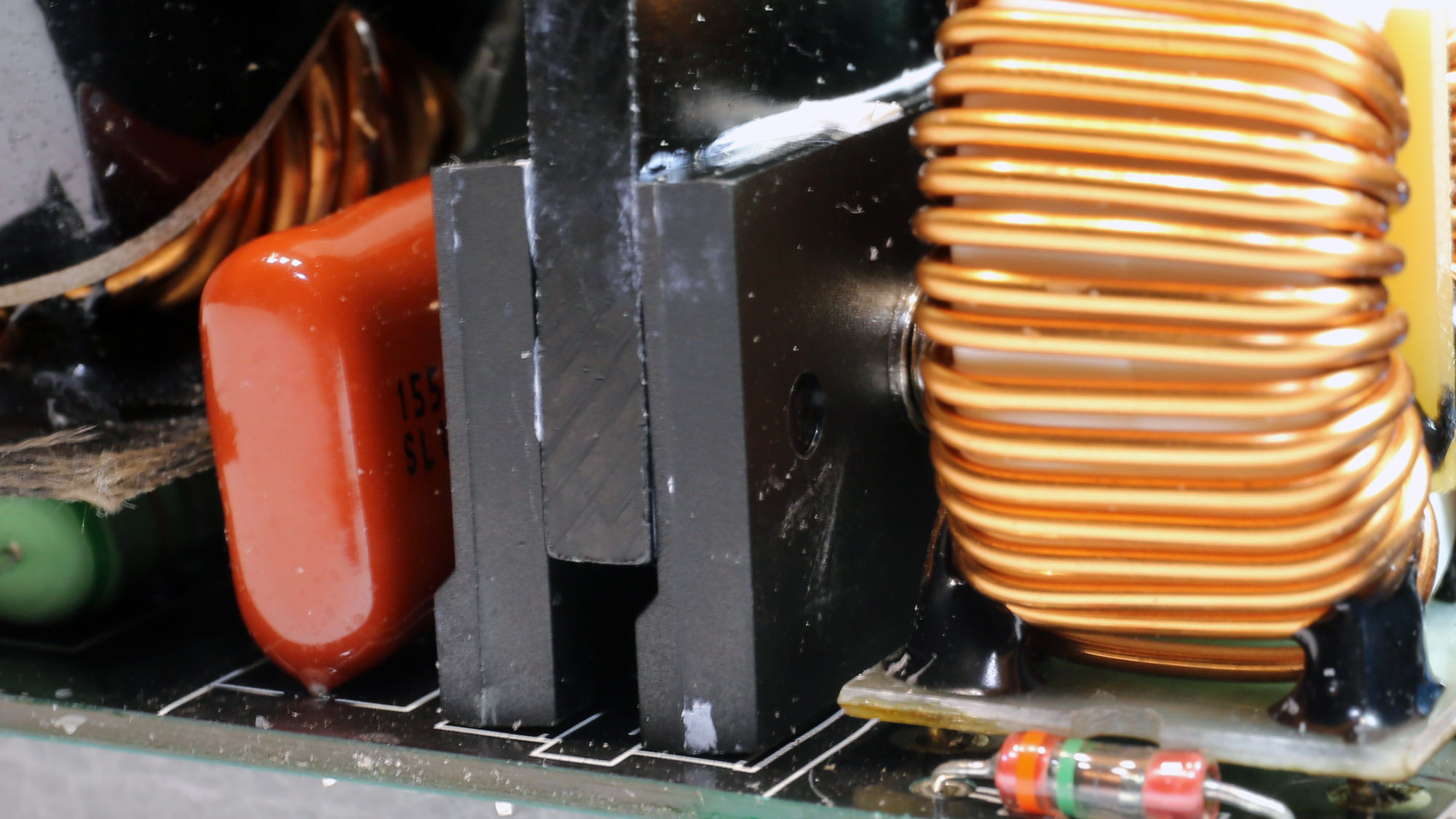

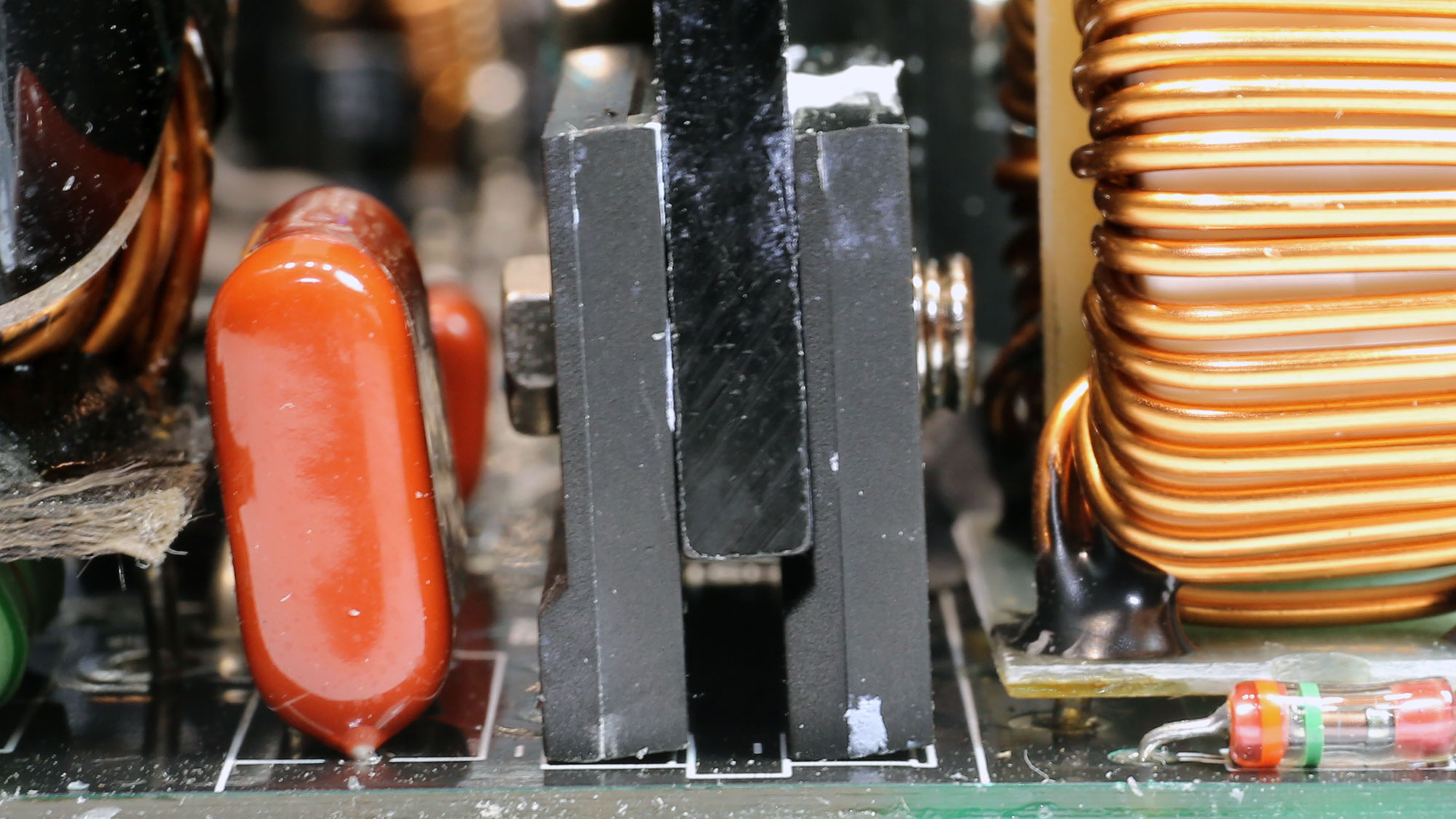

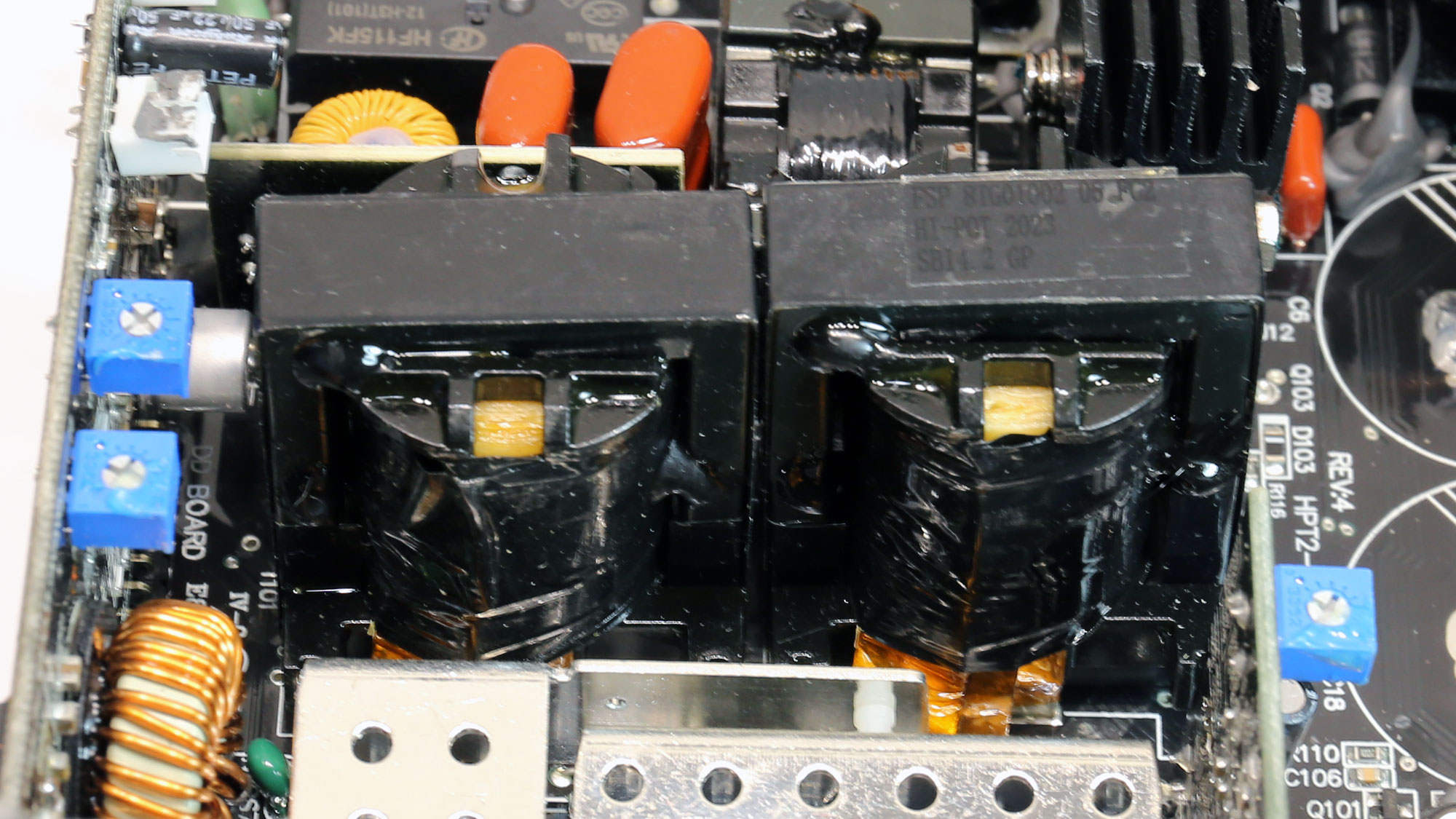

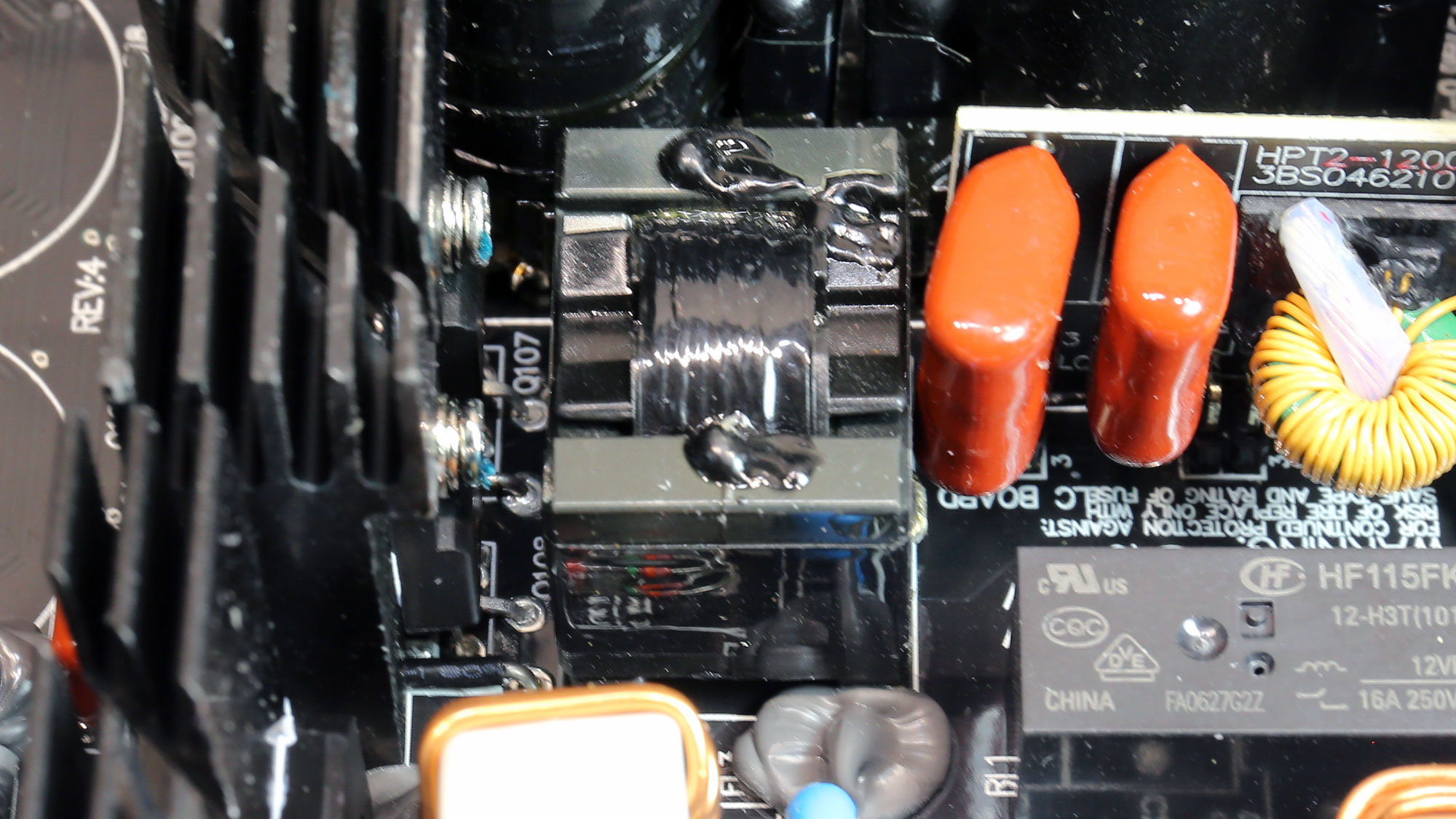

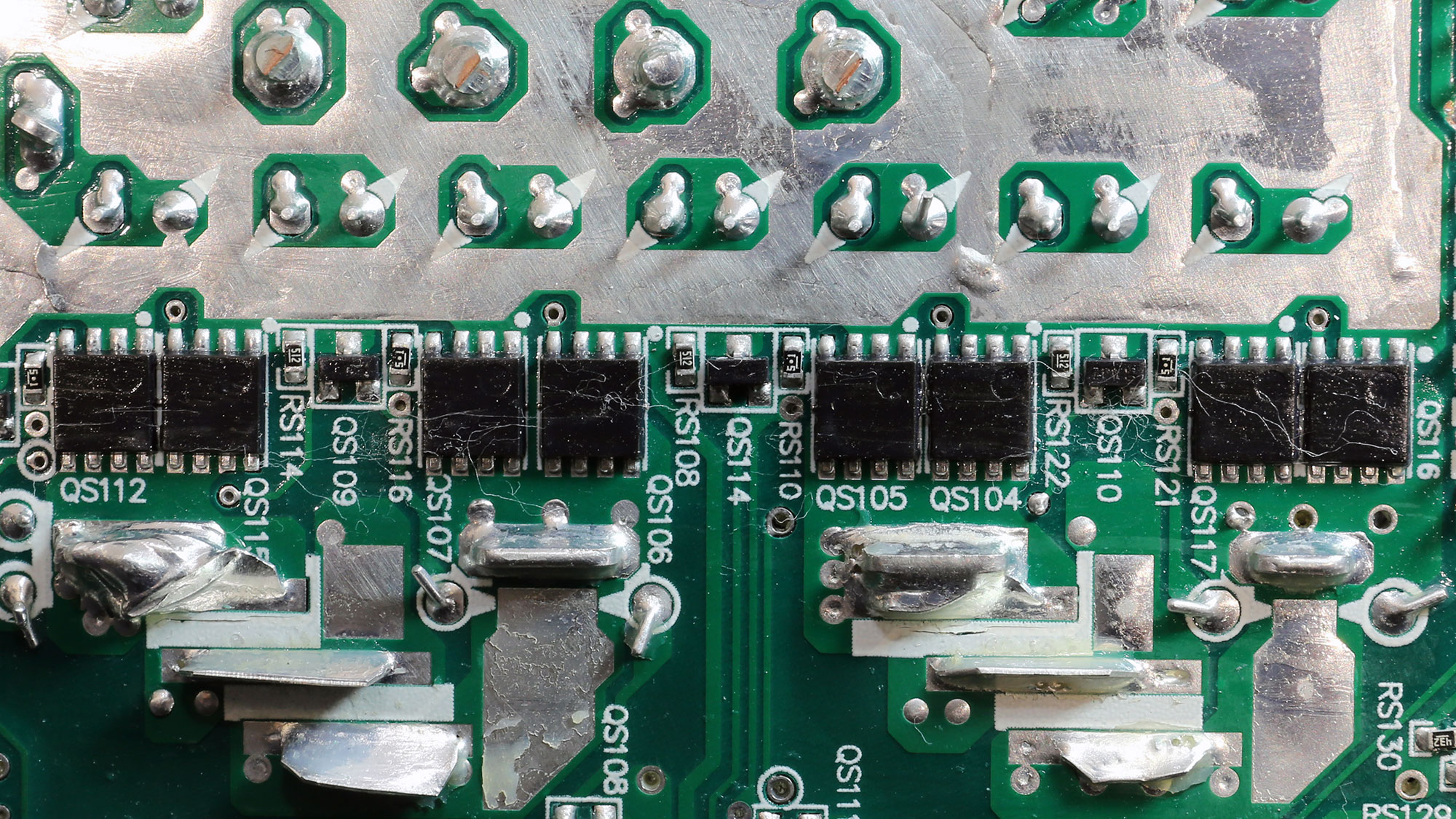

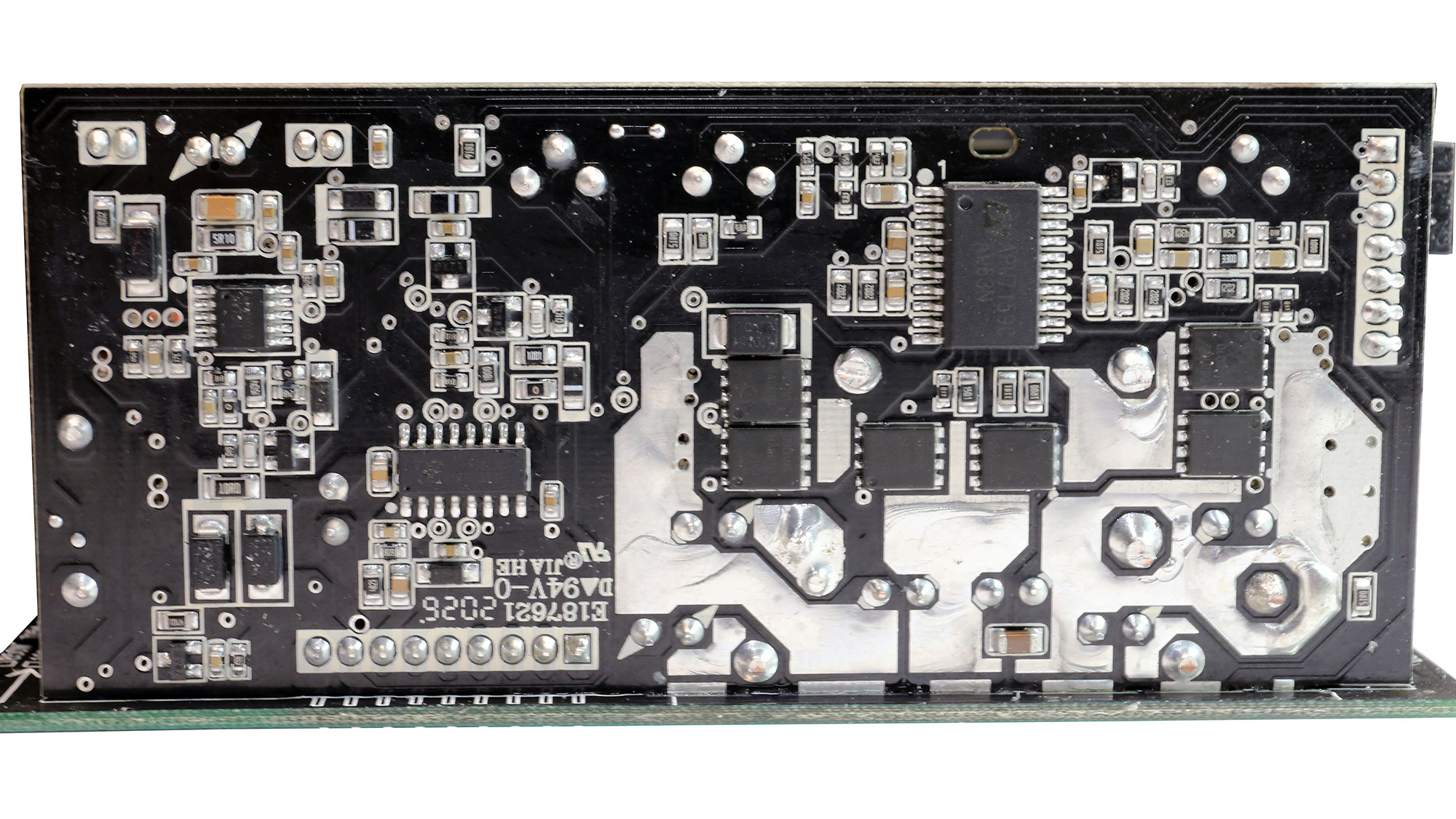

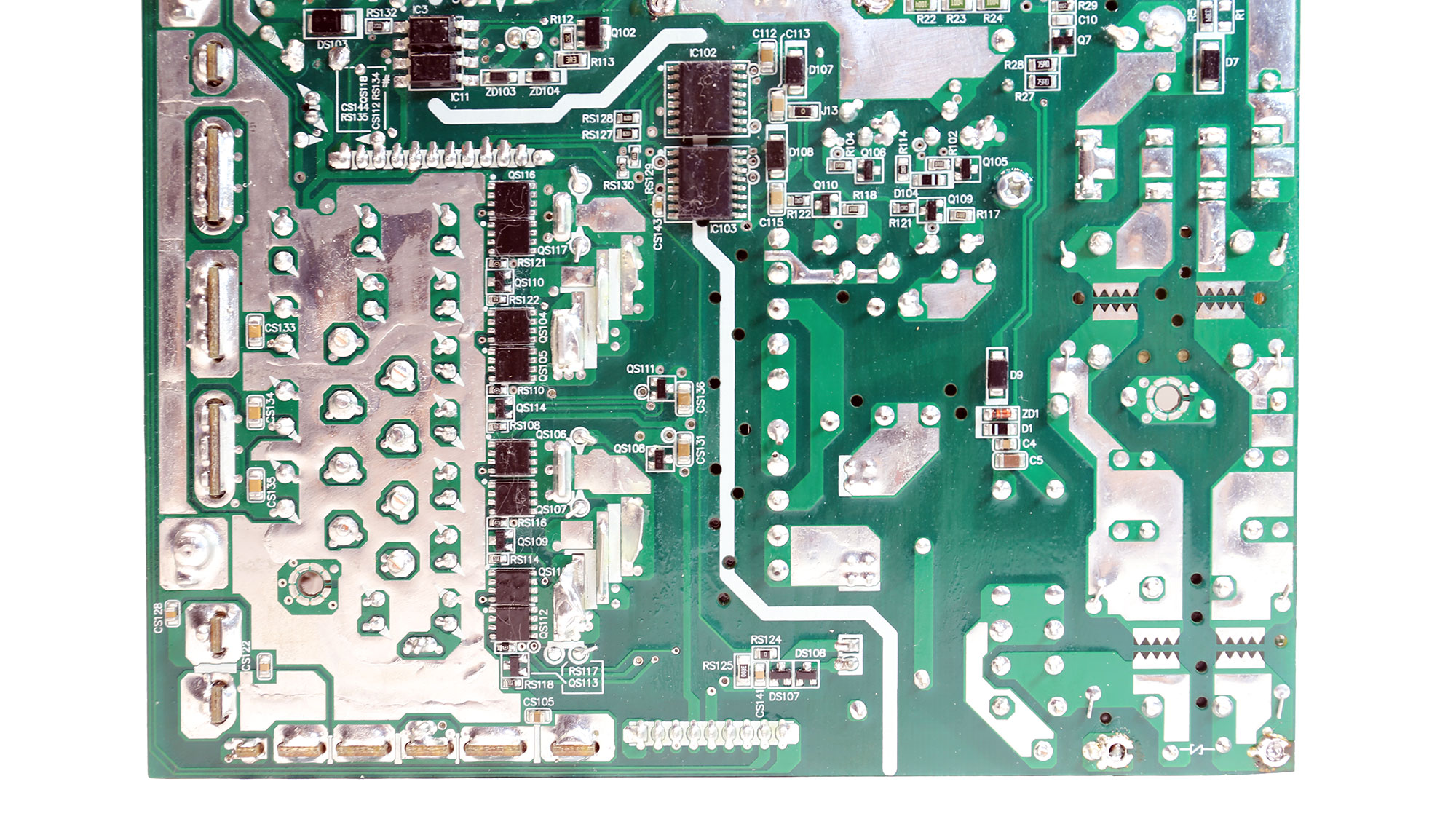

This is an interesting platform by FSP. What caught our immediate attention, besides the compact dimensions of the PCB, is that the main transformers are not properly aligned. There are also some potentiometers in view, but it is better not to mess with them. Usually, most manufacturers don't allow any modifications through potentiometers, but this is not a problem, from the moment the owners of this product are not supposed to open it, as we did.

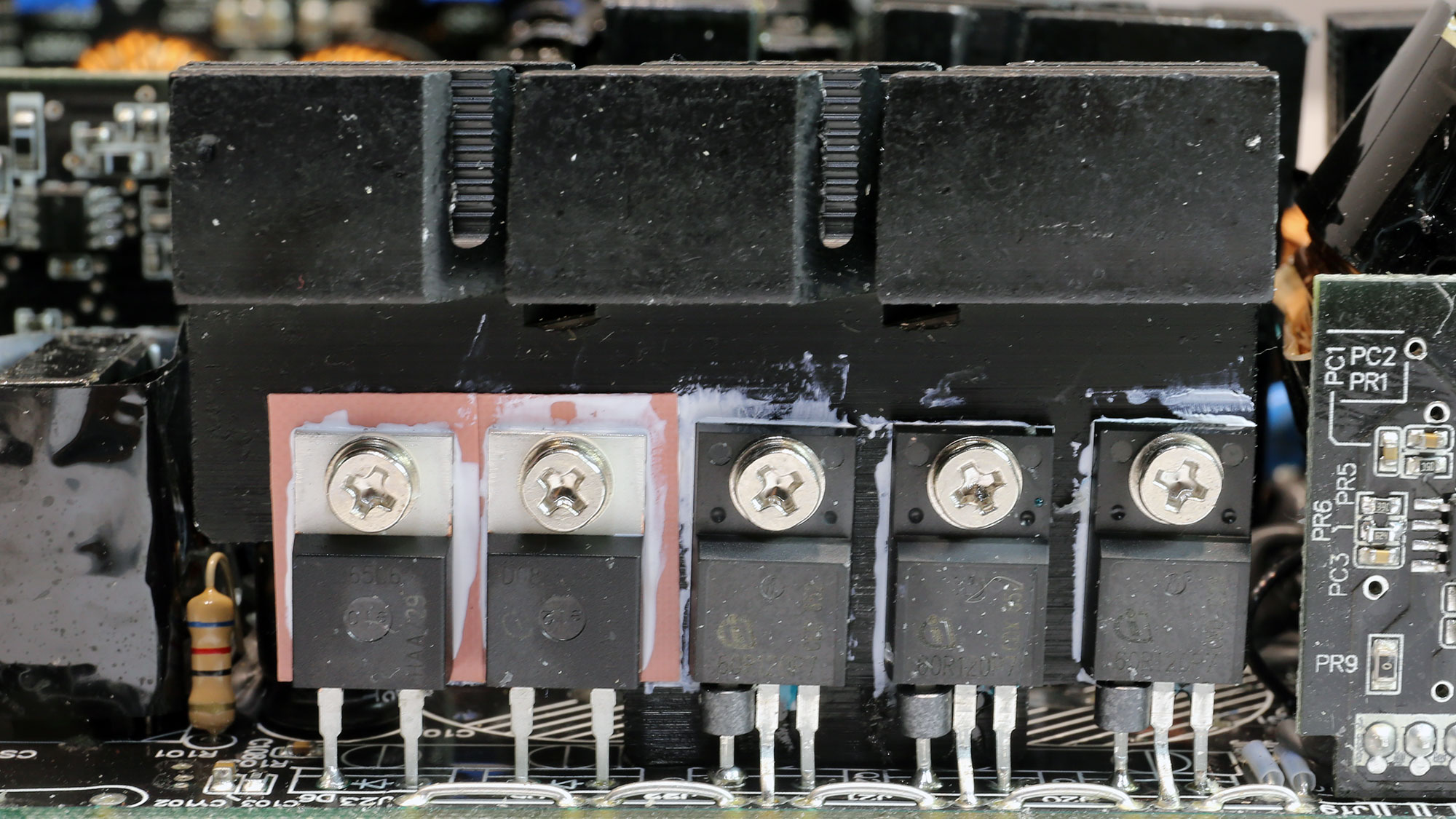

The heat sinks on both primary and secondary sides are super small if you consider a 1200W power supply. The PCB is also large enough to allow for good airflow, especially for the secondary side's electrolytic caps.

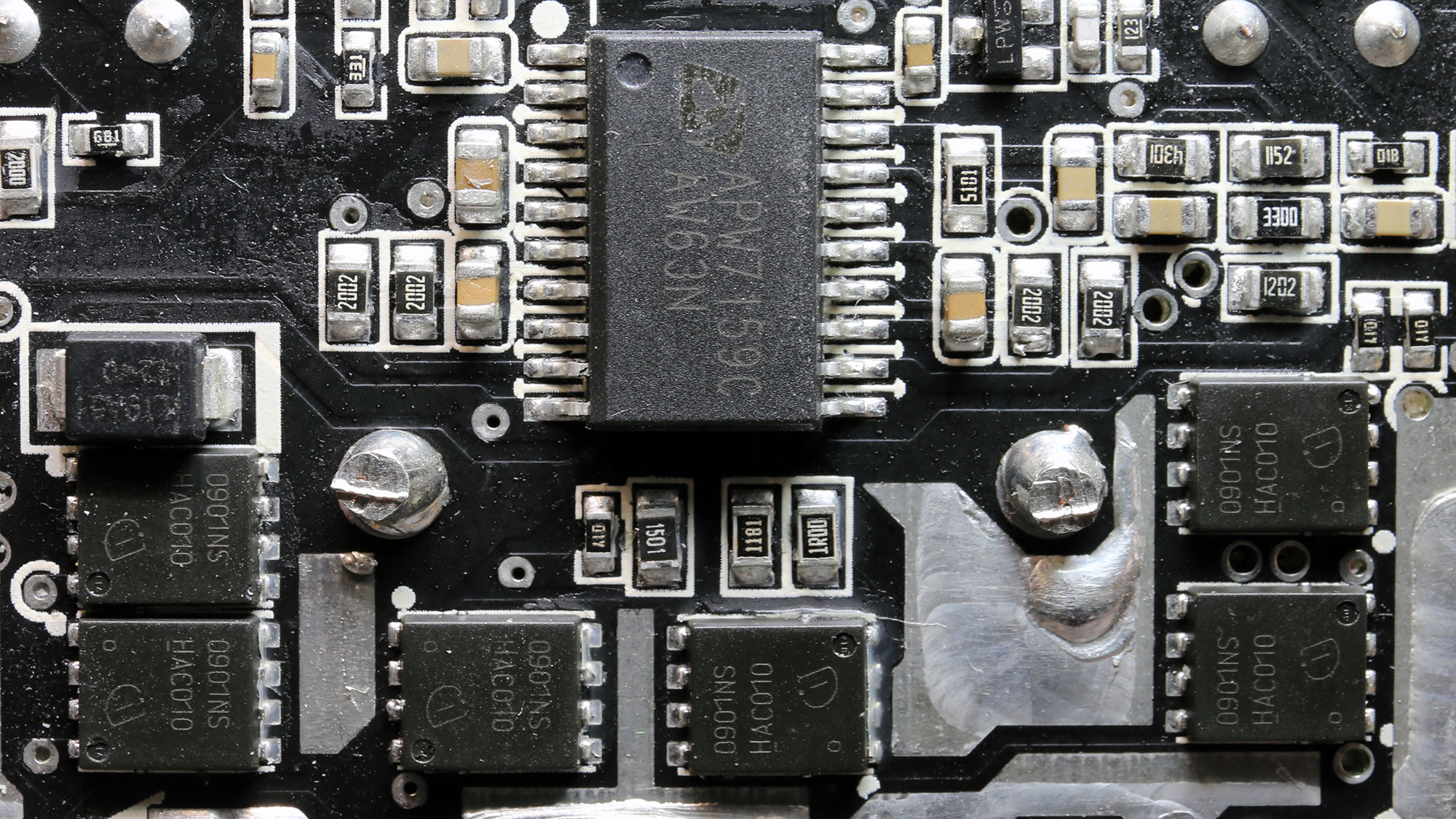

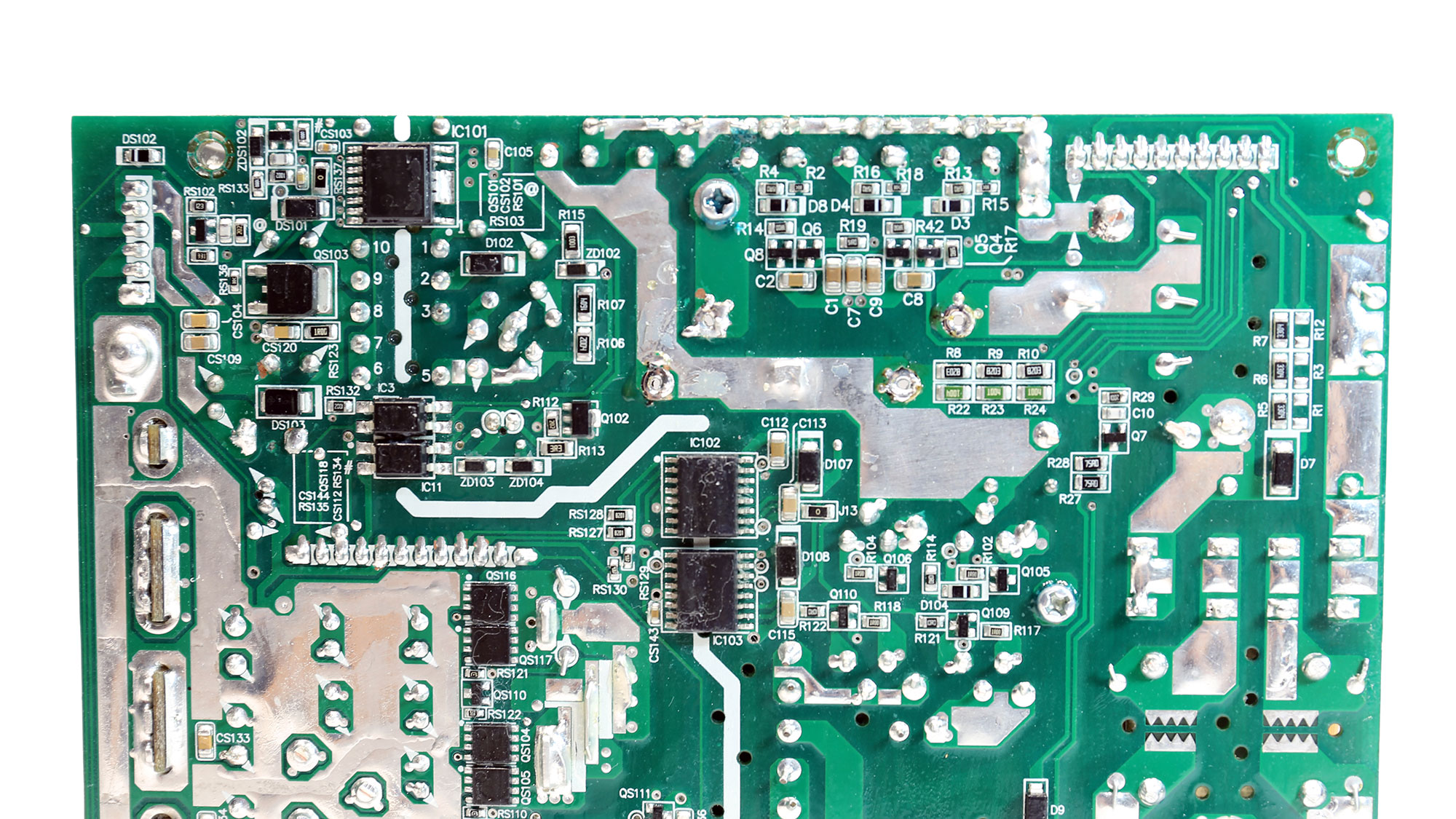

On the primary side, we meet a full-bridge topology supported by an LLC resonant converter. A synchronous design is used on the secondary side, and a pair of DC-DC converters generate the minor rails.

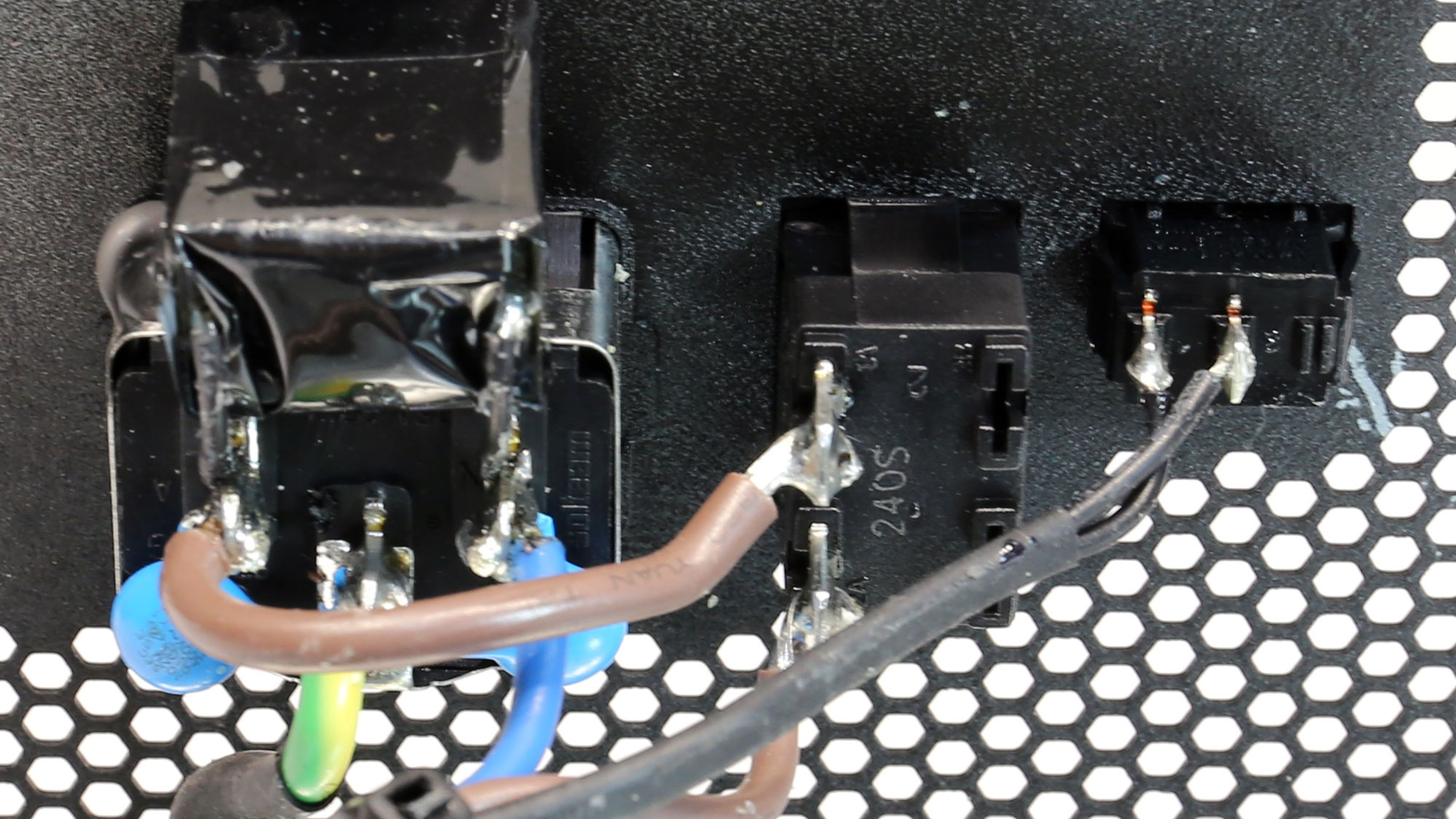

Transient filter

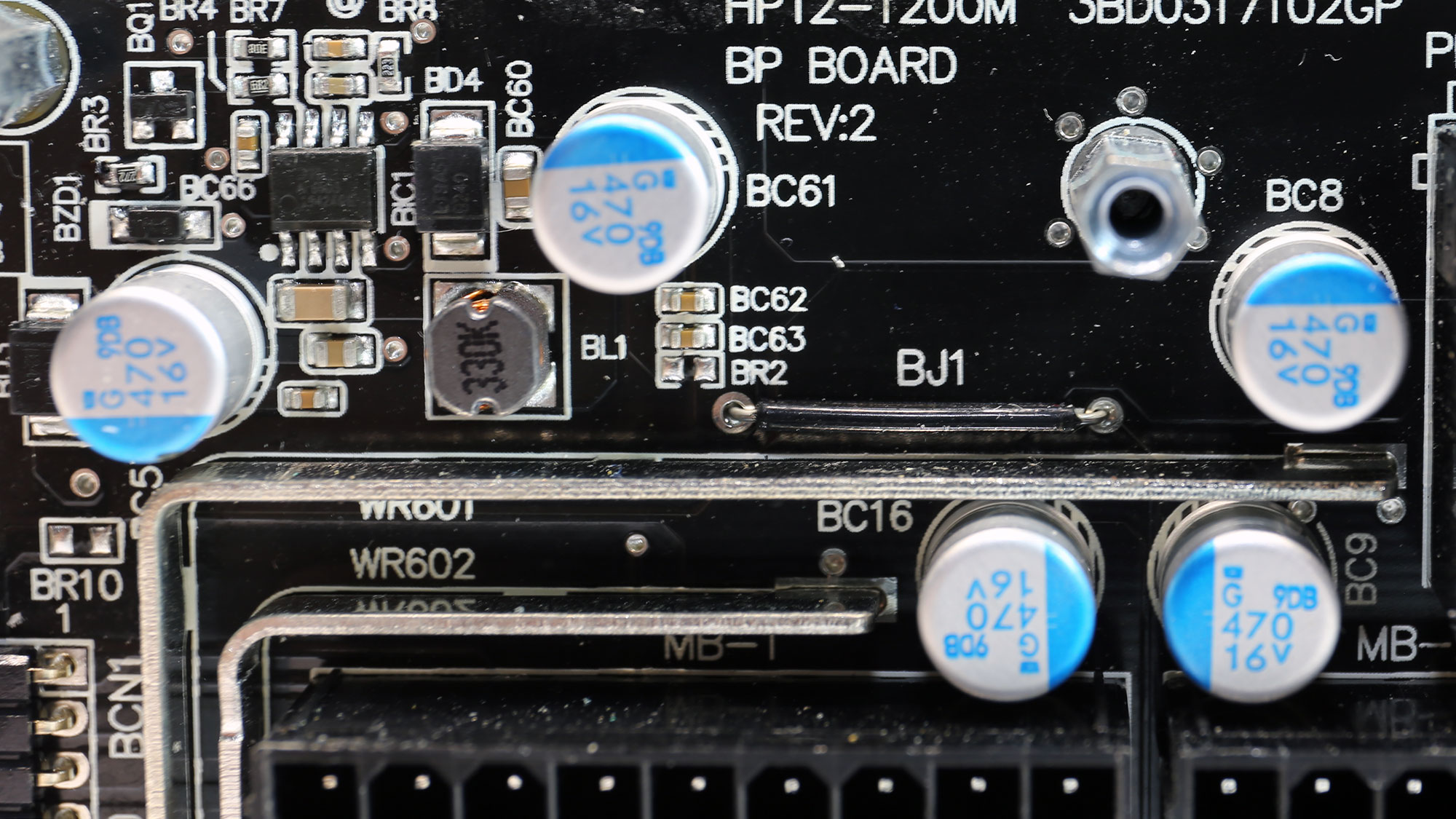

The transient filter uses four Y and three X caps, two CM chokes, and an MOV. There is also an NTC thermistor, supported by a bypass relay, for protection against large inrush currents.

Bridge rectifiers

There are two bridge rectifiers capable of handling up to 50A of current, so they easily meet this PSU's requirements.

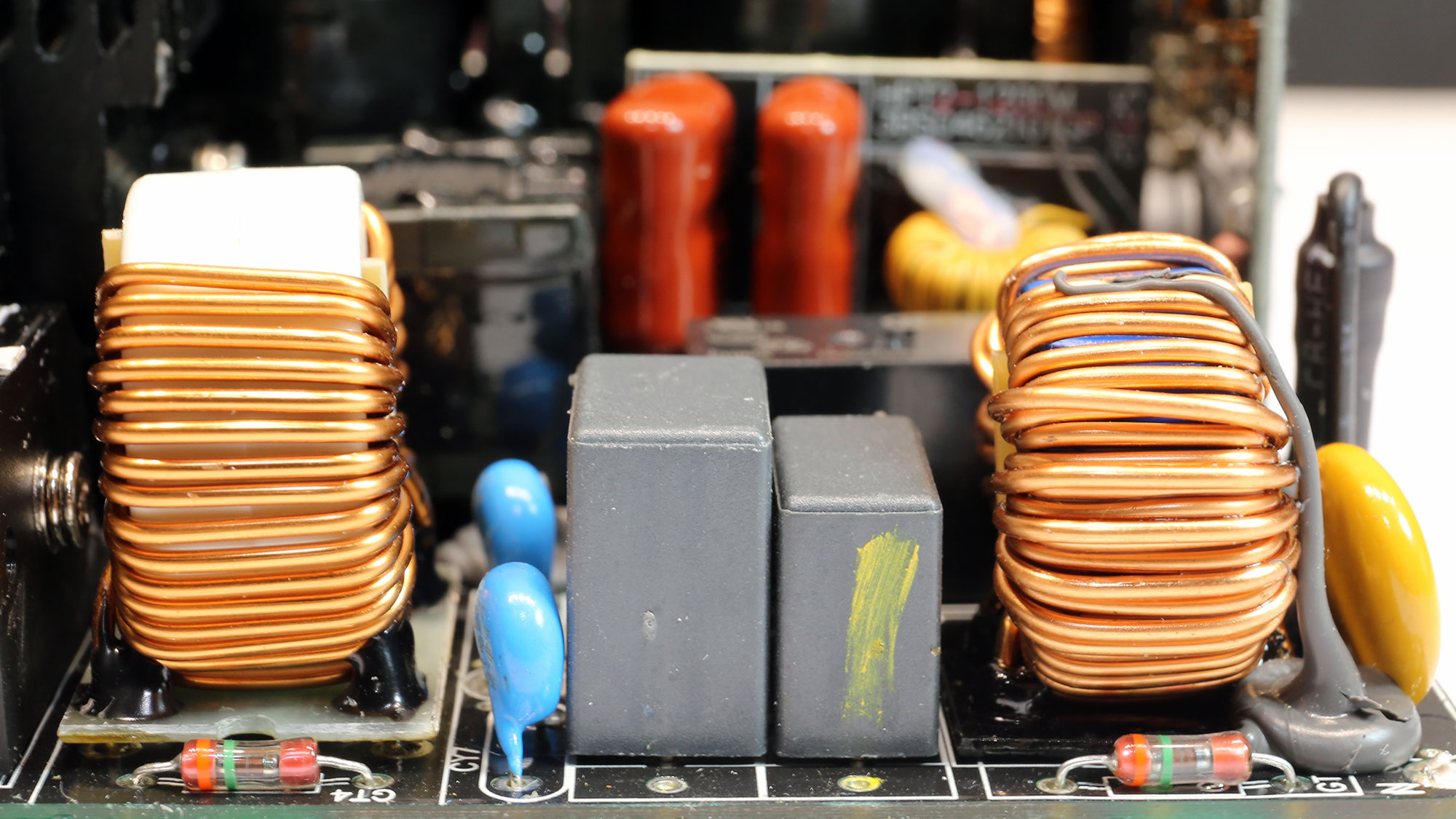

APFC converter

The Active Power Factor Correction (APFC) converter uses three FETs and two boost diodes. The bulk caps are provided by Hitachi and have enough capacity to provide a longer than 17ms hold-up time.

Main FETs and primary transformer

Four STMicroelectronics STF26NM60N FETs are installed in a full-bridge topology. An LLC resonant converter supports them, and the controller is a Champion CM6901T2X IC. The aforementioned FETs are driven by a pair of Silicon Labs Si8233BD ICs.

12V FETs and VRMs

Eight FETs regulate the +12V rail. It was impossible to identify them since all markings were erased. The aforementioned rail feeds two DC-DC converters, which generate the minor rails. The common PWM control of these converters is an ANPEC APW7159C.

Besides the VRMs of the minor rails, this daughter-board also hosts the supervisor IC, a SITI PS223H, and an operational amplifier.

Filtering caps

The electrolytic filtering caps on the secondary side are by Chemi-Con and Rubycon. Most of them belong to good lines, with four large ones from the mainstream, but still worthy, Chemi-Con KZE line. A large number of polymer caps are also used.

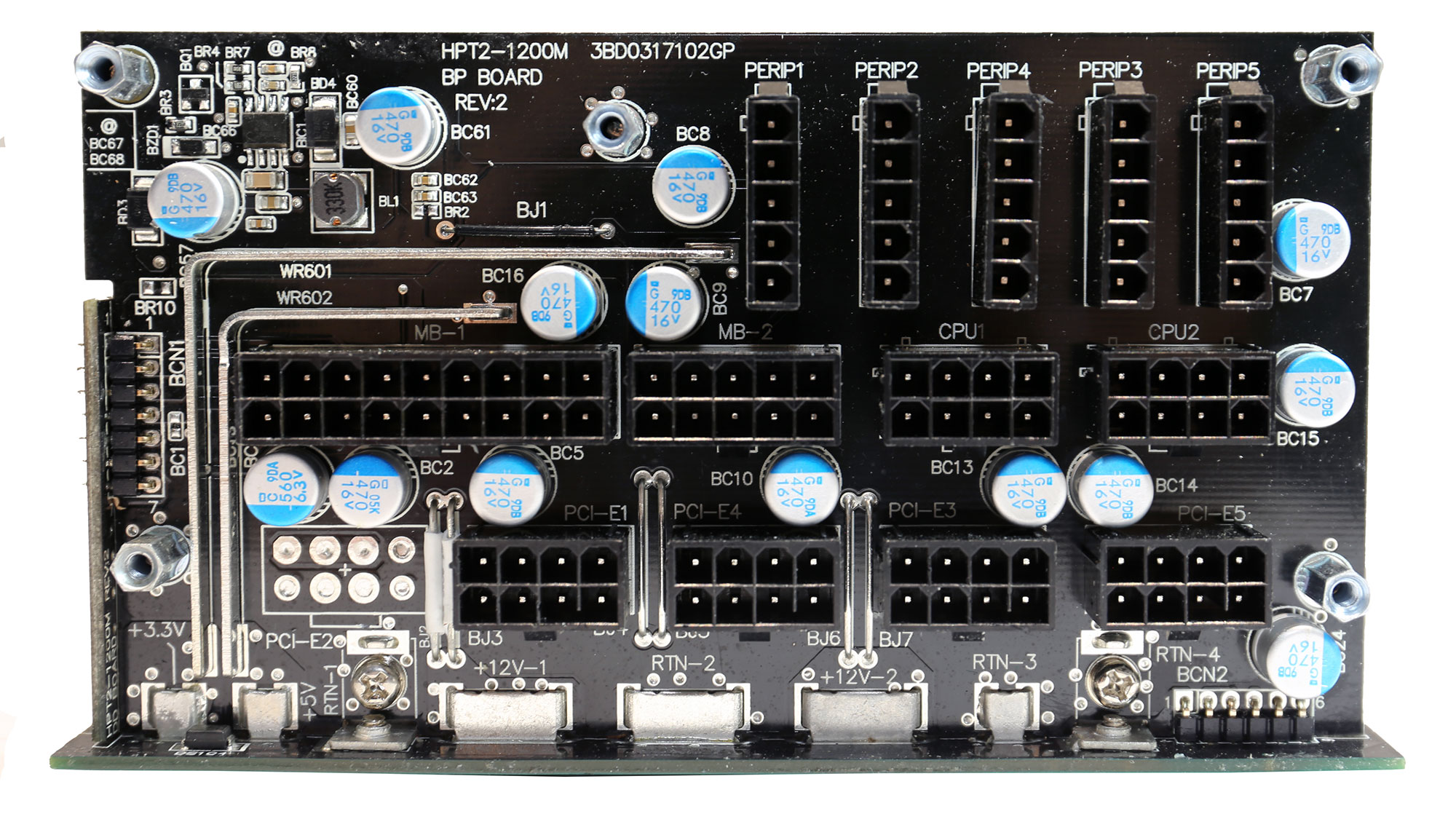

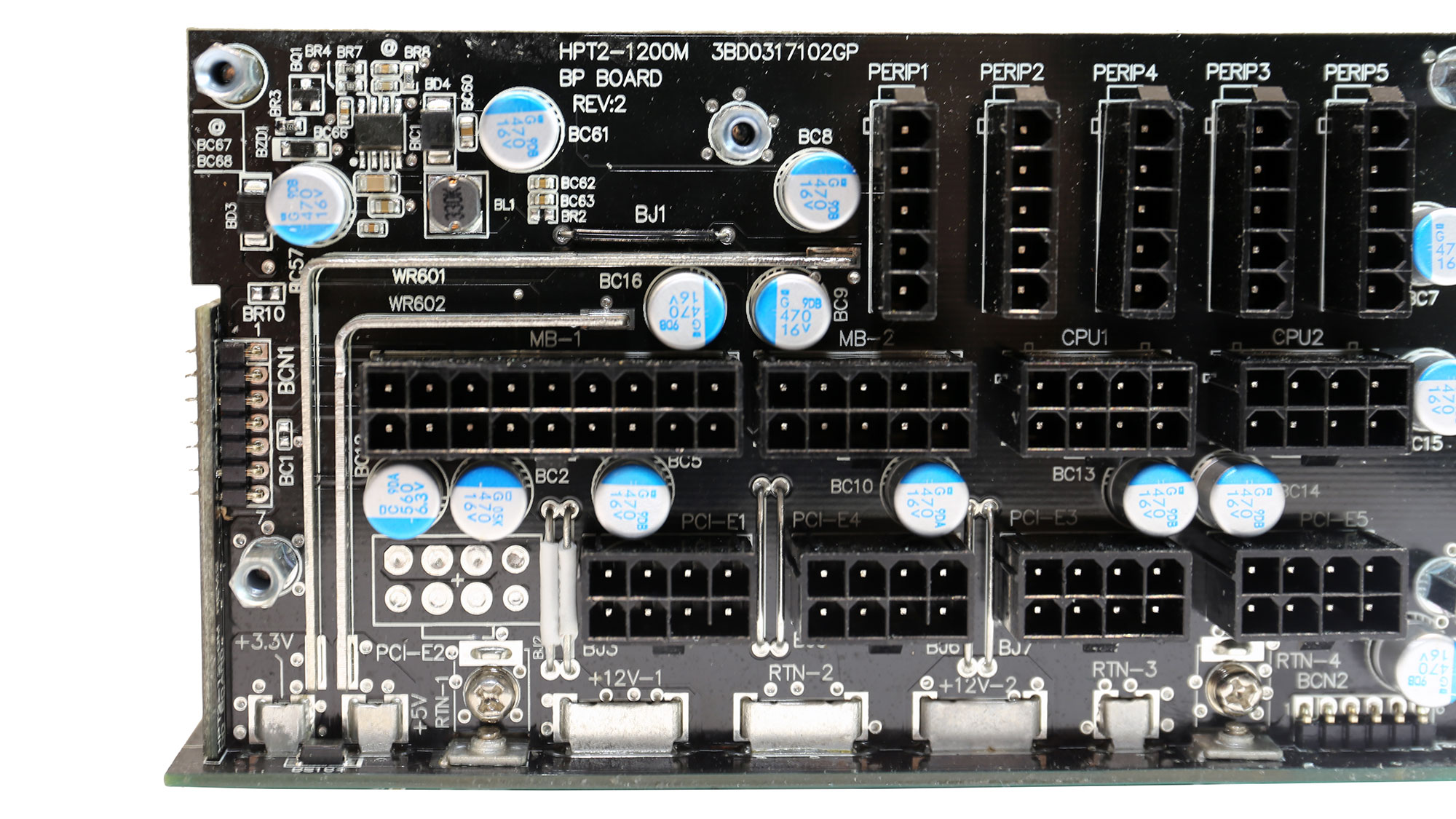

Modular board front

Besides bus bars, we also find many polymer caps on the modular board.

Soldering quality

Soldering quality is good and all component leads are short enough.

Cooling fan

The cooling fan is of high quality. You cannot go wrong with Protechnic Electric fans. They are not affordable, but you get what you pay for. The fan controller is an APW9010 IC.

MORE: Best Power Supplies

MORE: How We Test Power Supplies

MORE: All Power Supply Content

Current page: Specifications and Part Analysis

Next Page Load Regulation, Hold-Up Time, Inrush & Leakage Current, Efficiency and Noise

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

Co BIY I would be interested in the reviewer's opinion of the conformal coating and anything he saw related to humidity-proof claims.Reply

Was it visible in the tear down ? is it actually different than other products ? -

Jeremy.L Reply

The conformal coating is hardly to find unless you use some devices to scratch the surface of the PCB board. Its overall performance is beyond my expectation.Co BIY said:I would be interested in the reviewer's opinion of the conformal coating and anything he saw related to humidity-proof claims.

Was it visible in the tear down ? is it actually different than other products ?