Micron 9100 Max NVMe 2.4TB SSD Review

Why you can trust Tom's Hardware

Endurance Matters And Management

Endurance Matters

The industry is migrating to lower endurance thresholds to reduce cost, so modern SSDs are designed to satisfy either typical read-centric datacenter workloads or more intense write-centric workloads. DWPD measurements (Drive Write Per Day) signify how many times you can write the capacity of the drive per day for the duration of its warranty period, and it is still a commonly-used metric. However, it is important to note that high-density SSDs require more data to fill them. This means that sometimes a dense device with a low DWPD measurement can absorb more writes than a smaller drive with a higher DWPD metric.

| Header Cell - Column 0 | 2.4 TB Micron 9100 MAX | 3.2 TB Micron 9100 PRO | 1.6 TB Intel DC P3700 | 1.6TB Intel DC P3608 | 3.2 TB Memblaze PBlaze4 | 2.7 TB Mangstor MX6300 |

|---|---|---|---|---|---|---|

| NAND | Micron 128Gbit 16nm MLC | Micron 128Gbit 16nm MLC | Intel 20nm HET MLC | Intel 20nm HET MLC NAND | Toshiba 15nm MLC | Toshiba A19nm eMLC NAND |

| Endurance PB/DWPD | 6.57 / 2.7 | 3.28 / 2.5 | 43.8 / 17 | 8.76 / 3 | 17.3 / 3 | 34.5 / 7 |

| Price | $3,240 | $3,520 | $2,700 | $3,600 | n/a | $9,845 |

| Dollar Per GB | $1.35 | $1.10 | $1.69 | $2.25 | n/a | $3.65 |

| Endurance (TB) Per Dollar | 2.0 | 0.93 | 16.2 | 2.43 | n/a | 3.5 |

| Cost Efficiency Index | 4.8 | 2.98 | 25.92 | 3.89 | n/a | 9.45 |

We boil SSD endurance metrics down to a three easily digestible value to help demystify endurance, cost and the advantage of extra capacity. We derive pricing information from vendor-provided MSRPs for unreleased products and average the prices we find at retail for shipping products (YMMV).

We calculate the price-per-GB to give an unfiltered view of cost and calculate the number of Terabytes that you can write to the SSD per dollar spent (Endurance Per Dollar) to provide insight into the value of endurance. We also consider the advantages of additional available capacity in tandem with our per-dollar measurement. For instance, the 3.2TB 9100 Pro weighs in at an endurance of 0.93TB per dollar, which is far less than the 2.03TB per dollar of its Max counterpart, but it features an additional 800GB of usable space, which adds value. We utilize our Cost Efficiency Index to provide an amalgamation of the available capacity, cost and endurance metrics by simply multiplying the capacity by the endurance-per-dollar.

The Micron 9100 series has a three-year warranty, compared to the competing products that have five-year warranties, so its DWPD measurement can be misleading. After normalizing the endurance and factoring in cost, the Micron 9100 Max is competitive with the Intel DC P3608 and the Mangstor MX6300, but it lags far behind the incredible endurance of the DC P3700.

The 9100 Pro provides more capacity than the Max, but it comes at the expense of endurance, so we note a significantly lower cost efficiency index result that pales in comparison to some competing devices. We await pricing information from Memblaze.

Management & Compatibility

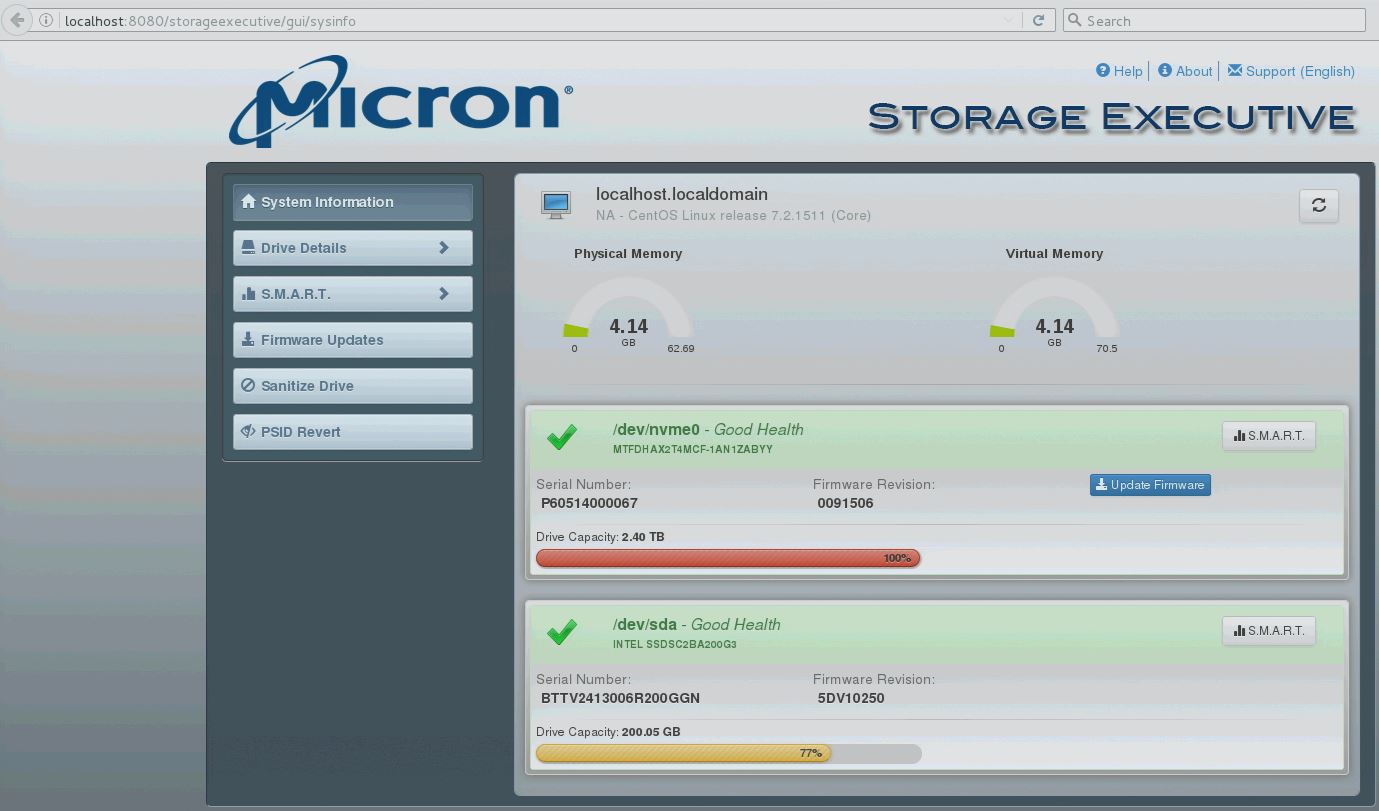

Micron employs its Storage Executive Software for management tasks, and it comes in both web GUI and CLI flavors. The utility lets users monitor drive status, capacity used, temperature, remaining life and SMART attributes. You can update the firmware and sanitize the drive, but there are no options for managing the thermal characteristics of the card, such as power limiting.

The GUI is simple and functional, but perhaps too simple. Micron spoiled us with the proprietary RealSSD Manager that it used with previous products. The old utility was more functional and provided real-time performance monitoring, which is a nice perk. Micron enabled some of the enhanced monitoring features with its custom driver, so the move to the standardized interface apparently led to some reductions in capability (although the card still offers SMBus out-of-band management). The NVMe protocol also supports all open source NVMe tools, which is a nice perk compared to a custom driver.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Micron employs NVMe 1.1b, which will go anywhere the regular inbox NVMe drivers will take you, such as newer versions of CentOS (our fave), RHEL, SUSE, Ubuntu and VMware. Windows 2016 is also on the menu, but Micron provides a custom NVMe driver for older Windows and Linux operating systems, as well as all Hyper-V releases. Micron's custom NVMe driver does not offer increased performance, so the company recommends sticking to the inbox drivers if possible.

Sorry everyone, but Micron indicates that the 9100 does not support booting. The company does not state that it will not work but mentions that you proceed at your own peril if you decide to have a little fun.

Current page: Endurance Matters And Management

Prev Page Teardown, Architecture And CPU Utilization Next Page 4KB Random Read And Write

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.

-

Flying-Q If the flash packages are producing so much heat that they need such a massive heatsink, why is there only one? Surely the flash on the rear of the card would need heatsinking too, even just a flat plate would suffice?Reply -

Unolocogringo It appears the heatsink is more for the voltage converters and controller chip to me.Reply -

Paul Alcorn Reply18234127 said:If the flash packages are producing so much heat that they need such a massive heatsink, why is there only one? Surely the flash on the rear of the card would need heatsinking too, even just a flat plate would suffice?

This is a standard configuration, though there are a few SSDs that have rear plates. Thermal pads were more common with larger lithography NAND, 20nm, 25nm, etc, because it generated more heat. New smaller NAND, such as the 16nm here, draws less power and generates less heat. In fact, it was very common with old client SSDs to have a thermal pad on the NAND, whereas now they are relatively rare. I think that they may be relying upon reducing the heat enough on one side to help wick heat from the other side, but the heatsink is primarily for the controller and DRAM with the latest SSDs. Also, it may just be convenient to add additional thermal pads to the NAND to keep the spacing for the HS even across the board.