Microsoft develops breakthrough chip cooling method — microfluidic channels can cut peak temps by up to 65%, outperform conventional cold plates by up to 3x

Embedded liquid cooling.

As data center-grade processors are getting hotter, companies invent more and more creative ways to cool them down. As Nvidia and its partners are reportedly experimenting with new cold plates and immersion cooling for next-generation AI GPUs, Microsoft is proposing to etch microfluidic channels on the back of an actual chip to reduce its peak temperature by up to 65%, making it three times more efficient than cold plates.

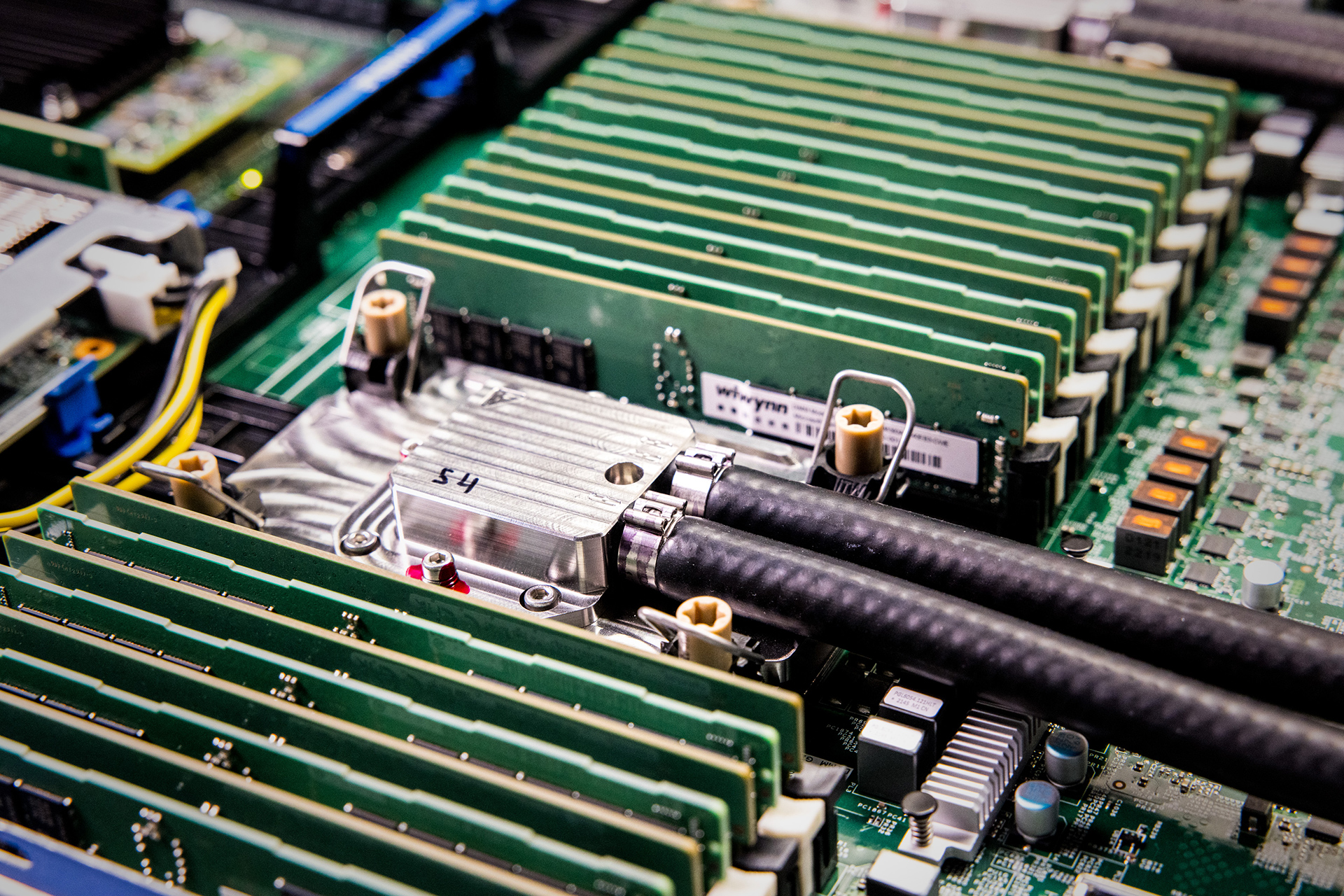

Microsoft says it has developed a cooling system that routes fluid directly into microchannels etched on the back of the silicon die to guide the coolant to high-heat regions inside the chip. Flowing liquid inside the chip greatly reduces the efficiency of the whole setup, as liquid can almost 'touch' hot spots inside the processor, whereas in the case of more traditional liquid cooling or even immersion cooling, heat emerges several layers away from the coolant.

To optimize thermal routing, Microsoft worked with Swiss startup Corintis, which used artificial intelligence to refine channel geometry. Rather than simple straight lines, the final layout mimics patterns found in nature, such as leaf veins or butterfly wings, to guide fluid more efficiently. Also, microchannels must be small enough to function effectively but not so deep that they weaken the silicon, risking mechanical failure.

However, etching microfluid channels can only be done as a separate sequence during chip manufacturing, which means additional steps and costs. Alternatively, Microsoft proposes to produce a microfluidic heat transfer structure separately and cool down one or two chips using the structure, according to a patent. Such integration requires new packaging methods to prevent coolant leaks and maintain durability.

By now, Microsoft has discovered the right coolant fluid, developed precise etching techniques, and managed to integrate these into chip production. Therefore, Microsoft considers its technology ready for full-scale production within Microsoft's chip development pipeline. Third-party customers may license the technology from Microsoft Technology Licensing, LLC.

"Microfluidics would allow for more power-dense designs that will enable more features that customers care about and give better performance in a smaller amount of space," said Judy Priest, corporate vice president and chief technical officer of Cloud Operations and Innovation at Microsoft. "But we needed to prove the technology and the design worked, and then the very next thing I wanted to do was test reliability."

Microsoft is testing the cooling solution on servers running simulated Teams workloads, where uneven heat loads across many services are handled more efficiently, enabling higher burst performance, which helps to reduce the number of servers that otherwise sit idle when not in use during peak loads that tend to happen on the hour or on the half-hour.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Lab tests showed that this new technique can reduce peak silicon temperatures by up to 65%, depending on the specific chip and usage. Compared to cold plates, the cooling performance improvement was as much as three times, depending on workload and setup. The method also enables cooling without relying on ultra-low coolant temperatures, saving energy otherwise needed for chilling, Microsoft noted.

Microsoft has been experimenting with its microfluidic channels liquid cooling technology for years and demonstrated the first prototype in 2022, so by now, the company has plenty of lab experience with the technology. Yet, Microsoft is not the only company to develop methods to produce embedded coolant channels inside a chip or chip package. IBM also has appropriate patents.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button!

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Eximo Pretty sure this isn't a new idea. I recall reading about IBM testing out this same concept. Even called it microfluidic.Reply -

Techsavi01 This tech has got me fired up! It's been a long time since we've had such a leap in cooling performance. This will transform gaming and allow for insane overclocks for cpu's and gpu's! I am using nanotube cooling for my processor and it easily cools by about 10C over liquid metal. I also carved very small channels into the backplate to allow the tubes to get closer to the die. But this tech will literally transform the industry not just for gaming but AI and computing all together. Exciting 😄Reply -

dimar This is just to cool the chip, right? But the heat still has to go somewhere. And my room gets hot when using RTX 5090.Reply -

usertests Reply

Who should I send my license payments to???! AaahhhhhrghEximo said:Pretty sure this isn't a new idea. I recall reading about IBM testing out this same concept. Even called it microfluidic. -

bit_user Reply

Details, please?Techsavi01 said:I am using nanotube cooling for my processor and it easily cools by about 10C over liquid metal.

You mean the IHS?Techsavi01 said:I also carved very small channels into the backplate to allow the tubes to get closer to the die. -

bit_user Reply

Yeah, this is just about getting heat out of the silicon more efficiently. As the article points out, if it avoids the need for chilling the liquid, there are some system-wide efficiency and cost-reduction gains to be had. However, I'd guess those are probably less of a motivating factor than simply being able to run the chips faster.dimar said:This is just to cool the chip, right? But the heat still has to go somewhere. -

Techsavi01 Reply

No I meant the die itself. The IHS is the heat spreader (metal backplate that covers the die). Adding small channels into the IHS works two fold. Allowing your thermal medium to make contact with the IHS in 3 dimensions not just 1. Secondly, shaving any of the IHS metal away allows for closer contact to the die itself. Less metal between the CPU die and cold plate means less insulation between copper cold plate and the source of the heat, the die. To elaborate on nanotube cooling tech... The tubes facilitate transfer of heat from point A to B more efficiently than other thermally conductive materials such as paste or liquid metal. They also increase in efficacy rather than decrease like your more standard mediums. Never having to repaste the CPU from wear.bit_user said:Details, please?

You mean the IHS? -

bit_user Reply

Yeah, not as bad as Judith Priest, I think!jg.millirem said:Judy Priest -> Judas Priest

: D

When I saw that, I wondered whether it was her maiden name and then couldn't decide whether her parents were metal heads or probably had never heard of the band.

Let's say it was her maiden name and she had a reputation for being very stern. Do you suppose some might've called her the Iron Maiden? Okay, okay, I'll stop!

🤣 -

Eximo Reply

It could very well be the same people having gotten jobs with MS instead of IBM. A little digging I found articles and research papers from 2016 on the subject. Though IBMs plan was a little more ambitious, they also wanted to use it for power delivery.usertests said:Who should I send my license payments to???! Aaahhhhhrgh