Micron 9100 Max NVMe 2.4TB SSD Review

Why you can trust Tom's Hardware

Teardown, Architecture And CPU Utilization

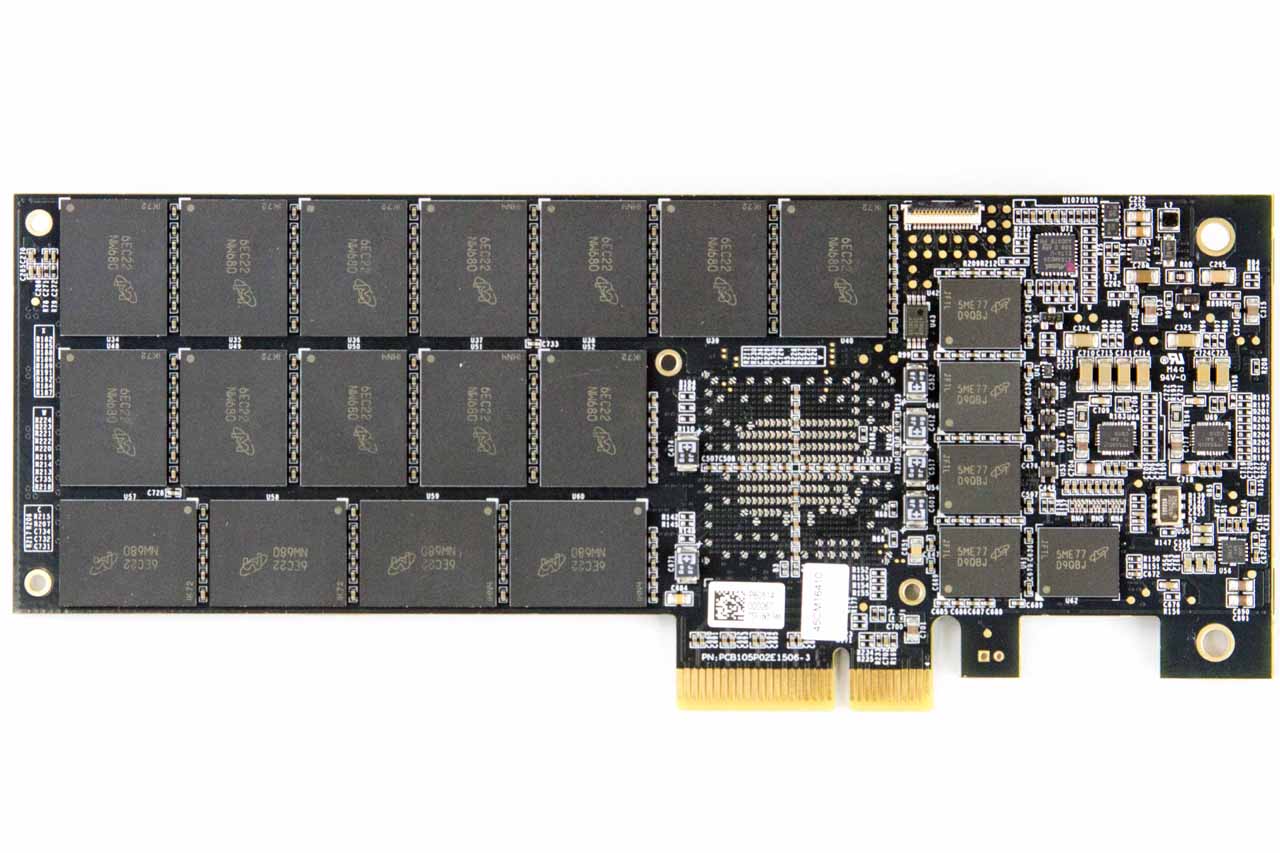

Teardown

Architecture

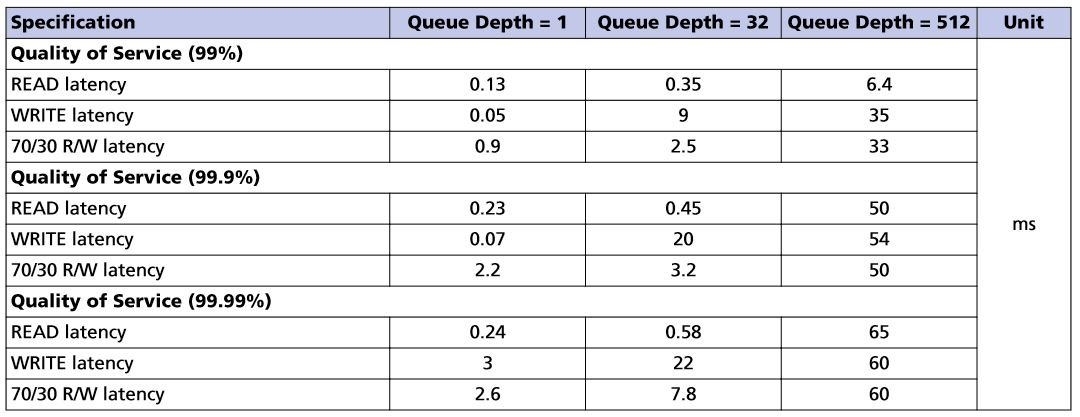

The Micron 9100 MAX comes in the standard HHHL (Half-Height Half-Length) AIC form factor, which is an immediate advantage over large FHHL (Full-Height Half-Length) competitors, such as the Mangstor MX6300, because the small form factor will slot into a wide range of servers. The 9100 connects via PCIe 3.0 x4. When we view the SSD from an angle, we note the internal air channel that leverages the linear airflow patterns within the server, thus boosting heat dissipation.

Like many other enterprise SSDs, the 9100 will begin throttling at 85°C. SSDs have progressed in this respect; now they initiate a dynamic throttling curve to reduce temperature to avoid a steep performance drop. The 9100 AIC model requires 300 LFM of airflow, whereas the U.2 (2.5") requires 450 LFM. This is the only differentiation between the two models, other than the different form factor. Micron also allows users to adjust the thermal profile of the 9100 series by selecting either the MAX, 25W or 20W thermal modes. The 25W and 20W modes restrict performance by limiting power consumption, which in turn reduces the thermal envelope. This allow users to customize the SSD for dense and coiling-challenged environments. This feature is not currently active (Micron will enable it soon), so we are not able to provide various test results at each thermal threshold.

The I/O bracket features a constellation of small holes that allow air to flow somewhat unimpeded out the rear of the server, which encourages thermal dissipation. We also spot two rectangular slots that house the two LEDs that provide a visual status indicator. The two liquid-filled electrolytic capacitors jut up near the bracket. These capacitors provide enough capacitance to flush data in flight from all caches and buffers to the non-volatile NAND in the event of an unsafe host power-loss event. The 9100 requires two minutes upon reboot after a power-loss event to resume normal operation. The 9100 features the typical 2 million hour MTBF and 1 per 10^17 UBER ratings.

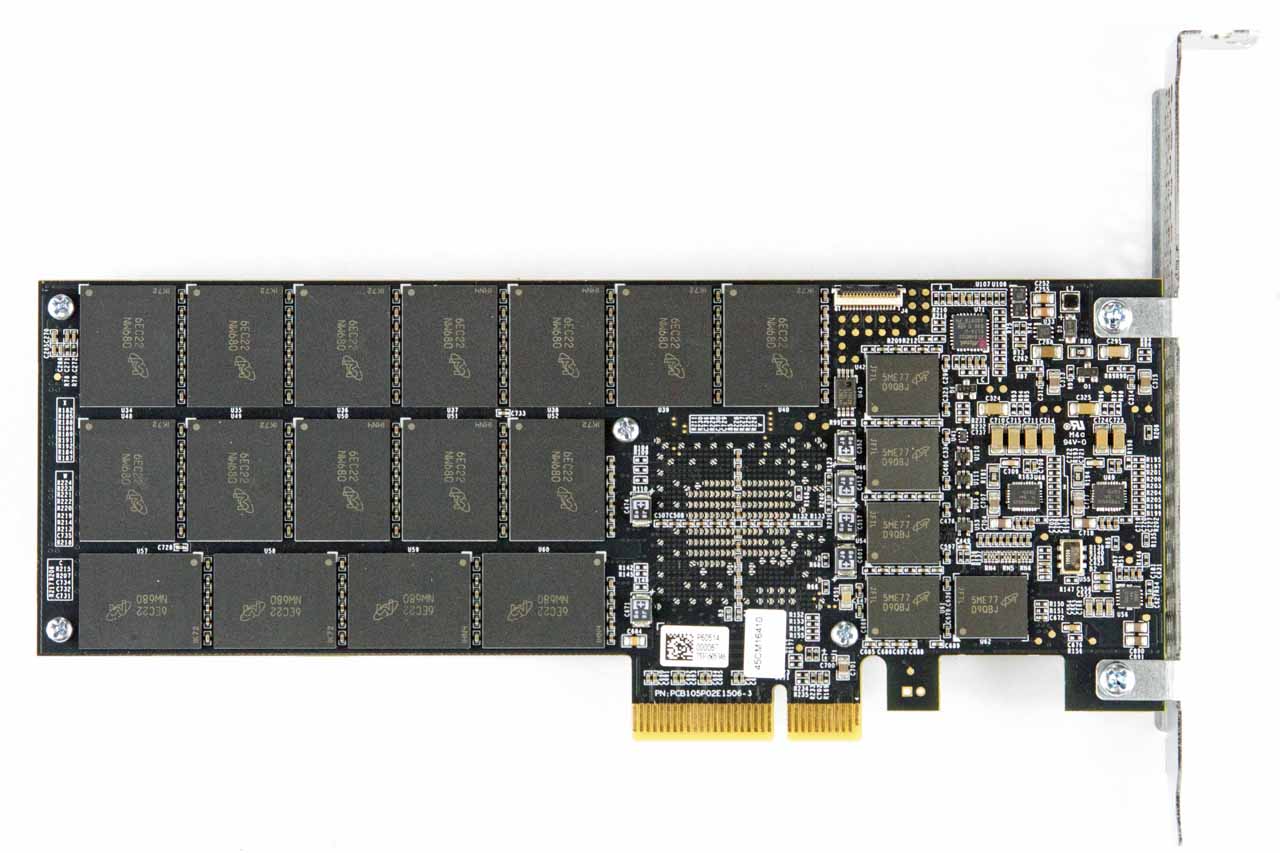

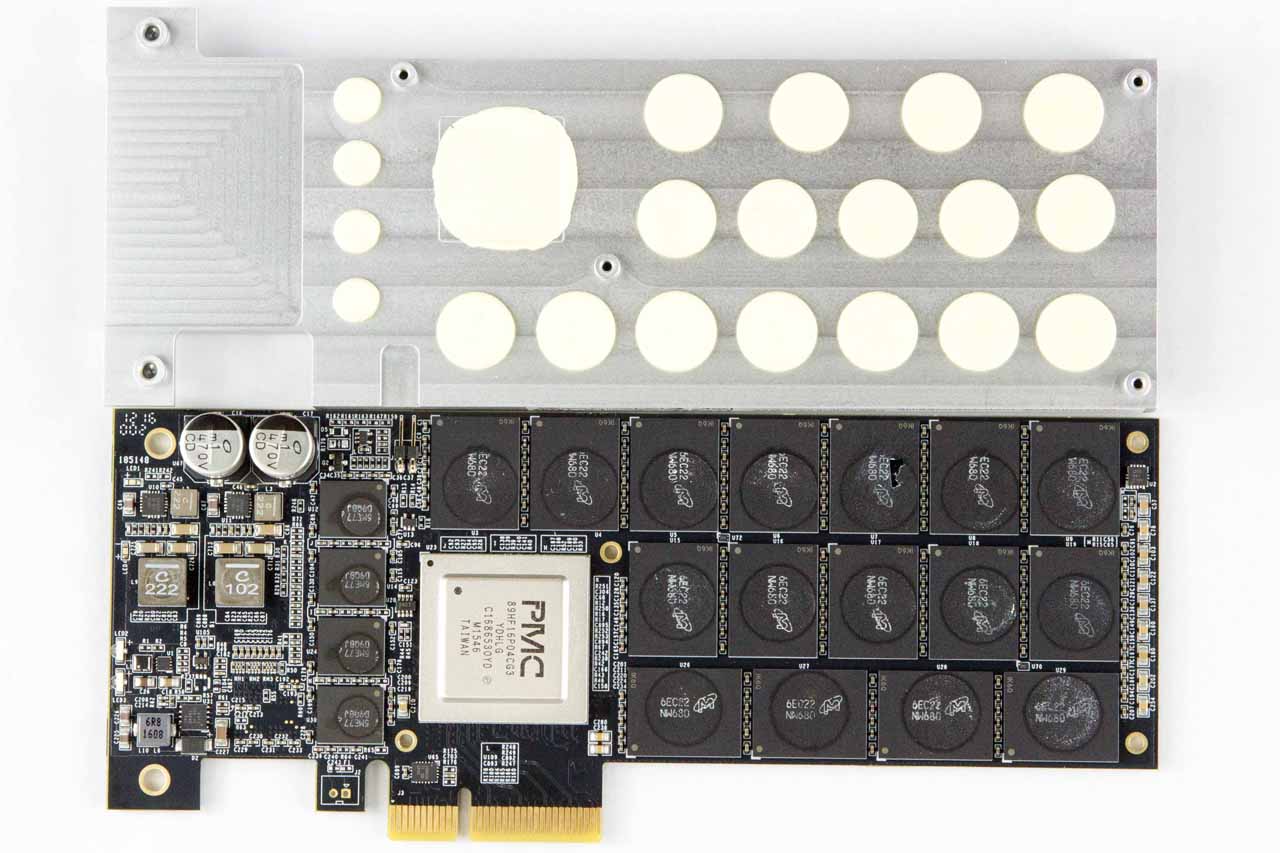

The Microsemi Flashtec NVMe1032 89HF16P04CG3 16-channel SSD controller comes into view when we remove the heatsink. This mature controller debuted in 2014 and continues to power a broad range of SSDs. Microsemi allows its customers wide latitude with the firmware, which fuels an incredible amount of differentiation between competing products.

| User Capacity | Raw Capacity | NAND Packages x Package/Channel x Channels | Package Type (128Gb/Die) | NAND Die Per Package x Packages | RAM Capacity x Packages |

|---|---|---|---|---|---|

| 800GB PRO | 1TB | 64GB x 1 x 16 | QDP x 16 | 4 x 16 | 256MB x 9 |

| 1.2TB MAX | 2TB | 64GB x 2 x 16 | QDP x 32 | 4 x 32 | 256MB x 9 |

| 1.6TB PRO | 2TB | 64GB x 2 x 16 | QDP x 32 | 4 x 32 | 256MB x 9 |

| 2.4TB MAX | 4TB | 128GB x 2 x 16 | QDP x 32 | 8 x 32 | 512MB x 9 |

| 3.2TB PRO | 4TB | 128GB x 2 x 16 | QDP x 32 | 8 x 32 | 512MB x 9 |

The previous-generation Micron products utilized a 32-channel controller that supported four targets (LUN) per channel, but the Flashtec controller supports up to eight targets for each of the 16 channels. This provides a similar amount of parallelism through the benefits of interleaving. Each target can consist of several NAND packages to increase density. Each of the 9100's 32 x 16nm NAND packages features eight 128Gbit NAND die per package, and each channel serves two individual packages.

The SSD also houses nine 512MB DRAM packages, but only 4GB of DRAM is available for use due to the ECC arrangement, which adds an extra layer of protection. The 9100 uses thermal pads on all of the critical components, such as the ASIC, NAND and DRAM, to facilitate cooling. Micron uses a 31:1 RAIN ratio for SSDs larger than 1TB, and 15:1 for SSDs 1TB and under.

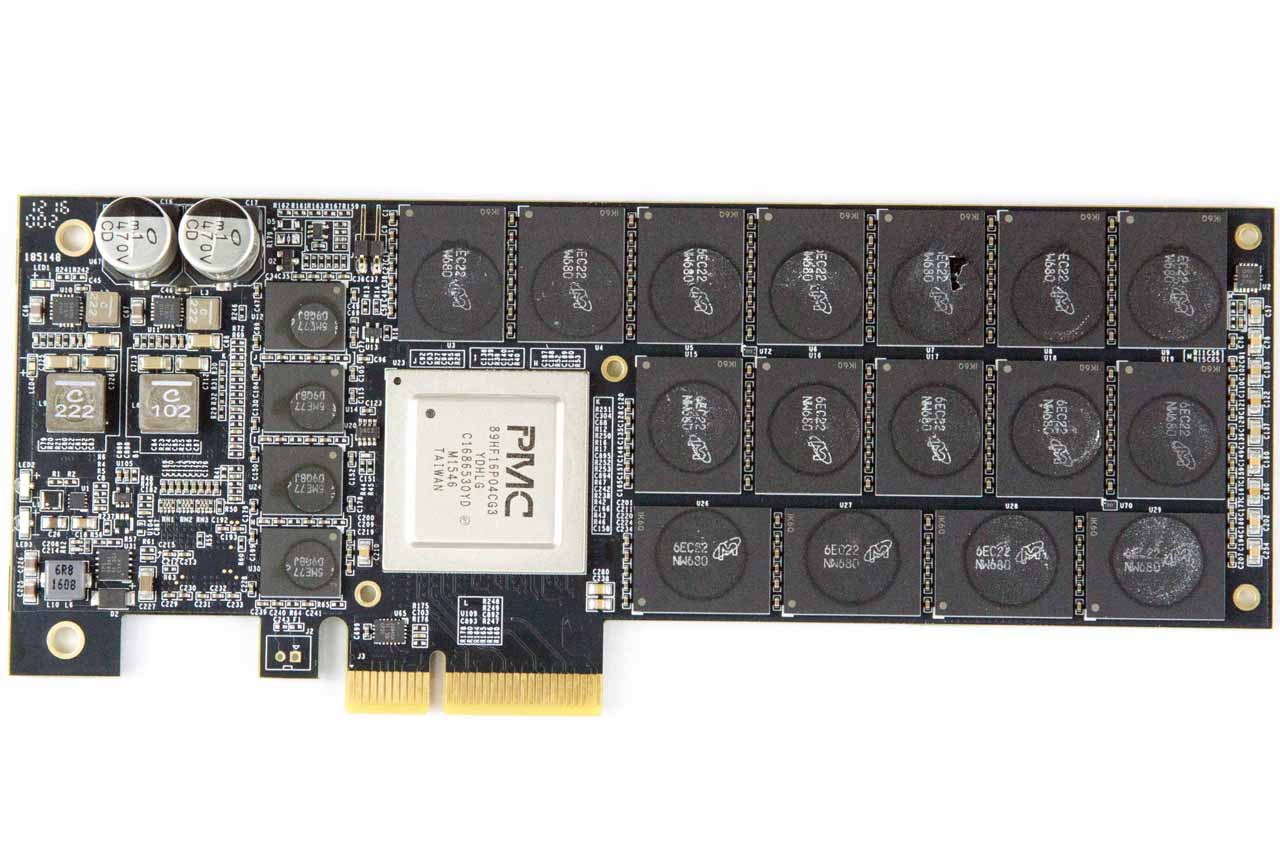

QoS Specifications

The SSD vendors are beginning to focus on more refined aspects of flash performance as SSDs, and our understanding of how applications extract data from them, evolves. In the past, performance specifications were relegated to basic random and sequential speeds and feeds, but now the major vendors also include QoS (Quality of Service) measurements to quantify performance consistency.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Micron joins the ranks of vendors focusing on the all-important metric, and according to our measurements (which we cover on the following pages), the company has conservatively stated its QoS specifications, which is somewhat of a Micron trait. We routinely measured values that were much lower, and thus better, than the rated specifications.

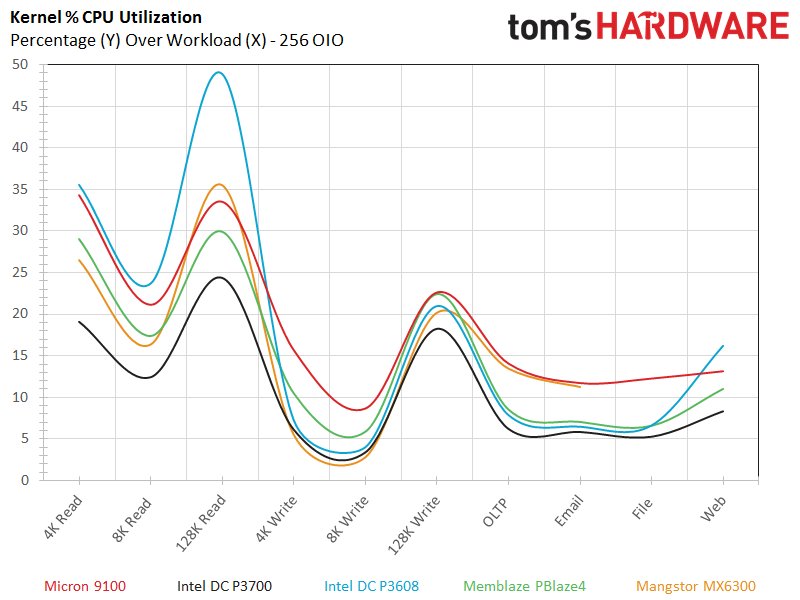

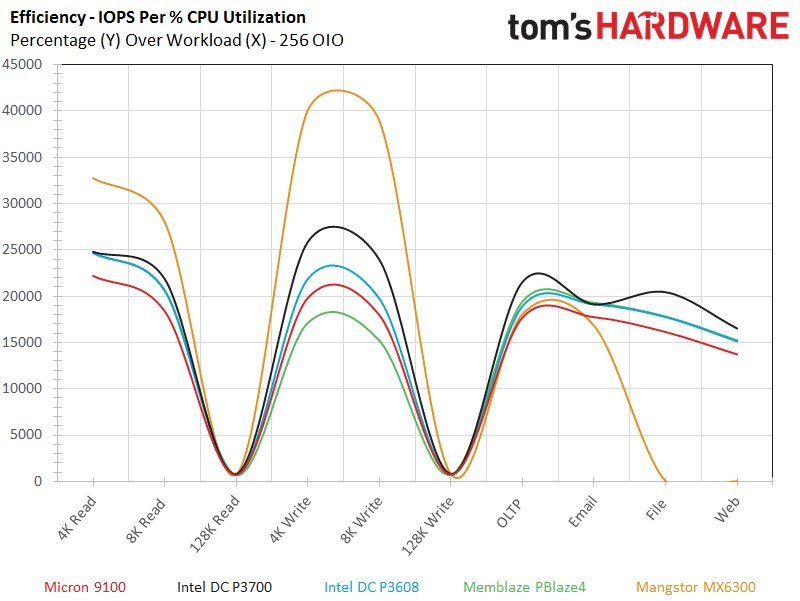

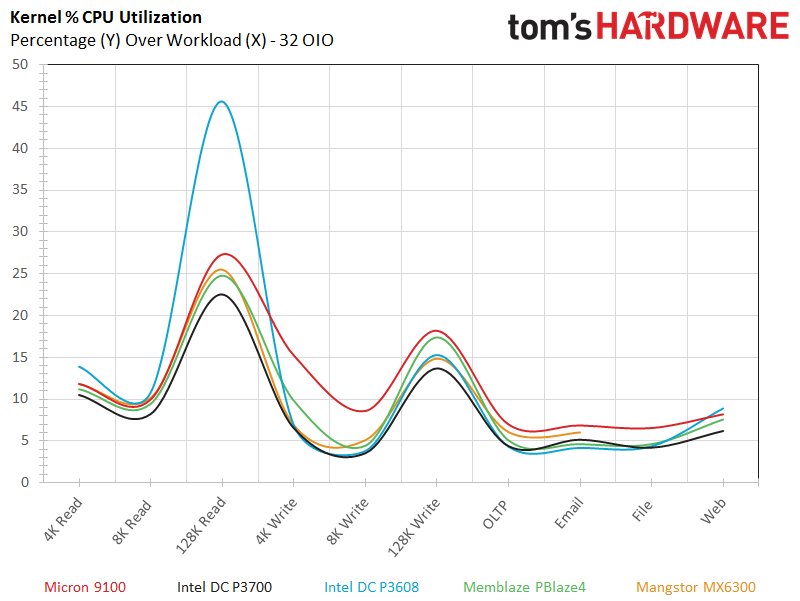

CPU Utilization

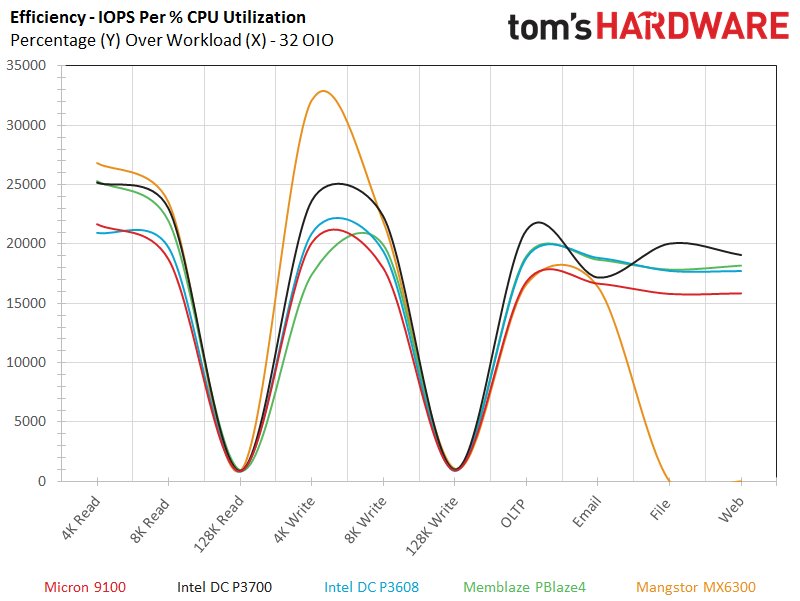

All of our test samples feature the NVMe interface, and the developers focused on reducing CPU usage during the protocol design. As such, there is little variation between our standard NVMe samples. The Intel DC P3608 is the lone exception to the rule, because it requires an RSTe-based RAID 0 implementation of its two separate internal volumes, which increases its host CPU consumption.

Current page: Teardown, Architecture And CPU Utilization

Prev Page Micron 9100 Max Makes An Entrance Next Page Endurance Matters And Management

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.

-

Flying-Q If the flash packages are producing so much heat that they need such a massive heatsink, why is there only one? Surely the flash on the rear of the card would need heatsinking too, even just a flat plate would suffice?Reply -

Unolocogringo It appears the heatsink is more for the voltage converters and controller chip to me.Reply -

Paul Alcorn Reply18234127 said:If the flash packages are producing so much heat that they need such a massive heatsink, why is there only one? Surely the flash on the rear of the card would need heatsinking too, even just a flat plate would suffice?

This is a standard configuration, though there are a few SSDs that have rear plates. Thermal pads were more common with larger lithography NAND, 20nm, 25nm, etc, because it generated more heat. New smaller NAND, such as the 16nm here, draws less power and generates less heat. In fact, it was very common with old client SSDs to have a thermal pad on the NAND, whereas now they are relatively rare. I think that they may be relying upon reducing the heat enough on one side to help wick heat from the other side, but the heatsink is primarily for the controller and DRAM with the latest SSDs. Also, it may just be convenient to add additional thermal pads to the NAND to keep the spacing for the HS even across the board.