Tom's Hardware's Custom Core i9 De-Lidder

To Delid At Any Price

Several generations ago, Intel stopped using solder between the die and the IHS for all of its processors. That doesn't help average users, and it certainly penalizes overclockers.

Without getting into the details, processor temperatures have greatly increased since Intel switched to thermal paste instead of solder. Initially, this change only affected the Socket 11xx processors. Intel spared processors with more than four cores, but that changed with the Skylake-X generation. Now, whether you like it or not, it's thermal paste for everyone!

"Delidding" is becoming more and more popular, and tools to facilitate manipulation have emerged. Unfortunately (or not), the latest Core i9 processors are very new, and we haven't found any tools available on the market. No problem, let's make one!

So we will take you through a small journey spanning the design and testing of our tool, and you will see that we made it indestructible!

MORE: Best CPUs for gaming

MORE: How to Overclock a CPU

MORE: CPU Benchmark Hierarchy

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

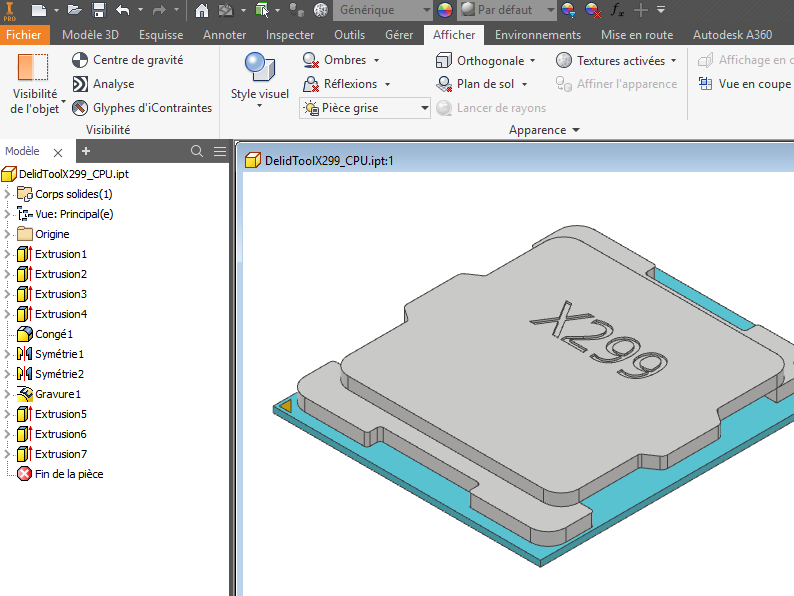

Modeling The CPU

Drawing the processor is the first step of our design flow. We grabbed our i7-7800X, the cheapest of the Skylake-X processors, to model (and risk). There's no need to dwell on unnecessary details such as engravings or gold contacts. On the other hand, it is essential to respect the dimensions so we don't damage the chip when we place it in the tool. We detailed the small components in front of the IHS: we will have to be very careful not to destroy them.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

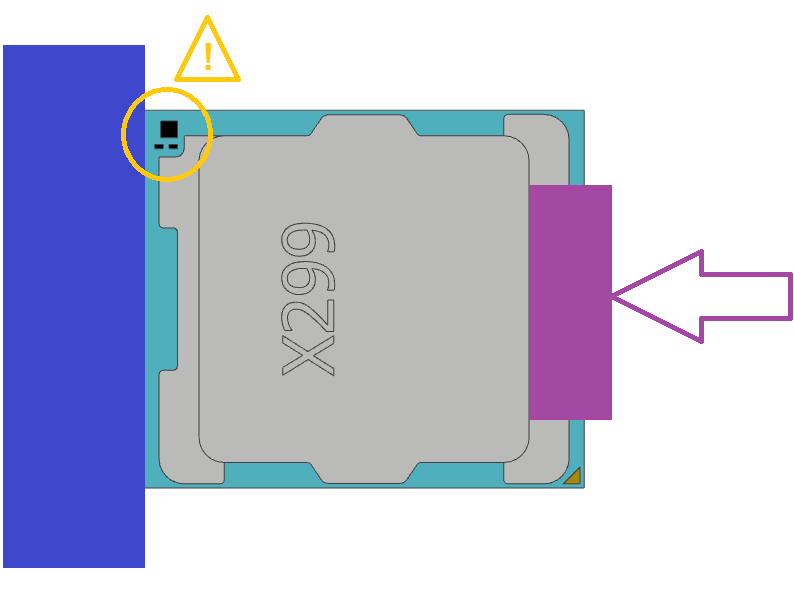

Simple, But Risky

Technically the operation isn't that complicated. We just need to hold the PCB (in green on the diagram) stationary and then push the IHS (in gray) with a slide and a screw (in purple). The IHS will start to move forward if you place enough force on it, and the glue that binds the two parts together will gradually give. Then you can disassemble the processor and replace the thermal paste. We will have to be especially careful not to advance the IHS too much, or it will tear off the black components!

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

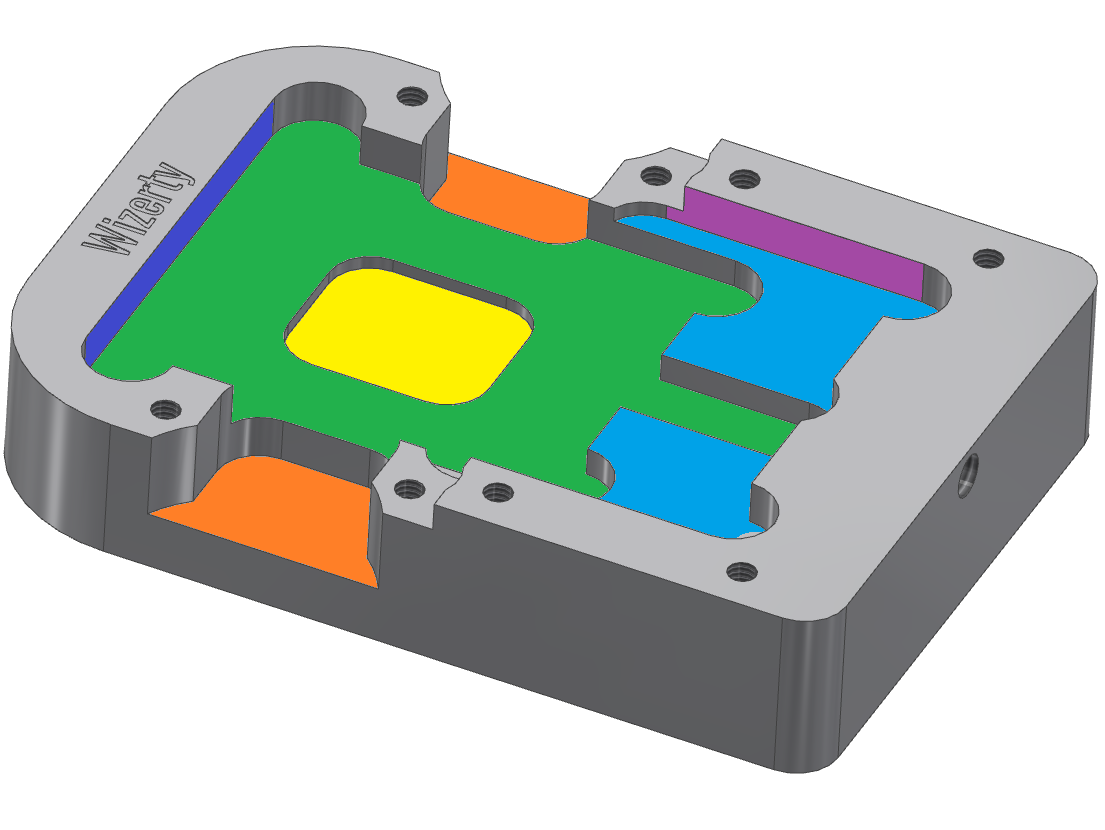

Careful Design

The main part of the tool will have several components: In green: the surface where the processor will rest - In yellow: a pocket to allow movement of the capacitors under the processor - In dark blue: a stop to prevent the processor from sliding when we tighten the screw - In orange: openings for your fingers that facilitate the installation and removal of the CPU - In light blue: the surface that slides inside the tool - In pink: the guide surface that prevents the slide from moving at an angle.

This all sounds simple, but the slightest error will cost us a processor and more than 10 hours of work, so we must be cautious.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

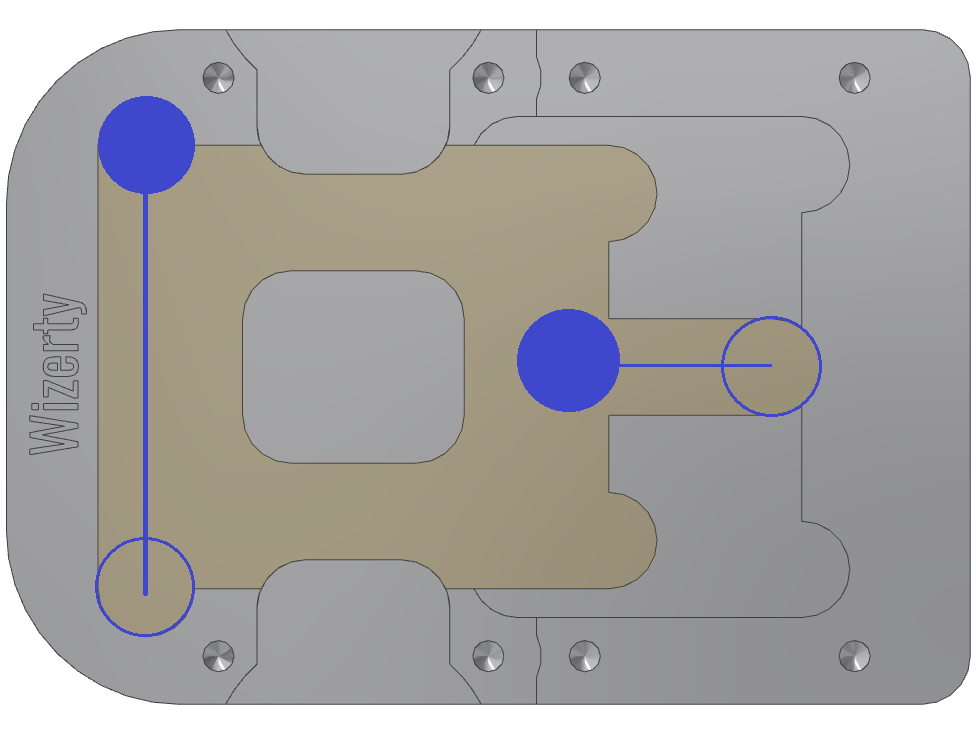

The Constraints of Machines

With a traditional machine, each pocket has to be designed and machined with rectilinear trajectories. The blue overlay indicates the moving tool. The process is relatively simple but time-consuming. Luckily that machine was not available, and we were able to secure a small time slot on a CNC machine.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

Final Preview

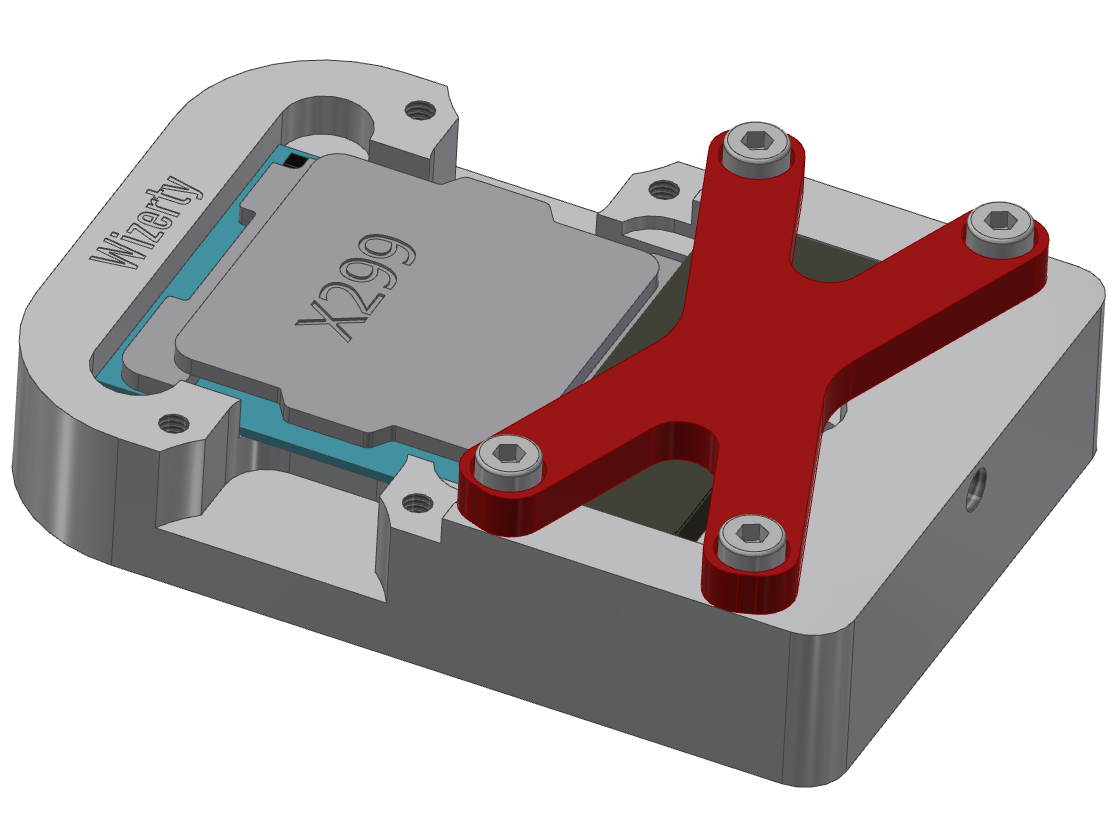

This is what the tool looks like when we model it with CAD tools (computer-aided design). Here the tool is in its CPU delidding configuration. The CPU is blocked in by the black part underneath, and the red "X" prevents it from moving upward.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

Multipurpose Component

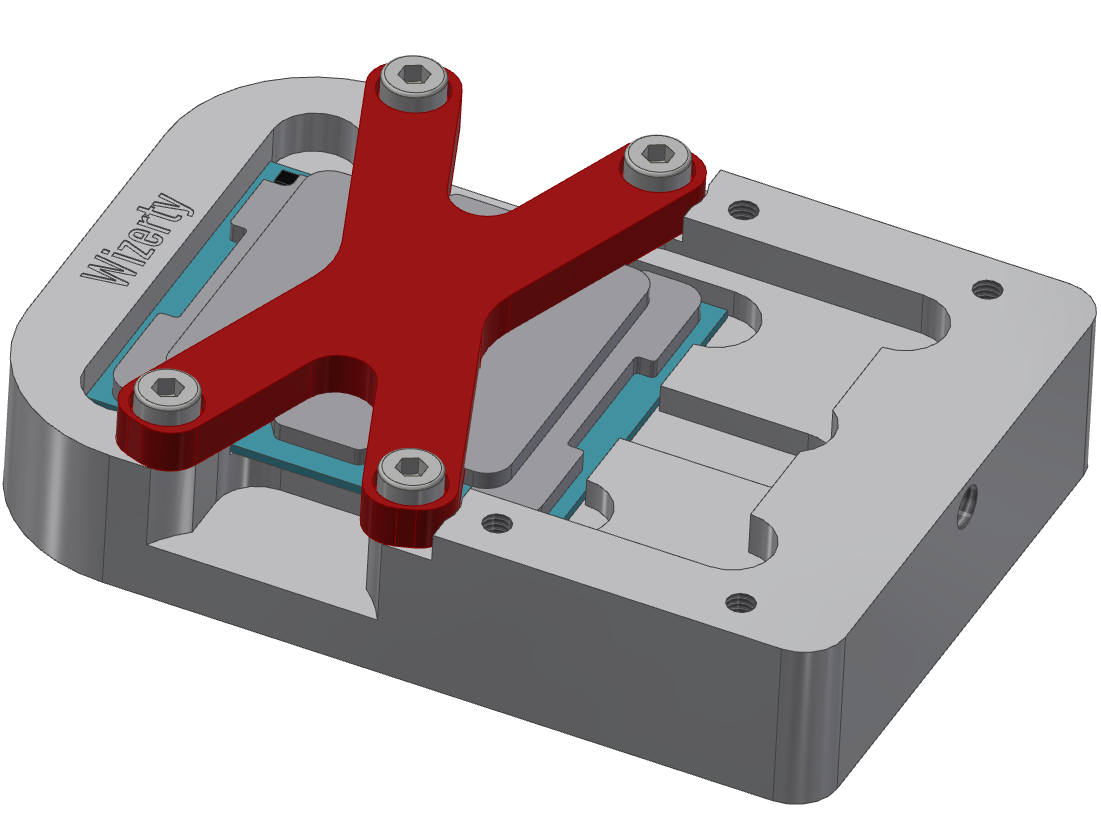

This is the configuration to reattach the processor once you have replaced the thermal paste. As you can see, for reasons of cost and machining time, we use the red part for both configurations.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

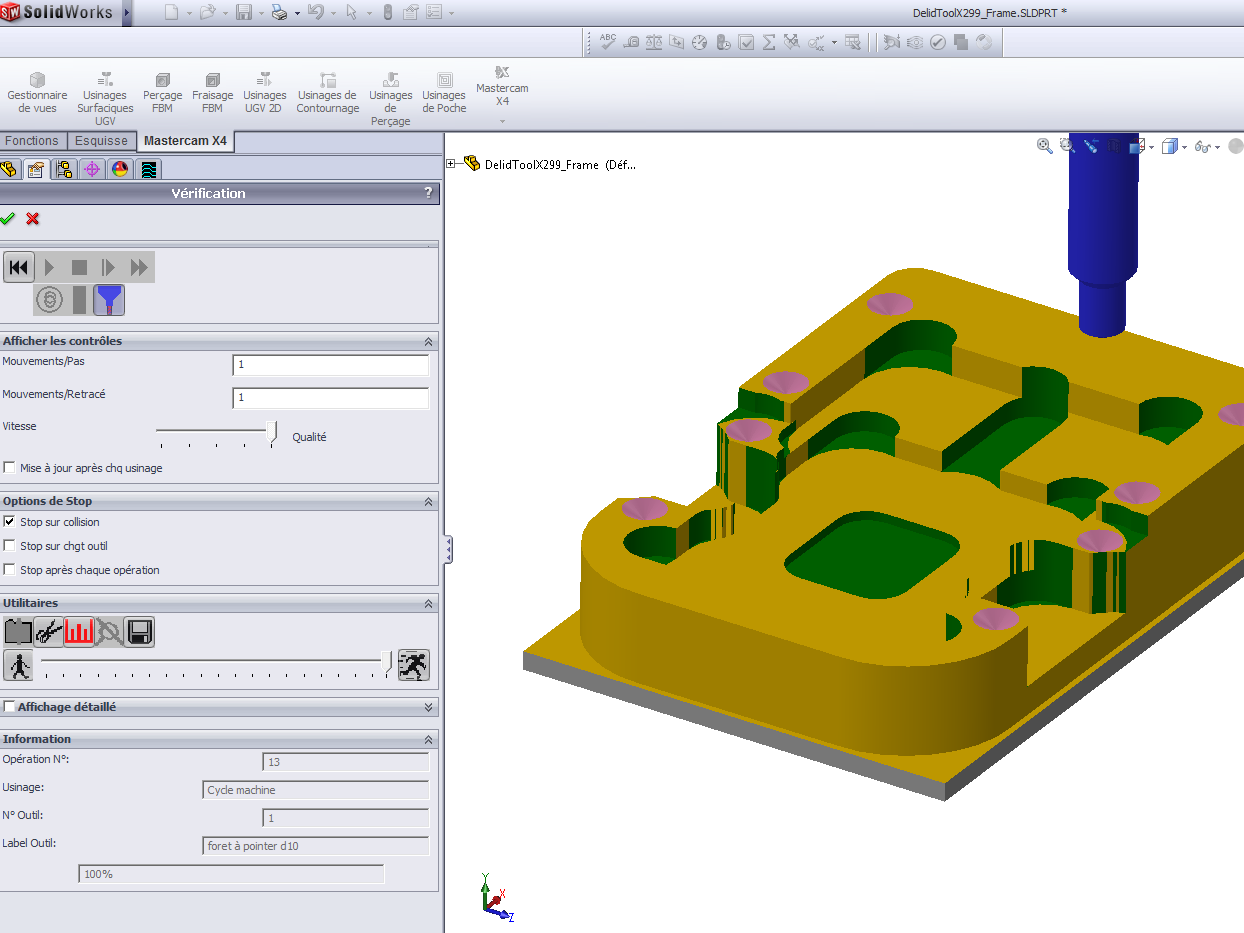

Programming The Machine

Now that we've designed the tool, it is necessary to create the program that we will use on the production machine. FAO (computer-aided manufacturing) makes life simpler, but it still requires some human work. Ludovic, a friend and colleague, and I worked hard on the design. More than ever, alertness is required: a wrong safety distance or a poor tool parameter could damage the production machine during machining. Once we have instructed the computer the order in which we want to perform the operations, we define the tools, speeds, and finishing passes. A program is generated with hundreds of lines of code that will tell the machine what to do, where to go, how fast to go, and what tool to use.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

Calibration

We move on to serious things. After we completed the programs defining the trajectories, we have to tell the machine where the part is located. Again, the operator must not be distracted. Otherwise, thousands of euros of equipment will be damaged.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

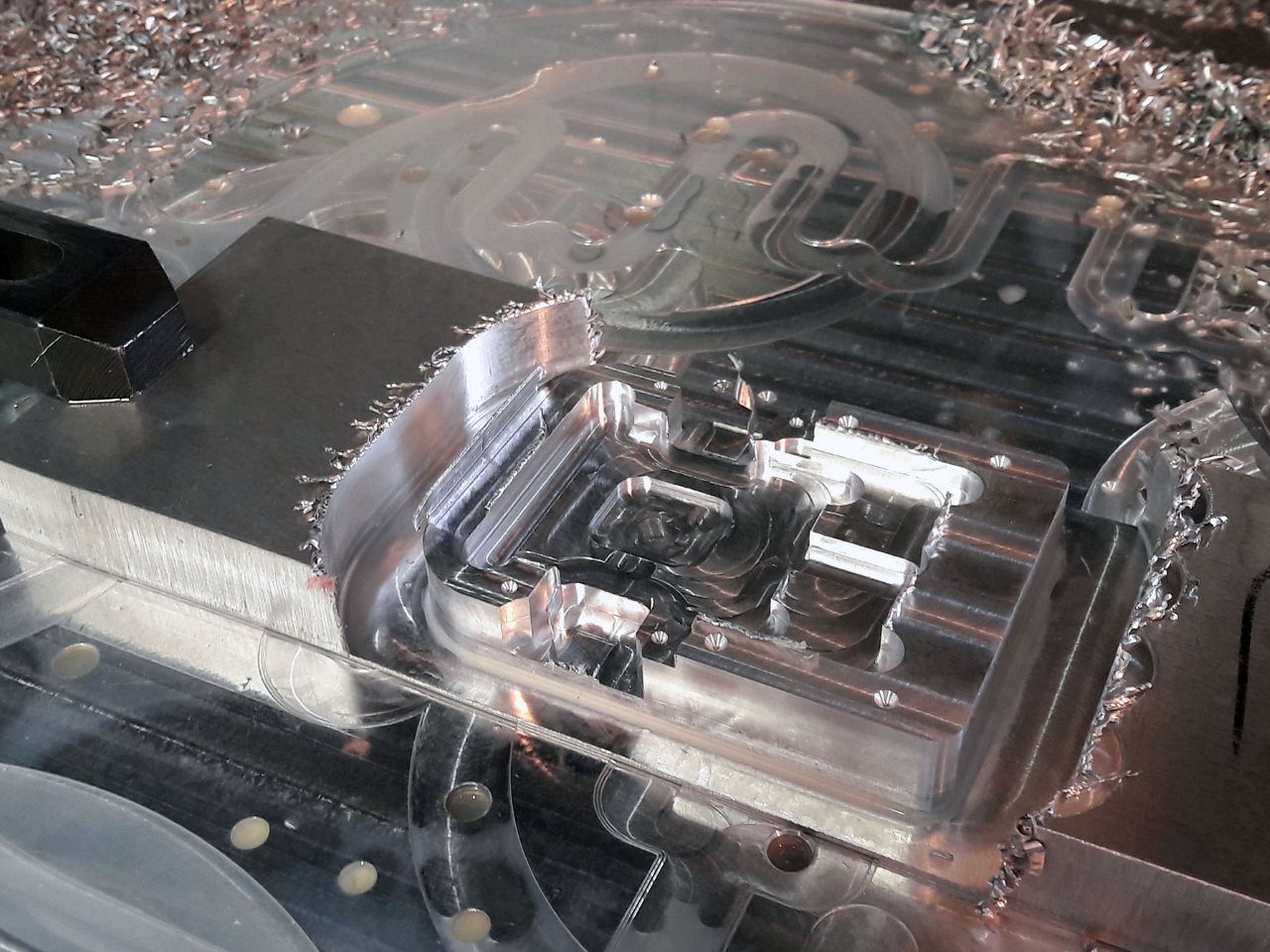

Machining and Finishing

To save time, the initial machining is done with a larger tool that works quickly. The surfaces are coarse, but the bulk of the work is done. This is what the tool looks like at the end of the rough sketches. Then it is the finishing tool's turn (visible in this image) to take action.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

Job Done!

Once finished, we can remove the part from the machine so we can move on to building the slide assembly and the retention mechanism. Ludovic sticks to it while I rework the freshly machined piece. Savvy machinists will probably grind their teeth when they see this assembly, but bear in mind that our goal was to make a single prototype and not a mass production part. The machine could not be "decommissioned" from its usual activity.

MORE: Best CPUs

MORE: De-Lidding and Overclocking Core i7-7700K

MORE: Extreme Overclocking: 10 Ryzen CPUs Under LN2

-

AndrewJacksonZA Hmmm... Taking inspiration from both the big X cross-bar and the fact that it's Skylake-X, I say "The X-inator!"Reply

"Delid with me if you want to live!"

-

Kridian Hmm, Firefox does not like your image carousel Tom's. Works with Opera & Chrome - no problem.Reply -

SockPuppet It's BS that this needs to even be a thing in the first place. Intel management couldn't possibly get any dumber. What a <mod edit>.Reply

<Moderator Warning: Watch your language on this site> -

doesitmatter Building on AndrewJacksonZA's idea to use the X in the name, I personally like "The Skylake-X-poser" (or more succinctly, "The X-poser"), since the idea is to expose the die.Reply -

ElMojoMikeo There is usually some common sense attached to Intel decisions. Not always appreciated at the time but usually when you look back you can see why. As an example the XEON 2687W vs 3970X. Essentially the same processor the XEON eight cores and locked. The X processor six cores ( two disabled ) and unlocked. The reasoning behind the two disabled cores was clock speed increases on eight cores caused thermal problems.Reply

At the time Intel were accused of doing this as a marketing strategy. Well it would appear that it was just good old common sense. Why did they remove the solder? It could be for any number of reasons.

We can safely say that Intel know exactly what they are doing, because they alone have all the information and data required to make such a decision. I would guess it caused a problem that outweighed the thermal benefits it offered.

I remember a previous thread ended up with some very expensive cooling solutions. I seem to remember some time ago someone was attempting to make a processor socket cooler. The processor pins made the normal contact with the metal in the socket holes and a ceramic under side that was actively cooled. The pins of course go all the way up to the processor die. The socket cooler was on the underside and a liquid AIO cooler fitted normally.

In theory this looked a good way to move forward. This would also avoid having to delid the processor. Why are there so few socket cooling solutions? -

silvermoongoddess Why have an X in the name? - Is it some 1960s-throwback-macho-thing? "Overclocker's CPU Upgrade Assistant" sounds good to me; if perhaps maybe a little long-winded.Reply -

killerchickens Reply20153172 said:There is usually some common sense attached to Intel decisions. Not always appreciated at the time but usually when you look back you can see why. As an example the XEON 2687W vs 3970X. Essentially the same processor the XEON eight cores and locked. The X processor six cores ( two disabled ) and unlocked. The reasoning behind the two disabled cores was clock speed increases on eight cores caused thermal problems.

At the time Intel were accused of doing this as a marketing strategy. Well it would appear that it was just good old common sense. Why did they remove the solder? It could be for any number of reasons.

We can safely say that Intel know exactly what they are doing, because they alone have all the information and data required to make such a decision. I would guess it caused a problem that outweighed the thermal benefits it offered.

I remember a previous thread ended up with some very expensive cooling solutions. I seem to remember some time ago someone was attempting to make a processor socket cooler. The processor pins made the normal contact with the metal in the socket holes and a ceramic under side that was actively cooled. The pins of course go all the way up to the processor die. The socket cooler was on the underside and a liquid AIO cooler fitted normally.

In theory this looked a good way to move forward. This would also avoid having to delid the processor. Why are there so few socket cooling solutions?

Yes I'm sure there is a good reason they use the worst thermal paste they can find too.

-

Altherix Reply

I use to think that too, but you apply logic to it and it doesn't make any sense other than a Big Business Strategy.20153172 said:There is usually some common sense attached to Intel decisions. Not always appreciated at the time but usually when you look back you can see why. As an example the XEON 2687W vs 3970X. Essentially the same processor the XEON eight cores and locked. The X processor six cores ( two disabled ) and unlocked. The reasoning behind the two disabled cores was clock speed increases on eight cores caused thermal problems.

At the time Intel were accused of doing this as a marketing strategy. Well it would appear that it was just good old common sense. Why did they remove the solder? It could be for any number of reasons.

We can safely say that Intel know exactly what they are doing, because they alone have all the information and data required to make such a decision. I would guess it caused a problem that outweighed the thermal benefits it offered.

I remember a previous thread ended up with some very expensive cooling solutions. I seem to remember some time ago someone was attempting to make a processor socket cooler. The processor pins made the normal contact with the metal in the socket holes and a ceramic under side that was actively cooled. The pins of course go all the way up to the processor die. The socket cooler was on the underside and a liquid AIO cooler fitted normally.

In theory this looked a good way to move forward. This would also avoid having to delid the processor. Why are there so few socket cooling solutions?

It is true that if you get soldering wrong, it can make the CPU unusable with time, using TIM is a better idea as it's more tolerant of mistakes and flaws in application. For run of the mill CPUs it makes perfect sense to use paste instead of soldering. On server CPUs, with 24/7 use a good thermal solution is necessary, so soldering is used, this is also why there's a premium on Intel server CPUs. 24/7 usage and warranty for normal use.

With this processor, we're talking, "Enthusiast's" you're already paying a premium for an unlocked processor to overclock, why not solder which IS the best thermal transfer solution and just charge a premium cost on top of that?

Big Business decision, "Enthusiast's" are going to push their CPU to the limits, so any flaws in the solder job will become apparent. This is a risk to the CPU manufacturer, having to warranty, "Enthusiast's" CPUs, putting in TIM means a real, "Enthusiast's" is going to delid the processor for the best thermal performance, thus voiding the warranty. Even if they don't, they don't have to deal with solder failure either, it's a win for them lose for the customer.

Enthusiasts, are a very small portion of the market, Intel isn't going to go broke soldering "Enthusiast's" CPUs and warranty them. This is just a big middle-finger to the "Enthusiasts" and plain greed, the only reason that makes sense.