ASRock M8 Mini-ITX Barebones Gaming PC Review

Some of us love compact gaming builds, but the best of these have always been pre-configured into custom enclosures. Is ASRock’s M8 the perfect open-architecture alternative? We load this $550 barebones up with hardware and test its mettle.

Is ASRock's M8 A High-End Mini-ITX Winner?

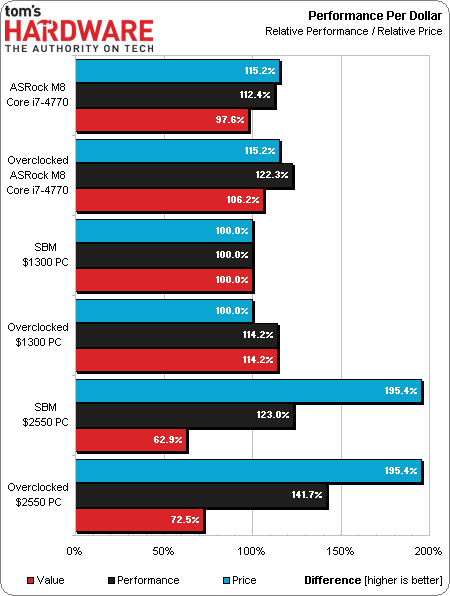

Lacking any other barebones PC to compare, I built ASRock’s M8 up as a competitor to Don’s $1300 System Builder Marathon machine. And it did well, enjoying a 12.4% performance lead. There’s still a matter of value though:

A value loss of 3% is still a loss, even if it is marginal. And I have to take credit for that, if only because the parts I chose made this configuration lose its value race. It might look like I over-spent on my effort. In reality, though, I over-saved. Rather than picking and choosing what I wanted to put inside the M8 during an online shopping trip, I used hardware I had in the lab.

The $550 ASRock M8 includes $150 worth of overpriced optical drive and power supply, and style is the justification for that disc drive. The remaining parts include a $180 motherboard and a case that, based on subtraction, needs to be worth $220. Since M8 buyers are paying over $100 extra for a bit of pizazz, I experimented with the charts and found that the parts I picked really weren't bad. If the M8 sold for $450, I would have even beaten Don's $1300 machine. Ouch.

It's not that there aren't enthusiasts who'll pay an extra $100 or so for style. We simply don't like paying for it with money and a performance compromise (that's why Chris was so stoked about the Tiki, with its then-fastest GTX 680 and a then-fastest -3770K at a constant 4.3 GHz). The M8 is supposed to be a high-end gaming machine, but it runs too hot for that. And if you want to make a case for HTPC placement, let me assure you that it's too noisy. And yet, everyone I’ve asked still loves the machine, with its thick aluminum side panels, cast aluminum handles, and splendid good looks. ASRock could justify its price by simply pointing to how much it costs to make.

I won't blame ASRock for the M8’s shortcomings. DesignworksUSA conceptualized this thing, after all. And even if BMW Group hadn’t specified the easily-correctable (and poor-performing) fan orientation, there are still problems with the size of these fans. The limited airflow of 70 x 10 mm fans forces ASRock to use 4000 RPM models, and the design team could have switched to 80 x 25 mm fans early on without significantly altering the case’s size or shape.

With the tooling paid for, there are few things ASRock could do to turn this barebones system into more of a winner. First, it could start shipping the machine with the fans configured for bottom-to-top airflow, since that solved the worst of my thermal issues. Second, it might want to include (and even charge for) a custom-fit CPU cooler to maximize surface area within its confined space. Third, it could lower the minimum fan speed below 1000 RPM, so that the machine at least idles quietly. None of those changes require ASRock to sacrifice the money already spent on manufacturing the M8.

Update October 28

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

ASRock has informed us that it has shipped the M8 with upgraded fans that have a wider RPM range, with an 800 RPM minimum, to reduce low-load noise. We can only hope that they also fix the fan direction.

A second look at the Page 6 airflow diagram appears to indicate that the chassis designer intended the CPU fan to receive air through vents in the side panel. Another photo on that page shows that this side panel is molded with faux louvers. Actual louvers have slots, and modders would likely find additional cooling benefits by slotting these louvers.

Current page: Is ASRock's M8 A High-End Mini-ITX Winner?

Prev Page Average Performance And Efficiency-

lpedraja2002 ReplyThe old saying that hot air rises is usually true because it's less dense. To take advantage of this phenomenon, I flipped the bottom exhaust and top intake fans. Both bottom fans were now intakes, both top fans were now exhaust, and all I needed to do was:

Completely gut the system, since the bottom panel is secured from the inside with four screws.

And then slice up the wire sleeves, since the guide on each fan frame was farther apart.

CPU load temperature immediately dropped by roughly 20°, but at the expense of messier cabling.

Awesome way of thinking Thomas, that's why I love you guys. I am curious however to know if you emailed them to tell them about this solution. Since it made such a dramatic difference they should change the way those fans are positioned. -

second_exodous I'm looking into barebones to build a steam box and I'm finding they all have noise/thermal issues. I hope that Valve has a hand in some sort of certification program and hires their own engineers to test these barebone systems before giving the stamp of approval as a system to be used as a steam box. I'm also a Linux user and if they can clear up Linux compatibility for me that would also be great.Reply -

jestersage I hope this fans the flames of trend and others follow suit - so innovation goes up and prices go down. I like the M8. And Thomas gives it a very good once-over - including answers to some issues. Good job!Reply -

razzb3d Just remove the plexiglass window and replace it with a nice honeycomb metal mesh. Cooling problem solved.Reply -

Onus This case looks like a good idea, that just needs some refinement to make it even more generic. Another 10mm of thickness to allow 80mm fans (and possibly a full-size optical drive) could go a long way.Reply

Does the added trace length or extra connection required to use a riser card impose any kind of penalty on graphics cards? Please test this, by using one on a typical motherboard just for some measurements.

-

Crashman Reply

It doesn't need extra thickness to support the larger fans, just a minor redesign of the top and bottom panel. But the top panel redesign would include a different locking mechanism, so the tooling cost would be high.11789583 said:This case looks like a good idea, that just needs some refinement to make it even more generic. Another 10mm of thickness to allow 80mm fans (and possibly a full-size optical drive) could go a long way.

Does the added trace length or extra connection required to use a riser card impose any kind of penalty on graphics cards? Please test this, by using one on a typical motherboard just for some measurements.

-

thespaceduck Maybe it is just me, but doing 9 different test for "performance" for a CHASSIS seems redundant and obsolete.Reply -

crenwelge I purchased an ASRock mini-ITX HTPC that never worked. It continually blue screened and crashed. I sent it to ASRock 5 times for repair before finally giving up. Its technicians are either incompetent or dishonest . Once they sent it back with parts loose inside the case, another time without the power supply. Every time they claim to have tested it, but every time it came back blue-screening and crashing. Newegg refused to take it back and instead offered me a $100 credit. When I tried to use it, I found Newegg had deactivated my account. ASRock may be a competent motherboard house, but they cannot build and service reliable systems.Reply