6 Common Cura Errors and How to Fix Them

Avoid these mistakes when using the popular slicer.

Just like any other application, Cura can experience occasional failures and common errors when one is preparing designs for 3D printing. The errors range in different forms, from issues related to the 3D model you’re using, like manifold errors, to Cura just not slicing files. These errors can occur even when you are using one of the best 3D printers and configured the profiles appropriately. Below, we discuss the main issues you can encounter with Cura and how to solve them.

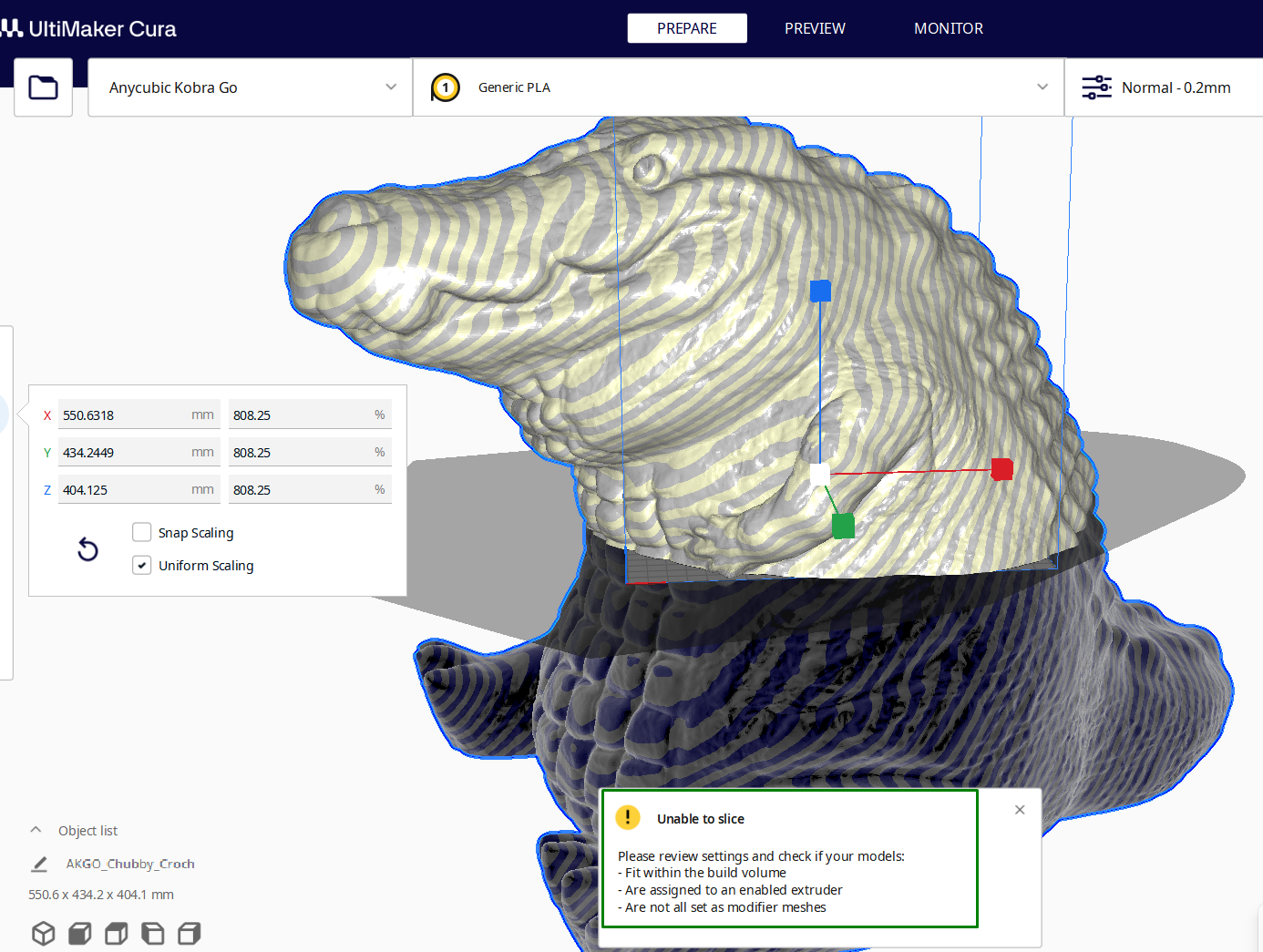

1. Cura Unable to Slice 3D Models

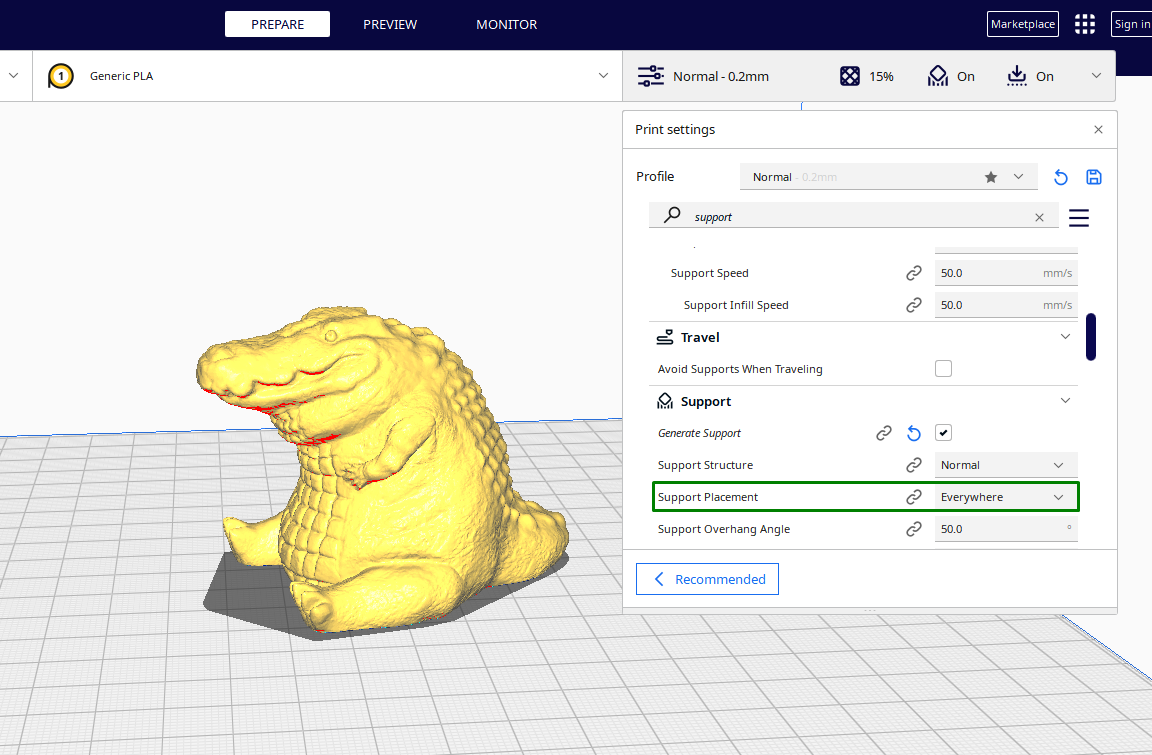

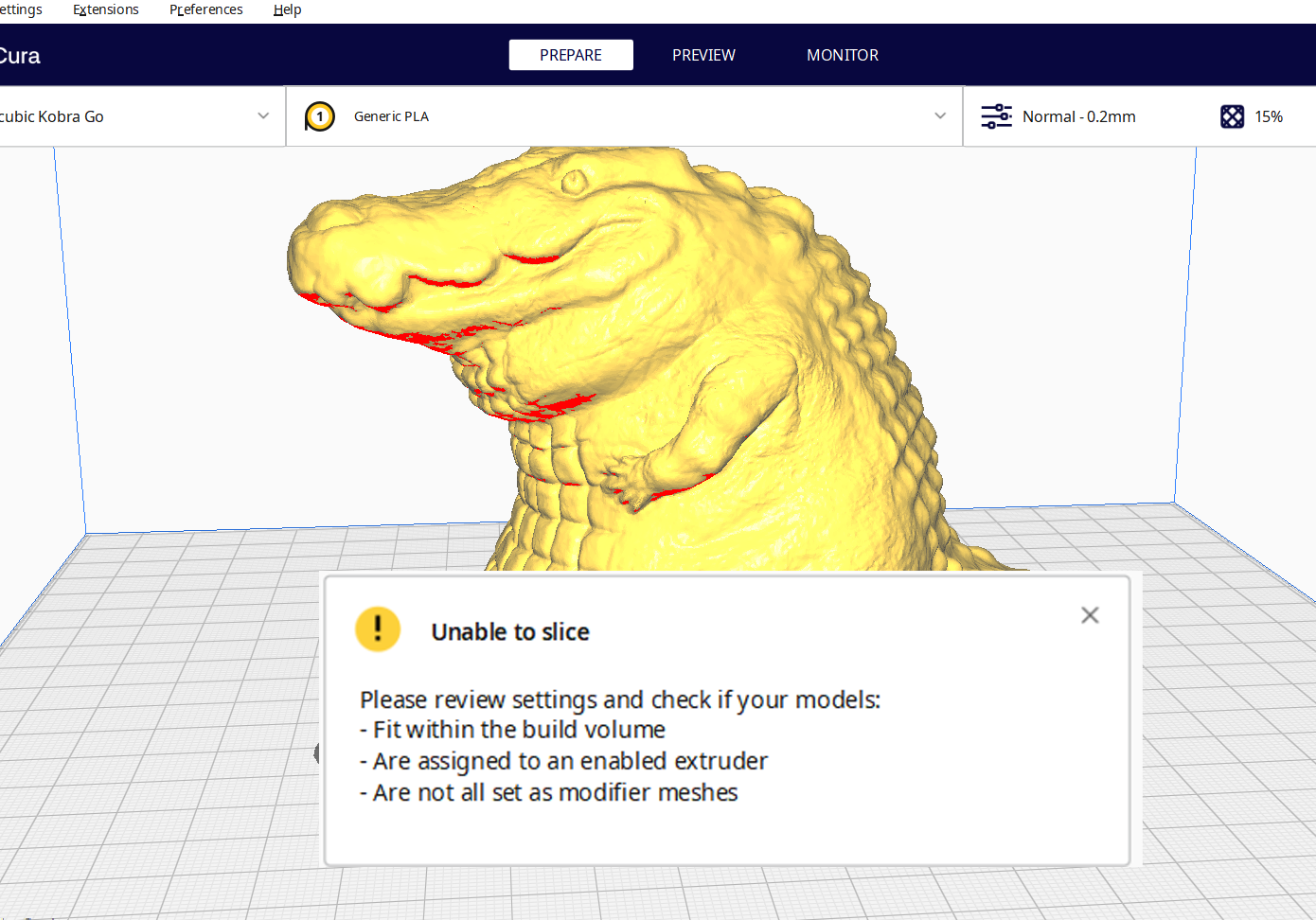

Cura not being able to slice can result from various factors, including problems with the file itself and issues with the software. To fix this, you need to check the model itself and ensure that it’s not too big for your build plate, and if it is, you have to reduce the size. For example, in the image below, the file is too big than the build plate and it generated the error “Unable to slice.

After scaling it down, it was able to slice appropriately. You can reduce the size of your file using the scale tool or you can split the 3D model into various separate files and arrange them on the build plate.

If the file fits the build plate well and Cura doesn’t slice, you can restart or update it to the latest version to see if it does. It’s also important to check your computer and ensure that it meets the system requirements for running Cura because if it doesn’t, it will struggle to slice files, especially complex ones, which require more memory and power.

If the model has issues that require repairing, Cura will give errors, which we will discuss more below.

2. Model Has Missing or Extraneous Surfaces

Missing surfaces errors usually occur due to incomplete geometry or some sections of the design missing during the 3D modeling process. Extraneous surfaces can occur because of overlapping geometries, duplicate faces, or other inconsistencies within the surface of the model.

To address this issue, you should inspect the model using 3D modeling software to identify and fix the issues before slicing. As you fix the issues with the model, you should also consider the orientation of the model when you import to the slicer to help avoid other issues that can occur.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

3. 3D Model Not Manifold

When you face such an error, it means that the model has geometric problems that prevent it from being sliced. These problems can include holes and gaps in the meshes, open edges, and even intersecting faces. The slicer cannot properly slice the file if there are these issues, as it relies on solid, closed geometry to generate toolpaths accurately. If you decide to continue slicing the file even with these issues, the final print will have gaps and missing sections, or it can even fail to print.

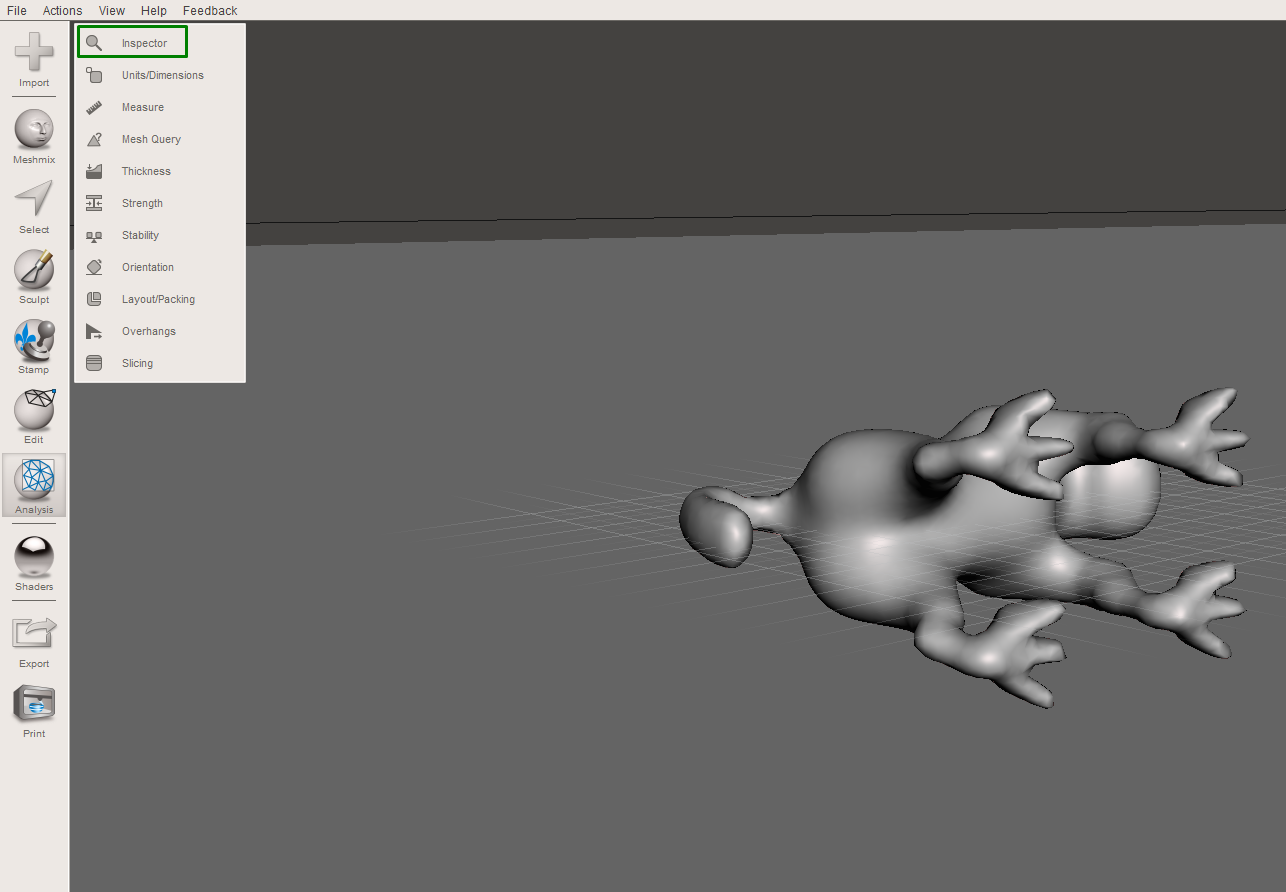

You can use various tools to fix this issue, such as Meshmixer. To use it, you will first import your file, then go to Analysis > Inspector to identify the non manifold parts.

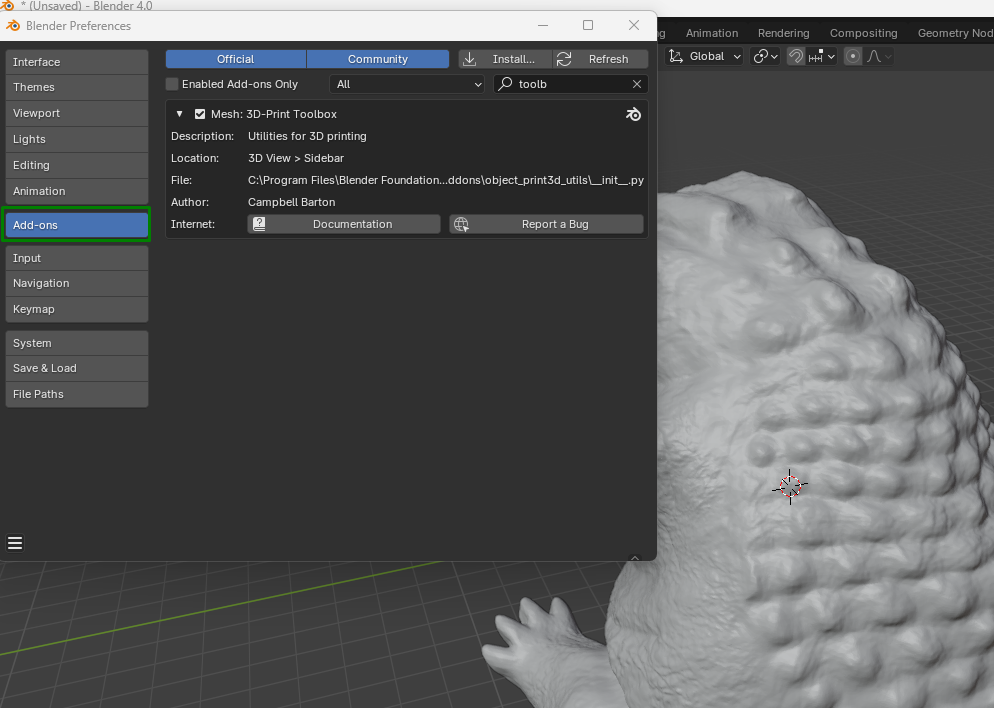

If there is an issue with the file, it will display in the new window that launches, and you can click on Auto Repair All to fix it. Another essential tool that you can use to repair your file is the Blender. Once you import your file, you need to activate the 3D printing add-on. To do this, go to Edit > Preferences > Add-ons then search for 3D-Print Toolbox and then select the checkbox.

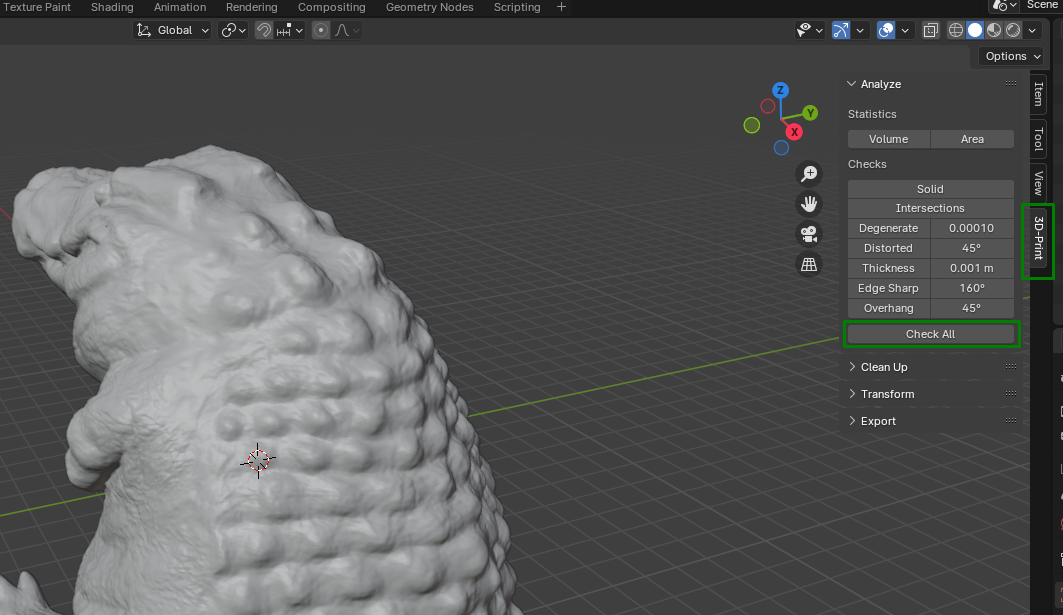

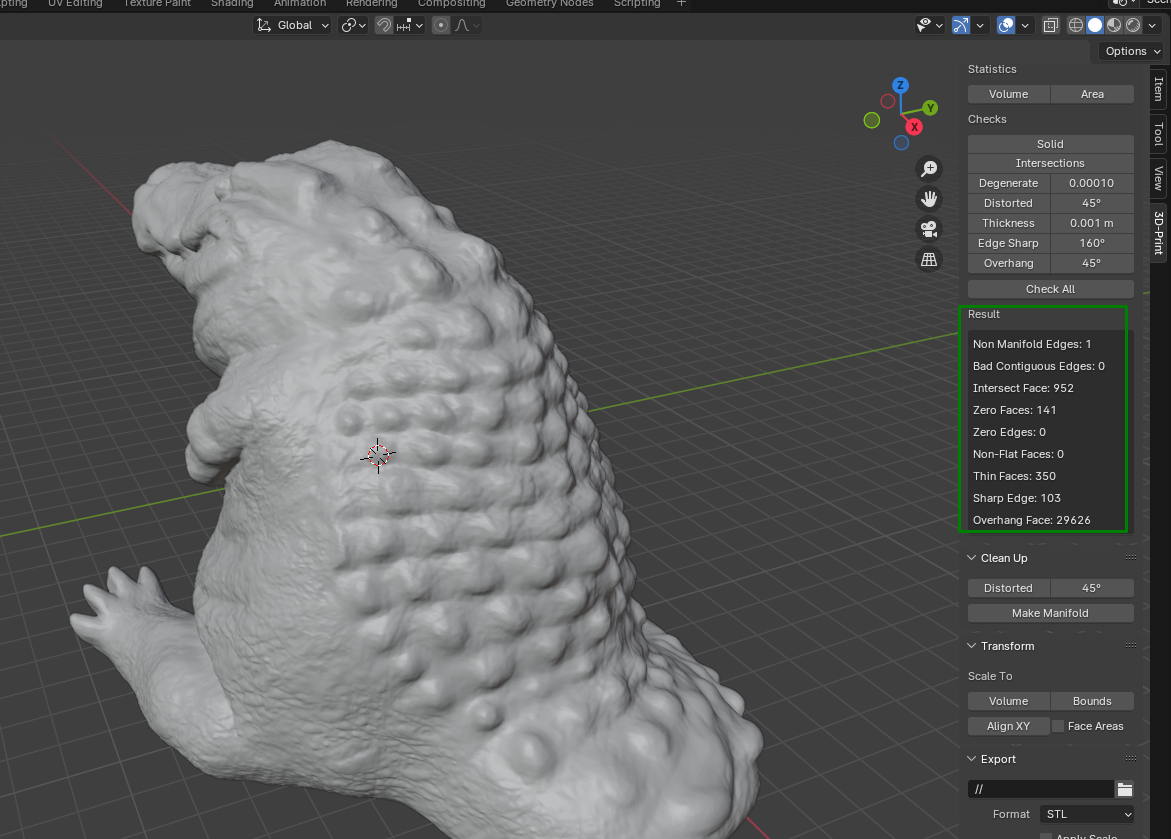

Click on the 3D-print option near the options section and then select Check All to start analyzing the model.

After analyzing, you will see if there is any issue with your 3D model. In my case, I see one non-manifold edge and other problems, as shown in the results section below.

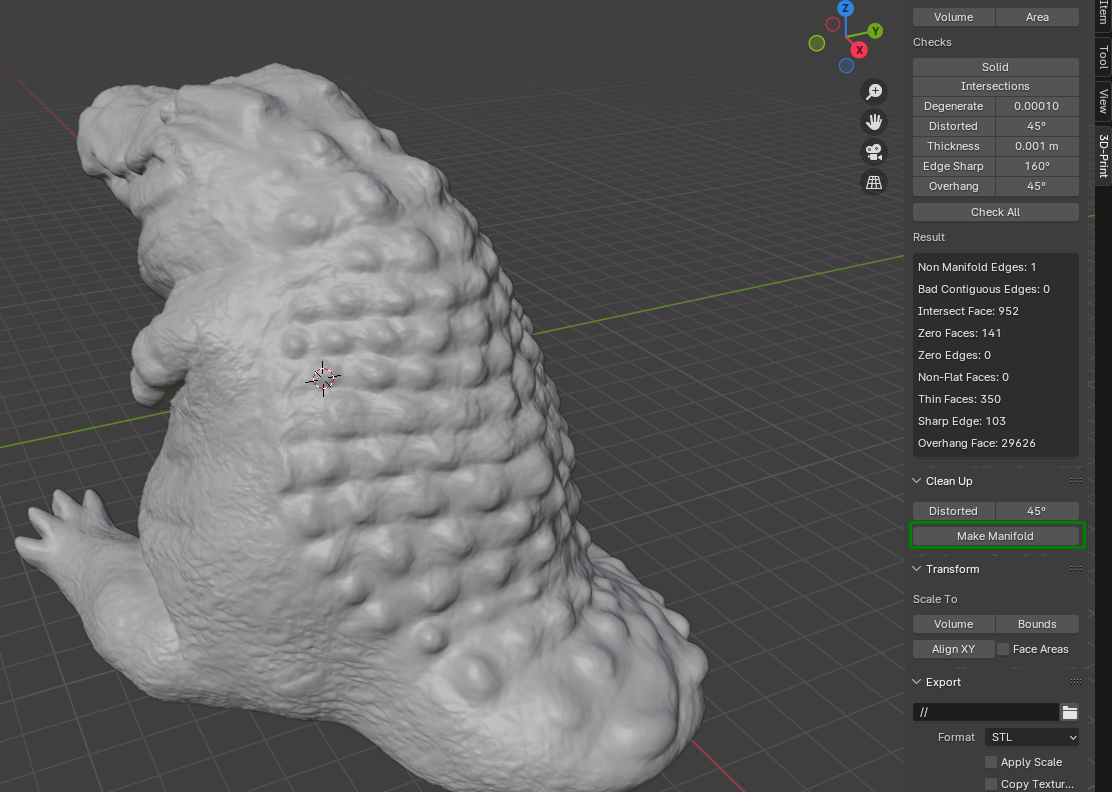

To fix the issues, we shall go to the Clean Up section and click Make Manifold.

The software will fill all the gaps, non-manifold edges, and inverted normals. Depending on the complexity of the model, it will take a while to finish. Once it is done and you check again, you will realize the issues have disappeared. You can then export the model and reload it to Cura to slice. Fixing this problem will also, in most cases, fix the other error of the 3D model not being watertight.

4. Configuration Errors in Cura

Configuration errors can result from factors like incorrect settings or issues with profiles. But the leading cause is material options. That is, when Cura fails to locate the material previously designated as the default for your specific 3D printer during the last session. This will make the software interpret this as a sign of configuration corruption.

In most cases, this error is not serious, and you can ignore it and slice your file and 3D print successfully. However, it can be annoying when it pops up whenever you try to slice your file, hence the need to fix it.

To solve this problem, you can reset Cura to factory settings. But if you have settings you don’t want to lose, you can use a Cura plugin like Startup Optimiser, which you can download from the Ultimaker marketplace.

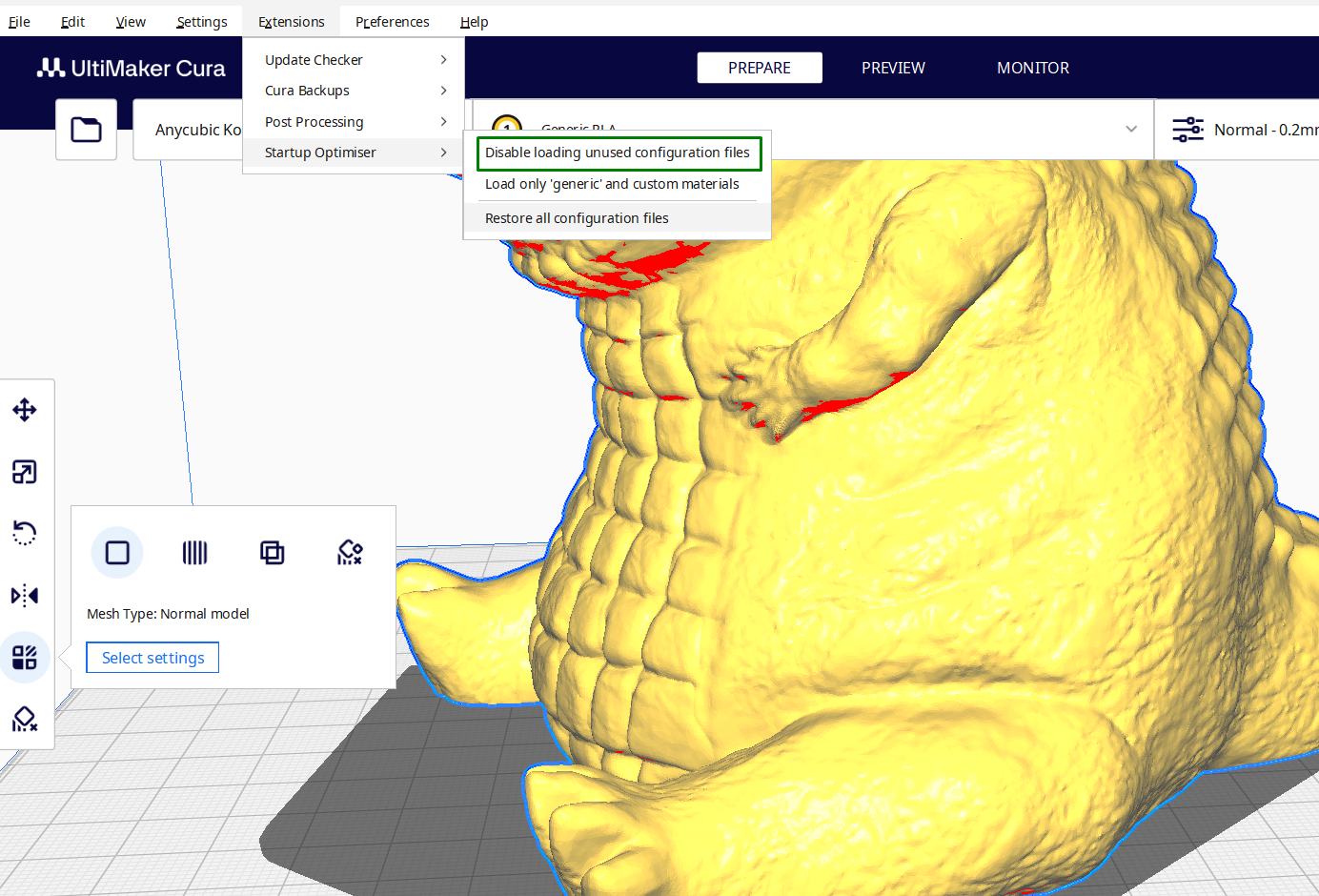

After installation, restart Cura, and in the error message box, choose Disable Affected Profiles and then restart Cura again, and the message will disappear. This plugin can also help you reduce the amount of time that Cura loads when you choose Disable loading unused configuration files.

(Image credit: Tom's Hardware)

5. Cura Not Generating Supports

If the support generation settings are correctly configured and Cura is still failing to generate them or only generating a few, you need to adjust certain settings to fix the issue. But before that, you need to ensure that you update the software to the latest version.

One setting to adjust when Cura is not generating supports is changing the support placement setting to Everywhere instead of the default Touching Build Plate.

Doing this, in most cases, will solve the issue. If the supports appear even in the areas that you don’t want, you can use support blockers to block them in those areas. In addition, to support placement, you must check the Minimum Support Area and Minimum Support Interface Area settings. These settings determine the minimum surface area required for the supports to be generated and the minimum area for support interfaces. If the values are too high, the software may not generate supports for smaller overhangs. So you lower them a little to allow Cura to generate supports for smaller overhangs.

6. Cura Settings Error

This error occurs when one inputs values for certain settings that exceed the software’s supported ranges. Just like many other 3D printer slicers, Cura has predefined limits for settings parameters, and when one attempts to exceed those ranges, Cura will generate a message indicating the specific setting causing the problem. Such error messages allow you to adjust the settings to ensure they fall within the supported ranges and this helps prevent errors or print failure.

To avoid such errors from occurring you should adhere to the limits of the software when adjusting the settings to avoid exceeding. Also, you should keep in mind that there are certain settings in Cura that are related, hence an increase or reduction in one affects the other and you should take note of that when adjusting your settings.

More 3D Printer Tutorials

Sammy Ekaran is a freelancer writer for Tom's Hardware. He specializes in writing about 3D printing tutorials and guides. You can find more of his work on various publications, including Makeuseof, All3dp, and 3Dsourced.