Tom's Hardware's Custom Core i9 De-Lidder

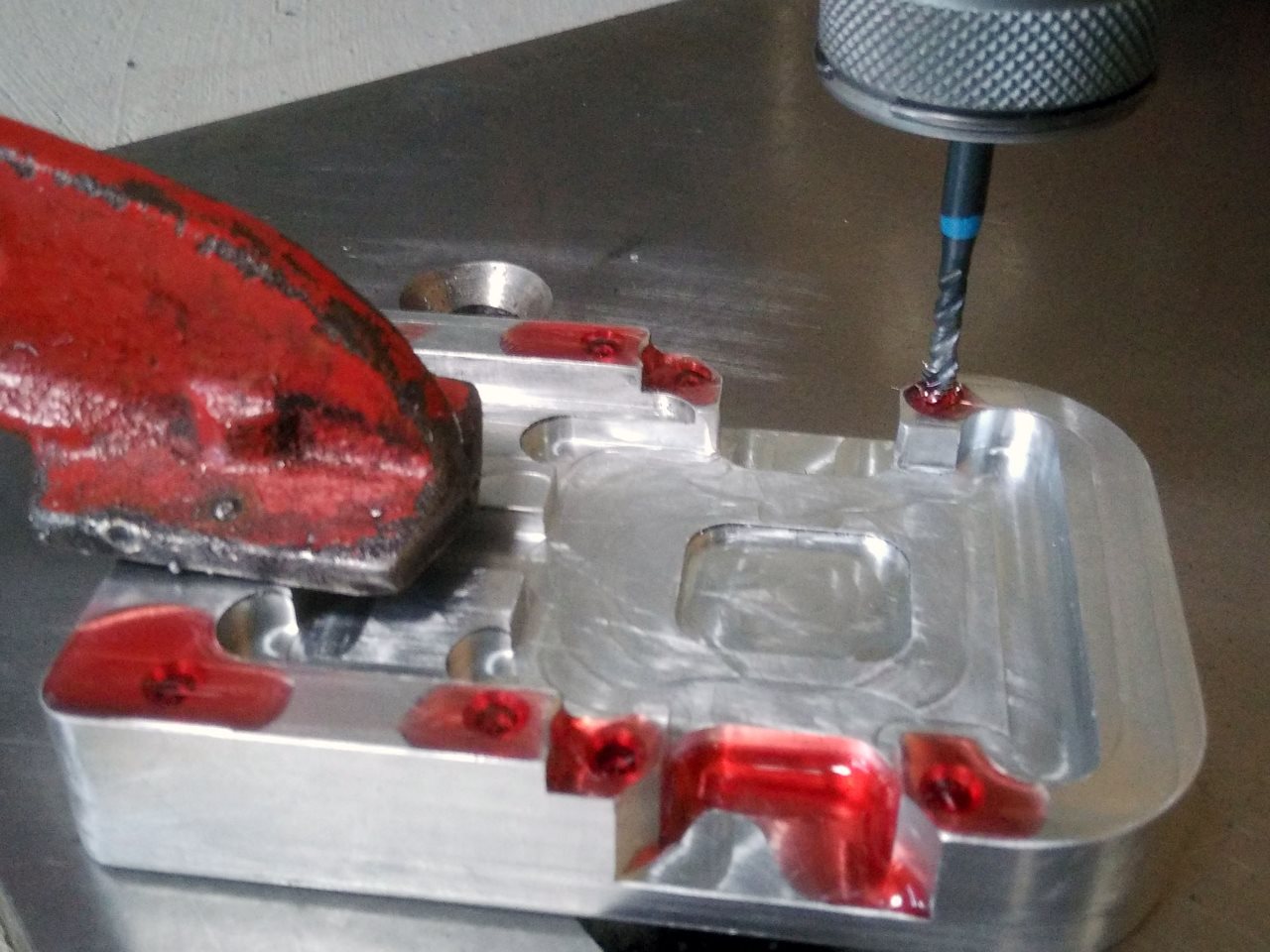

Tapping

We reach the goal, but now have to create the threads that will hold the screws in place. We make these threads with a tapping arm. You can carry out this operation by hand, but using this "assistant" is faster and ensures perfect accuracy.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

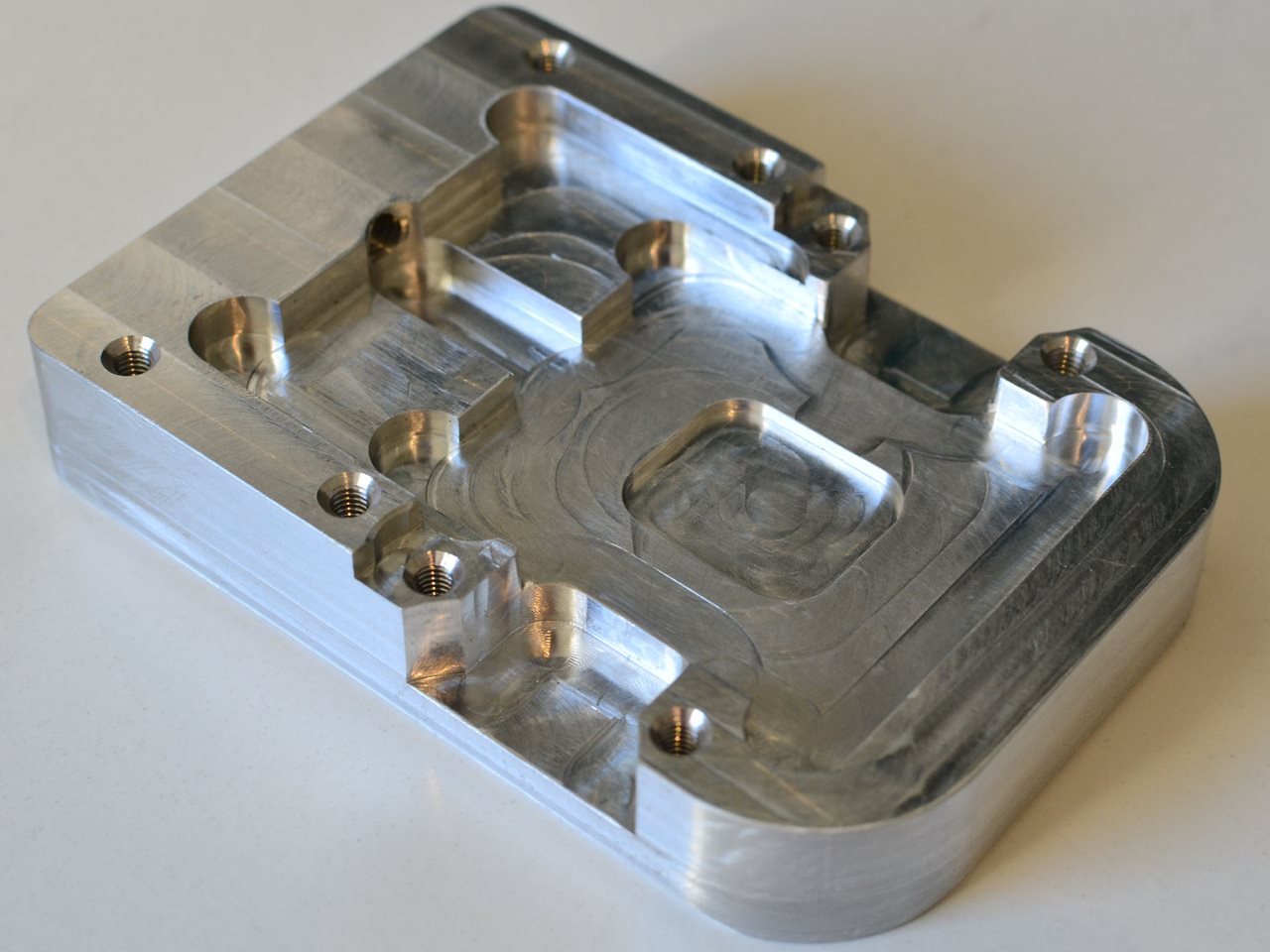

Assembly Begins

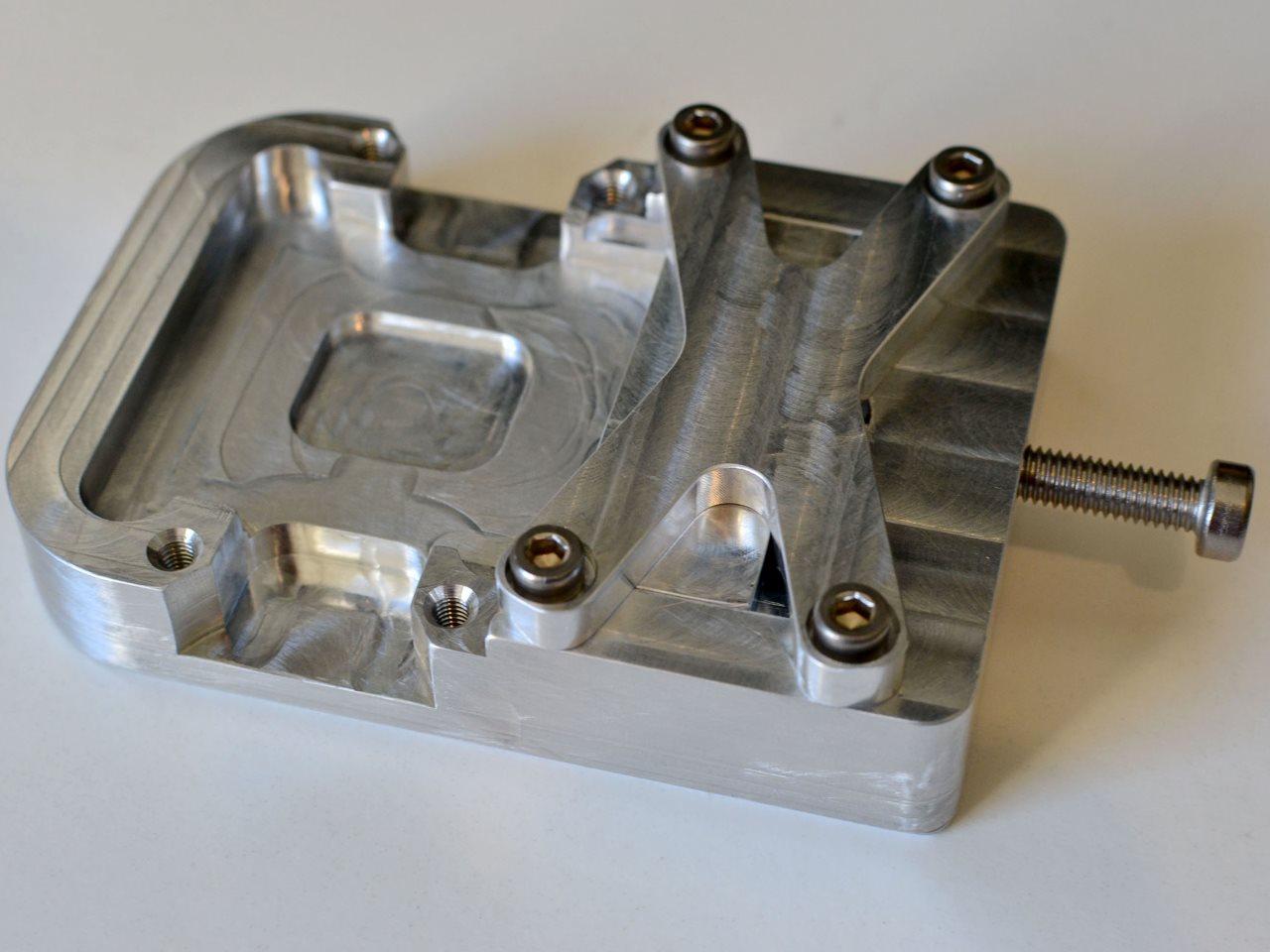

This image shows the completed body of the tool. All the operations have gone well, so now it is time to assemble our prototype.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

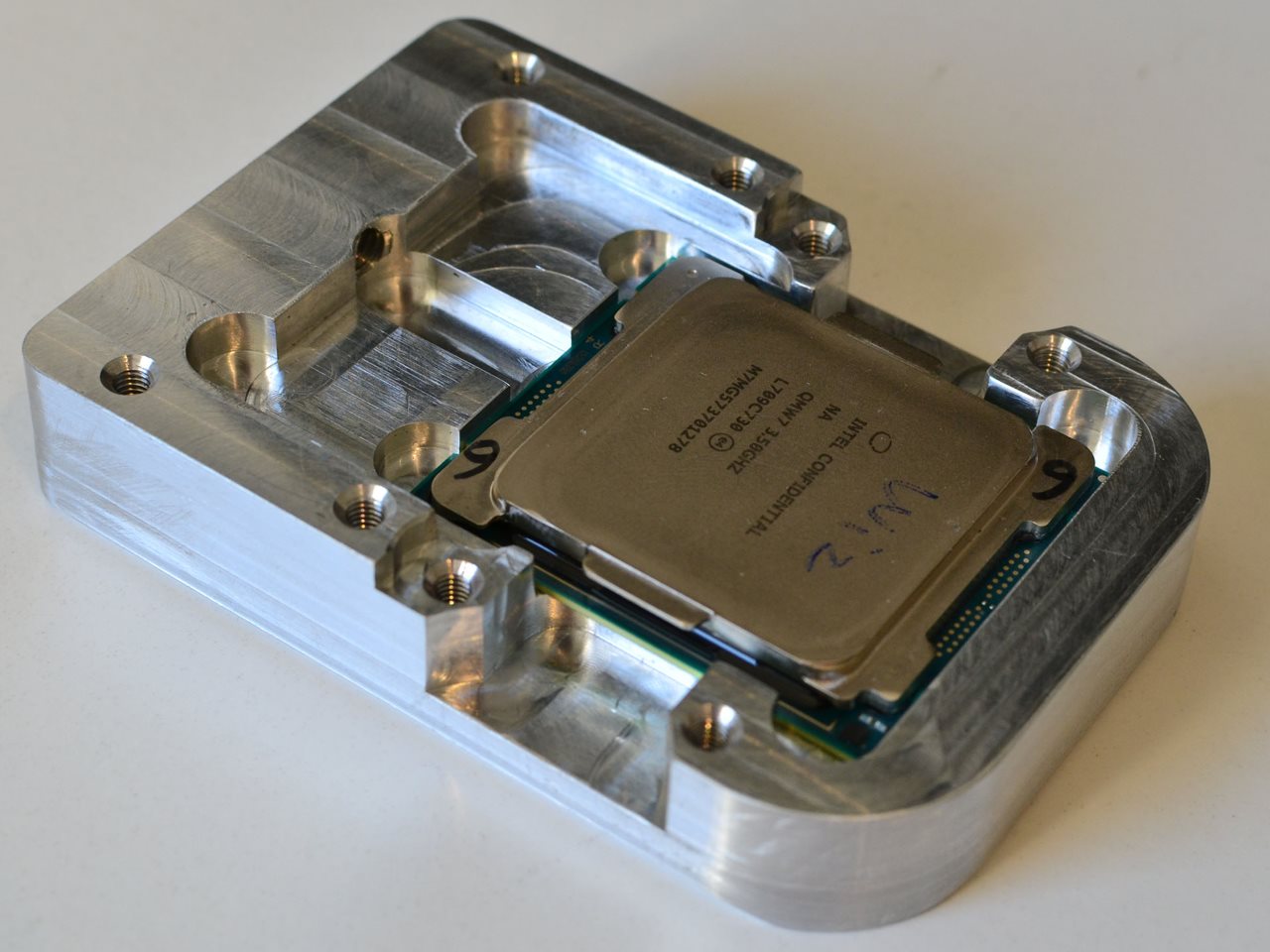

CPU? Check.

The processor returns for our first check of the tool. It is too early to claim a victory, but it is not bad!

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

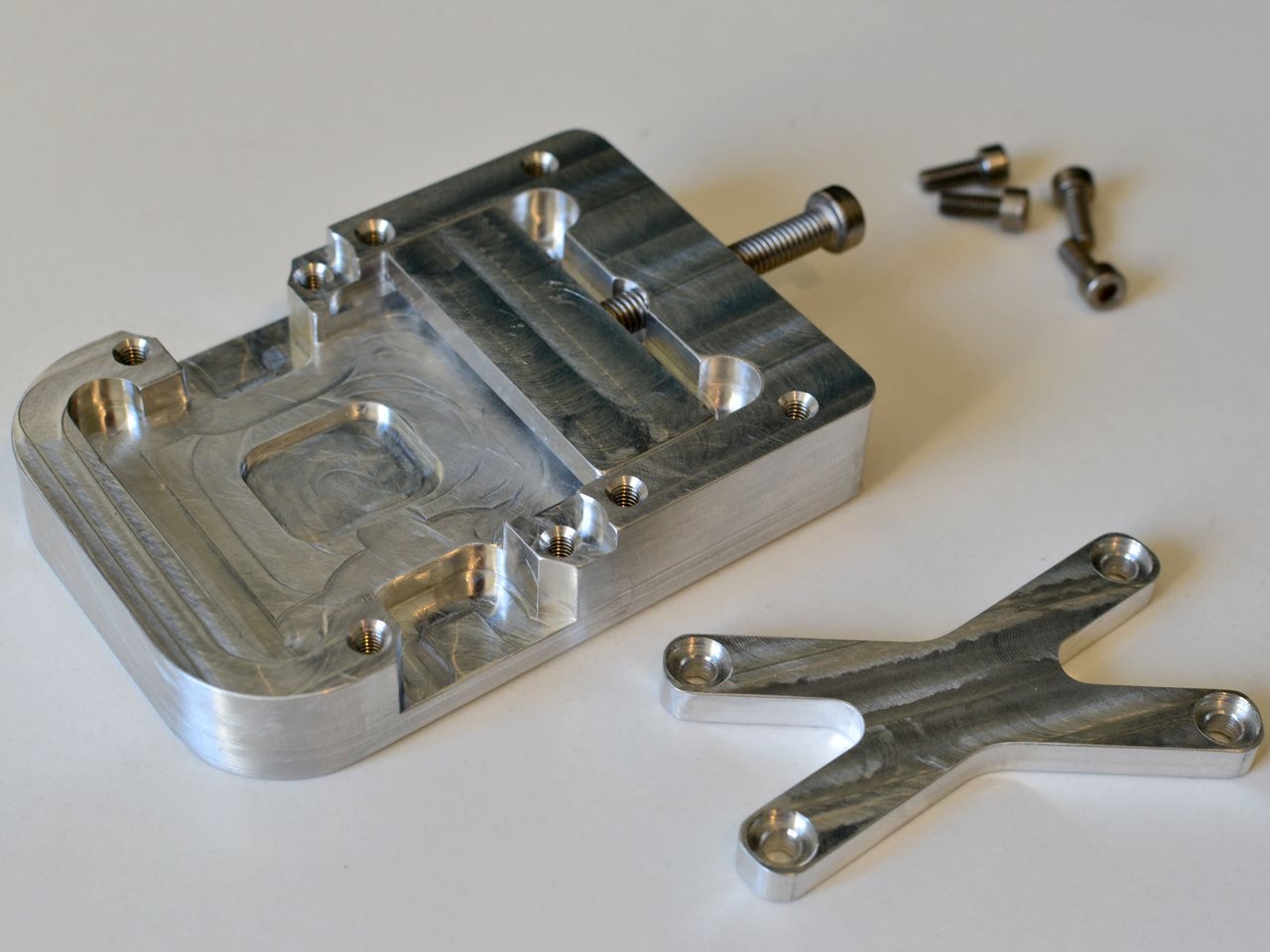

Installing The Slide

The slide installation is also a success. The guidance is perfect; there is no force required to move the slide back and forth fluidly. On the right side of the tool, you can see the stainless-steel screw that will advance the slide. One turn of the screw will advance the plate only 1 mm, and no more, so we don't shatter the CPU.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

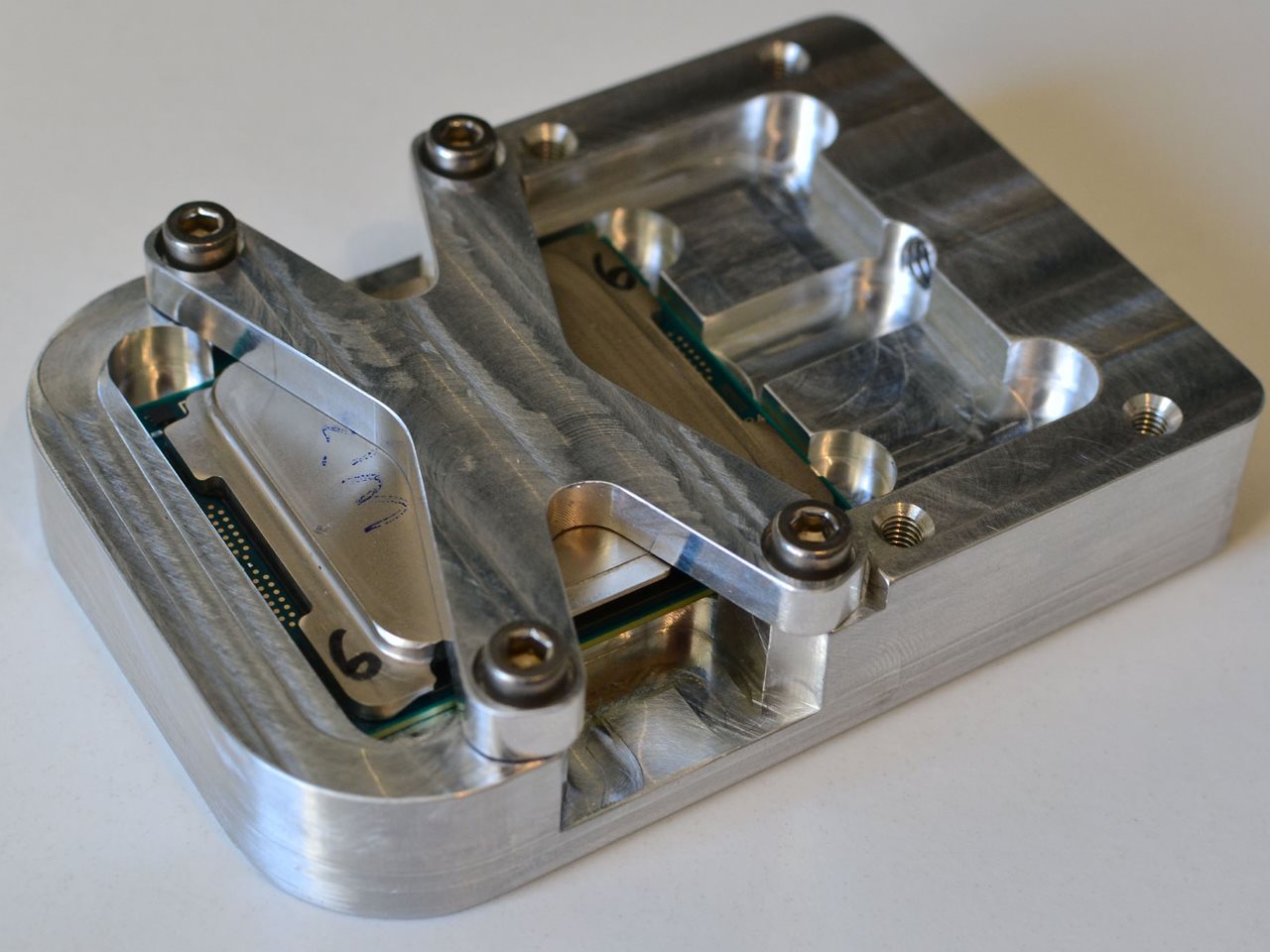

The Completed Assembly

Finally, the adjustments are finished, and the tool only lacks the star of the day; the Core i7-7800X. Hopefully, this day will not be his last... the pressure is definitely rising!

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

The End Result

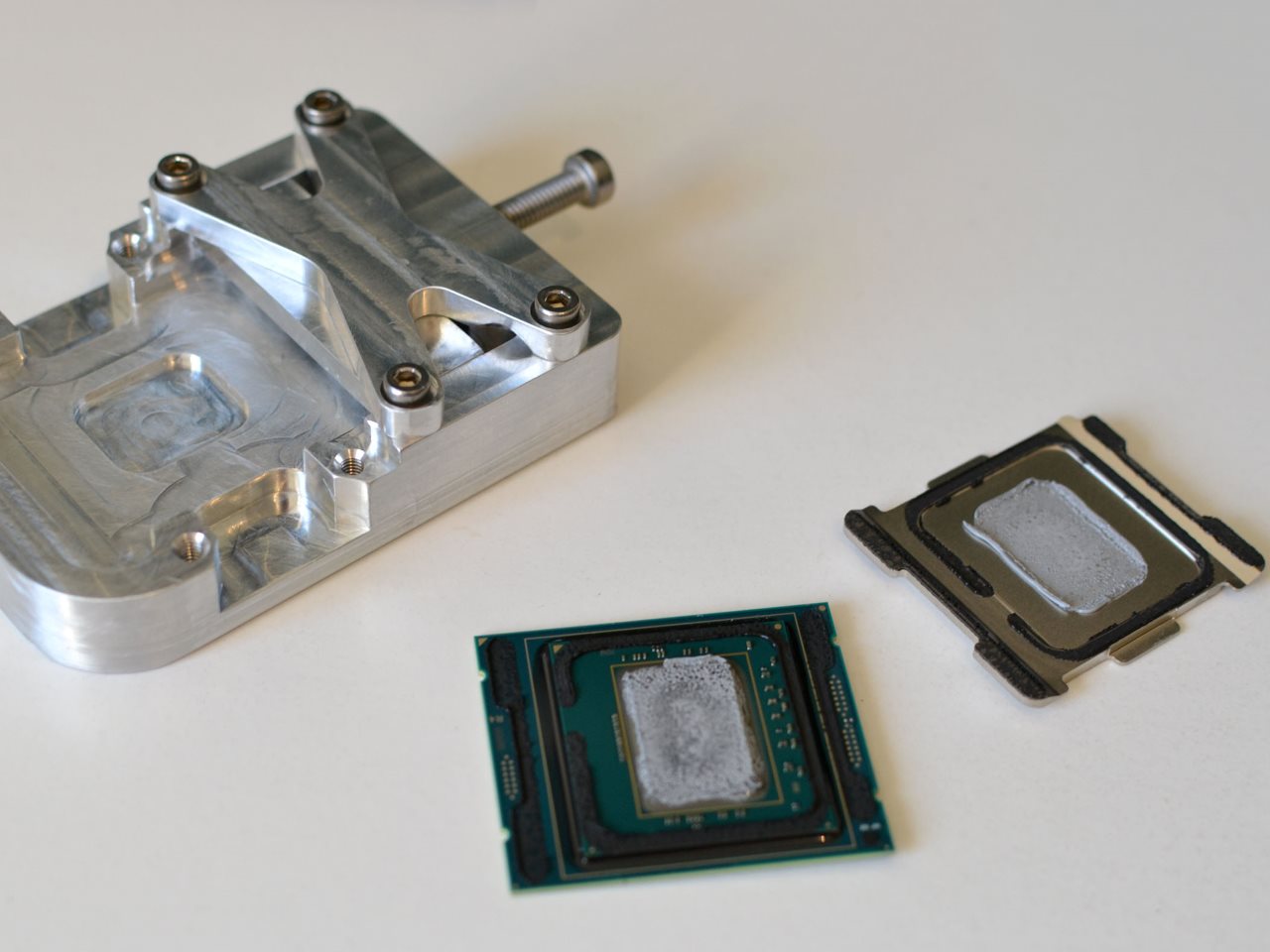

In the euphoria of the moment we forgot to take the picture. The most important thing is that the delidding worked perfectly! Here you can see the processor without its IHS.

Unlike the usual processors, the Skylake-X's have two superimposed PCBs. We don't know why Intel chose to use a second PCB, but it makes it impossible to delid the CPU with a normal razor blade; the inner glue is unreachable.

This makes delidding more difficult because the processor is larger and there are two levels of glue layers. It takes more force to slide the IHS, which is why we made our tool of aluminum and not plastic. Probably a bit of overkill, but when you can...

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

Ergonomics Validated!

Before applying metallic thermal paste, we test the processor quickly to check that it is still functional. A sigh of relief escapes when the X299 Xpower's BIOS appears! In passing, we check that the openings of the tool are wide enough for our fingers.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

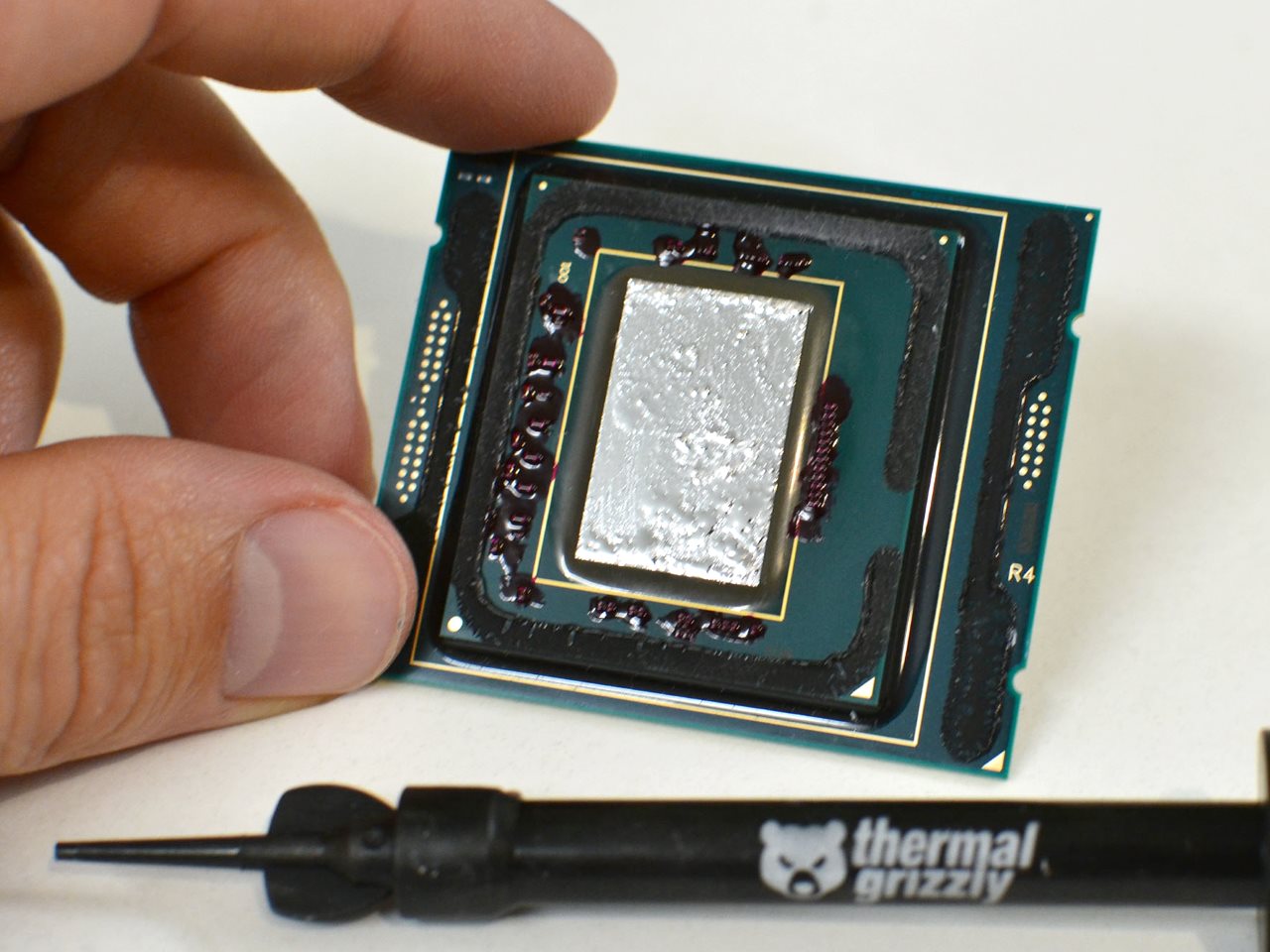

Rigorous Insulation

The metallic thermal paste is conductive, so we recommend that you put an insulating product on the small components around the die, especially those we marked in pink. For those in yellow, it's up to you, but we covered everything to be safe. You can use black silicone glue to insulate, or even nail polish. Now you can put your favorite paste on the die and arrange the glue on the IHS to prevent it from moving when the processor is not in the socket.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

Mode examples

We have applied Thermal Grizzly Conductonaut liquid metal. It's one of the best on the market (see our comparison). Despite its delicate application and constraints (high electrical conductivity, very liquid), it offers the best heat transfer between a die and its IHS, as we proved in in our Core i7-7700K extreme overclocking article.

What did we use for the components around the die? Simple nail polish!

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

Positioning and Re-gluing

The "X" piece places pressure on the IHS so we can glue it to the package at the correct height. If it is too high, you will have a bad IHS-to-die contact and high temperatures. If the IHS is too low, the die might break under pressure.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

-

AndrewJacksonZA Hmmm... Taking inspiration from both the big X cross-bar and the fact that it's Skylake-X, I say "The X-inator!"Reply

"Delid with me if you want to live!"

-

Kridian Hmm, Firefox does not like your image carousel Tom's. Works with Opera & Chrome - no problem.Reply -

SockPuppet It's BS that this needs to even be a thing in the first place. Intel management couldn't possibly get any dumber. What a <mod edit>.Reply

<Moderator Warning: Watch your language on this site> -

doesitmatter Building on AndrewJacksonZA's idea to use the X in the name, I personally like "The Skylake-X-poser" (or more succinctly, "The X-poser"), since the idea is to expose the die.Reply -

ElMojoMikeo There is usually some common sense attached to Intel decisions. Not always appreciated at the time but usually when you look back you can see why. As an example the XEON 2687W vs 3970X. Essentially the same processor the XEON eight cores and locked. The X processor six cores ( two disabled ) and unlocked. The reasoning behind the two disabled cores was clock speed increases on eight cores caused thermal problems.Reply

At the time Intel were accused of doing this as a marketing strategy. Well it would appear that it was just good old common sense. Why did they remove the solder? It could be for any number of reasons.

We can safely say that Intel know exactly what they are doing, because they alone have all the information and data required to make such a decision. I would guess it caused a problem that outweighed the thermal benefits it offered.

I remember a previous thread ended up with some very expensive cooling solutions. I seem to remember some time ago someone was attempting to make a processor socket cooler. The processor pins made the normal contact with the metal in the socket holes and a ceramic under side that was actively cooled. The pins of course go all the way up to the processor die. The socket cooler was on the underside and a liquid AIO cooler fitted normally.

In theory this looked a good way to move forward. This would also avoid having to delid the processor. Why are there so few socket cooling solutions? -

silvermoongoddess Why have an X in the name? - Is it some 1960s-throwback-macho-thing? "Overclocker's CPU Upgrade Assistant" sounds good to me; if perhaps maybe a little long-winded.Reply -

killerchickens Reply20153172 said:There is usually some common sense attached to Intel decisions. Not always appreciated at the time but usually when you look back you can see why. As an example the XEON 2687W vs 3970X. Essentially the same processor the XEON eight cores and locked. The X processor six cores ( two disabled ) and unlocked. The reasoning behind the two disabled cores was clock speed increases on eight cores caused thermal problems.

At the time Intel were accused of doing this as a marketing strategy. Well it would appear that it was just good old common sense. Why did they remove the solder? It could be for any number of reasons.

We can safely say that Intel know exactly what they are doing, because they alone have all the information and data required to make such a decision. I would guess it caused a problem that outweighed the thermal benefits it offered.

I remember a previous thread ended up with some very expensive cooling solutions. I seem to remember some time ago someone was attempting to make a processor socket cooler. The processor pins made the normal contact with the metal in the socket holes and a ceramic under side that was actively cooled. The pins of course go all the way up to the processor die. The socket cooler was on the underside and a liquid AIO cooler fitted normally.

In theory this looked a good way to move forward. This would also avoid having to delid the processor. Why are there so few socket cooling solutions?

Yes I'm sure there is a good reason they use the worst thermal paste they can find too.

-

Altherix Reply

I use to think that too, but you apply logic to it and it doesn't make any sense other than a Big Business Strategy.20153172 said:There is usually some common sense attached to Intel decisions. Not always appreciated at the time but usually when you look back you can see why. As an example the XEON 2687W vs 3970X. Essentially the same processor the XEON eight cores and locked. The X processor six cores ( two disabled ) and unlocked. The reasoning behind the two disabled cores was clock speed increases on eight cores caused thermal problems.

At the time Intel were accused of doing this as a marketing strategy. Well it would appear that it was just good old common sense. Why did they remove the solder? It could be for any number of reasons.

We can safely say that Intel know exactly what they are doing, because they alone have all the information and data required to make such a decision. I would guess it caused a problem that outweighed the thermal benefits it offered.

I remember a previous thread ended up with some very expensive cooling solutions. I seem to remember some time ago someone was attempting to make a processor socket cooler. The processor pins made the normal contact with the metal in the socket holes and a ceramic under side that was actively cooled. The pins of course go all the way up to the processor die. The socket cooler was on the underside and a liquid AIO cooler fitted normally.

In theory this looked a good way to move forward. This would also avoid having to delid the processor. Why are there so few socket cooling solutions?

It is true that if you get soldering wrong, it can make the CPU unusable with time, using TIM is a better idea as it's more tolerant of mistakes and flaws in application. For run of the mill CPUs it makes perfect sense to use paste instead of soldering. On server CPUs, with 24/7 use a good thermal solution is necessary, so soldering is used, this is also why there's a premium on Intel server CPUs. 24/7 usage and warranty for normal use.

With this processor, we're talking, "Enthusiast's" you're already paying a premium for an unlocked processor to overclock, why not solder which IS the best thermal transfer solution and just charge a premium cost on top of that?

Big Business decision, "Enthusiast's" are going to push their CPU to the limits, so any flaws in the solder job will become apparent. This is a risk to the CPU manufacturer, having to warranty, "Enthusiast's" CPUs, putting in TIM means a real, "Enthusiast's" is going to delid the processor for the best thermal performance, thus voiding the warranty. Even if they don't, they don't have to deal with solder failure either, it's a win for them lose for the customer.

Enthusiasts, are a very small portion of the market, Intel isn't going to go broke soldering "Enthusiast's" CPUs and warranty them. This is just a big middle-finger to the "Enthusiasts" and plain greed, the only reason that makes sense.