How To: Properly Plan And Pick Parts For An Air-Cooled PC, Part 2

After discussing the theory of PC cooling, in Part One, we now move on to technology and implementation, discussing case fans, CPU coolers, and thermal grease. We even wrap up with a recipe you can use if you fail to cool your PC properly.

Case Fans: Air Flow And Noise Level

What Does Air Flow Really Mean?

The simple answer is that air flow corresponds to the volume of air moved through the fan in a set interval. Thus, it is a very important parameter for us. Unfortunately, it's often conveyed using different units, making it potentially confusing for the beginner. In English (and in most data sheets), the typical parameter is CFM, or cubic feet per minute, while in Europe, m³/h (cubic meters per hour) is more common. Yes, it'd be easy to mix the two up, but here's a handy conversion chart to keep your comparisons straight.

| Input Value | Conversion Factor | Conversion Result |

|---|---|---|

| 1 m³/h | x 0.58867 | 0.58867 cfm |

| 1 cfm | / 0.58867 | 1.69874 m³/h |

Example Conversion:

At an end-of-summer clearance, we bought a desk fan sporting 840 m³/h at an appliance store in Germany. What would be the corresponding CFM value for the same fan purchased in the U.S.? We apply the conversion factor and get:

840 x 0.58867 = 494.4828 CFM

See? That wasn’t too hard, after all.

What Is Fan Noise, And How Does It Come About?

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Typically, noise is a mix of several frequencies, which makes it hard to define and compare. Looking at the data sheets of fans, noise levels are either specified in dB (decibel), dB(A), or in Sone (loudness). The drawback of merely looking at a specified acoustic spec is that it's hard to imagine how unbearable that number is in the real world.

Whether noise is considered annoying is a multi-faceted issue affected by several factors. Is the disturbance slight, is it a humming motor, or a squeaky bearing? Unfortunately, a fan that boasts a low noise level on its data sheet can be more annoying than one with a less attractive spec as a simple consequence of its tone.

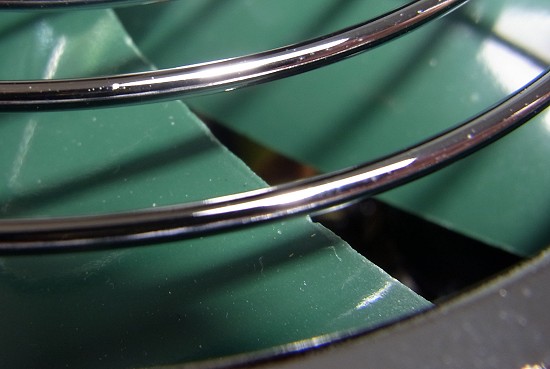

This looks like it could potentially be pretty noisy. First and foremost, a fan's blades impact its acoustic profile through more or less audible flow separation, which depends on build quality and rotational speed. To that end, surface quality, the blade's angle, and the number of blades all directly influence whether or not a fan is noisy. Many manufacturers claim to minimize acoustics with curved blades and golf ball dimples. But more than anything, you can help mitigate noise by not placing fans too close to case openings and meshes, which can result in the dreaded siren effect.

Sleeve, Ball Bearing, Or Something Entirely Different?

A fan's motor can contribute to noise output as well. Many times, motor noise is most annoying at low speeds, and is manifested as humming. Grinding or clanking sounds from the motor bearings are tough to quantify in a specification, but those are super annoying as well. Ball bearings endure less friction than sleeve bearings, and they typically last longer as well (depending on lubrication and design). However, some cheap ball-bearing fans only employ a single bearing, and the rotational forces (plus air pressure) may cause torsion, leading to premature bearing failure. Fans with double ball bearings do not exhibit this problem.

Sleeve bearings are typically quieter than ball bearings, and a ceramic sleeve bearing has the longest life span of all bearing types, since ceramics with a high-quality surface finish offer the least amount of friction. In general, however, double-ball-bearing fans present the best compromise between noise and longevity. Other design features fall into the category of personal preferences; in general, most high-quality fans perform equally well.

Keep in mind that even experts have a tough time predicting how a given fan will perform in the real world.

Interim Conclusion

Regardless of marketing proclamations about innovations like liquid bearings, the best product isn't always the most expensive one in the shiniest box. The true quality of a fan is determined by the ratio of its air flow to measured and perceived noise level. The lower the noise level for a given (high) air flow, the better we consider it for our purposes.

Current page: Case Fans: Air Flow And Noise Level

Prev Page A Foundation For Case Cooling: Fans Next Page Case Fans: Decoupling Done Right

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

Ragnar-Kon Helpful even for myself (who has been building PCs for years). Granted all it really told me is that I was doing it right all along, but it did give me some useful bits of information that I didn't know before.Reply

Kind of disappointed that the process of aftermarket GPU cooling wasn't explained more. That is something I have never done before, but always wanted to try out on one of my older cards. -

drutort gloves? who uses gloves :P I use my finger :) I have been doing it before there was even aftermarket paste :PReply

the trick is, that i did and do twist, BUT i double check how much paste there is on the heatsink and the cpu, if there is enough I then fix it up on both ends and press the 2 together and do small twist... in fact if you have it lapped, you can twist a bit and it starts to give some resistance... IMO this tells me that access paste has distributed even and any access is gone...

This works so well that you cant separate the heatsink and cpu if you try to pull it straight off most of the time, but have to switch and move it.

How do I know it works? wouldnt be getting the results i did.. my old 720 be unlocked 4 cores and running at 3.3ghz .. I recently replaced it recently with Noctura D14 and phenom II X6, that I dialed into 4.13ghz

but then again I would say don't do this at home :P (the way I do it works good enough when using thicker pastes, such as the arctic silver 5)

***I forgot to mention that this works for those heatsinks were you have a strap and not screws... I agree that those that have high pressure through screws you probably should not move or twist... but all those heatsinks that can create a lopsided effect due to the strap, this way works very well, especially when having thermal paste on both ends, and best way is to strap it down and take it apart, examine it and then fix it up add/remove any paste and place it back on.***

For the noob this is a good enough article... -

fancygoods On page 5 the second picture the top case fan points down yet hot air comes up.Reply

Im curious although it wont have a large affect, if the CPU cooler fan would act like a puller if put on the left side whether it would hurt or help the memory temps -

ojas Really good article, and a real help. Just thought i'd chip in with what i know/have to ask....Reply

I remember reading that sleeve bearing fans should not be used horizontally, that shortens the life span of the fan and makes it noisier over time. Something to do with the fluid in the bearing. Other bearings don't have this problem.

I also remember watching a program on NatGeo on submarines. Apparently modern day subs use propellors with a large number of thin blades. This basically avoids pressure diferences between water in front of the blade (in the direction it's spinning), thus prevents excessive low pressure in the region through which a propellor has passed. This avoids small bubbles of steam from building up and then popping, causing noise.

Seeing that air is a fluid too, i wonder if a similar principal will apply to it. Of course, there wont be any air bubbles popping in air, but i'm wondering if turbulence has any role to play, since i assume more blades=less turbulence. not sure though.

dB(A) is the A-curve...what about the C-curve? That's got more bass, which may be audible as a hum...C-cure measurements seem to ba a decible or three higher than A...

If the fans are connected to the mobo, you could use SpeedFan too...

With respect to the positive pressure section:

You say it goes against natural convection. What if i set the front and side panel as intake and the rear and top fans as the exhaust? I'm assuming the PSU is bottom mounted. Would it still go against convection?

What about neutral air pressure?

If, for example, the cooler needs to be re-seated following improper installation, is it a good idea to use isopropyl alcohol (Doctor's Alcohol) to clean the CPU and heatsink?

Cooler Master fans are pretty good, their higher quality fans 120mm fans move 79 to 90 CFM, their 200mm megaflow moves about 110 CFM. In both cases, rated noise is 19 dB(A). however, no rubber screws or frame so a that's a con.

BTW there's no prob with exposed heatpipes and the Arctic Silver, is there?

-

gio2vanni86 I've been doing the whole spread the paste evenly flat onto the CPU/Cooler for almost 8 years now. I'm not a professional when it comes to this solution, nor do i have eyes of a hawk to know if i do it right all the time, the temps seem to be right. I wish you guys did a temp difference on how the paste was spread in a lot different ways to give me a point of view of if there is any difference in temps, obviously the one where you can see the writing more then likely is not effective. Great article as always, cheers!Reply -

Augray37 @ ojasReply

I'm not sure about all the other questions, but i know 90% isopropyl alcohol will work to remove thermal paste. "Goof Off" or similar products are even better. Also, i'd suggest using a coffee filter to apply the alcohol or goof off and wipe away the paste. that's what i do, works every time. -

icepick314 I read years ago that thinner the layer of thermal paste, the better.Reply

Well...not THIN as in barely there thin but just enough to make lettering opaque, not completely covered.

I thought the paste is just to fill in cracks and imperfections on the heat sink and the surface of the processor...

also any word on Zalman's heat paste that comes in liquidy paste? it comes in a small bottle with a brush like nail polish...been using that all this time... -

Branden i've sometimes moved a fan's molex wires from 12v to 5v for silence's sake, but sometime it was too much. never knew i could get 7v by crossing the 12v and 5v lines like that (and wouldn't have dared try if i'd even thought of it anyway), glad to know there's another option there!Reply -

mjmjpfaff I would have liked to seen silverstone's air penetrater fans in here. Just to see how they stack up against other fans.Reply -

chesteracorgi I think that you may have proven my case for GPU cooling being superior as a case exhaust design over the shroud design. The shroud design produces temperatures from 10-30 C above the case exhaust designs.Reply

My own experience with a GTX 470 (from PNY) with a shroud showed an idle temperature abour 45-48 C. When I modded the card with a Zalman 2000F cooler the temperatures dropped to 30 C at idle. This (delta) temperature reduction was consistant for all uses: from idle to load. Similar loads produced temperatures that were 15-20 degrees C cooler with the case exhaust method over the shroud.

Just two weeks ago I added a second GTX 470 (from Galaxy) in SLI. This model has, what is touted to be, superior cooling to the reference design. It consistantly runs about 10 C hotter than the PNY cooled by thge Zalman aftermarket cooler at idle. Because of space considerations the shroud design had to be mounted above the case exhaust GPU. When the GPU load is increased the shroud design temperatures show a increase (delta) of 15- 20 C over the case exhaust. This is expected, as the top mounted GPU is the one with the major work load.

I ordered the mesh sided side door from Corsair (600T) to provide extra ventillation from a side panel fan blowing on the GPUs. If this configuration works, I expect a 5-7 degree C in the top mounted

GPU. I will be using the 200 mm fan (from Corsair) that was modded out from the top of the case when I replaced it with two 120 mm fans (from Xigmatek).