Thermal Paste Comparison, Part Two: 39 Products Get Tested

It's time for the numbers. In addition to testing liquid metal compounds and thermally conductive adhesives, each paste is discussed on its own merits before we chart out the results of four usage cases. After all, these products behave differently.

Coollaboratory Liquid Ultra: Application Problems And Clean-Up

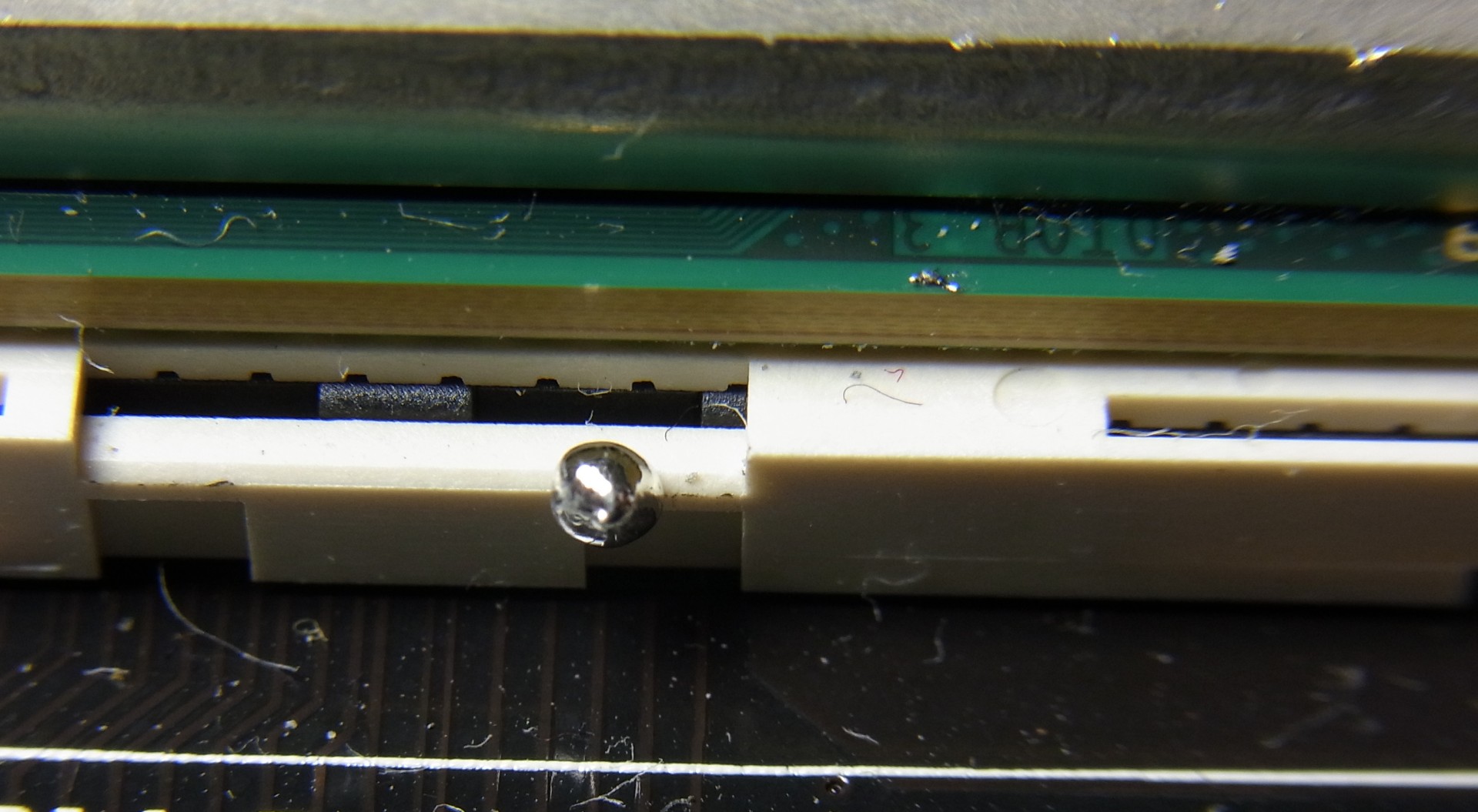

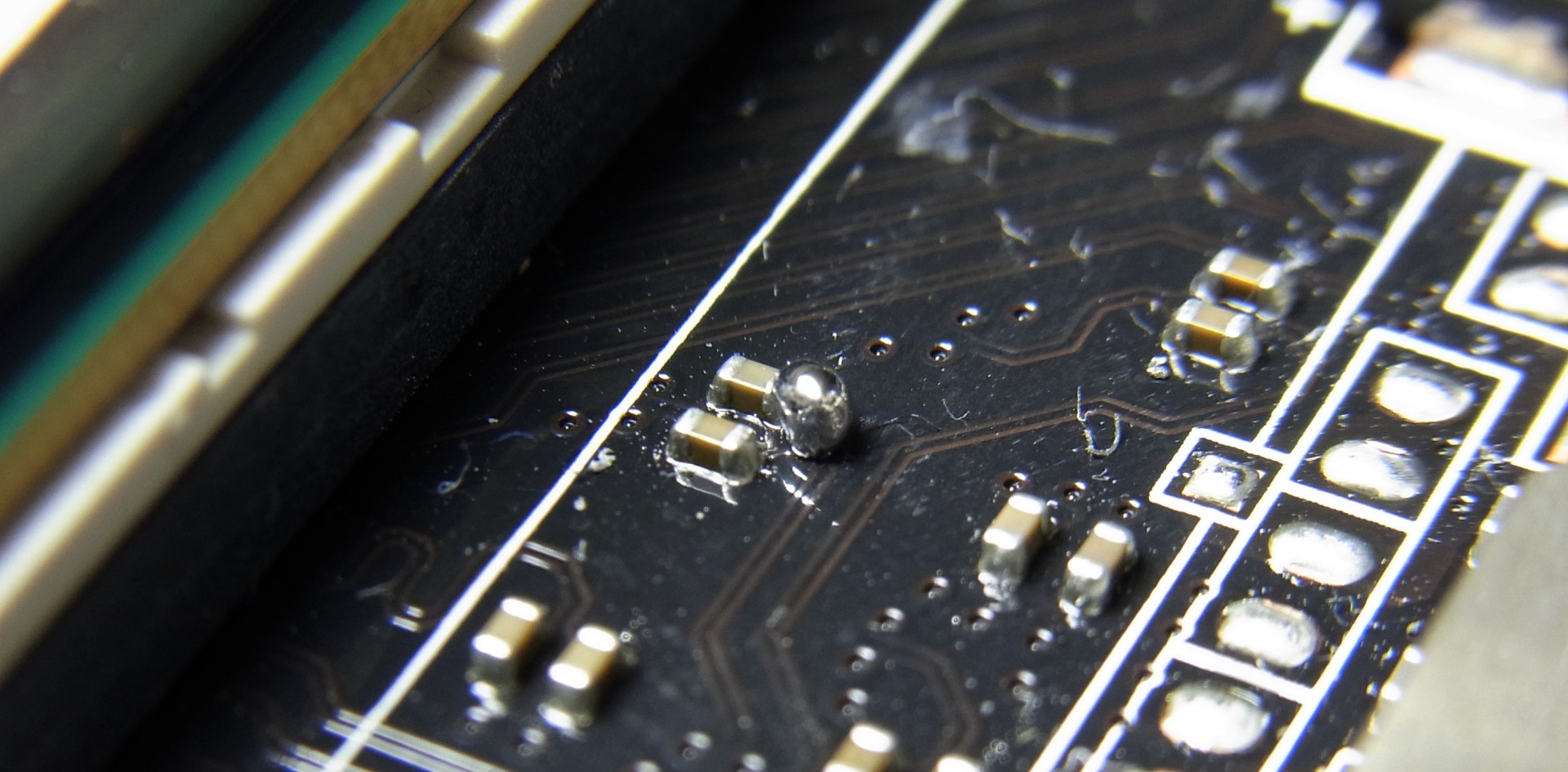

The pictures below are staged. But their purpose is to warn you what might happen if you're not careful, or if you don't pull the CPU from its interface before applying the liquid. Even if you're being meticulous, small droplets will separate and run away. So, keep a thin, clean brush handy to deal with them. Don’t spread them or wipe them away; instead, lift them up!

If you have never experienced the sinking feeling of spotting a liquid metal droplet between CPU pins, look at the bottom picture. However, the tiny droplets at the PCB’s edge may be even worse because they're barely visible to the naked eye.

Cleaning with Chemical Agents and a Wire Brush

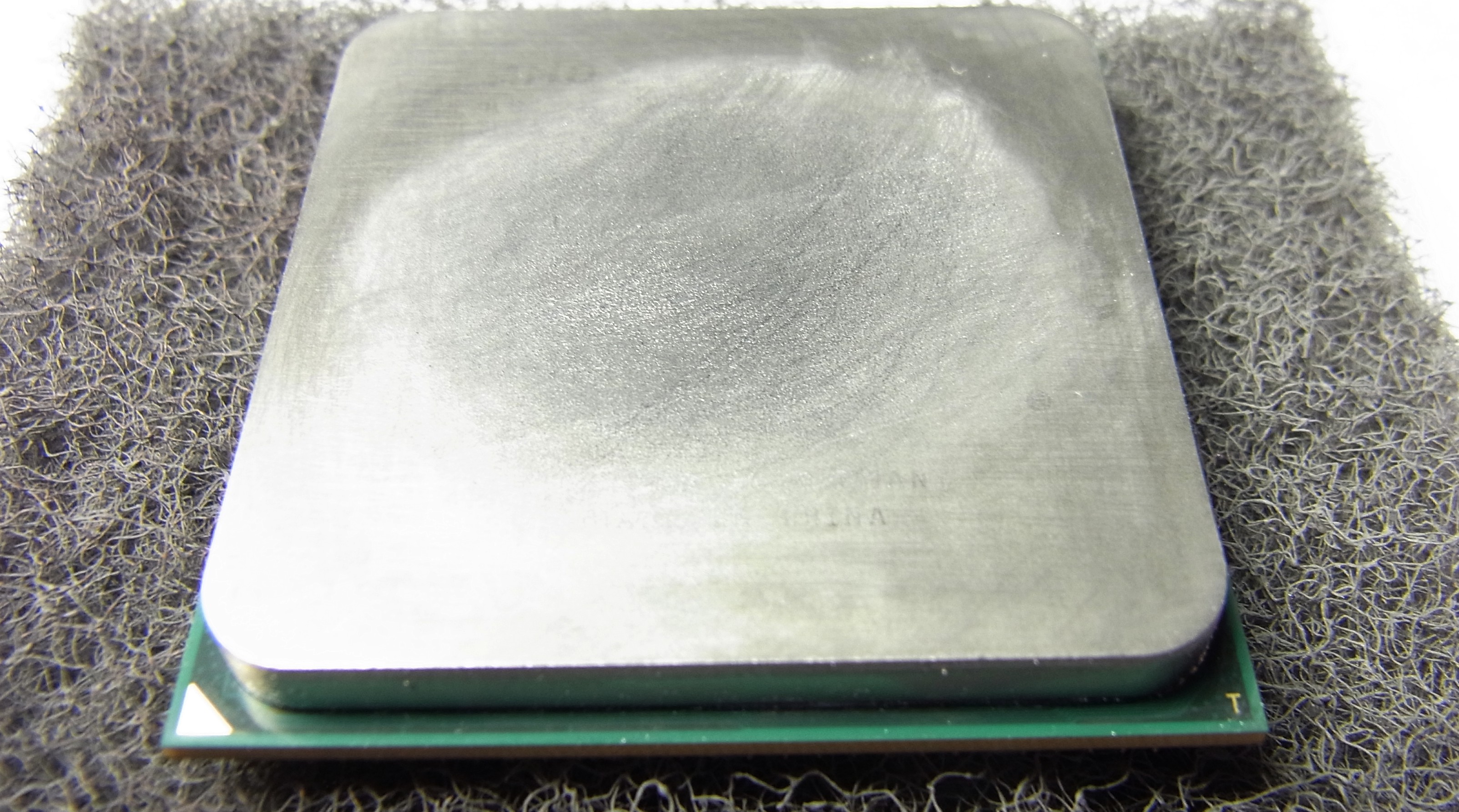

It's one thing to apply liquid metal. Removing it is an entirely different ballgame. Even popping off the heat sink can be a challenge. It's very easy to pull an AMD processor right out of its locked socket if you're not extra careful. Make life a little easier by starting the process while the processor is still hot, and detach the heat sink by gently turning it left and right. If you roughed both the heat sink and spreader, you're going to be met with resistance. You might be best off mounting a smooth heat sink on a roughed spreader. This combination seems to come apart most easily.

The cleaning agent from Coollaboratory's cleaning set works, but it won't get everything off. Thus, you still have to use the wire brush. Scrape, apply more solvent, wipe, rinse, and repeat. As you might guess, this takes some time.

In the end, you'll probably wind up with two scratched-up surfaces. Luckily, I bought two closed-loop liquid coolers, allowing him to continue testing conventional pastes with a smooth sink.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Coollaboratory Liquid Ultra: Application Problems And Clean-Up

Prev Page Coollaboratory Liquid Ultra: Application Next Page Coollaboratory Liquid Ultra: Performance Measurements

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

dragonfang18 I loved the toothpaste part. What about Vicks Vaporub? I wonder how that thing would do.Reply -

TehDudeMan Great article guys! As a reader for over 10 years pretty much daily, this reminds me of the old Tom's Hardware. These type of in depth articles on enthusiast products are what I love.Reply -

Matt Edwards A great article, agree the application of the compound, not the compound itself is most important.Reply

Like ledpellet I too am curious about these diamond compounds. Wonder if it offers similar results to the Coollaboratory products with an easier application, or if the results simply don't justify the price. E.g in Australia, Innovation Cooling IC7 Diamond 7 Carat Thermal Compound Paste - 1.5G can be found for as much as $25. The cheapest I have managed to find it for is $15. For that price it would want to be good considering the leading GELID GC Extreme, can be found for around $8. -

danwat1234 Coollaboratory Liquid Ultra isn't all that good after a year of hard use. In fact, it completely hardens / dries. On my X9100 after 9 months of nearly 24/7 100% load, I started seeing high temps and after 1 year auto shut downs while crunching. Turns out it was shutting off because it hit the 105 C thermal protection.Reply

Opened it up; thermal compound was as hard as a rock. has to pocket knife blade and sand it down.

So for longevity it sucks. That is something to consider, not just initial performance, but performance months and years down the road. Especially for laptops that aren't designed to be opened up frequently for repasting.

After trying Liquid Ultra many times and having it fail on me, I've put on Arctic MX-2 that has a supposed 8 year durability rating. Initial performance is great, we'll see how it lasts (been 3 weeks so far). -

slomo4sho CLU and Arctic MX-4 are both great products. MX-2 and MX-4 can often be found free after rebate so they are an exceptional value.Reply