Overclocking Core i7-3770K: Learning To Live With Compromise

We recently took our first look at Intel's Ivy Bridge architecture. Then, we evaluated its efficiency. Now, we turn to overclocking. Recently, each of Intel's die shrinks has helped increase frequency headroom. This time, however, we ran into some walls.

Digging Into Ivy Bridge's Overclocking Issues

Why do Ivy Bridge processors behave this way? How come 32 nm Sandy Bridge-based processors stay cooler, even at higher clock rates and voltage settings? Is this Intel’s Ford Edsel moment? We don't necessarily think so, but let's take a look at the factors that cause us to be concerned.

More Heat Output Per Mm2

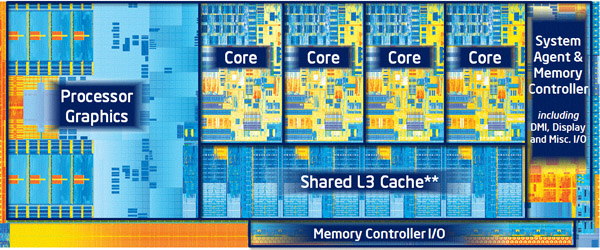

The Ivy Bridge-based Core i7-3770K sports 1.4 billion transistors on a die area of 160 mm2. The Sandy Bridge die measures 216 mm2 and contains 995 million transistors. While we're comparing, we should also keep in mind that the HD Graphics 4000 engine occupies about one-third of the largest Ivy Bridge die. On Sandy Bridge, HD Graphics 3000 is closer to one-fourth of the package. In total, the CPU's area shrank by roughly 40%.

Now, let's approximate the surface area consumed by everything except graphics resources:

- Ivy Bridge: ~105 mm2

- Sandy Bridge: ~160 mm2

The Sandy Bridge-based Core i7-2600K has a TDP of 95 W, whereas the Ivy Bridge-based Core i7-3770K’s TDP is 77 W. Suddenly, it becomes a clearer that overclocking causes the smaller Ivy Bridge die to emit as much heat per square millimeter as Sandy Bridge. This naturally affects how much higher than Sandy Bridge we should have expected Ivy Bridge to scale.

New Transistor Technology

Another variable we've seen presented are the new tri-gate transistors. Intel claims that, in a typical use case, they use up to 50% less energy compared to a traditional transistor, as their three-dimensional structure of one horizontal gate together with two vertical ones effectively triples the field effect of the gate, which should reduce leakage current drastically.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

We want to emphasize the phrase “typical use case” here because the more you overclock, the further away from typical you get. While we can confirm the claimed power reduction for typical use cases (just wait until we get to the benchmarks), at this point, it is not entirely clear how these transistors perform at substantially increased clock rates. Maybe they're just not optimized for the speeds an overclocked chip pushes yet. It might be necessary to wait for Ivy Bridge's successor, Haswell, to see if the limits of 22 nm manufacturing can be pushed harder.

Thermal Engineering

Increased density and new transistor technology can certainly give rise to more heat. But we've seen these things before, and each time, cooling and packaging technology manage to cope with the resulting output. What could be holding Ivy Bridge back? It could be the fact that Intel decided to use thermal paste instead of the usual fluxless solder (you'll need to have a solid grasp of Japanese to understand the original article, or use Google Translate) between the CPU die and heat spreader.

Using a box knife (we do not recommend doing this at home), the author of the linked story pried the heat spreader away from the chip and was able to replace the cheap paste Intel used, trying out both OCZ Freeze Extreme and Coollaboratory Liquid Pro thermal pastes. The OCZ offering allowed for 1.55 V at 4.9 GHz, while the Coollaboratory material ramped up to 5.0 GHz, operating stably. This was accomplished even with air cooling, although the author did not use a stock heat sink, opting for a Thermalright Silver Arrow SB-E instead (Ed.: this information was pulled from the original Impress PC Watch site with Google's rather shaky translation of Japanese). If there is a smoking gun in this equation, we think this is it, especially considering that the researchers at Impress PC Watch managed 20% more efficient cooling.

Current page: Digging Into Ivy Bridge's Overclocking Issues

Prev Page More Voltage, More Heat Next Page Practical Advice: Sandy Or Ivy Bridge?

Patrick Schmid was the editor-in-chief for Tom's Hardware from 2005 to 2006. He wrote numerous articles on a wide range of hardware topics, including storage, CPUs, and system builds.

-

mayankleoboy1 Nice review!Reply

1. Are there plans to release any K CPU's without the HD4000? will they OC higher?

2. Any chance of intel releasing a second stepping of K-series IB chips? -

mayankleoboy1 i agree that SB chips spoiled the OC world by making OC so easy and fruitful. IB has nothing to compare it to except SB.Reply -

vilenjan Good old Intel. No competition and look what happens, the new generation is barely an upgrade over the previous. Anyone remember Intel PII 450s and the PIII 450s?Reply -

ta152h I'm not sure why the reviewers spent so much time figuring out the shrink made the core more dense, and somehow thought this was significant. I mean, really, this happens virtually every shrink, and this time the power dropped more than normal. Common sense should be telling people this is not the cause, but somehow people aren't understanding this.Reply

It's very interesting that replacing the paste makes so much difference. This is obviously something Intel is aware of, since they do plenty of testing, and obviously chose anyway. Would a few pennies be worth it for a processor that is clearly on the higher end of the scale? Probably not.

Most likely, they want to keep selling their real high end processors, and it just won't do to have the 3770K beating their 2011 processors, or being very competitive with the successors to that line when they come out. It makes perfect sense. The 3770K is still a great processor, but if you're really looking for the best, it simply will not do. You're forced to buy the more expensive 3960X, and later the even better IB successor to it, which you can bet will have far better paste, and so will overclock significantly better.

It's genius. A great product for the vast majority, while leaving more expensive products as the best option for that elite that will actually spend $600 to $1000 for a processor.

Well done, Intel. It's not like AMD has anything to say about it. -

Without the baseline clock for clock comparison (4.5 sandy vs 4.5 ivy), i'm afraid these results are pretty much useless. It's like doing an uncontrolled experiment and passing it off as real science.Reply

-

digiex as the manufacturing process gets smaller = Smaller die size, supposed to be cooler temperature,Reply

but, with small die size = small area for heat dissipation,

...an irony that needs to be solved. -

slicedtoad Recommending a closed loop liquid cooler? really?Reply

They perform worse than decent air coolers. The lower end ones (think corsair's h60) perform like mid-low range air coolers and cost more. The better ones (h100 or antec's 920) perform on par or worse and with more noise than a similarly priced noctua. If noctuas looks too ugly for you, phantek and several others offer similar performing models.

The only reason to get closed loop lc is for looks. I admit they do give your build a nice clean look. That doesn't warrant "So, we're recommending a closed-loop liquid cooling setup, at least" though. If you'd changed that to "We're recommending higher end aftermarket coolers for a decent oc", it would've made more sense.

Anyway, I'm just nit-picking a single line from the article. All in all, it was a good read. It just makes me upset to hear wrong advice. -

_Pez_ there is no performance advantage over the i7 2600k except for power consumption. I better buy an i7-3930k.Reply -

mesab66 Absolutely true, digiex.......not far off the animal world parallel - check out the different temperature regulation methods here between large and small animals, particularly how difficult it is to regulate as the size becomes smaller.Reply -

I would like claims that Ivy Bridge procesor is overheating considerably more then Sandy Bridge addressed. And I thin k Intel really should make a better overall product and not cheat us like this.Reply