Tom's Definitive 10.1" Netbook Buyer's Guide: Fall 2010

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

MSI Wind U160 (U160-007US)

MSI’s new Wind 160 (160-007US model in the labs) is based off of its U135/L1350 platform.

There are really only two differences with the previous generation:

- new touchpad design

- a higher density 6-cell battery

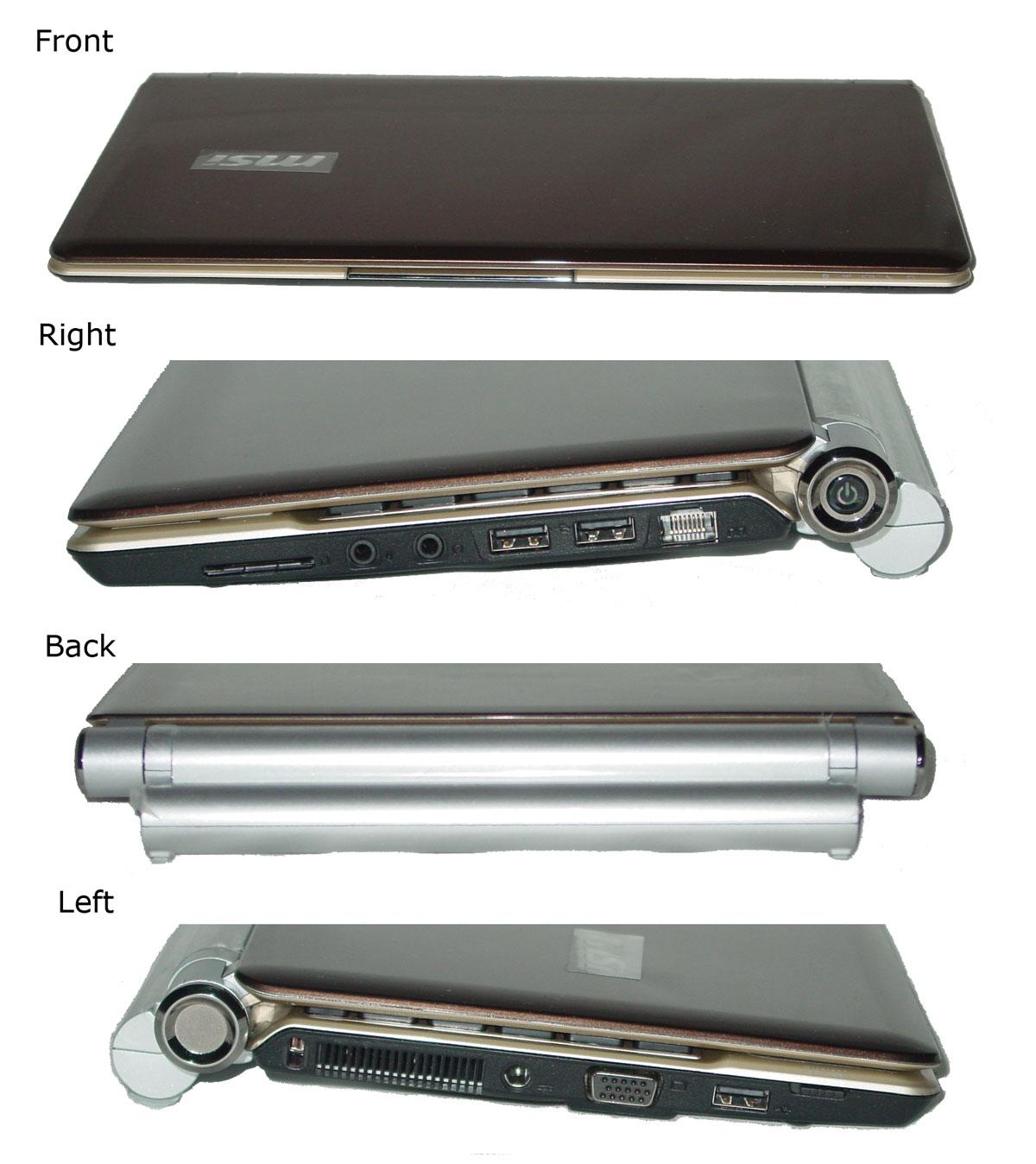

Note that the U135 and U160 share almost exactly the same specifications, minus the aforementioned. Despite identical specs, the U160 features a complete redesign at the internal hardware level, which is apparent in the port arrangement. However, the internal components (LCD panel, WiFi card, and so on) largely remain the same.

Along with an internal rearrangement, the physical appearance underwent a slight refresh. The construction of the notebook is still based on a high-gloss fingerprint-loving concept. The entire notebook seems to be made of ABS, which is common given the price range of netbooks. There are a few noticeable changes though: the display hinge is now based on a rod design, the matte frame around the display, the reposition of the microphone to the left side of the screen, and the borderless touchpad.

The chiclet design of the keyboard is pretty common these days, but the keyboard here has a texture similar to that found on Dell notebooks. It is something that MSI definitely has gotten right, though the size of the keys on this 93% keyboard seem to be the smallest in this roundup selection. This isn’t necessarily a penalty, but is noteworthy considering other chiclet keyboards, on average, have larger keys.

We have some misgivings about MSI’s version of an “integrated touchpad:” mainly, the idea is that there is nothing to delineate where the case starts and where the touchpad begins. The only thing that gives away the touchpad's location is the small raised bumps. Whereas Gateway took its chassis and added texture-sensing points on its LT21 series, MSI fabricated the bumps with the enclosure, so everything is high-gloss, which serves as a detriment. There simply isn’t enough of a texture difference, and as a result, tracking seems somewhat “slippery.” A matte finish similar to the border around the display would have been preferable. Plus, the use of noticeably raised bumps makes the entire navigation process feel oddly unnatural. MSI should take a cue from Asus and Gateway if it wants to see how integrated touchpads can be well-designed and well-received.

The touchpad button, like the U135, remains a high-gloss metallic finish on a narrow plastic bar. Honestly, this could use some rework alongside the touchpad to match a decent keyboard. Other netbooks in this roundup have more real estate given the same form factor, and MSI likewise should look to do the same. The depression space is fairly low and the bar suffers from middle-click confusion.

We should point out that MSI is still a relatively new player in the mobile market and it is out to show its chops. The U160 shows MSI’s improving eye toward quality, but it’s often the small details that matter. There are two specific things here that stand out. First, we noticed the wireless toggle jiggles. It is loose and isn’t up to par with the quality we are seeing from the top four system vendors. Second, the left side of the hinge bar has an unsecured plastic cap. Where the right side is fully secure and has a flawless center cutout for the power button/LED, the left side seems to fall off if you apply some friction. We aren’t even so sure the cap on the left side is made of the same material, but it might just feel this way because we can’t compare it to the right-side cap. Some epoxy here will save grief later down the road if MSI hasn’t fixed this issue by the purchase time.

To be fair, MSI explains the latter as a batch-related issue, because units in its warehouse don’t seem to exhibit this defect. If this isn’t batch-related, we may just be nit picking over how much force is needed to loosen the cap. However, this shouldn’t have been implemented as a twist-off part in the first place. In the day-to-day hustle and bustle of things, this could still eventually fall off in some inconspicuous location. Honestly, small pieces of a highly mobile system that aren't meant to be serviceable should either be fabricated as a single piece or glued down with some “super adhesive” like epoxy.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

-

frederico Very indepth excellent review. Pleasantly surprised. A lot of people out there have little clue of netbooks or even their uses. I got a little samsung last year and now I use it more than my main PC, obviously not for gaming, but watching webcasts/films at night, listening to music, grabbing it while watching TV to check something on the web, etc, etc. Not to mention completely essential when travelling on train/bus/wherever - 6 hours batt life still holding up.Reply

Very handy little things - easy to become addicted to. Theres some new models coming out this month that can handle HD but still have great batt life, will be tempted to pick one up.

-

ScoobyJooby-Jew I have used a Gateway netbook with vista and 2 gigs of ram. I loved it. The 2 gigs really helped smooth things out. And when I loaded the netbook distro of ubuntu, it was ridiculously awesome. It satisfied everything except gaming. Which is what I wanted it to do.Reply -

Luscious That's the best performance rundown I've seen to date on the Broadcom Crystal HD - nice to get critical, hands-on info without the marketing BS. That said, AMD's Nile platform is seriously spanking Intel.Reply

I recently tested the HP Pavilion dm1z with the dual-core K625. Only slightly heavier/bigger than the 10" HP 210 Mini, but far superior when it comes to performance:

http://lgponthemove.blogspot.com/2010/09/first-impressions-hp-dm1z-notebook.html -

lashabane Huh, never knew that a full propane tank weighs ~38 lbs.Reply

*Ninja edit*

Super good roundup/review. I'm in the market for a netbook this season and this review helped a lot. -

braneman I actually found that on my last netbook (toshiba satalite, amd based) with a ram upgrade the only game it couldn't play passably on lowest settings(resolution included) was red faction guerrilla, even then it was graphical errors, you could even bring Crysis up to MEDIUM on some settings. meh now I got an m11x, it's very nice.Reply -

KingArcher OMG this review is like drugs for the technically inclined.Reply

Good....no, Excellent job Andrew Ku. Amazing stuff. Really learned something new.

I look forward to reading more reviews from you. :bounce:

P.S. Editors, give this man a raise ;) -

super_tycoon If you're doing a 12 inch in the near future, I hope you include the Asus 1215n. I've had mine for three weeks and it's brilliant. ION2 and Optimus are easily worth whatever I paid for them. Playing any HD youtube video yields unicorns and butterflies while my friend's gateway (the one reviewed here) only gets the look of disapproval.Reply

My concern is that drivers for ION2 are a bit -fast- slow and loose now, the stock asus drivers were crap, the Nvidia update at launch was crap, but about two weeks ago there was a major update that requires manual installation. It gets roughly double, yes double, the fps of the old pos. Now I didn't write the thing, but it felt like it addressed the PCI-Ex1 link narrowness. (After all, what else could it be? It's just a 210m at it's core, but whatever's drawn on the Nvidia gpu also has to go back down the PCI-E link to be written to the Intel gpu vram (Optimus))

Anyhow, forget the broadcom thing, my friend (a different one, I promise they're real and actually have these things!) has the dell and it's pretty bad. Even I couldn't get that stupid thing to work reliably except for WMP. At least he got his with his new xps 16.

TL;DR I've actually used the gateway and dell netbooks reviewed here and they're both crappy. The gateway gets good battery life though and feels nicer. I love the asus 1215n with it's ION2 gpu and Optimus, and you should too.