Overclocking Intel's Core i9-7900X CPU Up to 5.8 GHz

Overclocking: Frequency, Power, And Temperature Scaling

As you overclock, there's always a point when the CPU no longer runs stably and you have to stop pushing higher. The most well-known symptom of this is the blue screen of death (or BSOD). When you start seeing those, there are three possible remedies:

- Dial in a lower clock rate to regain stability.

- Modify other BIOS parameters and hope for a better outcome.

- Use a more effective cooling solution.

Cores versus Vcore: IHS In Place

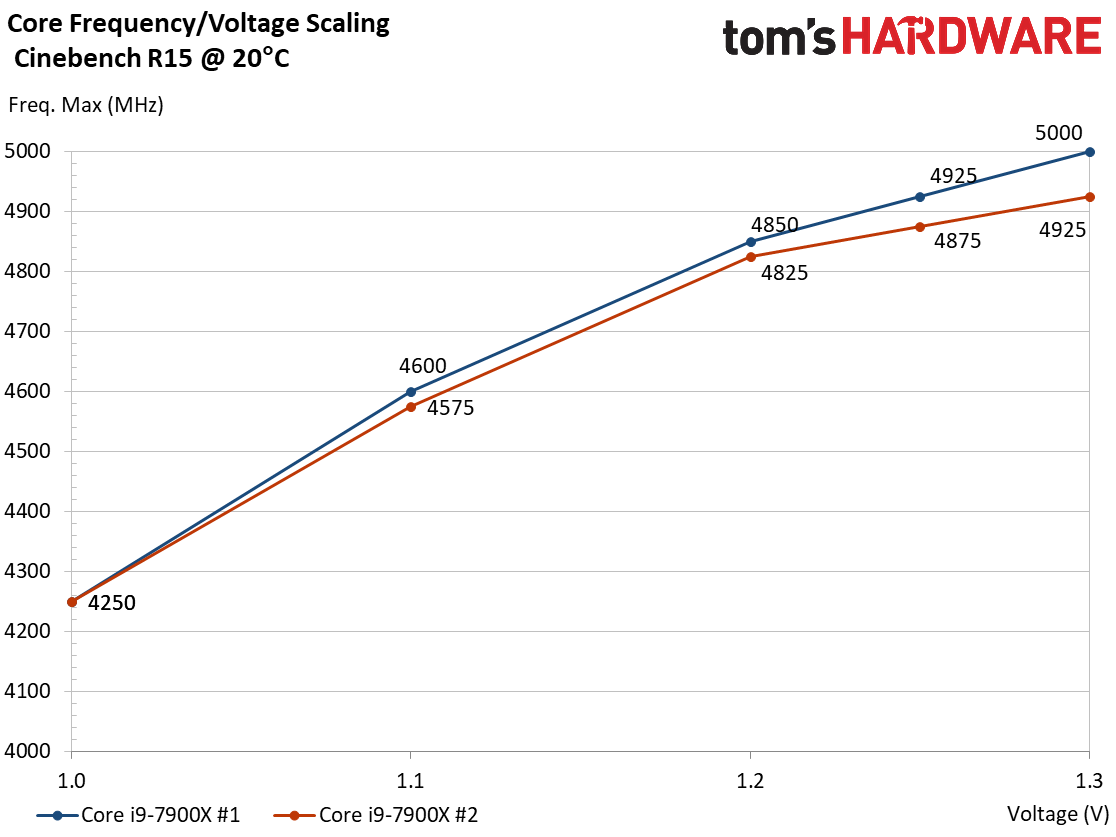

What does increasing the Vcore setting do to frequency scaling? To answer this question, we used two different Core i9-7900X CPUs at various supply voltages in order to determine the highest clock rate able to complete a run of Cinebench R15. The voltage rose in 0.1V increments up through 1.2V, at which point we added a 1.25V setting for more granularity. Frequency measurements are reported with a precision of 25 MHz.

At their base frequency, both processors performed identically, completing the test at 4250 MHz. Increasing the Vcore by 0.1V bought us a maximum clock rate of 4575 MHz on our second sample, and 4600 MHz on the first one. That's a nice speed-up for a relatively small voltage increase. The next increment was similar, maintaining a 25 MHz gap between the CPUs for a total increase of 250 MHz on both of them. With 1.3V applied, the progression slowed. One Core i9 jumped 100 MHz and the other overclocked 150 MHz higher, widening the gap between them.

Adding Vcore is the primary means by which enthusiasts coax more frequency from their CPUs. But this approach is not without its limitations, as processors run hotter and their scaling slows. When the chip gets too hot, or when it requires a lot of extra voltage to hit slightly higher clock rates, it's time to stop.

Cores versus Vcore: Direct Die

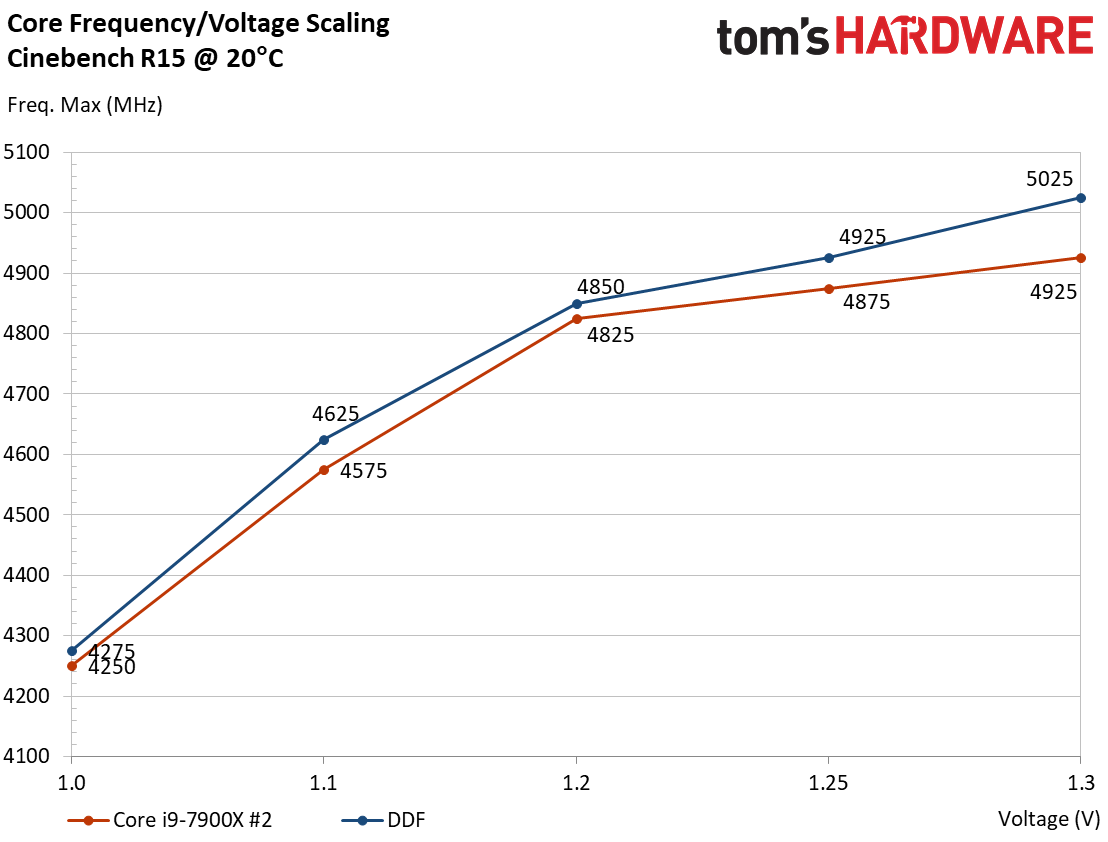

This test zeroes in on our second Core i9 sample, comparing its frequency gains before delidding to direct-die cooling.

Even at the lowest voltage setting, direct-die cooling proved advantageous. However, the gap widened beyond 1.2V. The explanation is simple: prior to delidding, the processor ran hot, keeping the cores from utilizing the extra voltage available to them. The DDF helped it run cooler, allowing the CPU to stabilize at higher frequencies.

Enabling a 100 MHz-higher overclock and a temperature drop of 20°C, direct-die cooling is looking a lot more attractive.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Cache versus Vring

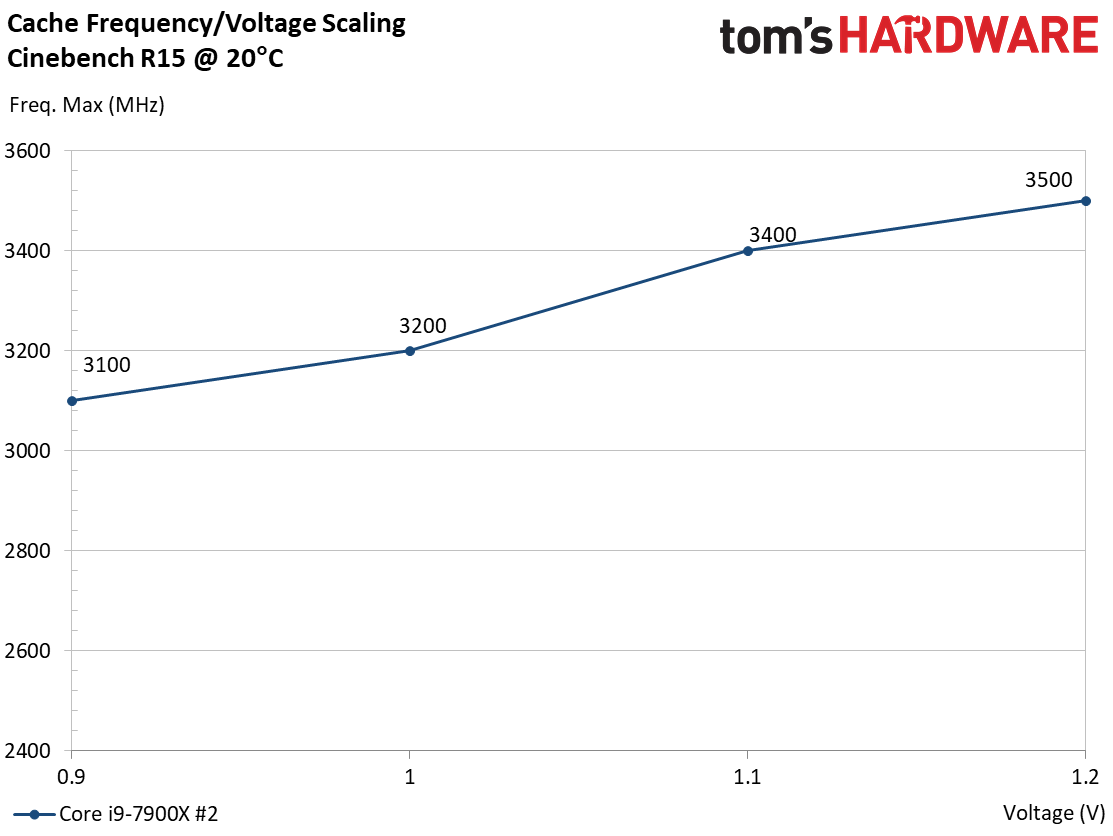

Now we're interested in exploring how the cache frequency scales as we increase the Vring setting.

Increments of 100 MHz explain the shape of our curve. Smaller steps would have yielded a smoother line. But the important take-away is that, for each 0.1V interval, we can hope for roughly 100 MHz of additional headroom.

Power Consumption and Temperature

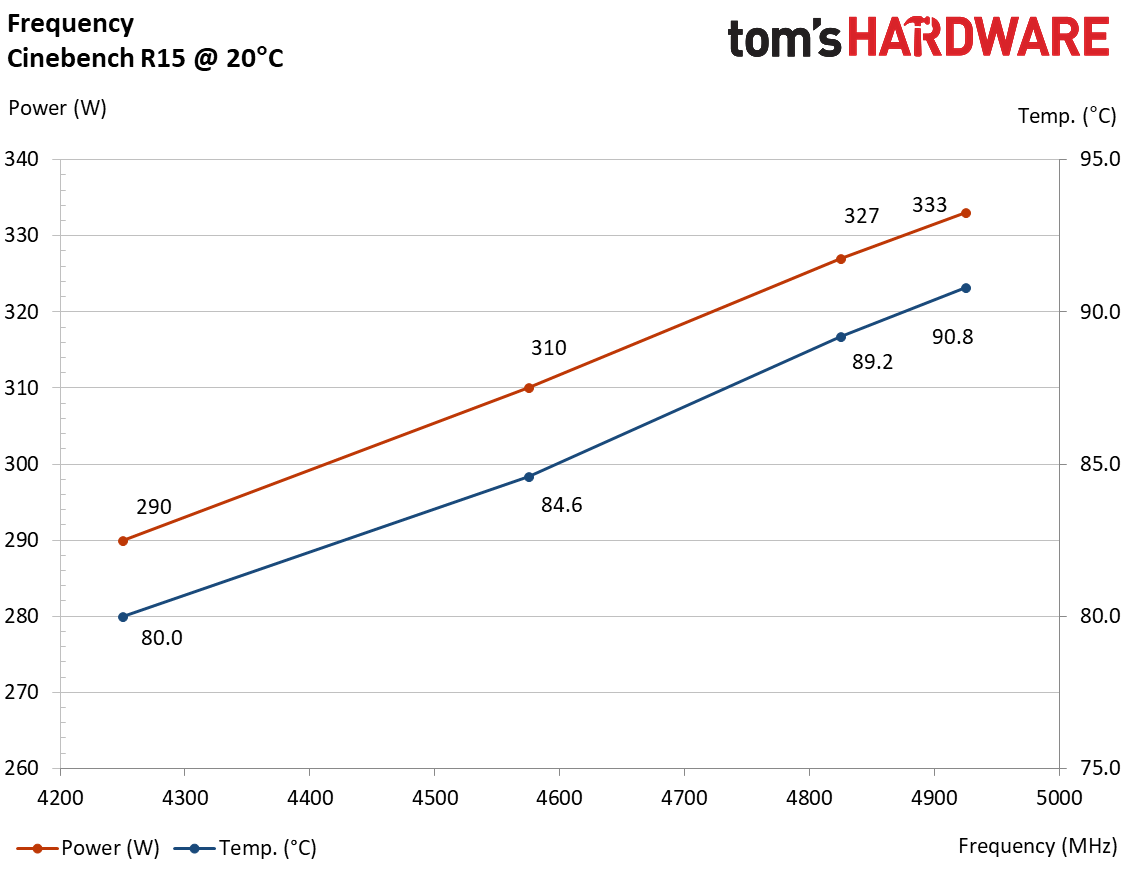

Next, we looked at the effects of overclocking on power consumption and processor temperature by fixing the Vcore at 1.3V and varying the clock rate.

The first thing we noticed was the almost perfect relationship between temperature and power. It's also remarkable that the progression was practically linear. By increasing clock rate by 15.8%, power consumption jumped 14.8% and the temperature rose 13.5%.

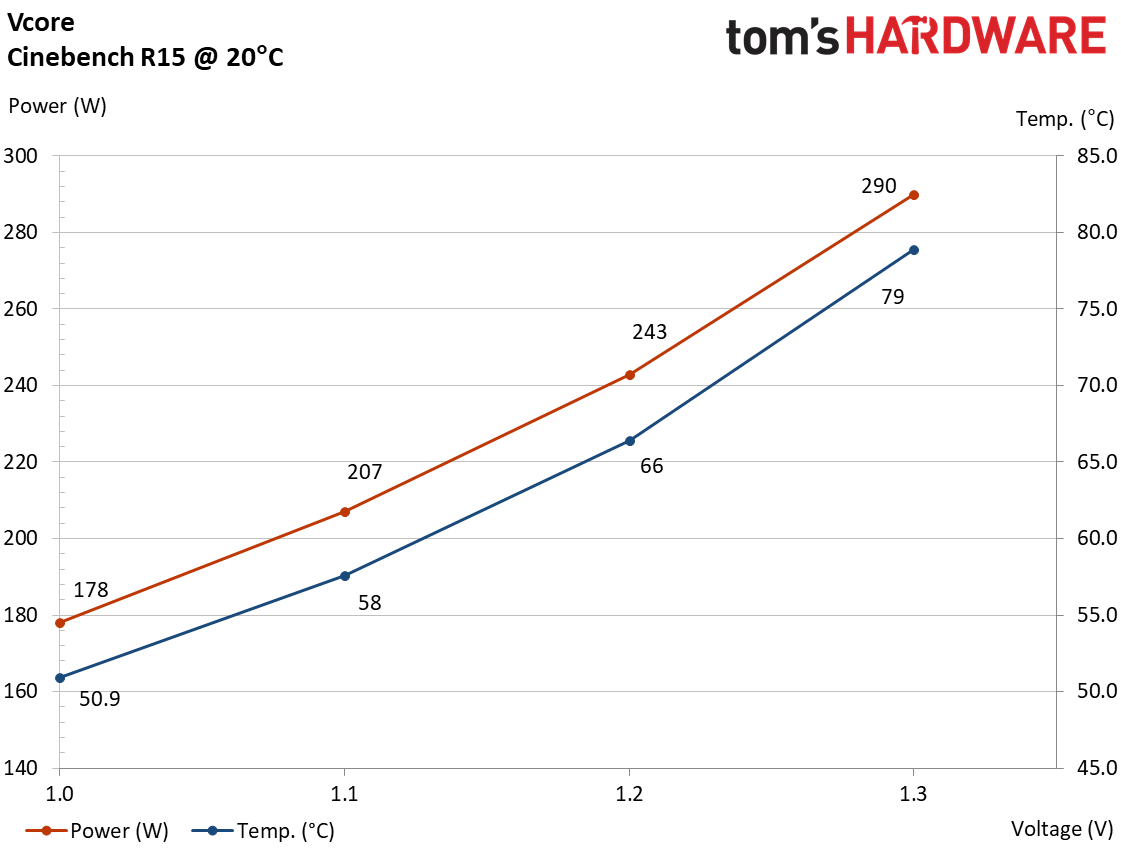

Next, we fixed the frequency at 4250 MHz and raised the Vcore from 1.0 to 1.3V. The temperature still seemed tied to power consumption, but its increase was no longer linear. According to our measurements, pushing Vcore up 30% caused power consumption to rise by 63% and temperature to increase 55%.

Our data illustrating the impact of Vcore on the processor's temperature and power consumption gives enthusiasts one more reason to take it easy with that parameter during an overclock attempt.

MORE: Best CPUs

MORE: Intel & AMD Processor Hierarchy

MORE: All CPUs Content

Current page: Overclocking: Frequency, Power, And Temperature Scaling

Prev Page Temperatures: Stock Vs. Delidded Vs. Direct Die Cooling Next Page Optimized Overclocking And Load-Line Calibration-

vasras Another excellent article, with temp, power and voltage scaling at various cooling/contact methods. Thank you.Reply -

Reynod I bet crashman is spewing he didn't get this gig ... :) Well done ... nice work PresencePC!!Reply -

AgentLozen Very interesting article. I liked your explanations of the expert bios settings on the first page. I usually just ignore the stuff in the bios I don't understand.Reply

While I enjoyed reading all of this, it's not something that would help me personally. I leave my CPU underclocked to >1Ghz so I can feel like I'm back in the 90's again. -

10tacle Besides the obvious awesome overclock detail story and results, I like the fact articles remind us of Intel's failure to use the highest quality manufacturing/assembly principles on their top tier CPUs. Especially their x-Series chipsets. There is no excuse for a near-$1,000 chip to have such poor thermal management quality from the factory. I mean how stupid is that.Reply

One of Intel's strongest advantages over AMD for many years now has been their overclocking ability to push them beyond comparable AMD chips. But not only that, to allow future overclocking headroom for keeping the platform longer when newer and faster replacement generation chipsets are introduced. Poor thermals remove those advantages and not many people want to risk messing up their four-figure chip by de-lidding mods.

I hope Intel takes articles like these in notice and will step it up for their next generation of high end i7 and i9 models. -

g-unit1111 Reply21039131 said:Why didn't you just use the EVGA Dark?

I'm guessing because the RAM limit is only 64GB? Where every other X299 board the limit is 128GB. That would make a huge difference in getting the higher speeds. -

Giroro I don't know much about extreme overclocking, tell me more about this "cooling pot".Reply

It is there to hold the liquid nitrogen and separate it from the die? Is there a reason you don't submerge the entire die in liquid nitrogen instead and lose the thermal compound entirely?

It looks like it has a significant copper plate on it. If you are already going through such extreme lengths, then why not use silver and make the plate as thin as possible?

Also, it's pretty interesting that cleaning the processor did not help with the delid, considering that people delidding older i5/i7s say the thickness of that glue is the primary reason that a delid is effective. -

AgentLozen ReplyGiroro said:it's pretty interesting that cleaning the processor did not help with the delid

I thought the same thing. I was expecting the processor to benefit from the cleaning. -

Giroro Reply21039536 said:Besides the obvious awesome overclock detail story and results, I like the fact articles remind us of Intel's failure to use the highest quality manufacturing/assembly principles on their top tier CPUs. Especially their x-Series chipsets. There is no excuse for a near-$1,000 chip to have such poor thermal management quality from the factory. I mean how stupid is that.

One of Intel's strongest advantages over AMD for many years now has been their overclocking ability to push them beyond comparable AMD chips. But not only that, to allow future overclocking headroom for keeping the platform longer when newer and faster replacement generation chipsets are introduced. Poor thermals remove those advantages and not many people want to risk messing up their four-figure chip by de-lidding mods.

I hope Intel takes articles like these in notice and will step it up for their next generation of high end i7 and i9 models.

The cynic in me makes me think that the primary reason Intel switched to thermal paste is for planned-obsolescence and to prevent people from using old platforms for a long time. I'm pretty sure Intel wants to sell you a new processor as often as possible.

Cheaper manufacturing, reduced ability to overclock, Thermal paste that will probably dry out and slow down the CPU within a few years (which will make new models look faster by comparison) ... All these things are positives to a marketing executive.

Hopefully AMD becomes even more competitive, because workmanship isn't going to improve until Intel can correlate their drop in quality with a loss of profit. -

cryoburner Reply

Isn't that the point? If someone messes up their CPU, they have to buy a new one. And delidding voids the warranty, helping Intel more easily recognize and avoid paying for the replacement of chips that have failed as a result of high overclocks. And of course, if people are deterred from overclocking their CPU, they may have more reason to upgrade to a faster one a few years down the line. Intel doesn't want people "keeping the platform longer", and they know that those looking for the highest overclocks will currently go with them either way. Considering it can cost around $5 or so extra to solder a CPU, and most people won't be overclocking, they undoubtedly don't see much point in spending the money to do so.21039536 said:Poor thermals remove those advantages and not many people want to risk messing up their four-figure chip by de-lidding mods.

AMD is willing to, since they currently can't achieve quite the same level of clock rates on their CPUs at the high-end, and know they need to do other things to make their chips more competitive with the market leader, like adding extra cores and using solder.