Thermaltake Toughpower DPS G RGB 1500W PSU Review

Why you can trust Tom's Hardware

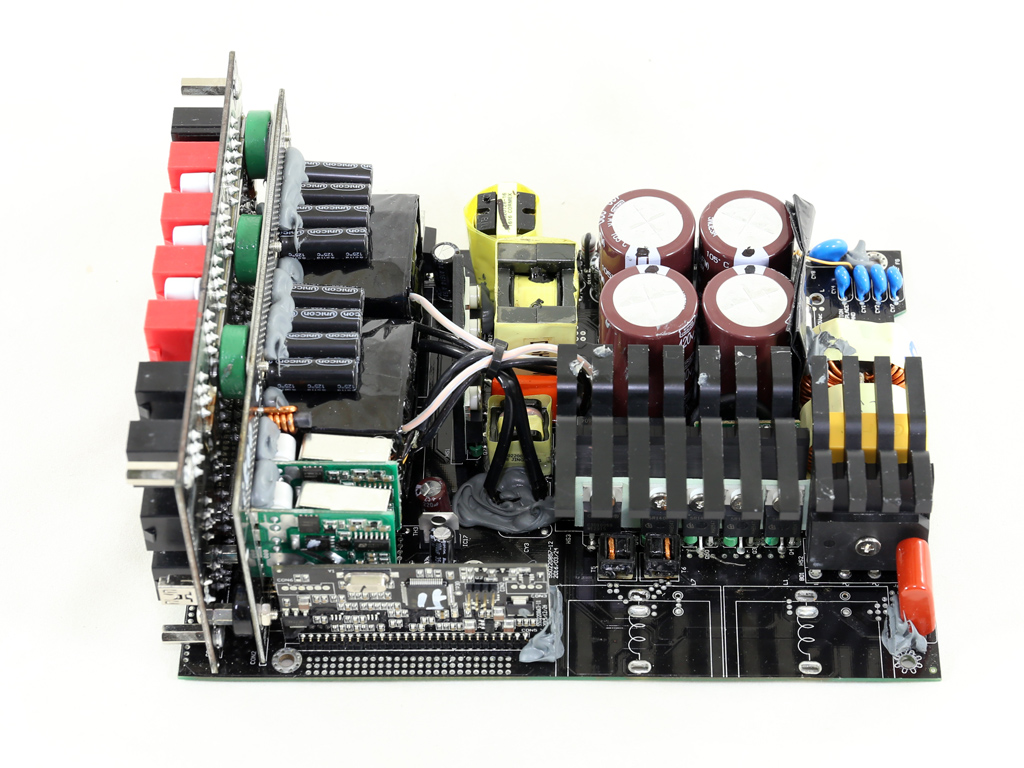

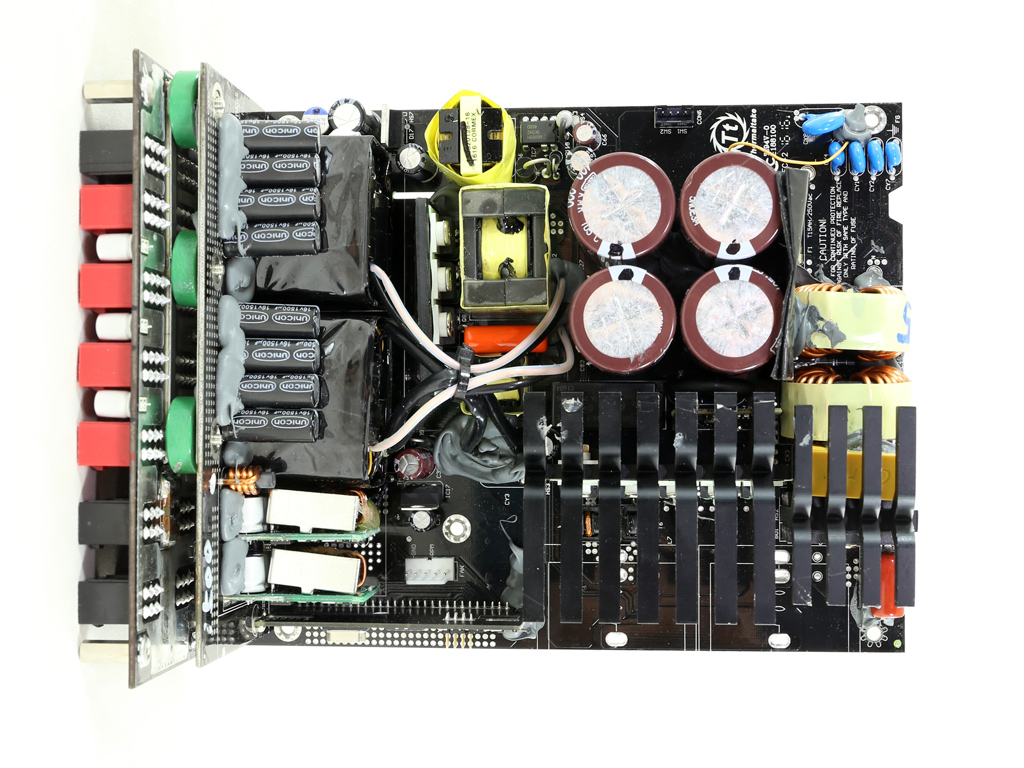

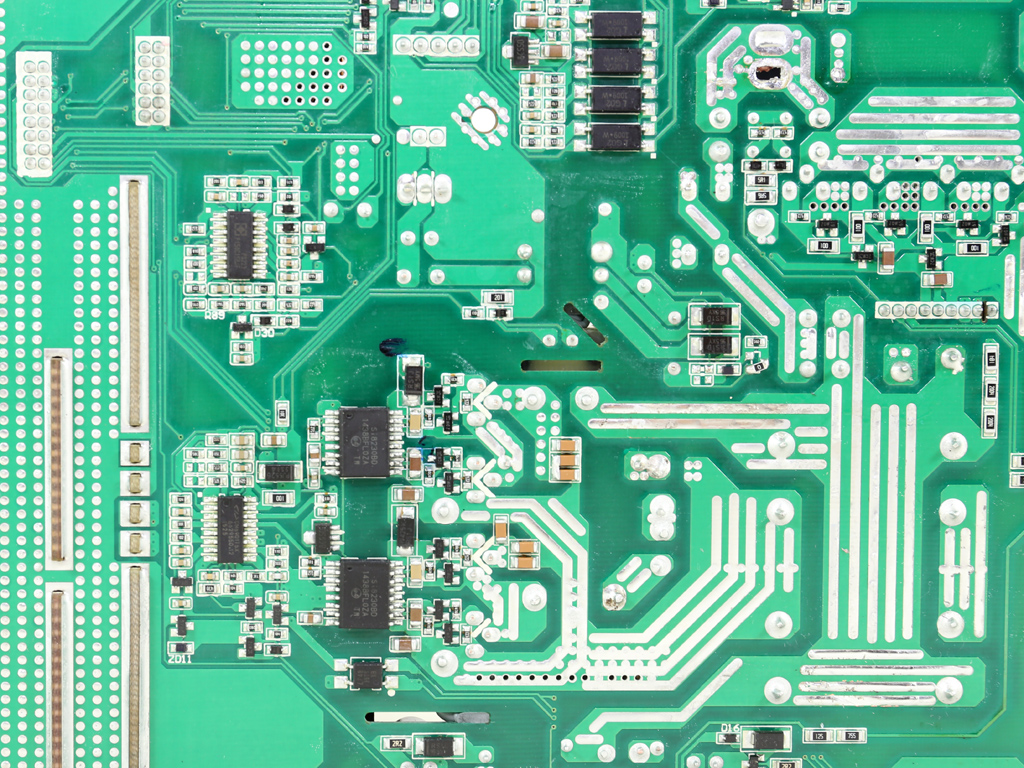

A Look Inside And Component Analysis

Parts Description

Before proceeding with this page, we strongly encourage you to a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss. Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station, and a Hakko FR-300 desoldering gun.

| General Data | |

|---|---|

| Manufacturer (OEM) | Enhance Electronics |

| Primary Side | |

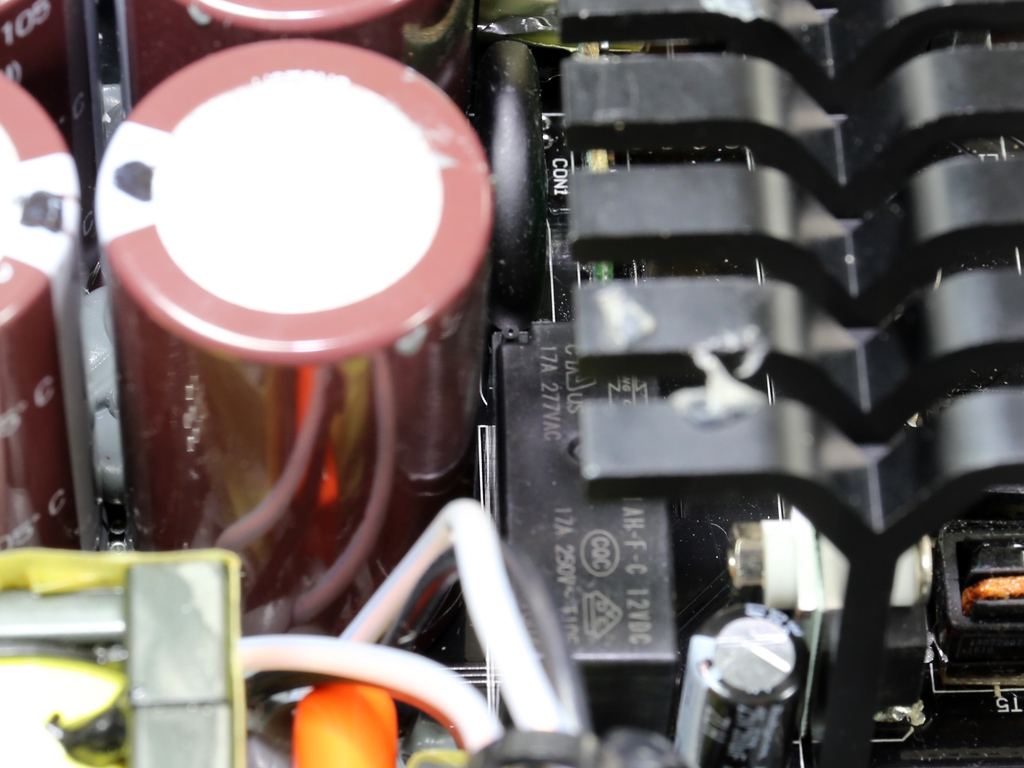

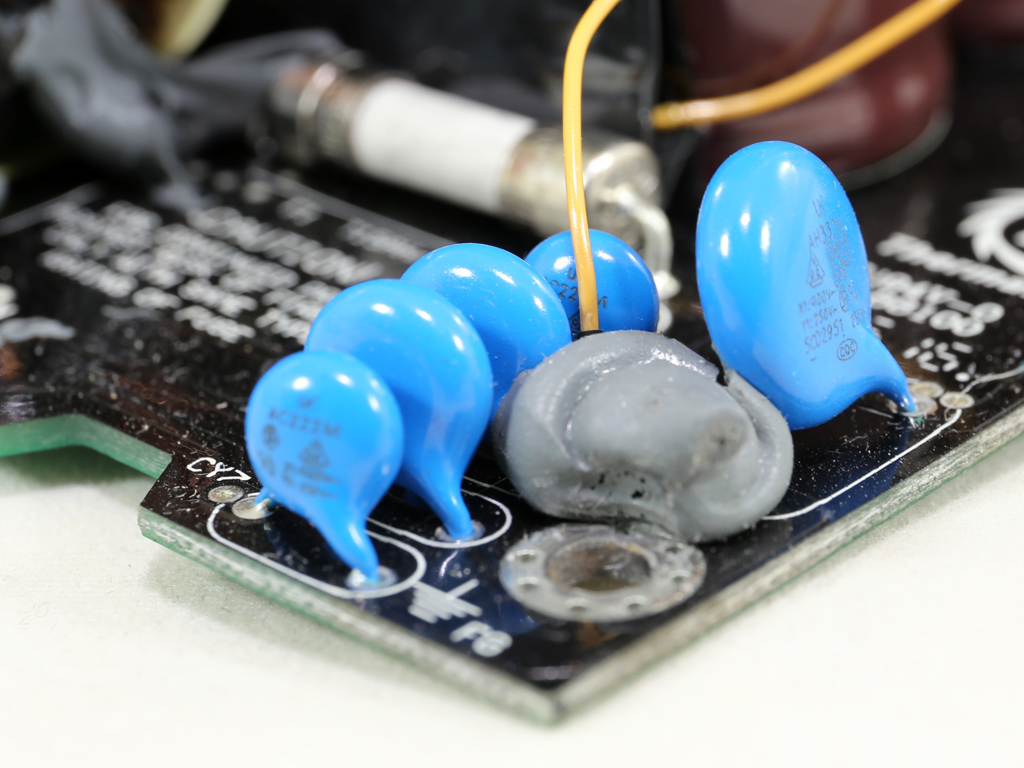

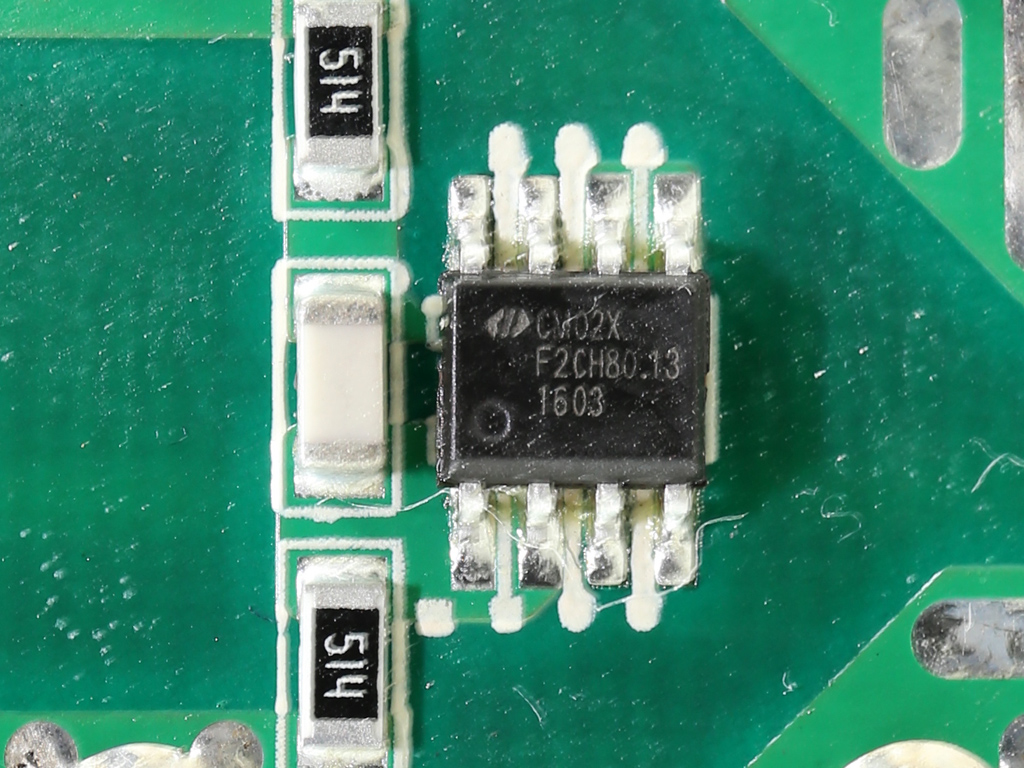

| Transient Filter | 6x Y caps, 3x X caps, 2x CM chokes, 1x MOV, 1x CM02X |

| Inrush Protection | NTC Thermistor & Relay |

| Bridge Rectifier(s) | 2x LL25XB60 (600 V, 25 A @ 113 °C) |

| APFC MOSFETs | 4x Infineon IPP50R140CP (550 V, 15 A @ 100 °C, 0.14 Ω) |

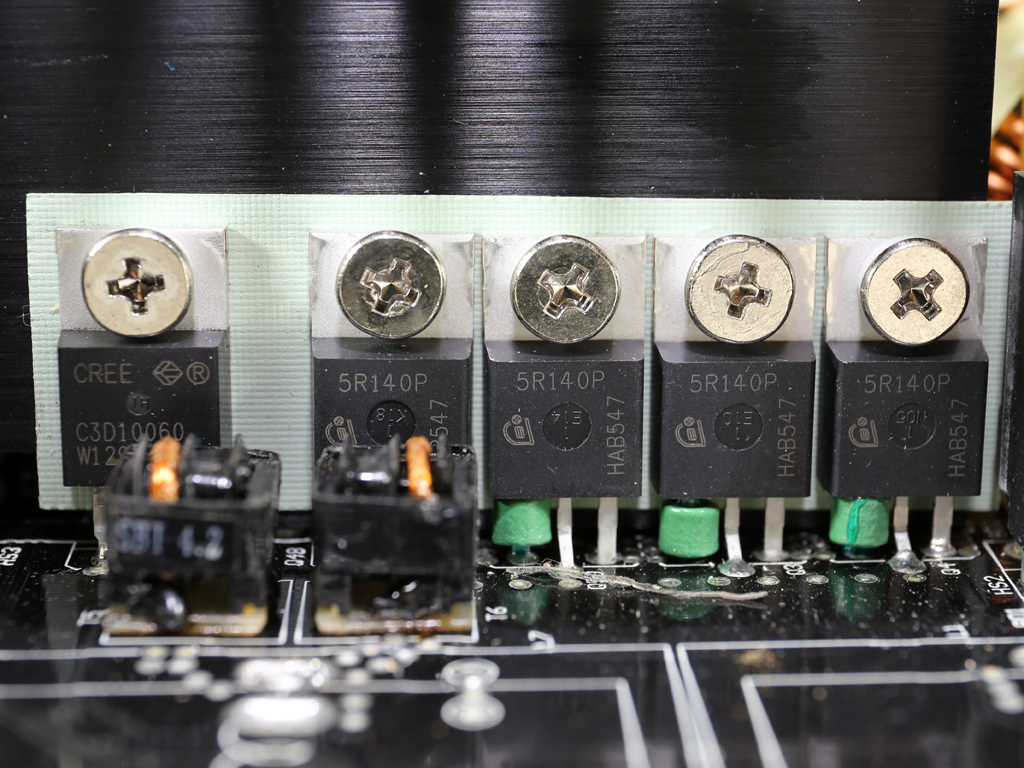

| APFC Boost Diode | 1x CREE C3D10060A (600 V, 10 A @ 153 °C) |

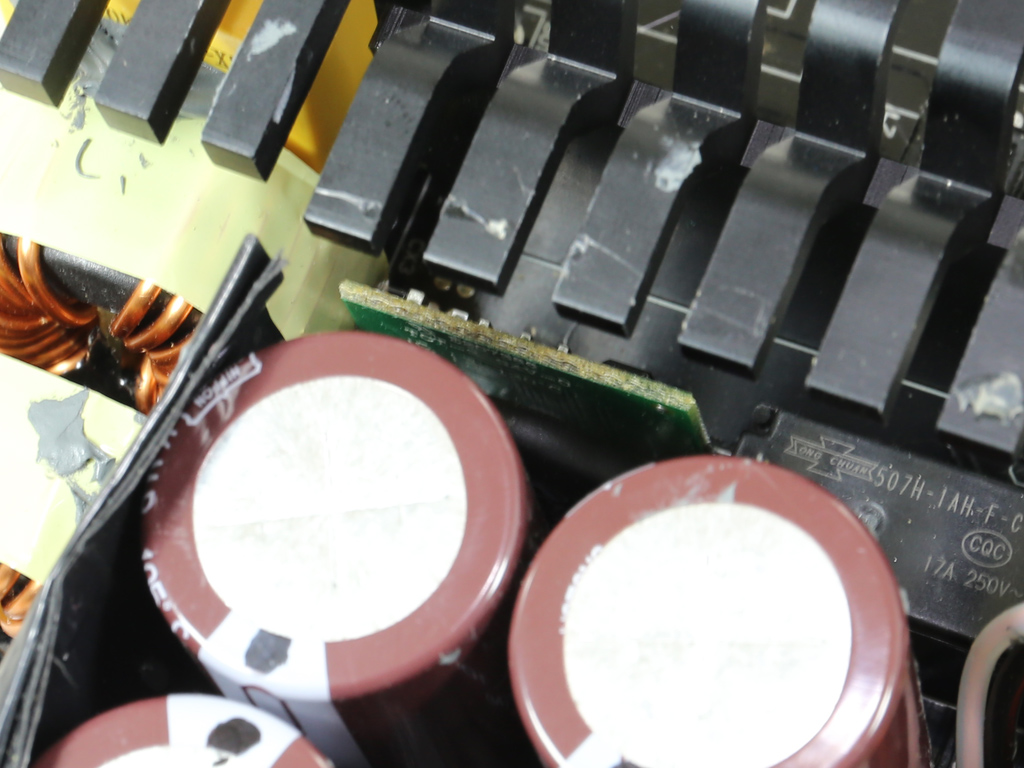

| Hold-up Cap(s) | 4x Nippon Chemi-Con (420 V, 330 uF each, 1320 uF combined, 2000 h @ 105 °C, KMR) |

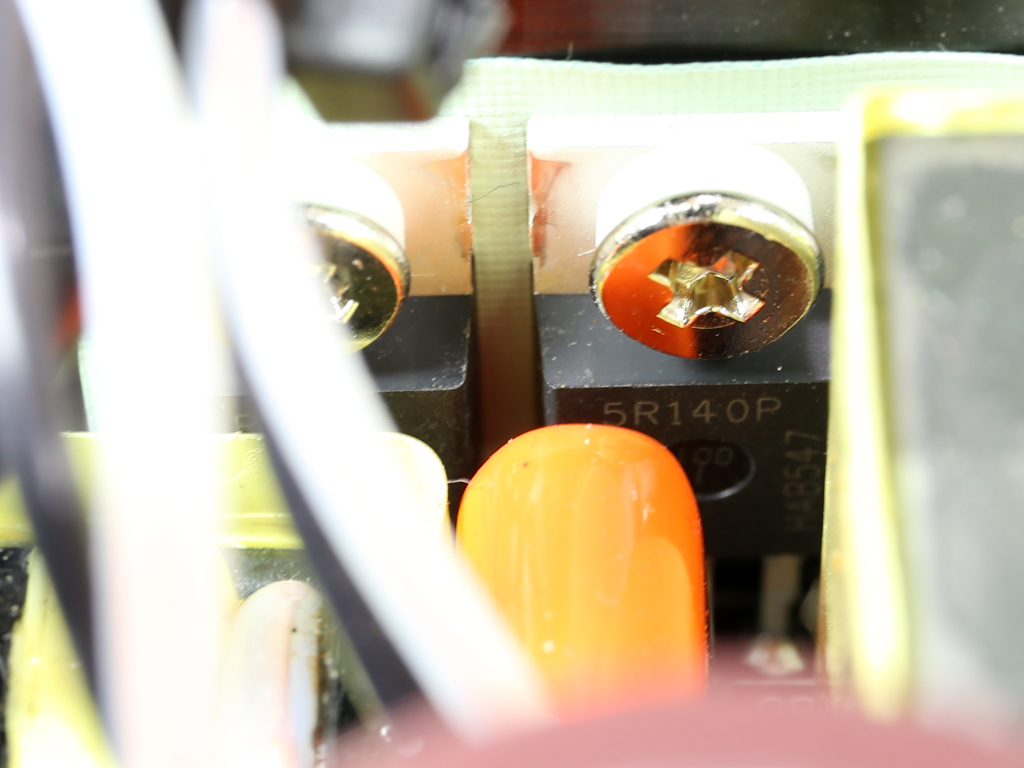

| Main Switchers | 4x Infineon IPP50R140CP (550 V, 15 A @ 100 °C, 0.14 Ω) |

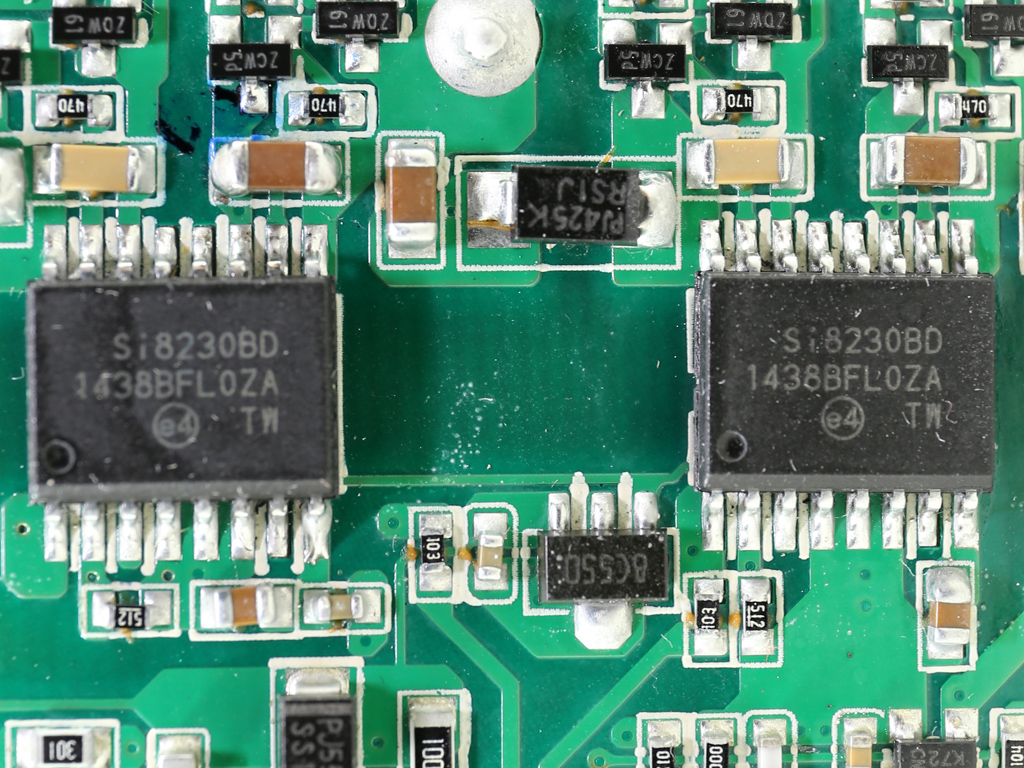

| FET Drivers | 2x Silicon Labs Si8230BD |

| APFC Controller | Champion CM6502S, CM03X Green PFC |

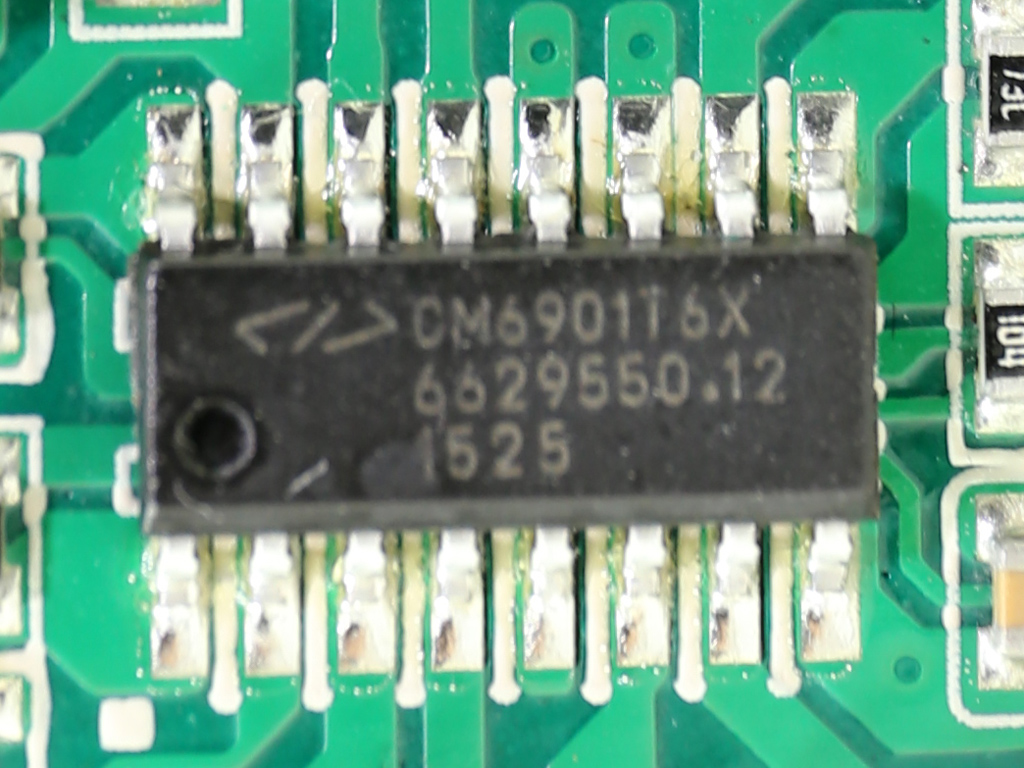

| Switching Controller | Champion CM6901 |

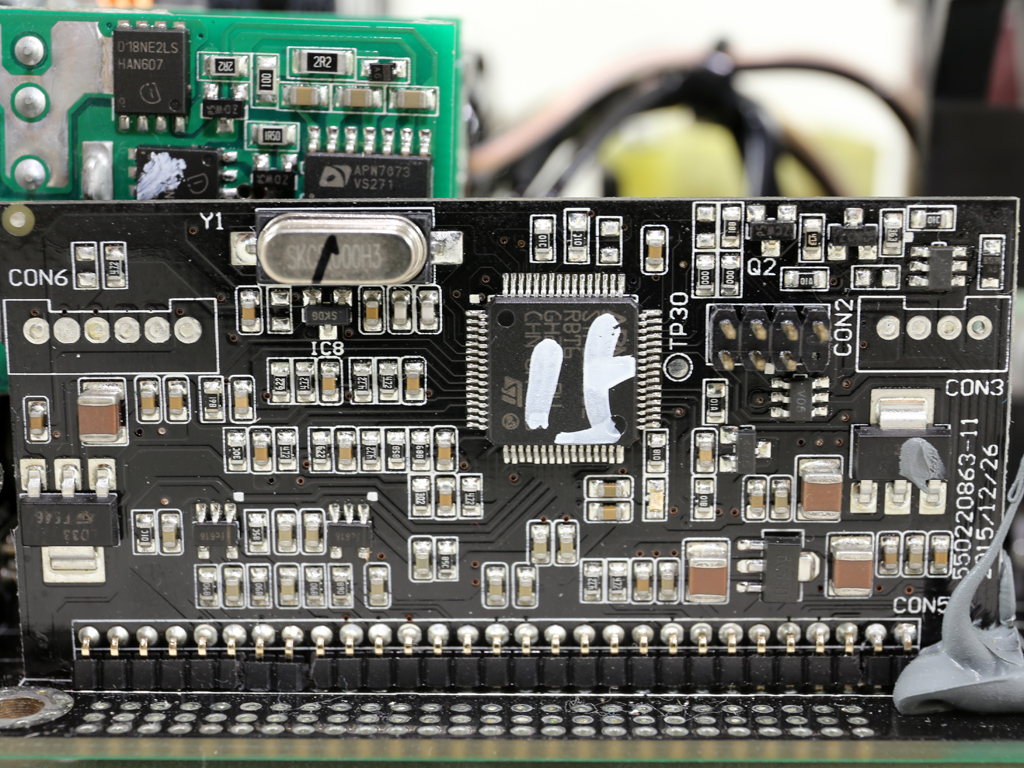

| MCU | STMicroelectronics STM32F302 (72 MHz, 12-bit DACs, USB interface) |

| Topology | Primary side: Full-Bridge & LLC Resonant Converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | Unknown number of FETs |

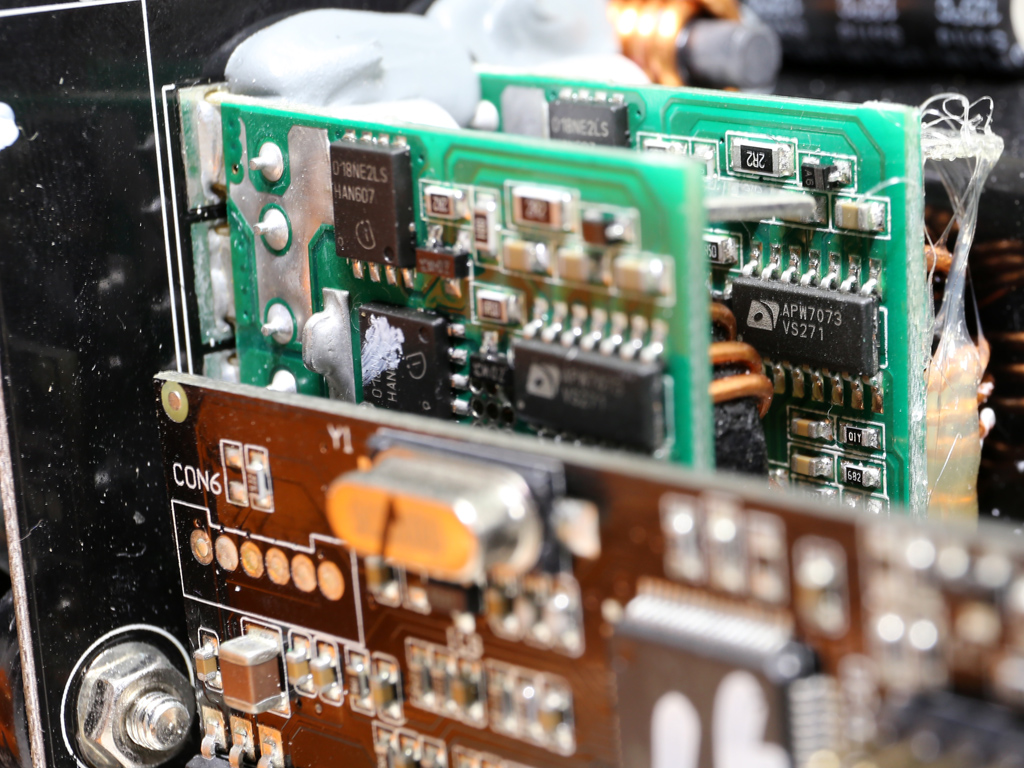

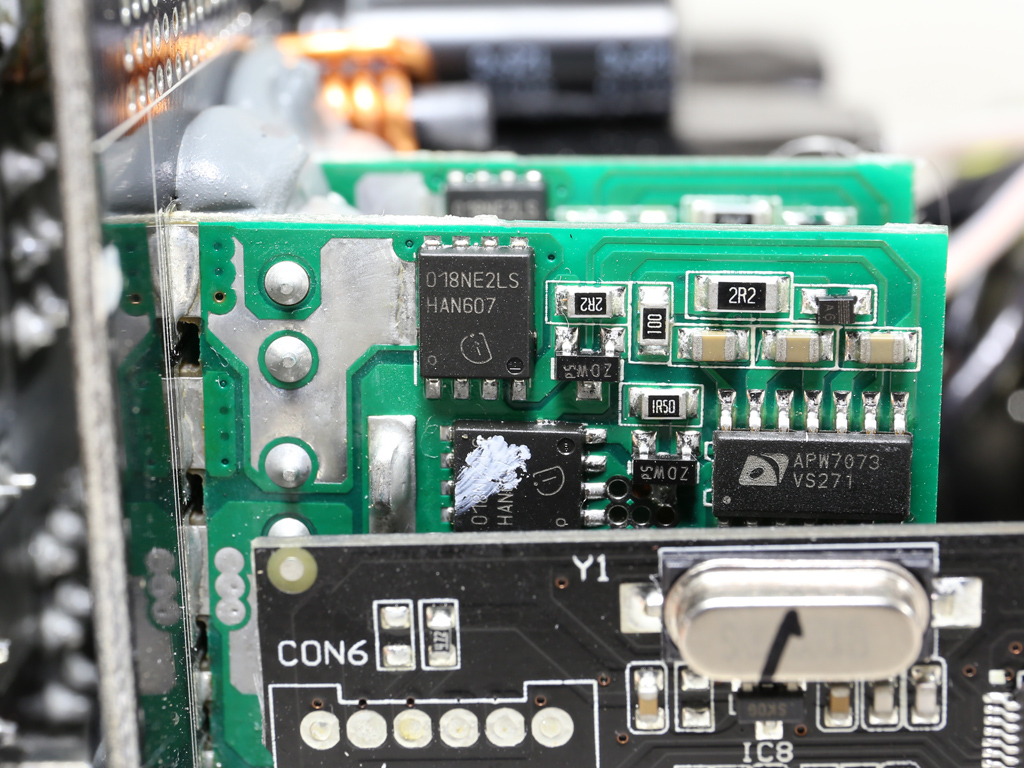

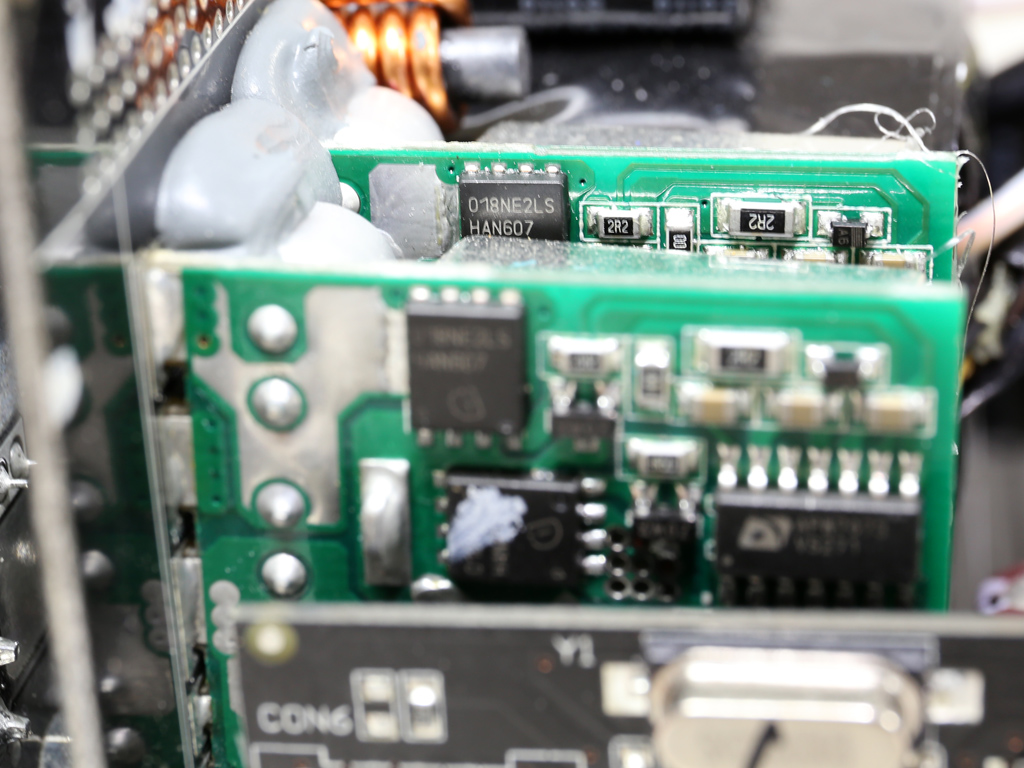

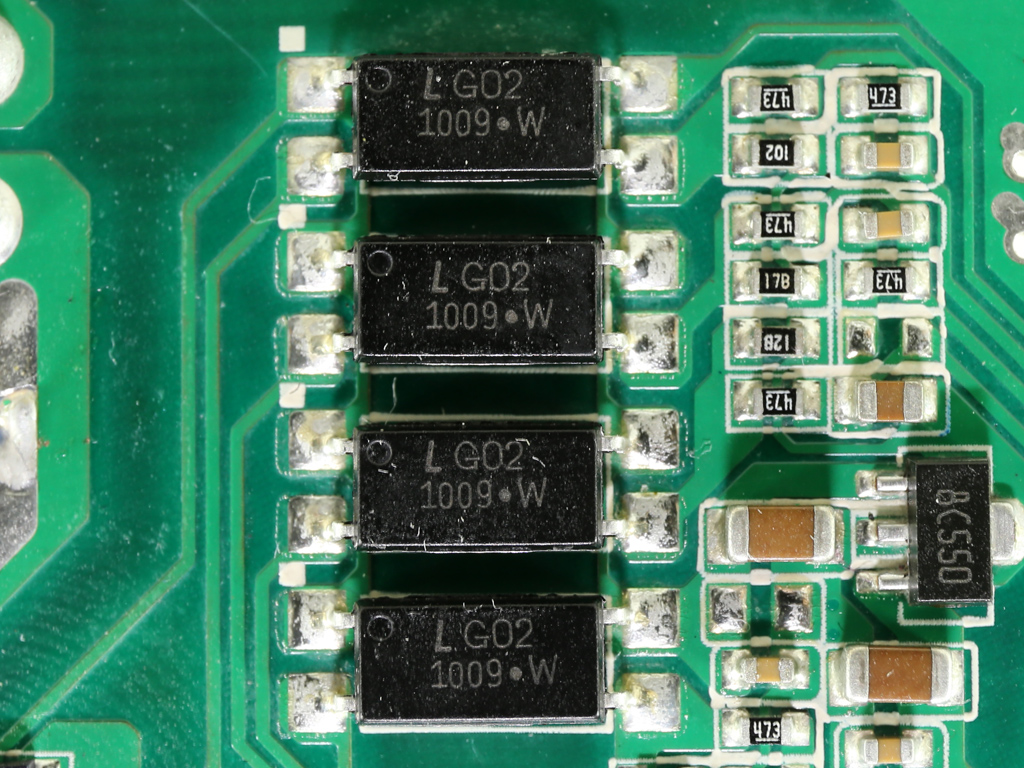

| 5V & 3.3V | DC-DC Converters: 4x Infineon BSC018NE2LS (25 V, 97 A @ 100 °C, 1.8 mΩ) PWM Controller: 2x APW7159 |

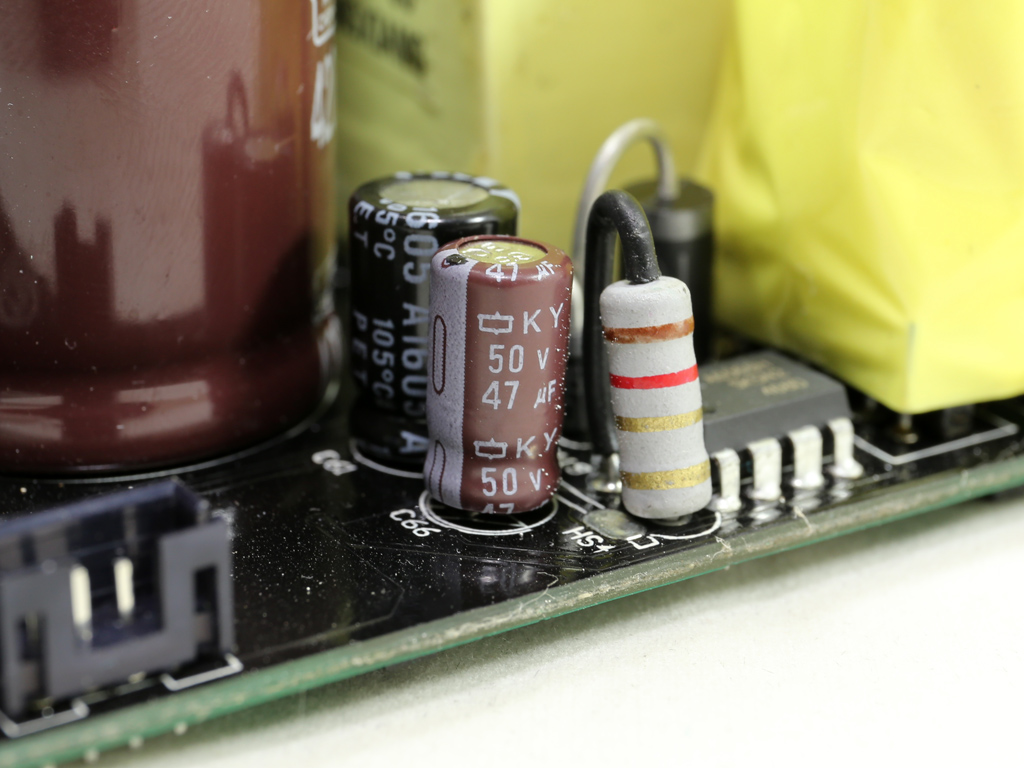

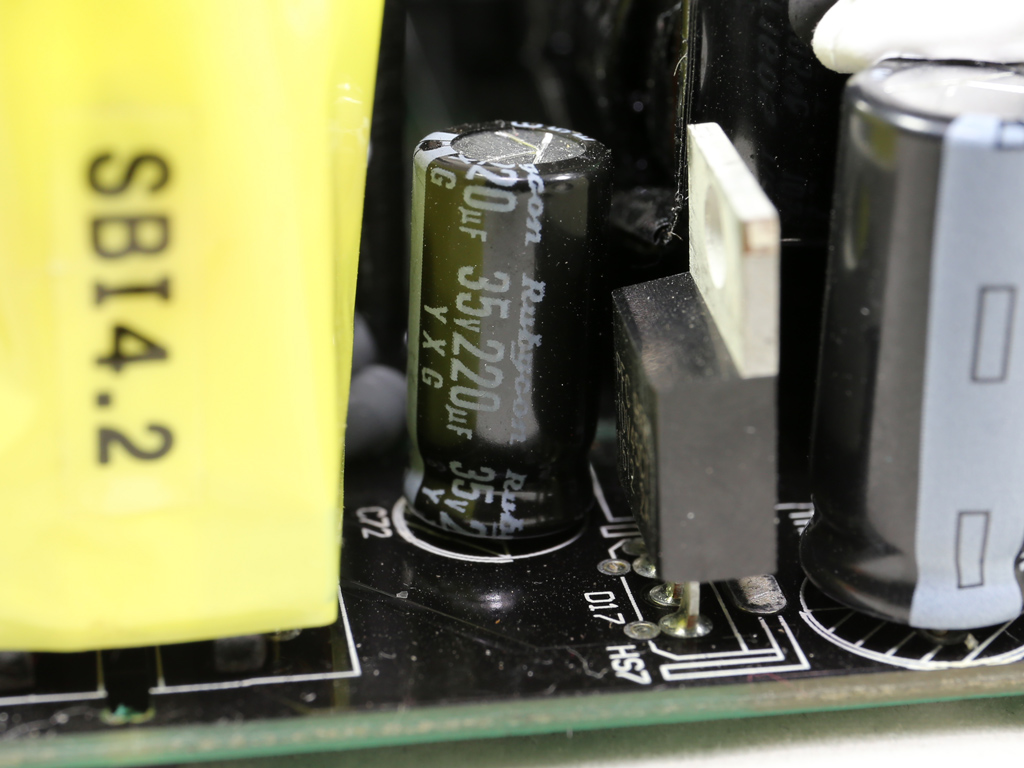

| Filtering Capacitors | Electrolytics: Unicon (TW, 2000h @ 125 °C, UPL), Nippon Chemi-Con (105 °C, KY), Rubycon (105 °C, ZLH, YXG) Polymers: Unicon |

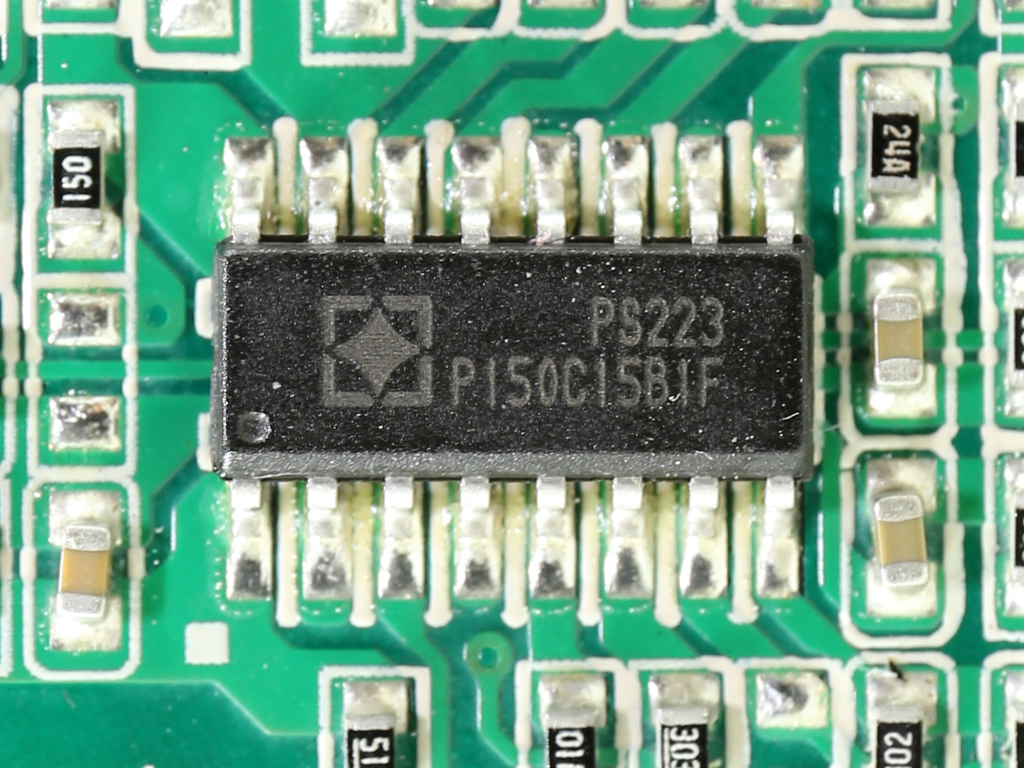

| Supervisor IC | SITI PS223 (OVP, UVP, OCP, SCP, OTP ) |

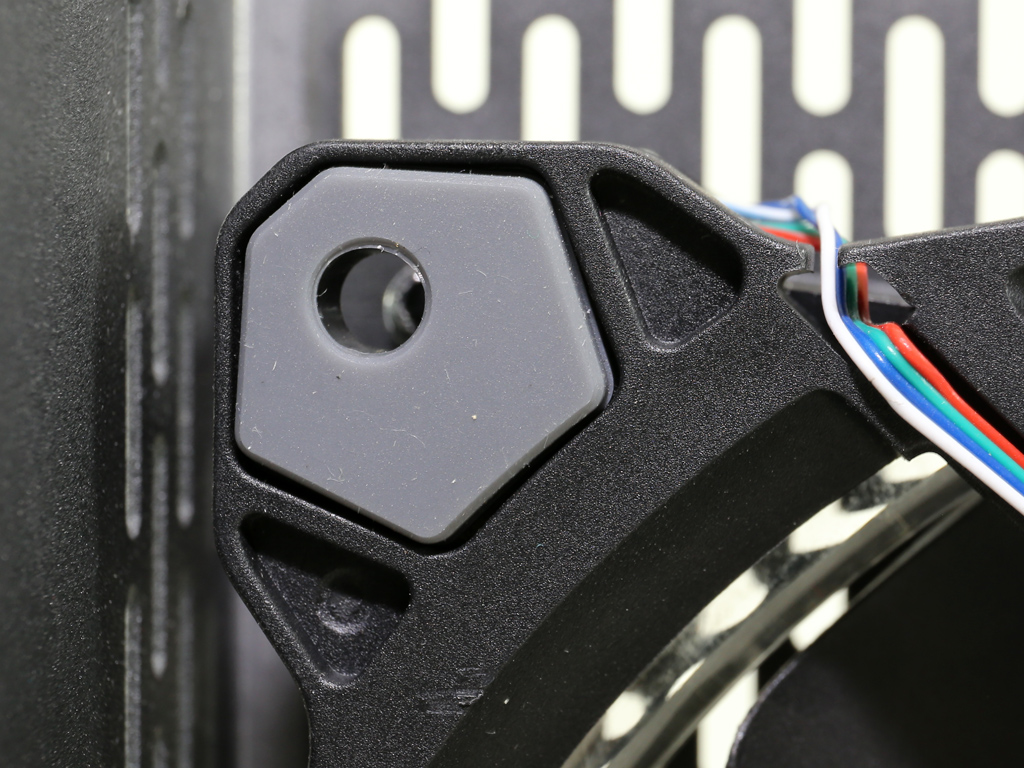

| Fan Model | Thermaltake TT-1425 (Hong Sheng OEM, A1425L12S, 140 mm, 12 V, 0.30 A, 2250 RPM, hydro-dynamic bearing) |

| 5VSB Circuit | |

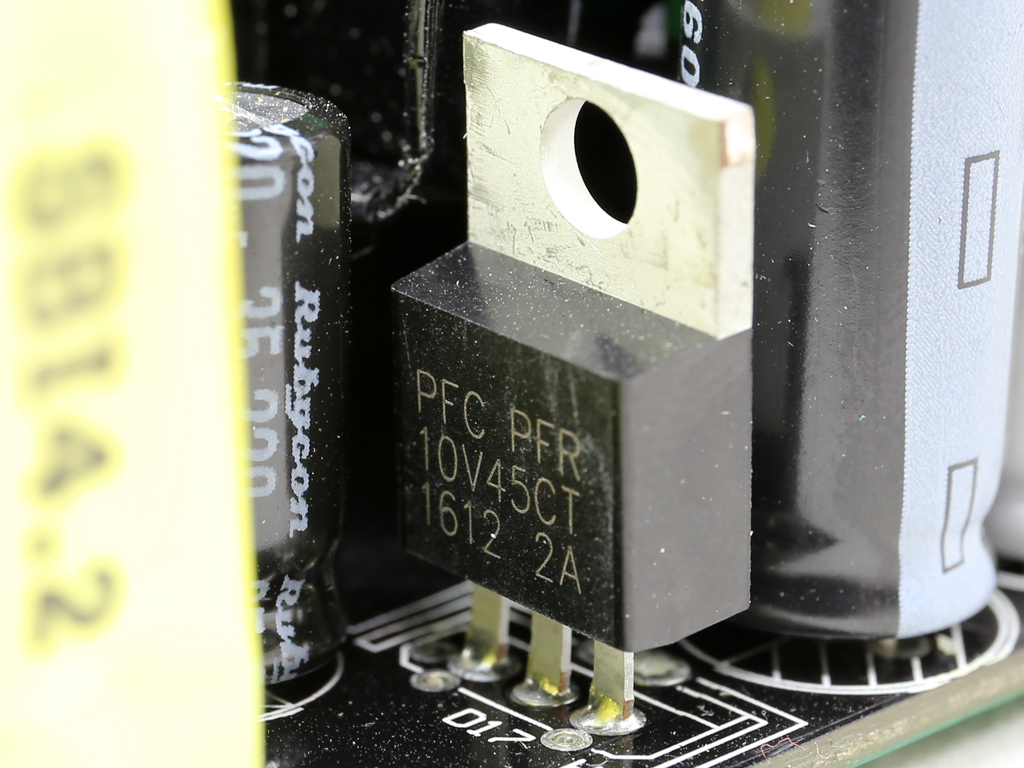

| Rectifier | 1x PFR10V45CT (2x 5 A, 45 V) |

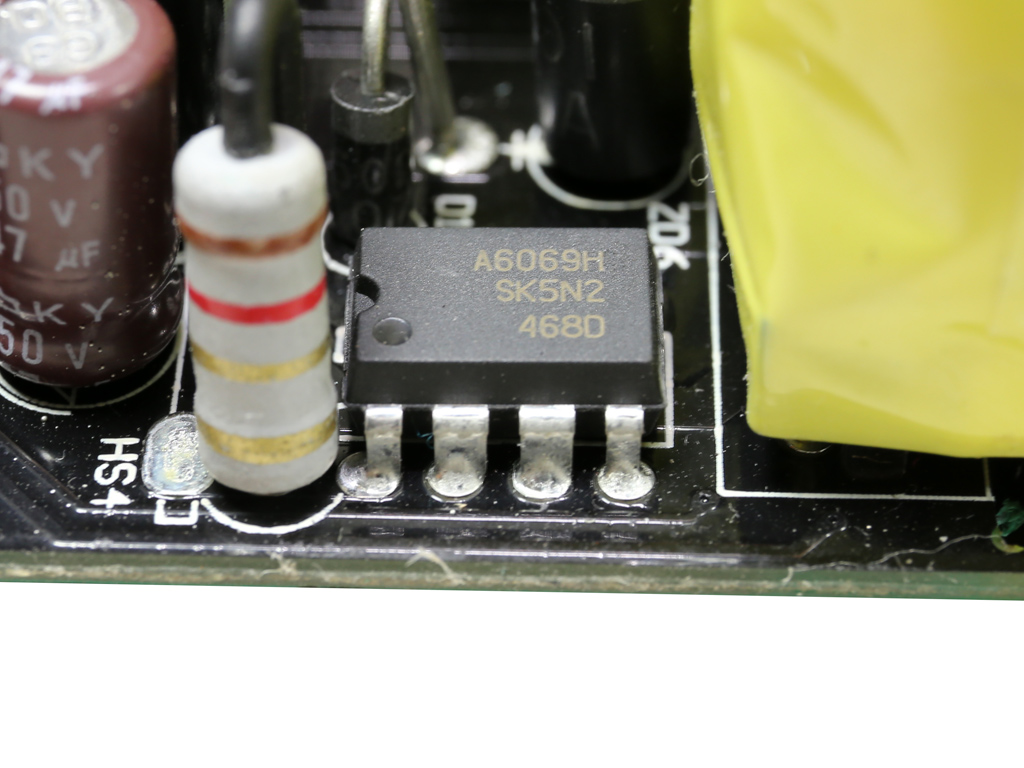

| Standby PWM Controller | Sanken STR-A6062H (26.5 W max) |

| -12V Circuit | |

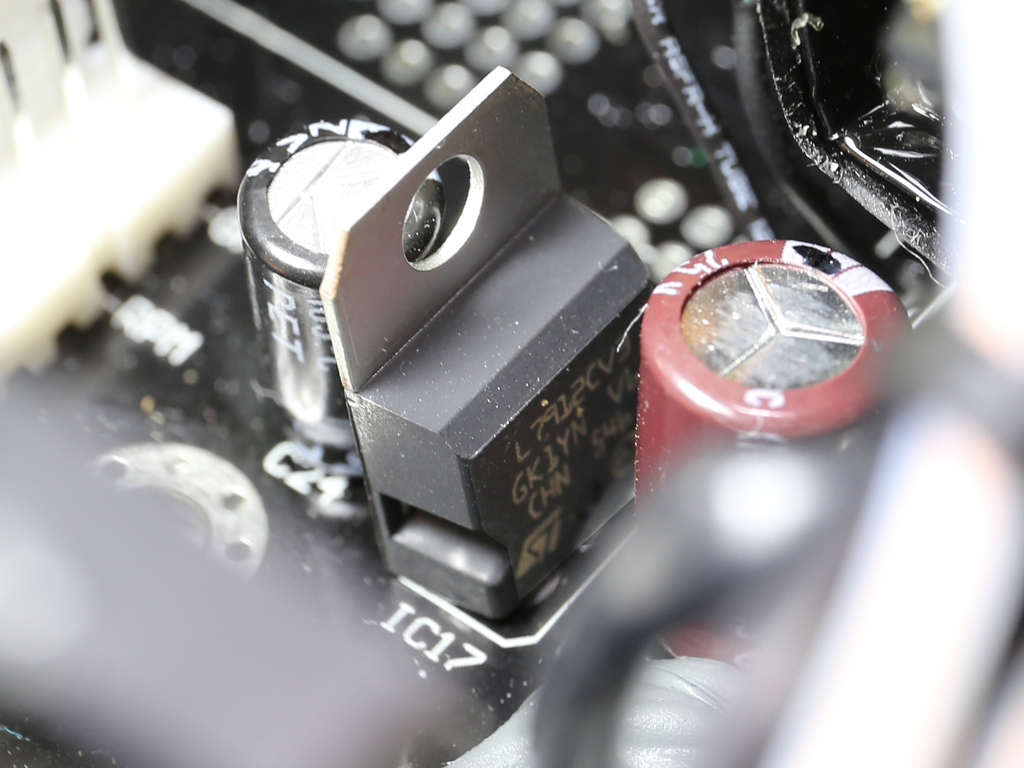

| PWM Controller | 1x STMicroelectronics L7912CV (TO-220, -12 V, 1.5 A) |

Again, the TPG-1500D-T's platform is provided by Enhance Electronics, and its design appears to share some similarities with Cooler's Master MasterWatt Maker 1200. This is a typical analog implementation enhanced with an MCU that handles communication with the system, allowing simultaneous monitoring of the PSU's status and control of its fan. In this price range, we frankly expected a fully digital platform where MCUs control the APFC converter, along with the primary and secondary sides. However, this isn't the case, and that's a huge let down. Compared to other digital units with similar or lower price tags, including the TPG-1250D-T, the TPG-1500D-T is in a difficult position because of its inferior platform. Enhance's semi-digital platform is probably used exclusively by Cooler Master, or it is even more expensive, preventing Thermaltake from utilizing it.

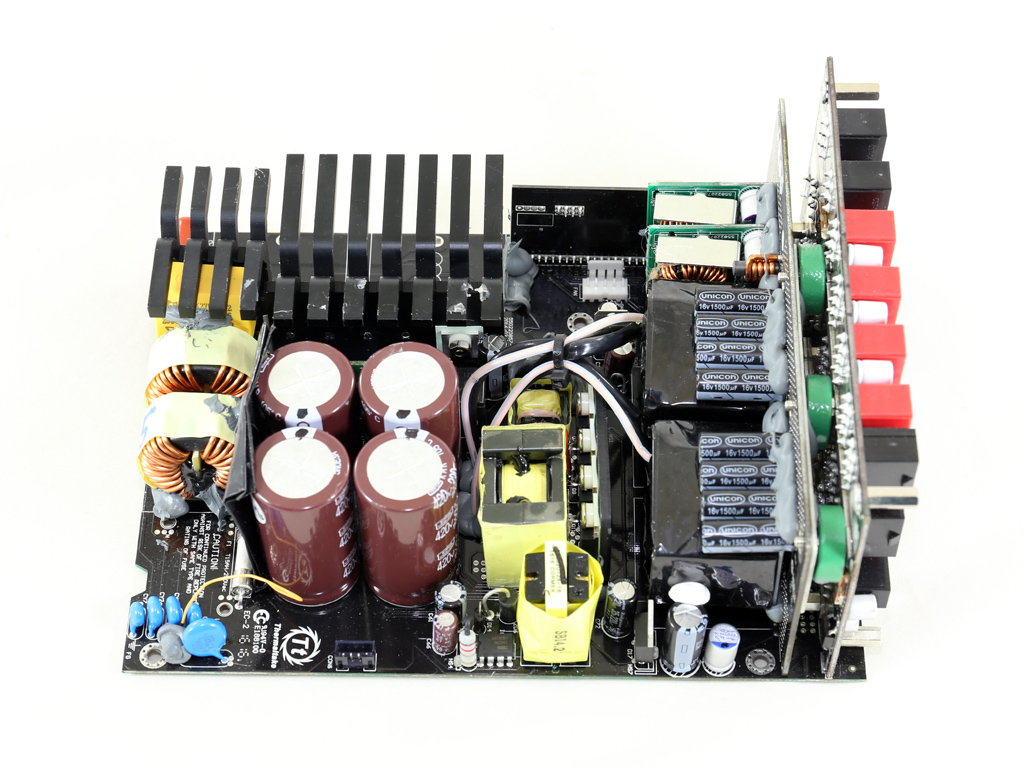

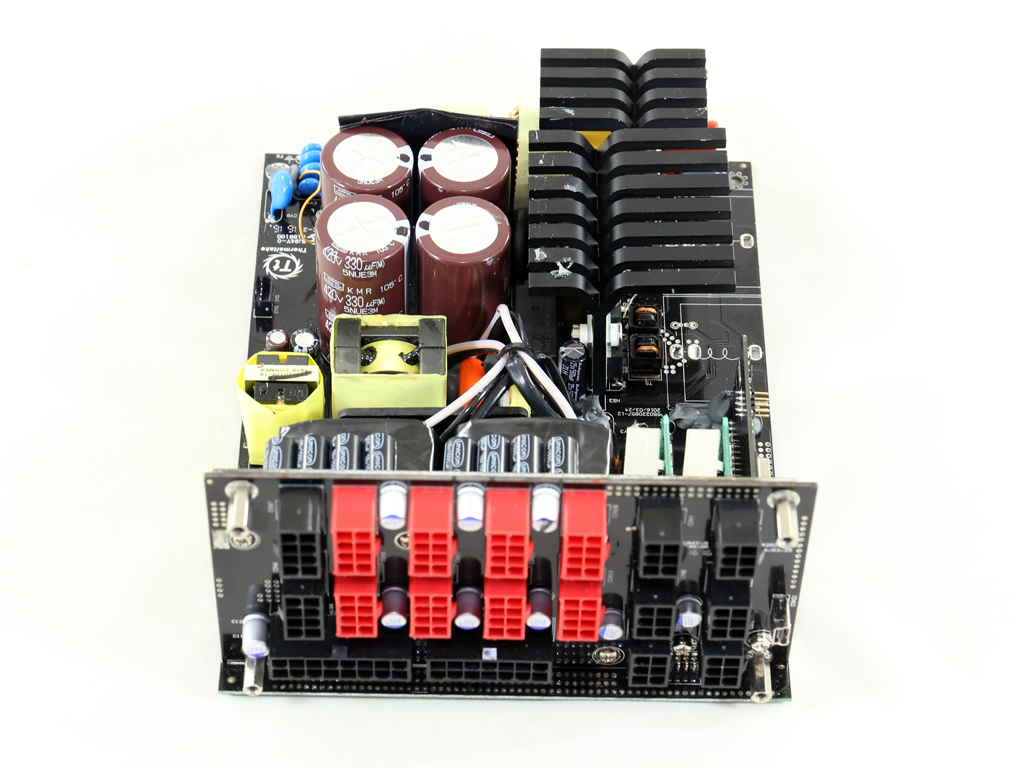

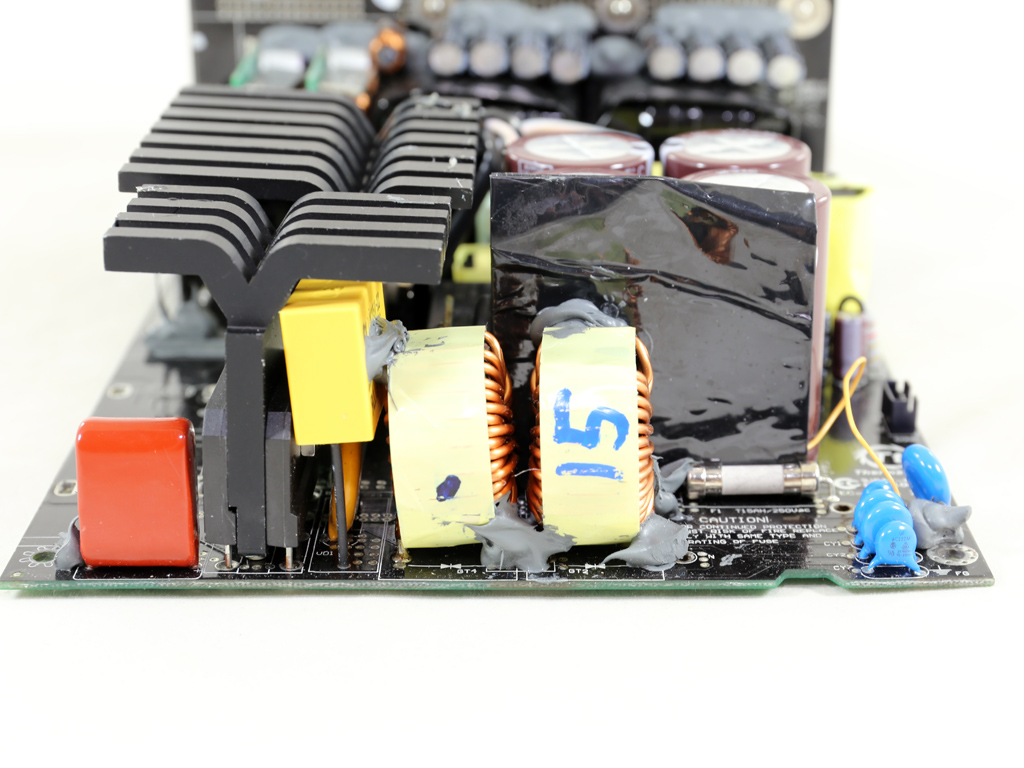

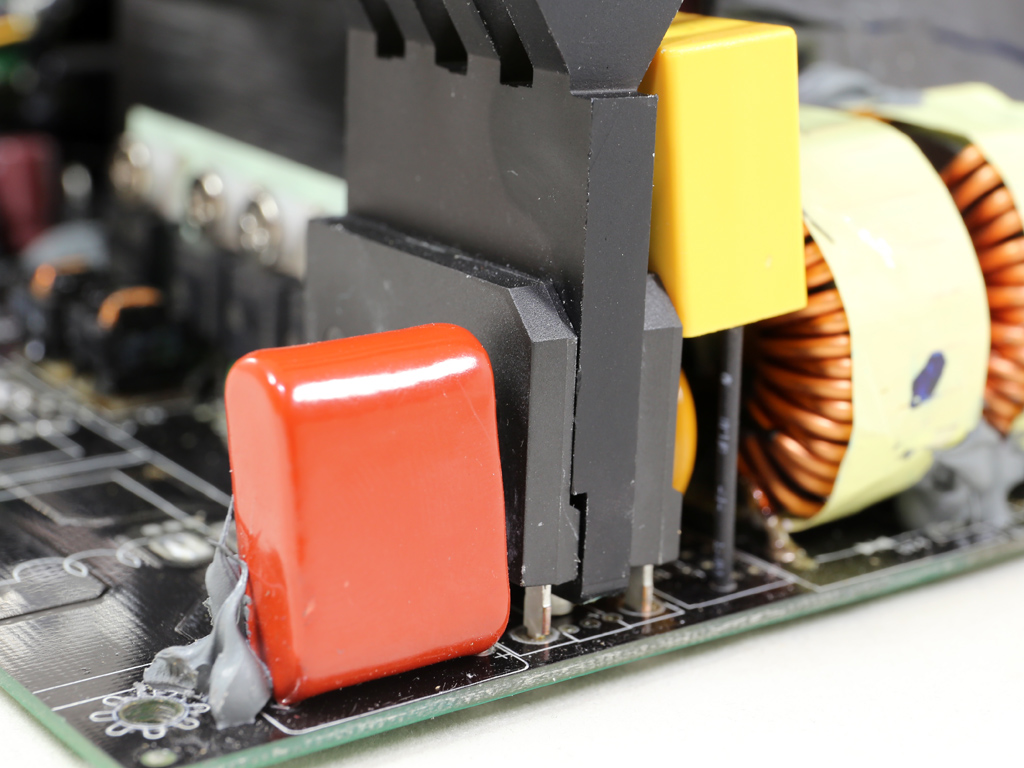

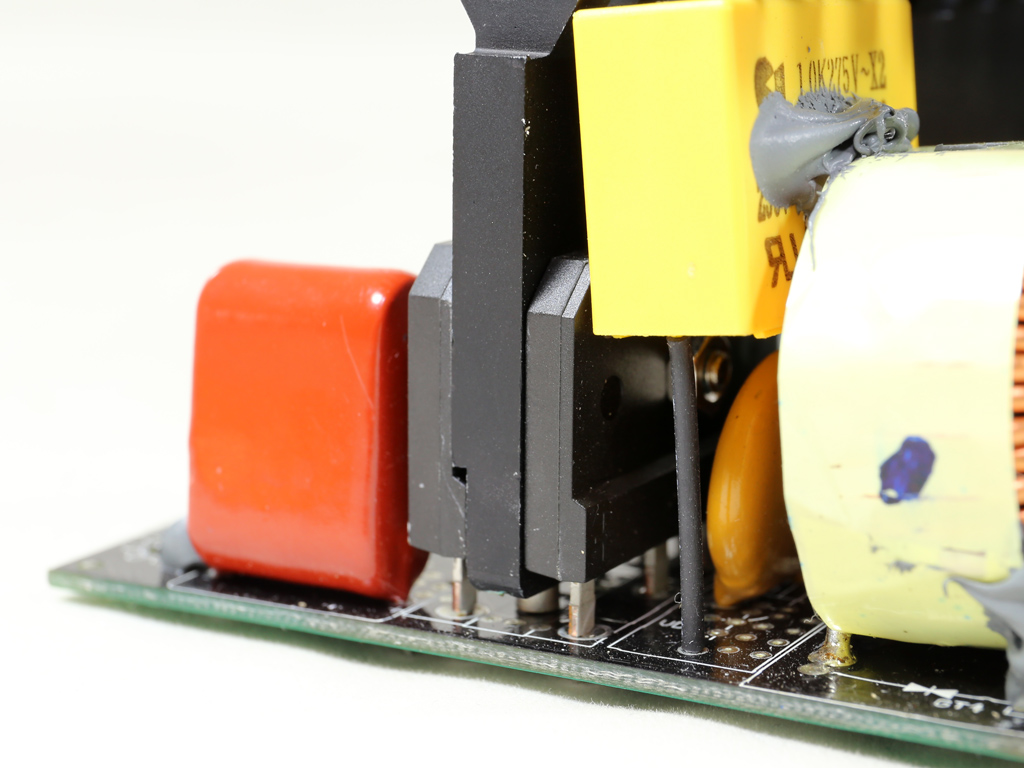

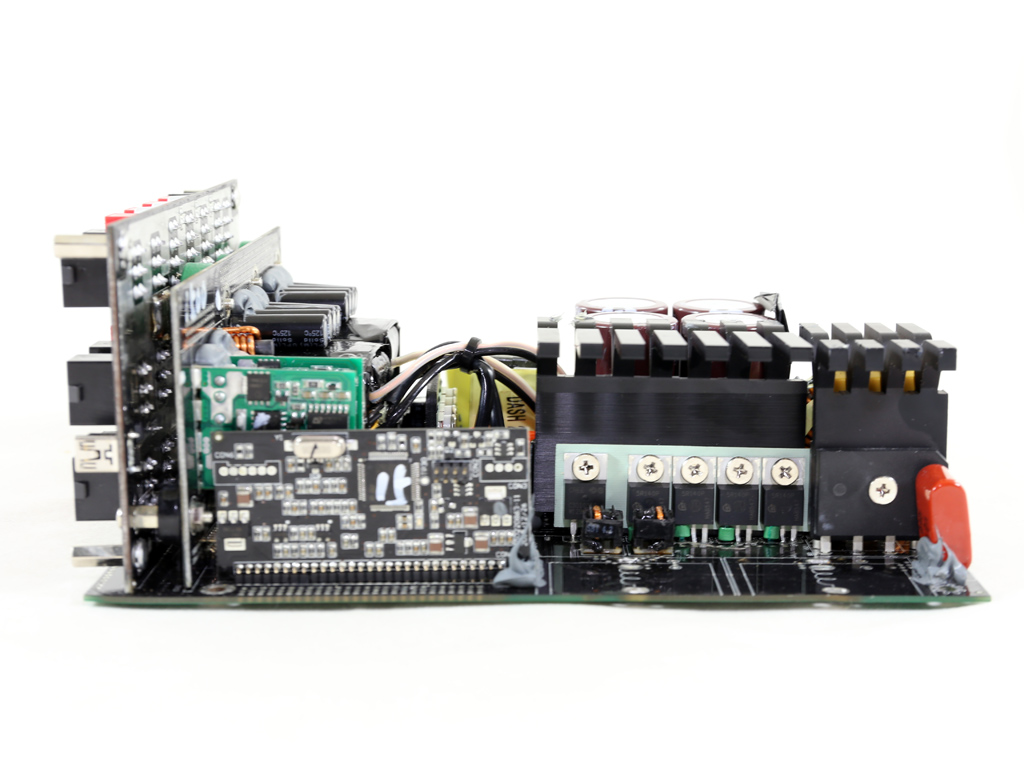

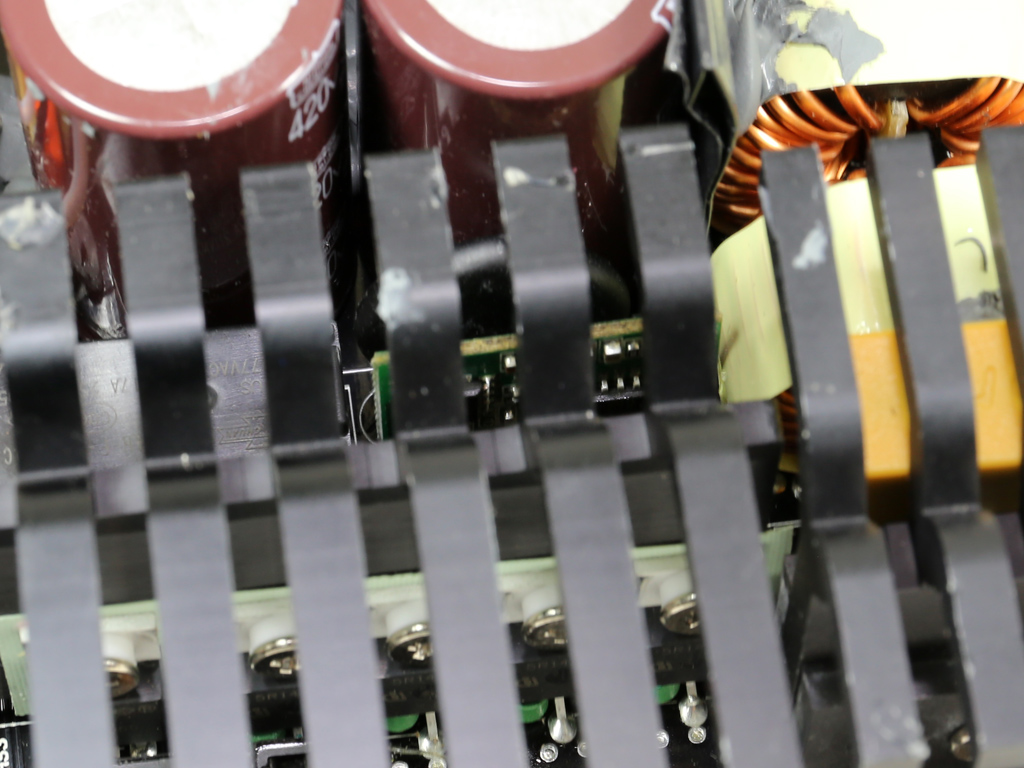

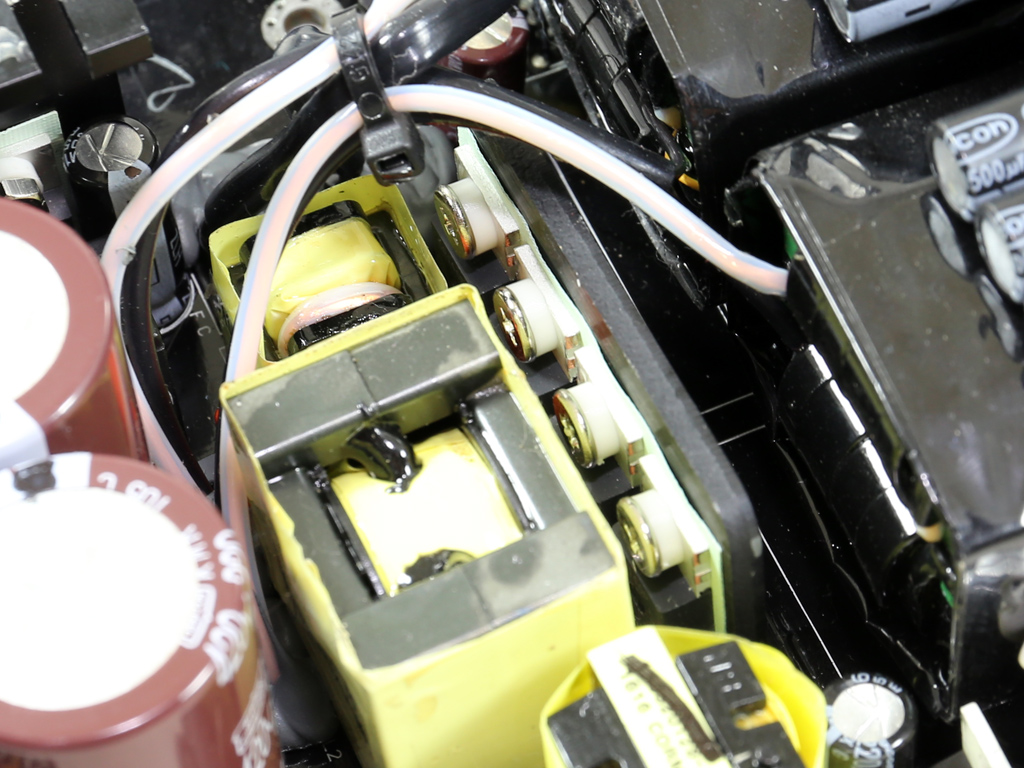

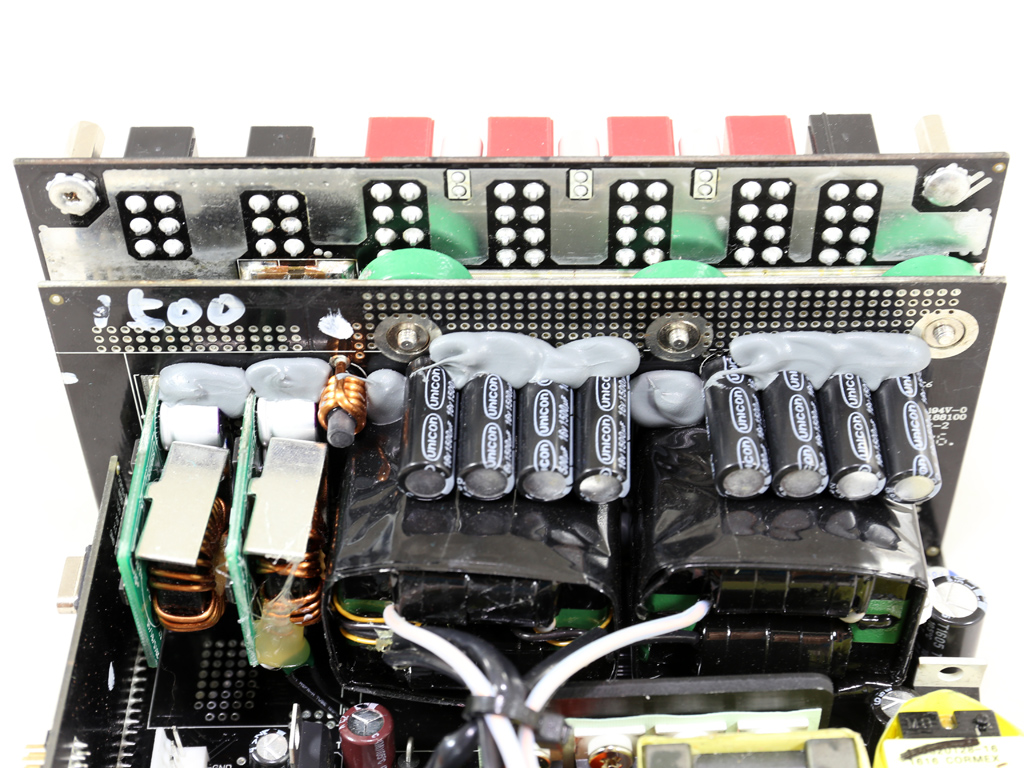

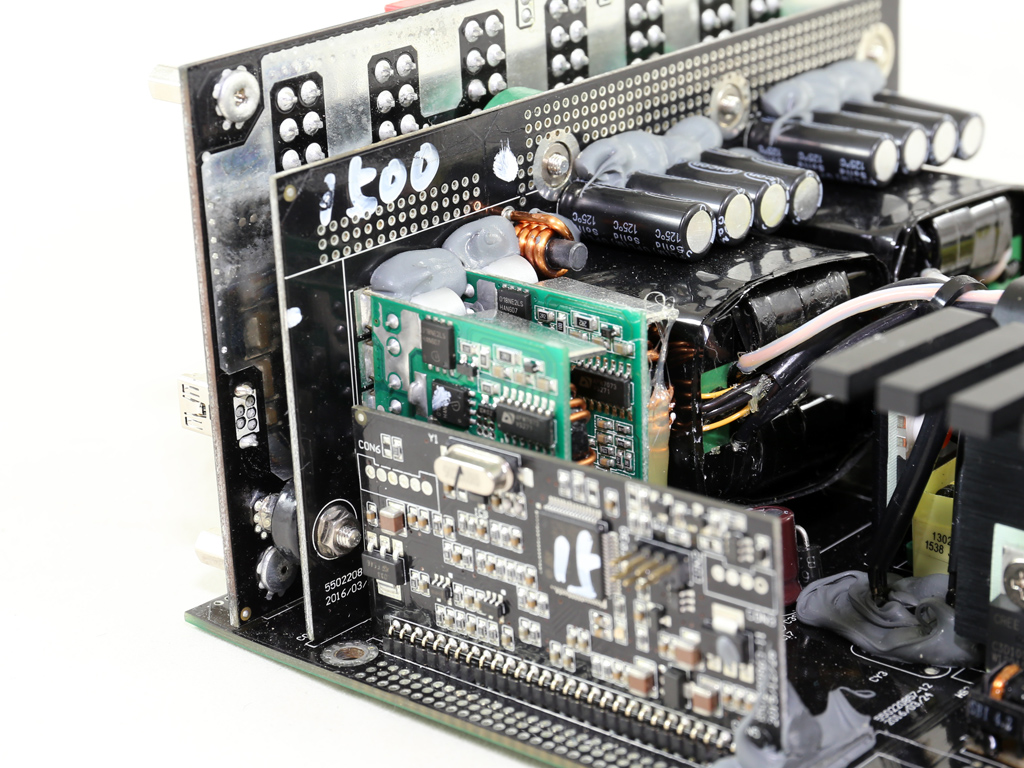

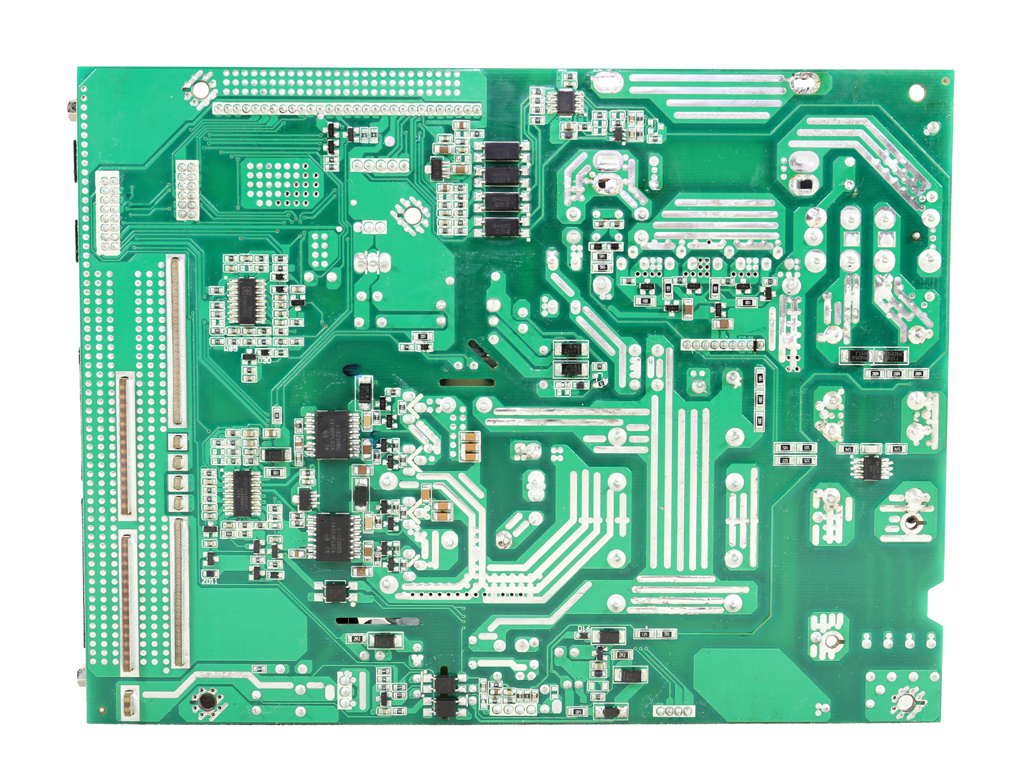

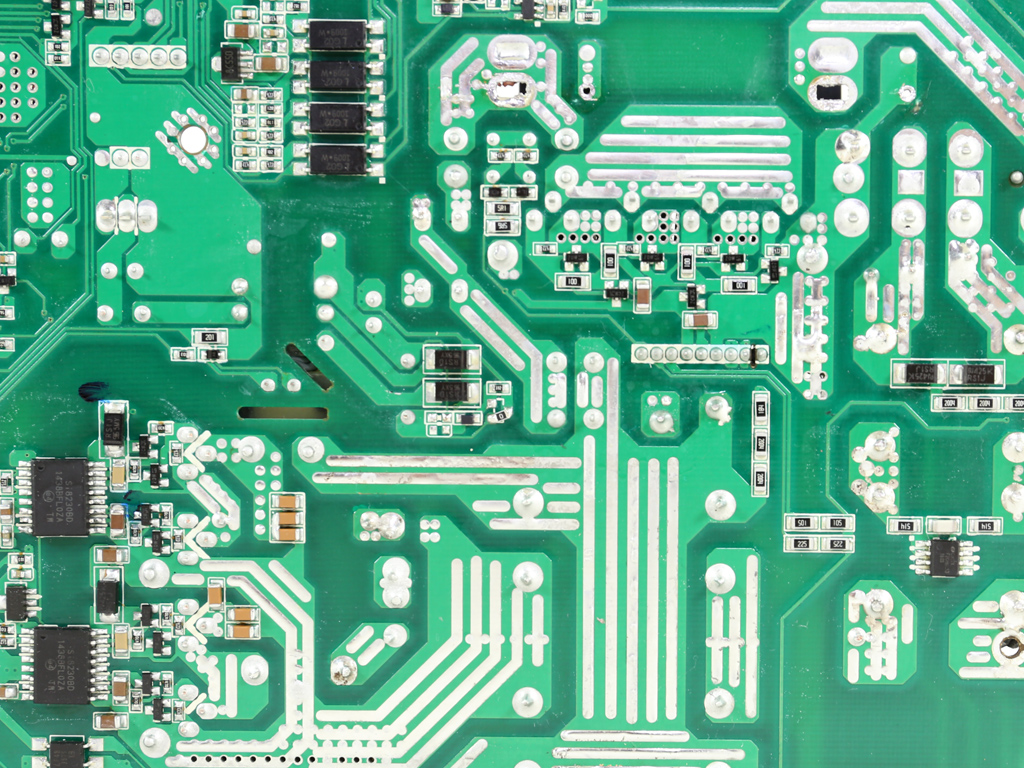

The main PCB is huge. Moreover, the primary heat sink (the only one, since the secondary side doesn't have any) is quite large and features the long fins found on all Enhance platforms. A full-bridge topology is used on the primary side, along with an LLC resonant converter. On the secondary side, a couple of DC-DC converters regulate the minor rails. The +12V rail is generated by several FETs installed close to the main transformers.

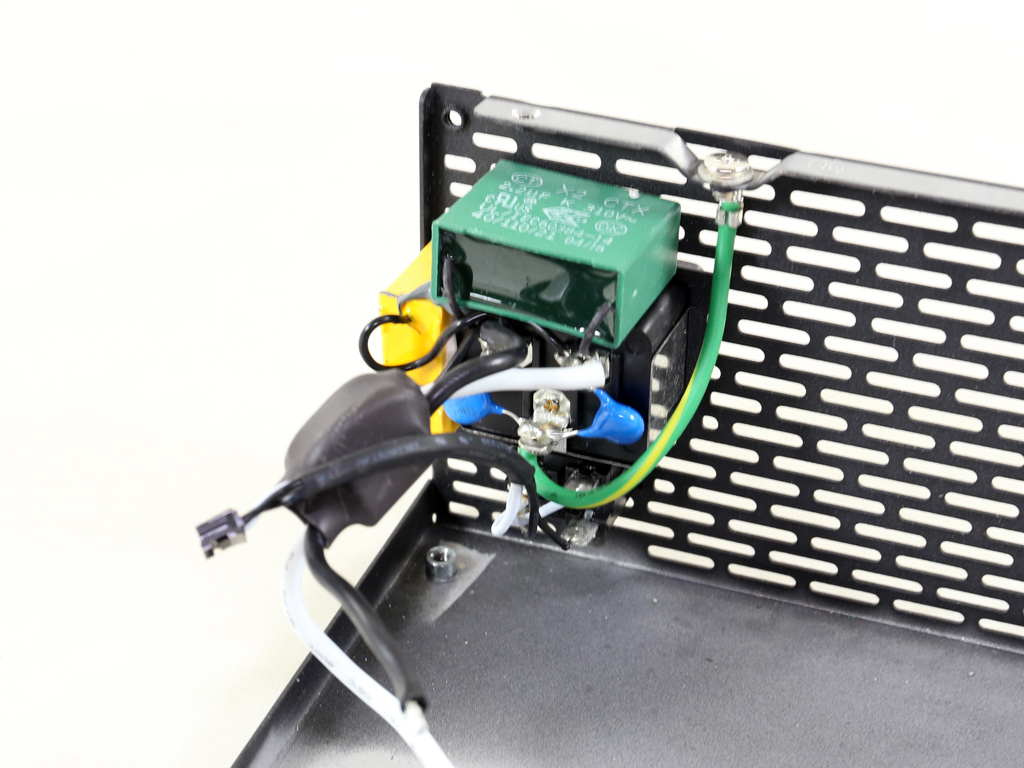

As usual, the AC receptacle hosts the first part of the EMI filter, which in this case includes two X and two Y caps. The second part of the same filter resides on the main PCB and consists of four Y caps, a single X one, two CM chokes, and an MOV. In addition, we find a CM02X on the solder side of the main PCB that blocks current through the X cap's discharge (bleeding) resistors once AC is connected, providing a small efficiency boost.

Two LL25XB60 bridge rectifiers are used, capable of handling up to 50 amps.

The APFC converter uses four Infineon IPP50R140CP FETs along with a couple of CREE C3D10060A boost diodes. We had to remove both PFC chokes in order to identify these parts. Normally we'd expect an interleaved PFC with so many components, where two PFC converters work in parallel with a phase difference among them, providing higher efficiency. However, this platform doesn't employ an interleaved PFC simply because the relevant controller doesn't support it. Finally, the bulk caps are four Chemi-Con KMRs with 330 uF capacity each, or 1320 uF combined. This capacity looks low for a 1.5 kW unit and our hold-up measurements confirm this.

An NTC thermistor protects against large inrush currents. It is supported by a bypass relay.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

A small board, located between the primary heat sink and bulk caps, hosts the APFC's controller, a Champion CM6502S IC. A CM03X Green PFC controller is installed on the same board, reducing power consumption when the PSU is in standby mode.

The main switching FETs are four Infineon IPP50R140CP, which are bolted onto a small heat sink. They are arranged into a full-bridge topology and supported by a Champion CM6901 LLC resonant converter that reduces switching losses and increases efficiency. A couple of Si8230BD ICs installed on the PCB's solder side drive the primary switching FETs.

This PSU's single micro-controller is an STMicroelectronics STM32F302 that provides the full-speed USB interface through which the TPG-1500D-T communicates. This MCU contains an ARM Cortex-M4 clocked at 72 MHz, and it also uses fast voltage comparators, a couple of op-amps with programmable gain, a fast 12-bit DAC, and 144 MHz motor control timers. An SKC-8 clock oscillator is also used.

The -12V rail is generated by a STMicroelectronics L7912CV regulator, which can handle up to 1.5 A.

The standby PWM controller is a Sanken STR-A6062H IC, while a PFR40V60CT SBR rectifies this output.

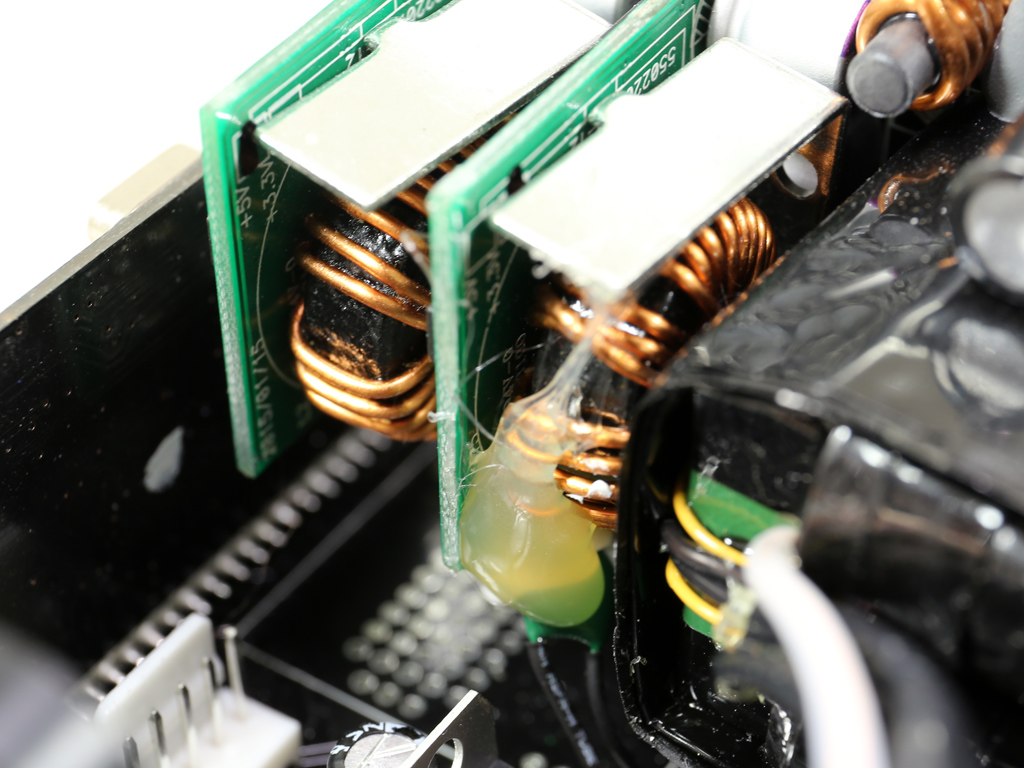

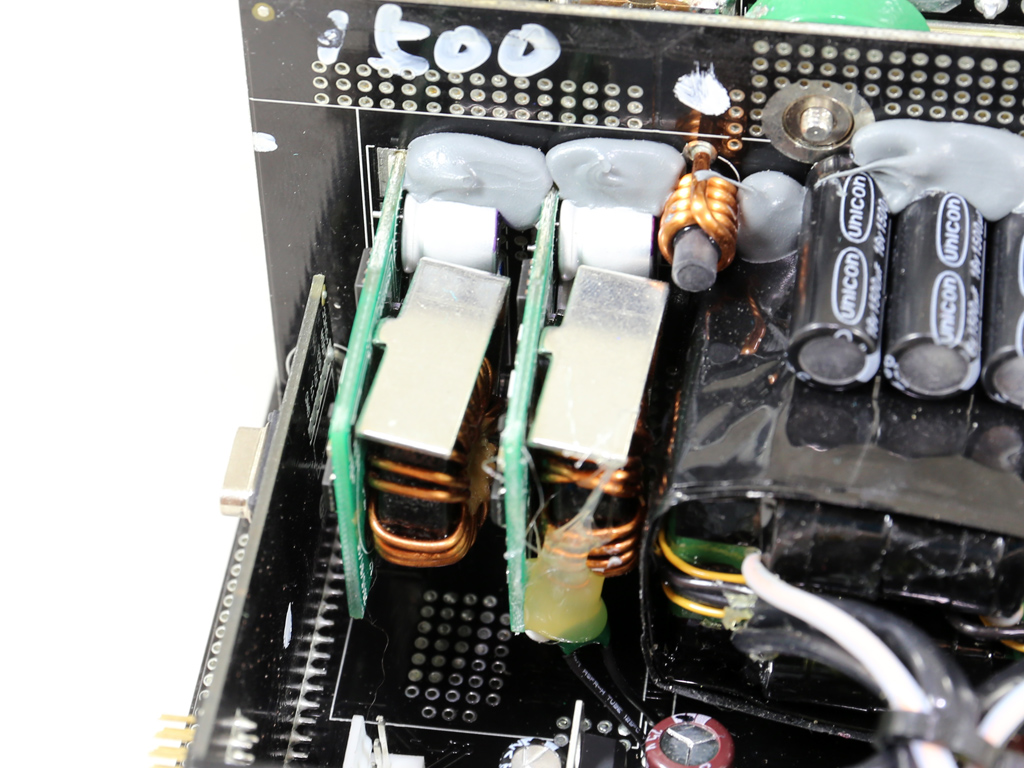

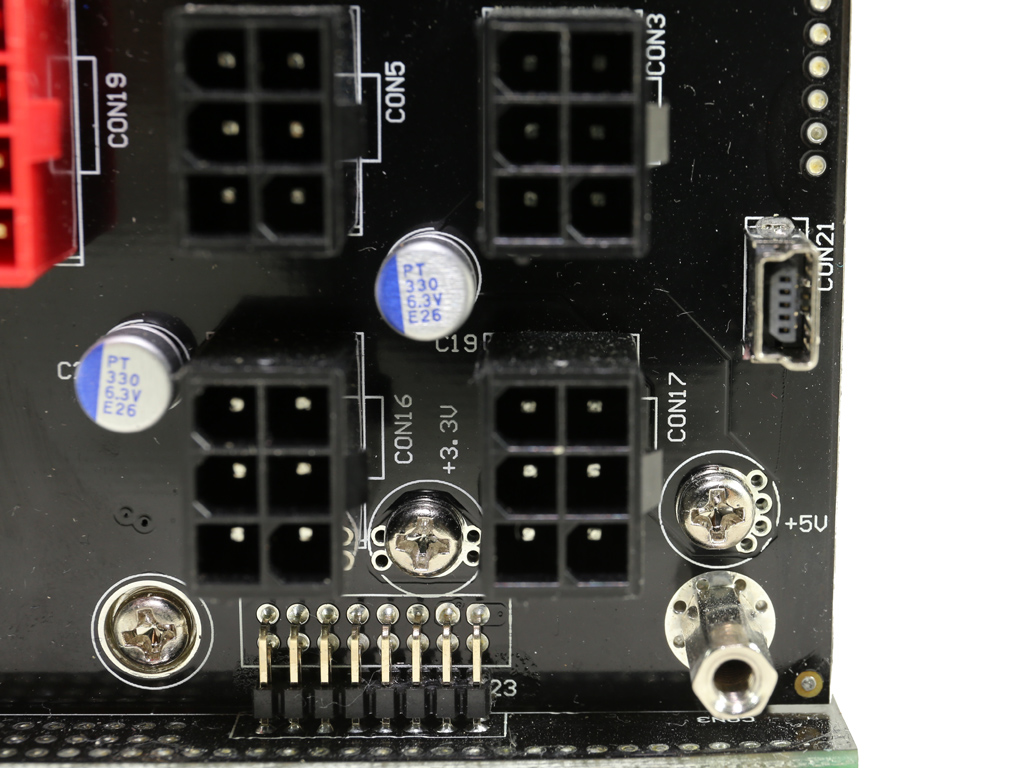

The FETs that generate the +12V rail are installed on a vertical PCB close to the main transformers, reducing energy losses especially under high loads. At the same time, the +12V board is close to the modular PCB as well, so current passes through shorter distances with decreased resistance. Several ferrite rings are installed between the modular and +12V boards in an effort to suppress EMI noise.

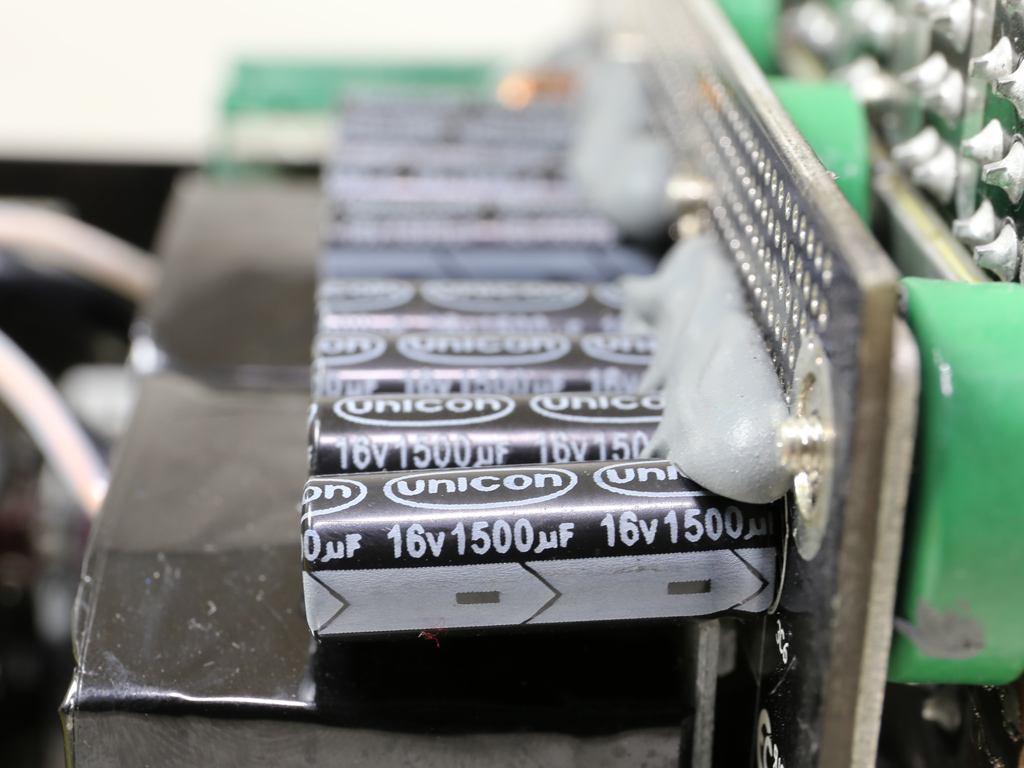

The electrolytic caps that filter the +12V rail are provided by Unicon and rated at 125 °C, thanks to the solid electrolyte that they use. Unicon is a respected brand, but we'd like to see even higher-quality caps in such an expensive PSU, perhaps from Rubycon's or Chemi-Con's high-end lines. The other electrolytic caps, used by the minor and 5VSB/-12V rails, are sourced from Rubycon and Chemi-Con. A number of Unicon polymer caps are also used for filtering purposes.

A couple of DC-DC converters generate the minor rails. Each converter uses two Infineon BSC018NE2LS along with a single Anpec APW7073 PWM controller. Lastly, polymer caps most likely provided by Unicon filter these rails.

We found a loose thermistor on one of the VRMs, which we secured in place with glue.

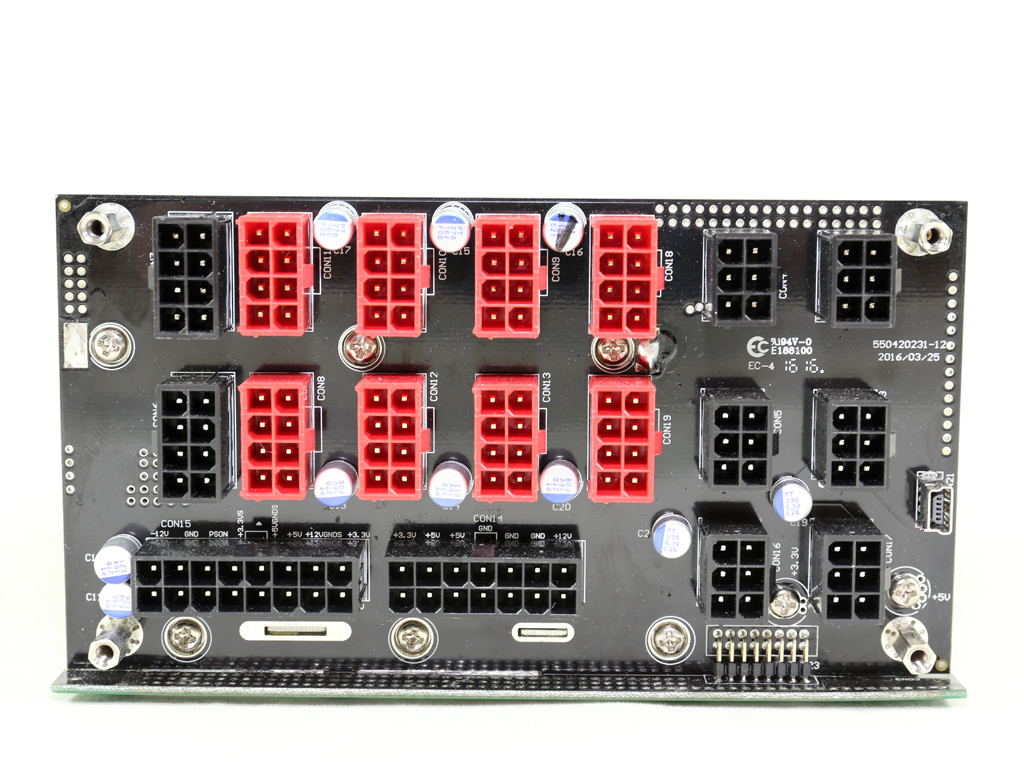

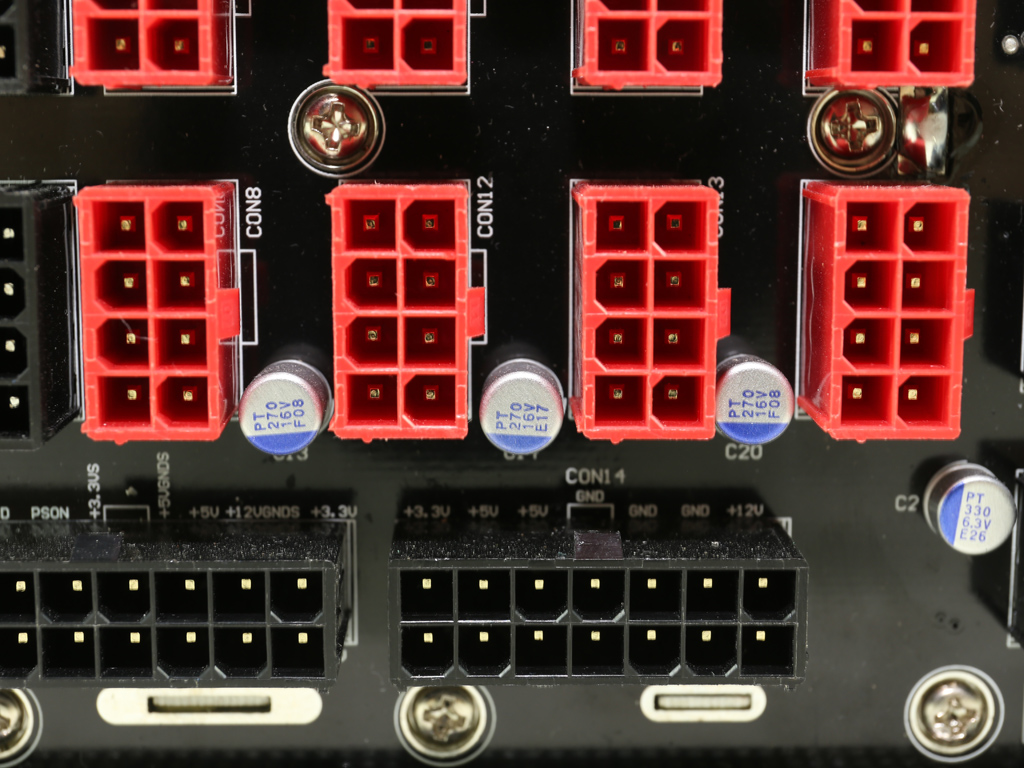

At the front side of the modular PCB, several polymer caps, provided by Unicon, filter the rails.

The protections IC is a SITI PS223, which supports OTP out of the box and also offers OCP for two +12V rails. Of course, this PSU only has one.

The soldering quality is pretty good. Enhance generally has good production lines and tight quality control, so its implementations are typically built well.

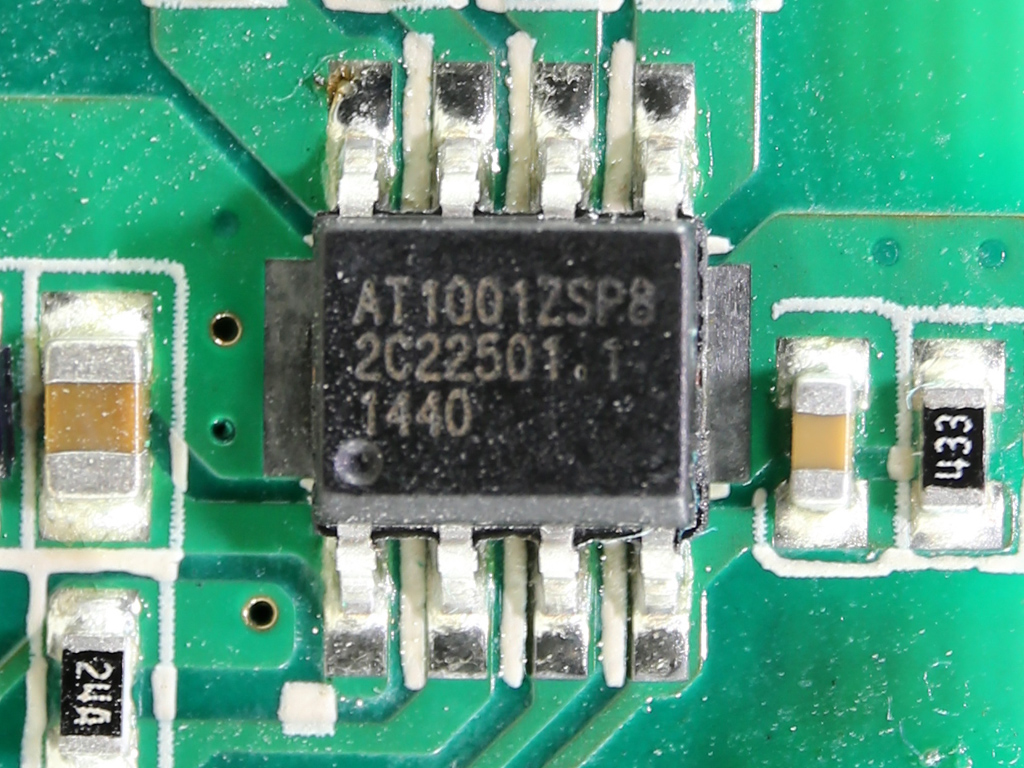

We spot a AT1001Z-DSF002 on the solder side. It's used to convert the analog signal to a PWM duty cycle, which feeds an energy measurement processor. In essence, this IC helps the MCU to monitor the PSU's in and out power in real time.

The fan is made by Hong Sheng and its model number is A1425L12S. This is a high-speed fan supported by a somewhat aggressive profile, so it is quiet only under light loads. According to Thermaltake, this fan uses a hydro-dynamic bearing. Moreover, there is a LED strip installed on the fan, which can be controlled through the DPSApp.

Although the TPG-1250D-T uses the same model, the TPG-1500D-T's fan is able to spin at significantly higher speeds, so these two fans clearly aren't identical. According to Thermaltake, the fan's blades allow for high static pressure, improving cooling. In addition, anti-vibration rubber pads are used on the frame's four corners for lower noise output.

Current page: A Look Inside And Component Analysis

Prev Page DPSApp And Mobile App Next Page Load Regulation, Hold-Up Time, And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

spat55 So basically a poor performing PSU at this price point and the only good thing is a RGB fan I won't see because my PSU is always face down and preferably under a PSU cover, okay got it.Reply -

g-unit1111 What's the point of having an RGB ring on a bottom mounted PSU where nobody will see the fan anyways? :??:Reply

Also those cables - the word "eyesore" comes to mind! I would be replacing those with some custom ones ASAP! :ouch: -

spat55 Reply18628558 said:What's the point of having an RGB ring on a bottom mounted PSU where nobody will see the fan anyways? :??:

Also those cables - the word "eyesore" comes to mind! I would be replacing those with some custom ones ASAP! :ouch:

Yeah it's just a crap unit which is hoping the kids orgasm over those RGB lighting, it's doing my head in but I'm sure it'll soon become mainstream then die. -

powernod Extremely dissapointed by Thermaltake.Reply

Only at the TPG-1250D-T they used the new & excellent CST platform by CWT.

For all the other wattage models so far, ( 850 & 1500watt ) they used mediocre platforms by Enhance.

I had high expectations for Tt's new line of PSUs, but they were proven futile. -

Virtual_Singularity Thanks for another thorough, excellent, psu review, great job Aris. Disappointed by TT, as well. That is one flawed, less than mediocre (esp for the price) unit, OEM'd to Enhance by another predictable 3rd party company. Some pretty lights on the fan and it's 1600 watt helm of their "flagship" series moniker is supposed to justify that $430 pricetag? Fails to meet minimum atx specs in several areas, hold up time for such an expensive unit is also unacceptable. Similar to the MasterWatt Maker, it can't hope to compete with similar units from their competitors, which are lower in price, better in efficiency and overall specs.Reply -

Nuckles_56 The 12V CL1 was certainly one of the more interesting waveforms I've seen in a while. But overall I'm pretty disappointed in Thermaltake for producing such a over priced under performing PSUReply -

Br1414 Typo? 16 amps is the max legal load on a 20 amp 120v plug, thus option A apparently. Option B appears to be the old wall A/C style 20 amp 240 volt plug. Both a t slot styles. So maybe you rig something, but more or less you need an electrician just to use this thing safely! I guess you got the money...Reply -

Valantar Individually sleeved cables in the traditional "ketchup and mustard" colours? Wow, that made me laugh. Out loud. Might be suitable to some kind of early 2000s retro theme build?Reply

Also, I love the pixelated 8-bit-ish thing you've got going on with the ripple graphs on page 9. Perhaps

Otherwise, this was pretty much as expected. A useless product (the world does not need more 1000W+ PSUs), with useless features (RGB in a place where it'll be invisible in 90+% of modern cases), at a useless price point. That it performs badly as well just adds icing to the turd.