AMD Radeon Vega Frontier Edition 16GB Review

Why you can trust Tom's Hardware

Disassembly, Cooler & Interposer

Disassembly & Cooler

Some tools are needed to remove the card's cover. Six small screws that hold the shroud in place can be unfastened with a small Torx screwdriver (T5). This reveals AMD's cooler, along with a frame responsible for adding rigidity and dissipating thermal energy.

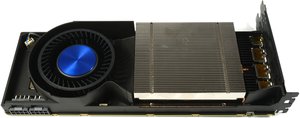

AMD leans on a direct heat exhaust cooler once again, and that's not a bad thing. We can see the radial fan sitting in its chamber, which brings in air from the case. This flow passes horizontally though the sink’s body and blows out of the card’s slot cover.

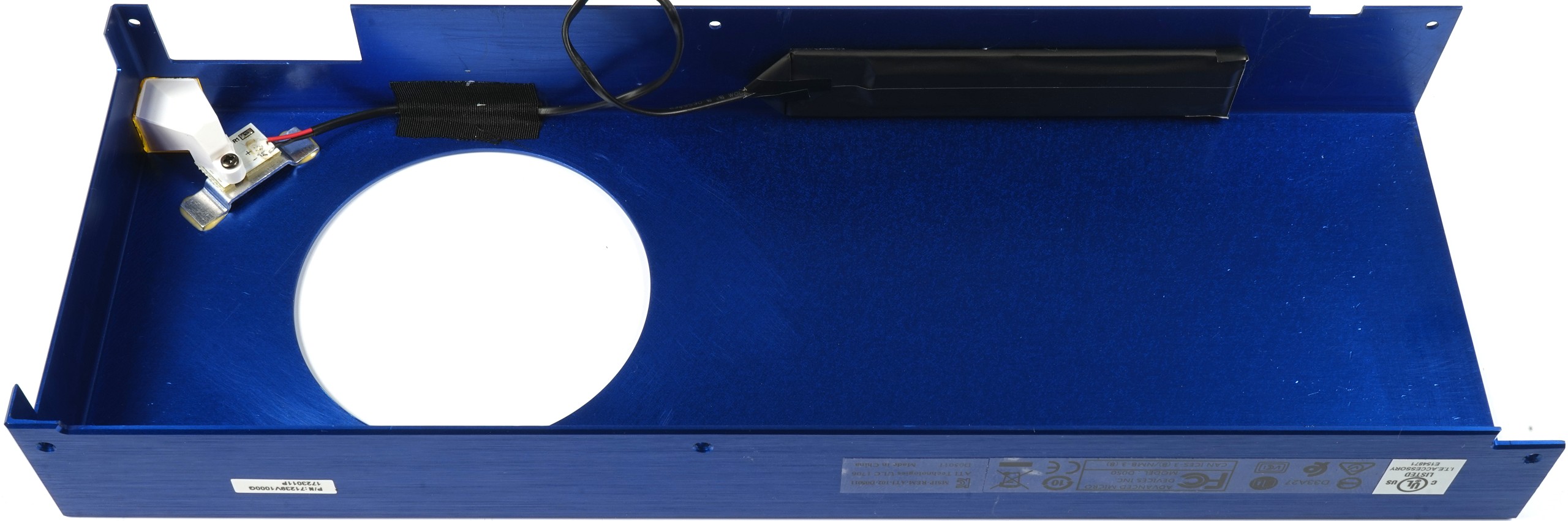

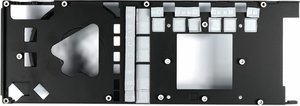

The backplate is made from blue anodized aluminum. Looking good is its only purpose, which is to say that the plate doesn't help with cooling. AMD secures this piece using six T6 screws.

Our attempt to make the backplate functional with thermal pads didn't get us very far; they didn't draw much waste heat away from the board.

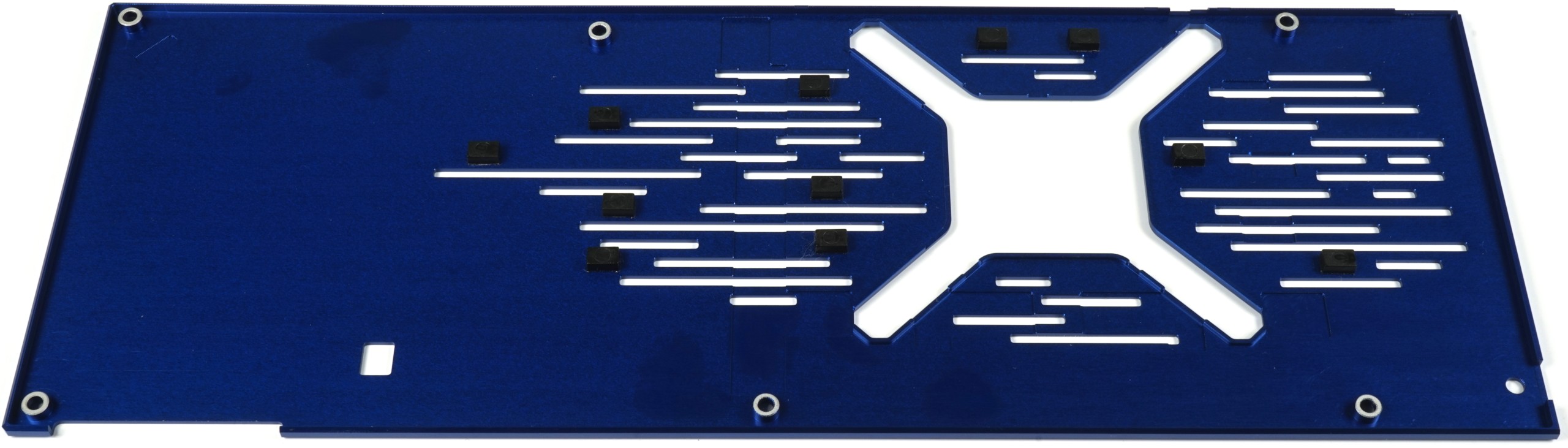

Up top, there's a massive cooling frame that helps keep the card's structure nice and rigid. It also looks like AMD implemented some of the design lessons it learned from past generations. Similar to Gigabyte's Aorus GeForce GTX 1080 Ti Xtreme Edition, the chokes transfer heat to the frame through thermal pads. Indentations in the metal accommodate voltage regulation circuitry as well.

The heat sink’s body is made of thin aluminum cooling fins attached to a large copper vapor chamber. Toward the bottom of the following two pictures, you can see the chamber's outlet, which was soldered shut and should never be snapped off. A large protrusion on the copper plate's surface is situated perfectly to make contact with AMD's GPU/memory package.

The 7cm radial fan is a simple ball bearing-based model from Delta. This is a first for AMD, and it’s certainly nice to see after generations of loud fans on the company's reference cards. Whereas those old fans spun at up to 10,000 RPM, the new BVB1012-family model hits its maximum speed at 5000 RPM. AMD’s target is around 40 to 41% duty cycle, translating to ~2000 RPM.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

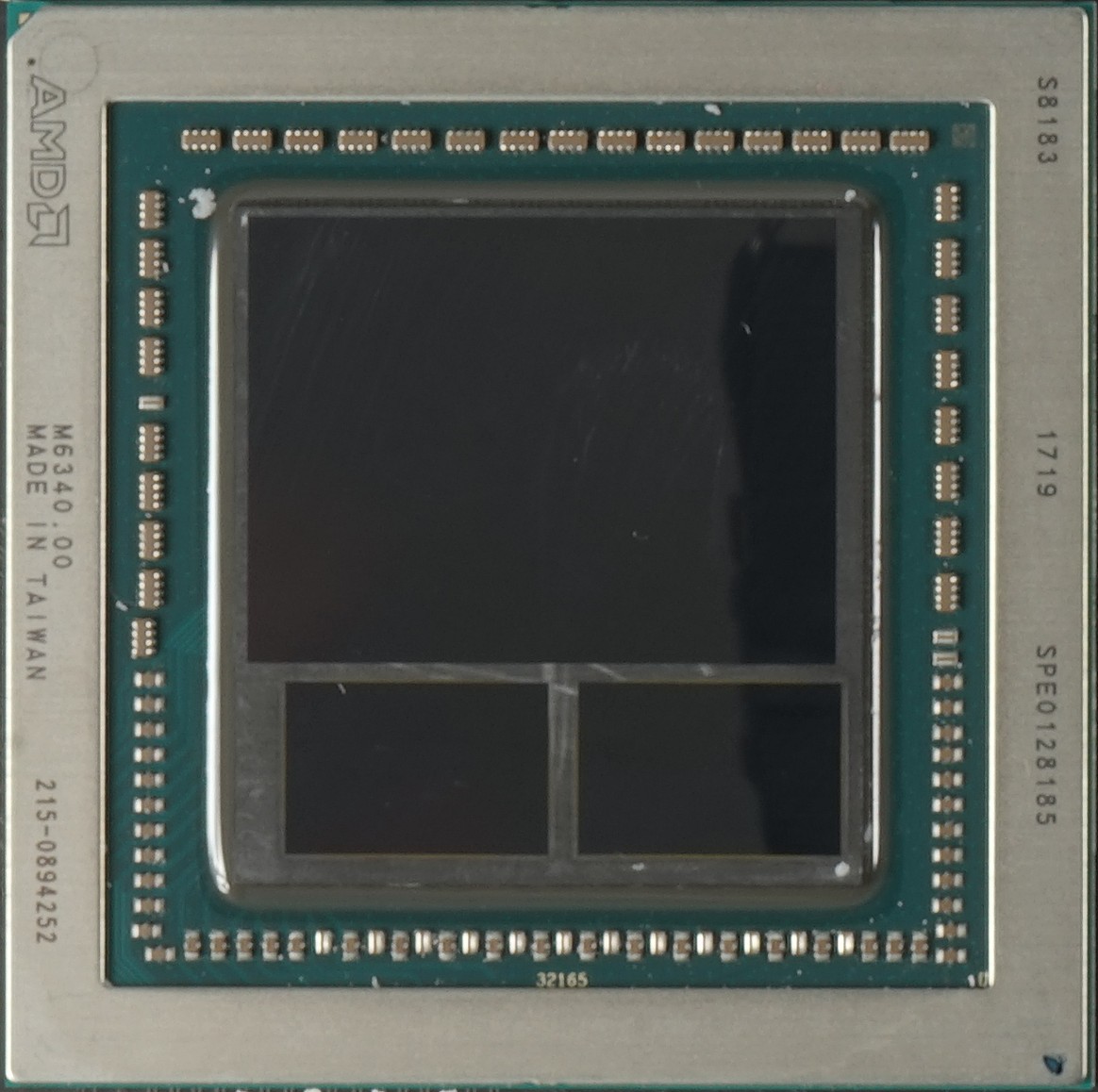

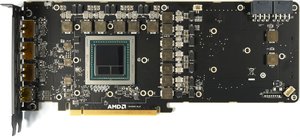

With the board completely exposed, all eyes turn to AMD's GPU and the HBM2 mounted together on an interposer, which sits on a large package substrate.

Of course, the GPU can't simply be soldered to the PCB. As with AMD's Fiji-based cards, Vega and its complement of memory go through a packaging process that's handled by specialty tools from companies like ASE. The resulting module is much easier for board partners to handle later on.

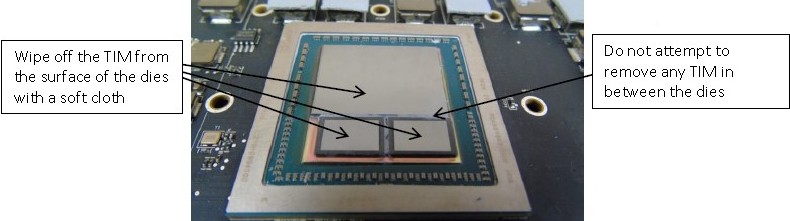

In the image below, you see the package as it was presented internally at AMD to its partners. There are deep channels between the GPU and memory modules since all three components are fairly tall. Conversely, the interposer is extremely thin and easy to break. That's why AMD warns everyone who touches the module to be careful when removing thermal paste from it.

Leaving the package this way for the automated production line would have risked manufacturing issues. But compare that early shot to what the shipping module looks like. AMD appears to have added molding. Filling the area around the GPU and HBM2 with a suitable material increases the package's structural integrity.

You should still be careful when handling AMD's new GPU, particularly if a cooler swap is planned. However, it looks like the company put a lot of effort into making sure its unique layout is just as robust as more traditional designs.

MORE: Best Graphics Cards

MORE: Desktop GPU Performance Hierarchy Table

MORE: All Graphics Content

Current page: Disassembly, Cooler & Interposer

Prev Page Vega Architecture & HBM2 Next Page Board Layout & Components

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

Ne0Wolf7 Too bad its been so well optimized for Creo, I hate that one... Anyways, is it possible to include Autodesk Inventor in the suite? I want a card that can be used as a hybrid like this (of course I'll have to wait for it to come down in price) but its hard to decide I want something if my main software is not included in the benchmarks. Either way, I'm exited and this is a good reviewReply -

cknobman Not sure what to think here (in regards to hopes for the fx versions).Reply

I cannot expect to see a huge % boost in games just on a driver update. Maybe 10% tops?

What bothers me the most is the heat/power and throttling concerns.

I dont think those will change with a fx version of the card.

So it would appear that 80-90% of the time Vega 64 will be running closer to 1200mhz, which is a major bummer and why it wont surpass a 1080.

Almost wish there had been a review of the watercooled version as well to see if it was able to maintain higher avg mhz. -

cats_Paw Dont know much about workstation so my comment does not take that into consideration.Reply

It seems like it eats a lot of power for a very similar performance to a 1080 in gaming but at the same time its faster than Titan Xp in some workstations?

Doesn't that suggest driver/optimization issues? -

Yarvolino Ho comes that Vega and 1080Ti specs are pretty much the same, even greater numbers for Vega, and the result is that Vega is 40% slower and it drains +50% of power ?Reply

Considering Vega also costs much more, I label it as an april fool -

LORD_ORION Wow, what a horrible review.Reply

2 games, 1 resolution... and just where does this card fit in the vega lineup? You didn't even list the details of the other vega cards in a handy chart for comparison.

*starts looking for reviews on other sites* -

demonsoldier So there has been a few people tackling this and i found that lowering certain things about the card undervolting by 110mv has found to fix the clock speed issue keeping at a stable 1600 mhz with better cooling and it out performs the 1080 at that point. Can you guys do a second attempt at this with undervolts to see if that helps anything? AMD cards have been this way everytime they come out needing to have power draw issues fixed later on.Reply -

sparkyman215 Reply20013128 said:Wow, what a horrible review.

2 games, 1 resolution... and just where does this card fit in the vega lineup? You didn't even list the details of the other vega cards in a handy chart for comparison.

*starts looking for reviews on other sites*

wh-what? Toms stated like four times that this *is not a gaming card* and shouldn't be treated as one. They simply included the gaming benchmarks to be inclusive. Also, there's not really a point in showing benchmarks under 4k for such high end cards, because at that point (like 1080p) it's a CPU bottleneck - the GPU has nothing much to do. Considering listing other Vega cards, those are in a different class and not relevant, however it would be nice to have the details of the other cards, I guess. -

yeeeeman Even though AMD says with each ocassion that this graphics card is not indicative of RX Vega's performance I would say that they are trying to avoid early dissapointment. The matter of the fact is that whatever feature they have disabled right now on Vega FE, it won't bring too much performance on RX Vega. Lets face it, if they were using half of CUs on Vega FE, then I would expect huge gains from RX Vega, but as it stands, RX Vega wil be ~ GTX 1080, one year later, + 100W and hot like a stove.Reply

I really wonder how could they make a new GPU on a big better process (28nm vs 14nm) and still get more power consumption compared to Fury X. What is more surprising is that they have the same number of CUs, approx same performance with Fury X, a lot more transistors, a lot more frequency and still the improvement is minimal.

They are either hiding some huge block which doesn't do anything in graphics scenarios which consumes a lot of power just idling or they are rubbish at power optimization or maybe the HBM2 consumes a lot of power, don't know.

Everything on this card is strange, starting with performance, specs, power consumption, everything... -

Pompompaihn Seems like a very nice card if you're a home office person and need your system to do double duty. Good enough for high end gaming and comparable to expensive NVIDIA pro cards.Reply