Stress Test: Power Supplies Under Full Load

BeQuiet BQT B5-520W-S1.3: Loose Transistor Triggers Failure

A loose transistor within the Be Quiet power supply tripped a circuit breaker in the THG Lab.

Features And Test Results

It happened late one evening in the THG lab in Munich. All the engineers had already left the premises. Around 10:58 pm the F25 safety device was triggered, which caused the power pack test platform, the camera server and the power supply to be cut off. The initial investigation showed that the Be Quiet BQT B5-520W-S1.3 was no longer working; in other words: it was defective. A more detailed inspection being carried out together with the manufacturer will soon discover the cause of the failure. The manufacturer Be Quiet suspects that the fatal crash was caused by the high load of 2 amps on the 5-volt standby line. Background information: Although this line is rarely loaded in normal operation, according to ATX12V specification (2.2) there is nothing standing in the way of using an additional standby current, like the one we use in the stress test. We received confirmation of this statement from former AMD chief engineer Bernd Willer, who also developed the power pack test platform for us. See our interview with Be Quite! for more on this issue.

Crashed: Be Quiet Power Pack with a maximum capacity of 520 watts - shown here in when opened. Externally, there are no clues as to what caused the crash.

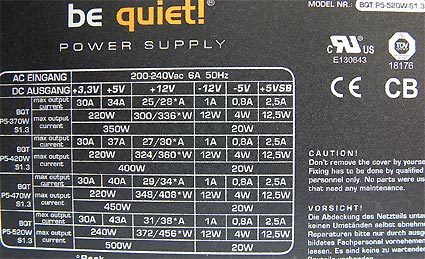

Be Quiet's label: It has details about many power packs, which makes it difficult for the user to determine the correct capacity data.

The last recordings before the safety device was triggered are rather obvious: The power pack drew 816 watts from the mains and delivered 520 watts of power. Therefore, the power loss at that moment was 294 watts. A connection between this and the failure of the power pack can't be ruled out.

Shortly before the crash: The Be Quiet power pack sucked an incredible 816 watts from the mains.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

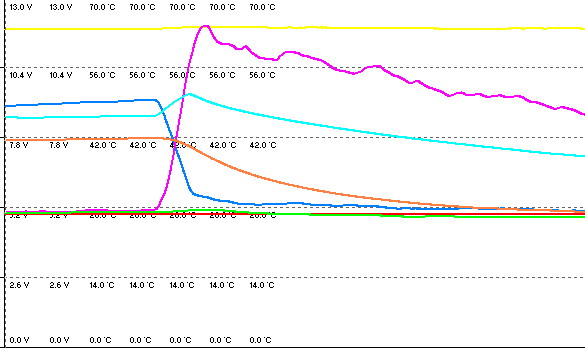

This diagram shows temperature progression during the crash. Because the systems are connected to various power supply systems, it was possible to continue to register temperatures. In other words, the temperature server didn't crash.

Additional information about the incident is provided by the temperature diagram: The violet curve shows temperature progression above the power pack. At the moment of the total crash, during which the power pack's fan also came to a halt, temperatures rose above the power pack and the electronic loads (also equipped with fans). This is shown by the violet and light-blue curves. The flow of warm air to the temperature sensors was unhindered. The dark-blue curve shows temperature progression at the power pack's outlet.

Just a small piece of info on the side: Because our temperature sensor is subject to direct solar radiation in the morning, outside temperatures of up to 104°F (40°C) are recorded.

| BeQuiet BQT B5-520W-S1.3 (520 watts) | |||

|---|---|---|---|

| Test Phase 1 | |||

| Event | Initial value | Maximal value | Outcome |

| Load increase of 20% to 100% of the rated power | 104 watts | 520 watts | Passed |

| Test Phase 2 | |||

| Event | Row 4 - Cell 1 | Load | Outcome |

| Continuous load at 100% of the rated power | Row 5 - Cell 1 | 520 watts | Failed |

Press Release From Listan BeQuiet

The company Be Quiet during a visit to THG having lively discussions about power supplies.

From left to right: Press spokesperson Ms Renger from Listan (Be Quiet) and Mr Schuhmann from THG.

| Possible short circuit or breakdown BQT P5-520W-S1.3Glinde, 07/18/2005. The power supply unit test platform's fuse has blown out, and we are trying to determine the cause as soon as possible. At the moment, it is impossible for us to provide an analysis of the reasons for this failure. We will investigate whether or not a defect in the power supply unit existed as soon as THG returns the tested equipment to us.Since we also carry out continuous stress tests in our laboratory, using extremely varied concentration points, in order to achieve sustained improvement in the quality of the power supply units, this failure is not only a surprise to us, but also an indication for the need to continuously further develop test methods.As we already informed THG by telephone, the continuous high load on the 5 volt standby line of more than 2 amperes in connection with a 100% load on all power lines could have led to the failure. Under normal operating conditions, however, this line is seldom used, so that we see a starting point for our investigations here.We want to deliver quality power supply units in the future as well, with which the customer can be satisfied in the long term. It is furthermore important for us in terms of our international expansion that confidence in Be Quiet! in Germany as well as neighboring$pean countries be maintained and/or reinforced.During the launch of the Be Quiet! power supply unit in July 2003 in Germany, we set up a customer hotline free of charge at the same time, as well as establishing a 48 hour replacement service free of charge for Germany. In the event of a defect, the buyer will be provided with a new device as quickly as possible, giving us the possibility to quickly analyze technical failures, so as to be able to provide input for new product variations in the future.We would like to take the opportunity to thank everyone for the confidence shown in our brand of products up to now. We will do everything possible to continue to live up to this, and will make the results of our examination of the failed power supply unit available as soon as possible. |

Current page: BeQuiet BQT B5-520W-S1.3: Loose Transistor Triggers Failure

Prev Page Aopen Prima Power 700: Super Results - No SLI Next Page Cooler Master Real Power RS-550-ACLY: Shutdown At Full Load