The Math Behind GPU Power Consumption And PSUs

Good Caps Or Bad Caps? The Legend Of The Japanese Dragon

Interlude: What Are The Benefits Of Polymer Capacitors?

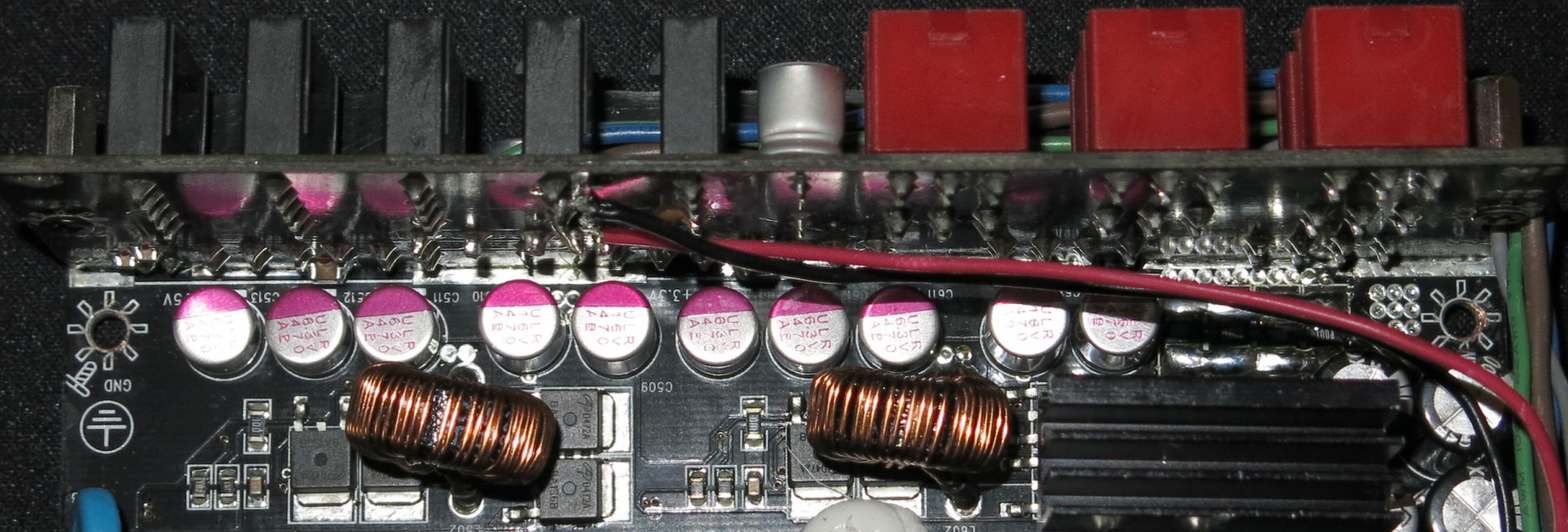

I stumbled upon an interesting finding when I tested two simpler PSUs with and without modular cable management. They were pretty much identical apart from their PCBs. I used a HIS R9 290X IceQ graphics card that produced plenty of spikes, and the result was surprising. I found that the additional polymer capacitors used in the modular PSU were able to deal with the spikes on the input side pretty well if they were placed in a way that made sense. There are a couple of reasons for this. First, the solid capacitors are a lot faster than the electrolytic capacitors. Second, the capacity required to be effective can be a lot lower, since the most extreme spikes don't last long.

This should have a positive, if indirect, effect on the secondary capacitors’ life expectancy. These polymer capacitors are primarily used for things like separating the main and cable management boards to avoid interactions where they aren't wanted.

In any case, the very useful side effect we could observe is certainly a welcome addition, even if it wasn’t implemented on purpose in all of the PSUs.

You can see a good example of calculated corner-cutting to optimize cost below: middle-of-the-road Samxons on the secondary side.

This makes for a great transition to our discussion of the electrolytic capacitors, many aspects of which remain unclear.

Low ESR, Low Impedance And Ripple

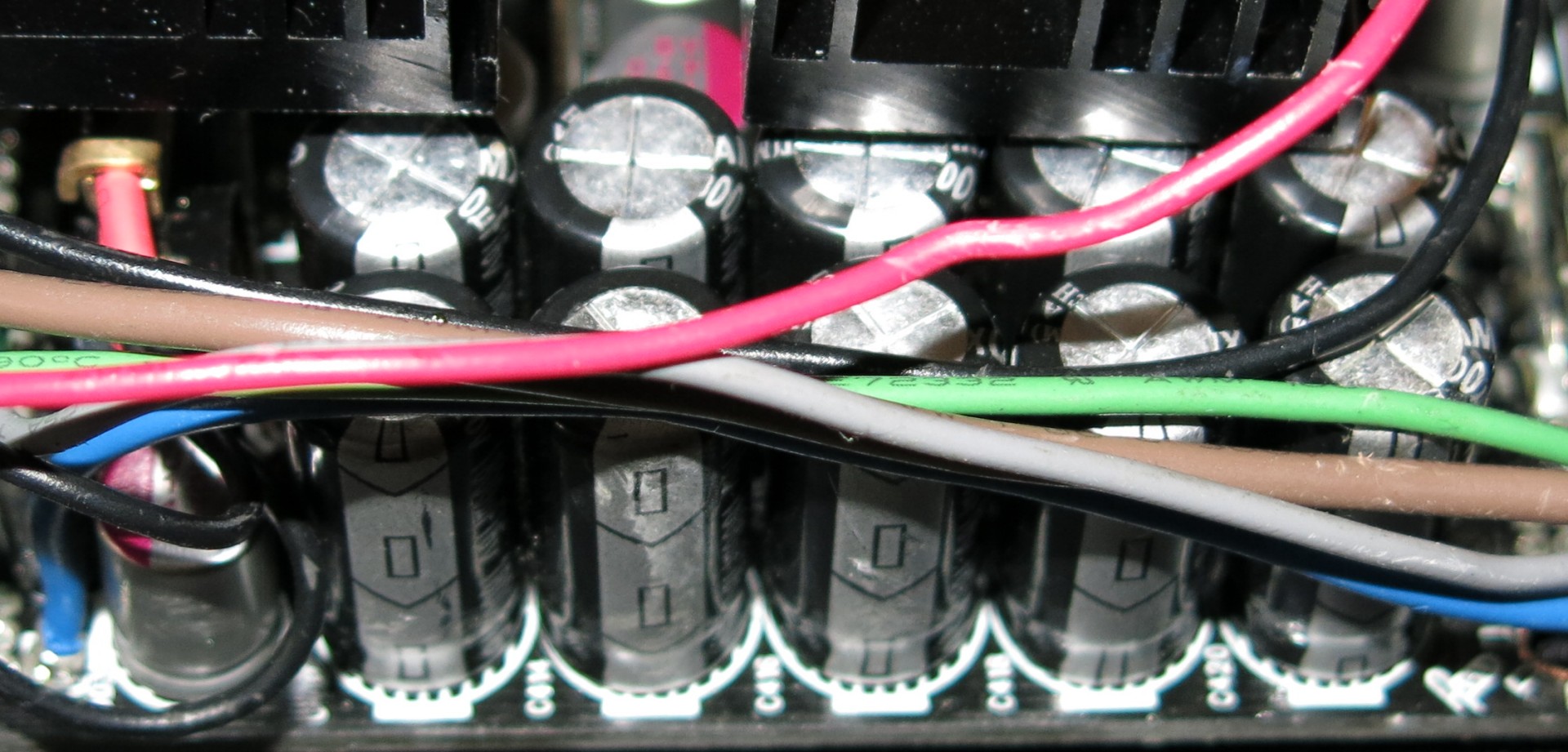

What capabilities does a good secondary capacitor need to have at the very least? It’s supposed to ensure that the PSU is able to consistently provide high currents and guarantee that load fluctuations are compensated for. So much for the theory. But not all electrolytic capacitors are the same. This is where things get really interesting. Let’s turn our attention to the capacitors’ quality according to their specifications and their suitability for their actual purpose, which aren’t necessarily the same.

Going a step further, what should an electrolytic capacitor be particularly good at, especially when taking our graphics cards’ unruly behavior into account? First, and, if nothing else, to make it last longer, it needs to have an ESR, or equivalent series resistance, that is as low as possible. This is why these so-called low-ESR designs can often be found on the output side of PSUs and on motherboards in the VRM area.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

What gives us reason for concern are our power consumption measurements with their load fluctuations that can follow each other so quickly that the capacitors don’t even have time to recharge in between them. Many manufacturers are now switching to special low-impedance capacitors that are supposed to provide low internal resistance at high frequencies, which normal electrolytic capacitors don’t offer at this level of perfection.

Some Calculations Make Us Wonder

As we know, no actual direct current flows through the capacitors, but so-called ripple currents can be found instead. These are essentially just the fluctuating direct currents we’ve been talking about. A peek at one of Teapo's specification sheets tells us which capacitor is most suitable for the task at hand. To guarantee that there’s enough of a wave left even for one of the slower PSUs, and taking the previously-discussed AMD Radeon R9 290X as a reference, we’d be looking at 20A, for which 3330µF per rail should easily suffice. It should be 4700µF for 30A. Any more should be handled by running the electrolytic capacitors in parallel.

The Teapo SY (low impedance) has gained some popularity of late. It has 3330µF as a 16V version with an impedance of 0.02ohm at 100kHz. At 20A, and including a self-discharge of approximately 0.25V (which is equivalent to a ripple of approximately 2.1 percent and results in a power loss of around 8W, according to the specification sheet), 2.88A (rms) for 5000 hours are expected. That would fit well, seeing that nobody will ever reach those maximums.

A KY-series model by Nippon Chemi-Con has the exact same specifications, but it’s rated for twice as long (10,000 hours) at maximum ripple currents. This appears to be an electrolytic capacitor that’s twice as good, right? You don't get the whole story, though. Seeing that nothing coming even close to the maximum load will ever be reached, any discussion of different hour ratings stays in the philosophical domain. Practically speaking, something other component is going to break first.

Even the CapXon capacitors, which are usually known as “bad caps” and “cheap junk,” can produce good results as long as you’re willing to pay for the higher-end models. Case in point: A CapXon GF (low impedance) with 3330µF as a 16V version has an impedance of just 0.018ohm at 100kHz and manages a respectable 3.49A for 5000 hours.

Then again, “cheap junk” can certainly be found as well. The Jun Fu WX with 3330µF (16V) manages a reasonable 0.022ohm, but it can’t keep up when it comes to a ripple current of 2.1A.

So Where Are (Or Were) The Possible Quality Problems?

Electrolytic capacitors need to have good conductivity so that the ripple currents don’t cause any damage, especially when the capacitors in question have a low ESR and a low impedance rating. A range of solvents and other additives are used to increase conductivity, one of which is usually water. The added water automatically increases the number of free ions, resulting in significantly better conductivity of the electrolytes.

At the risk of boring you with too much chemistry, even slightly contaminated water damages aluminum. It corrodes in an exothermic reaction, which produces a hydroxide molecule (AlHo3) and a gas that increases the pressure in the capacitor’s casing.

We can see the resulting bumps and predetermined breaking points in the casings, which are supposed to pop if the pressure gets too high. If they do, you’ll hear a hiss and have a big mess on the board. Or they don’t pop, in which case you find an even bigger mess after a bang.

Manufacturers should really have the water’s antagonism toward the aluminum under control by now. Unfortunately, particularly in the technology’s early days, certain vendors' design and production problems turned a lot of electrolytic capacitors into ticking time bombs.

Many capacitors’ bad reputations go back to these times, and a lot of them are consequently outdated by now. The content of the so-called “bad caps list” is just not accurate today. Manufacturers might still make the same models, but the actual product isn't the same.

So What Should You Buy?

This question is really not that easy to answer, because the answer depends on a lot of specifics.

A Taiwanese- or Chinese-made secondary capacitor specifically chosen for its purpose can perform the same or even better than a Japanese product with worse technical specifications but a powerful brand name behind it. This is as long as the PSU manufacturer uses high-quality products, which should also avoid high engineering tolerances.

In the end, you get what you pay for from practically all manufacturers these days. This doesn’t make evaluating the components inside of a PSU any easier, so it falls to reviewers to provide informed judgments and not just repeat back brand names. The actual quality of the capacitors needs to be taken into account.

It’s easy to pretend that this is someone else’s problem as a graphics card reviewer, even though the interactions with the PSU are a factor that shouldn’t just be dismissed.

Current page: Good Caps Or Bad Caps? The Legend Of The Japanese Dragon

Prev Page Switching Sides: A Look Inside The PSU Next Page The End Of A Long Journey

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

Vorador2 Man, everytime i'm truly fed up with Tom's posting news that read as press releases, and badly written opinionated pieces, a jewel of a deeply researched original article shows up.Reply

Thanks for reminding me of the reasons i started reading Tom's Hardware. -

FormatC It is always difficult to break down the complex content to find an understandable level for all. We may lose a lot of information by this way (and some experts and nitpickers will kill me) or write boring and extra dry stories for a handful of readers without simplifications. It is always hard for us to find a good compromise.Reply

This equipment, shown in the review, is a good basement for a lot of other in-dept reviews in Germany, like the efficiency analysis of Nvidias GeForce GTX 970. You simply need exact numbers to do this. :D

I've also visited PSU manufacturers in Asia this year and this VGA-PSU problem is now more in focus...

But all this are another stories and I hope, that we get for all this more translation capacity here in US/UK. If not: it is a good reason to learn German :D

-

gofasterstripes Tom's Hardware delivers another piece of technical journalism at the gold standard.Reply

Well done to all involved, thank you. -

s3anister This was an excellent read; thank you for the incredible amount of work done for this article.Reply -

justin2003jclc Hi Toms Hardware,Reply

Can you clarify on your rule number3 ? Do you means that most of the PC PSU in the market are linear power supply when you mention about analog? Do you mean that there is only minorities of PC PSU available in the market are using switching power supply design? -

This is GOLD! Kudos to Igor for writing such a superb article. I hope he makes all the PSUs he reviews, undergo the same tests. Can't wait for his PSU reviews :)Reply

-

pecul1ar Congratulations on finishing this year long experiment, and thank you for sharing us your findings. This must have lifted a load off your shoulders..Reply

Oh, so this was translated? Thank you for that as well :) -

NoShot So, my take away from this is my PC builder (will not name here but is one of the larger ones offering custom builds) mislead me on their configuration setups when they said a Corsair RM850 PSU would be fine for a r9 295x2 and a i7 4970k. Not surprisingly, I am having random issues with this build where the 29 295x2 would only activate one GPU after system reboot or awake from sleep mode. I was thinking it was a driver issue, but looks like I need to drop a couple hundred dollars on a replacement PSU.....great. Genuine thanks for the article though.Reply