TSMC rumored to receive High NA EUV machines from ASML this year

TSMC is thought to be the last of the big three to get a High NA EUV machine from ASML.

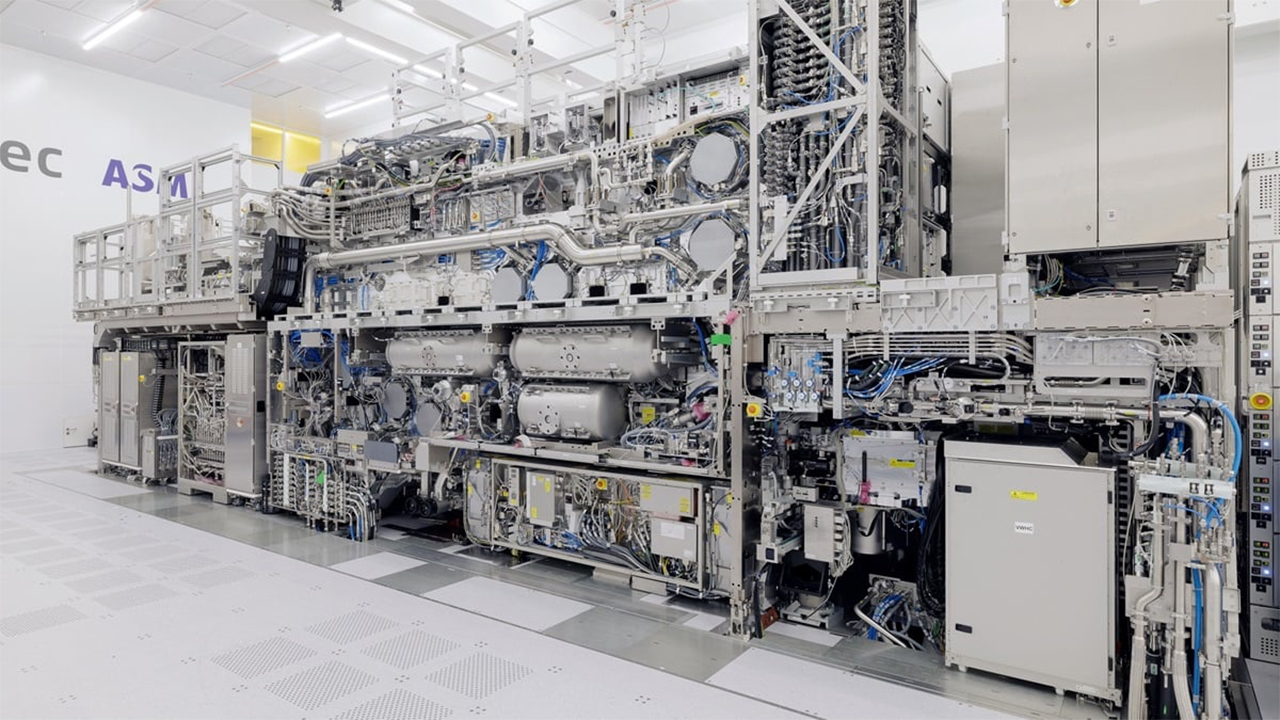

Nikkei Asia's sources say that Taiwan Semiconductor Manufacturing Corporation (TSMC), the largest semiconductor fab in the world, is set to receive the ASML’s most advanced chipmaking machine this year. The high numerical aperture extreme ultraviolet (High NA EUV) machine, which is said to cost more than $350 million apiece, will allow chip makers to print features smaller than before. Nikkei Asia reports that TSMC is considering using its High NA EUV lithography machines to make processors that use angstrom 10 (A10) technology, about two generations ahead of the 2nm node that it plans to put into production by the end of next year. This means that we likely won’t see this machine used for mass production until after 2030.

Although TSMC is the biggest semiconductor manufacturer globally, it’s not the first company to get ASML’s latest, most advanced machine. Intel was the first to adopt the machines, having received the very first High NA EUV machine in the first quarter of 2024 at its Oregon facility. It also received a second machine during the second quarter of this year — a testament to the company's focus on regaining its technological edge over the competition, especially in AI chip manufacturing. Sources also say that Samsung will install its own High NA EUV machine sometime between today and the 1Q25.

This news of installations of ASML’s most advanced machines doesn’t mean that we’re getting sub-nm nodes next year, however. Instead, companies are investing hundreds of millions of dollars to develop the technologies needed to harness its ability to pack in transistors in record-breaking densities. That’s because High NA EUV has a smaller imaging field versus current NA EUV machines, so chip manufacturers need to adjust their designs based on that. Furthermore, High NA EUV machines are significantly larger than current lithography machines, so these fabs must reorganize their production lines or build a new factory from the ground up to accommodate ASML’s most advanced offering.

At the moment, these three companies — Intel, Samsung, and TSMC — are the only ones that are known to be working on more advanced chips that will take advantage of ASML’s High NMA EUV lithography machine. This is especially true as Chinese firms have been blocked from accessing ASML’s products and services by America’s bans and sanctions. Nevertheless, the company says that it already has received 10 to 20 orders for these multimillion-dollar machines.

ASML has a practical monopoly on advanced EUV lithography machines. It’s the only one that has know-how and capability to manufacture these machines required for making the next generation of semiconductors. But even if ASML is based in the Netherlands — a known American ally — the U.S. is still investing EUV research so that it could bring its semiconductor supply chain home. While it will take years, if not decades, for this move to bear fruit, this should at least give chipmakers more options in the future, furthering technological advancements through healthy competition

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Jowi Morales is a tech enthusiast with years of experience working in the industry. He’s been writing with several tech publications since 2021, where he’s been interested in tech hardware and consumer electronics.

-

kjfatl This makes a lot of sense. TSMC is in a position that there is no value for them to pay a premium for first delivery. For the next few years, they can do what Intel did with double and triple patterning with their 10nm+(+)(+) processes and utilize existing EUV equipment. Intel does not have this option since they have minimal investment in the last generation of EUV equipment. This will delay TSMC a couple of years, but it doesn't hurt them with the 5% of their business effected by this. Intel on the other hand needs it for 50% of their silicon in the coming 2 years.Reply -

rluker5 Reply

Apple counts for more than 5%. If the smaller nodes are better Apple will want some chips on them.kjfatl said:This makes a lot of sense. TSMC is in a position that there is no value for them to pay a premium for first delivery. For the next few years, they can do what Intel did with double and triple patterning with their 10nm+(+)(+) processes and utilize existing EUV equipment. Intel does not have this option since they have minimal investment in the last generation of EUV equipment. This will delay TSMC a couple of years, but it doesn't hurt them with the 5% of their business effected by this. Intel on the other hand needs it for 50% of their silicon in the coming 2 years. -

kjfatl Reply

TSMC can build Apple's chips using their existing equipment with double or triple patterning, vs single exposure with the new equipment. TSMC is reducing their capital expenses significantly, at the expense of more passes through equipment in the factory. Intel, on the other hand does not have the old EUV equipment so they have to buy new.rluker5 said:Apple counts for more than 5%. If the smaller nodes are better Apple will want some chips on them.

Double patterning and such to extend the process is nothing new.

Doing this will allow TSMC to extend the life of their existing nodes by 1 or 2 process generations, just like Intel did. This will give them time to build new fabs to stay competitive with Intel's leading edge fabs. -

thestryker Multipatterning is not cheap and it's definitely not something they want to be stuck doing. That being said this is largely in line with TSMC's history. They have rarely jumped on bleeding edge, but rather stuck with their long term development roadmaps. There's also the fact that Samsung is still having yield problems with their GAA nodes and Intel won't have 18A for external until 2026 at the earliest.Reply

It makes sense that they wouldn't be in a rush to order volume quantities of High-NA machines. -

Mama Changa Reply

Everything is relative. It's a hell of a lot cheaper than spending $400 million on a high NA machine currently. Semianalysis did a detailed breakdown and showed multipatterning will be much more cost effective until sub 2nm. And it looks like TSMC agrees as this will be used for not N2 but A16 at the earliest.thestryker said:Multipatterning is not cheap and it's definitely not something they want to be stuck doing. That being said this is largely in line with TSMC's history. They have rarely jumped on bleeding edge, but rather stuck with their long term development roadmaps. There's also the fact that Samsung is still having yield problems with their GAA nodes and Intel won't have 18A for external until 2026 at the earliest.

It makes sense that they wouldn't be in a rush to order volume quantities of High-NA machines.

But it doesn't matter at all. N2 is already being touted to being massively better than N3 and miraculously even shows good SRAM scaling for the first time in something like 10 years. -

elmeastr00 “the U.S. is still investing EUV research so that it could bring its semiconductor supply chain home. While it will take years, if not decades, for this move to bear fruit, this should at least give chipmakers more options in the future, furthering technological advancements through healthy competition”Reply

https://research.ibm.com/blog/high-na-euv-lithography-albany

the gool is to learn how to use asml machines in the overall proces of chip making (a good oven does not make one a good chef) .

This will be North America’s first and only publicly owned research and development center with a high-numerical aperture extreme ultraviolet lithography (High NA EUV) system. This machine from ASML can perform a new technique that could pave the way to developing and producing chips at nodes even smaller than 2nm. -

jp7189 Reply

Intel 4 uses EUV, just not high NA.kjfatl said:Intel, on the other hand does not have the old EUV equipment...