How to Calculate 3D Printing Costs

Estimate 3D Printing Expenses

Just like in any other project where proper planning is essential before initiating the work, estimating the cost for 3D printing is important, especially if you are working on a big project. This is important in helping you anticipate the financial resources you will spend in the process so that you can plan accordingly. Getting a detailed cost analysis is also crucial in helping you know how much you should charge your client if you are running a 3D printing business.

The cost of 3D printing is influenced by various factors, including the cost of materials and even the size and complexity of the part to be printed. Also, the cost of a 3D printer itself varies depending on the use case as there are even best 3D printers that cost less than $500, and there are those that cost thousands of dollars.

Below, we give a breakdown of the various factors that affect the 3D printing cost and how you can do an estimate.

Cost of 3D Printing Material

The choice of the 3D printing material you use influences the overall cost of 3D printing and the properties of the final product. Before you start the 3D printing process, you need to know what the final product should look like. Different materials have distinct characteristics, from plastics like PLA and ABS to metals like steel and aluminum to more advanced materials like composite filaments.

Most common plastic materials are generally more affordable and suitable for cost-effective projects and they cost between $20-40/kg. Metal-infused and composite materials, on the other hand, are a bit more expensive. Also, market demand and availability of the material can affect the prices over time. So, once you determine the requirements of your project, you can select the appropriate material.

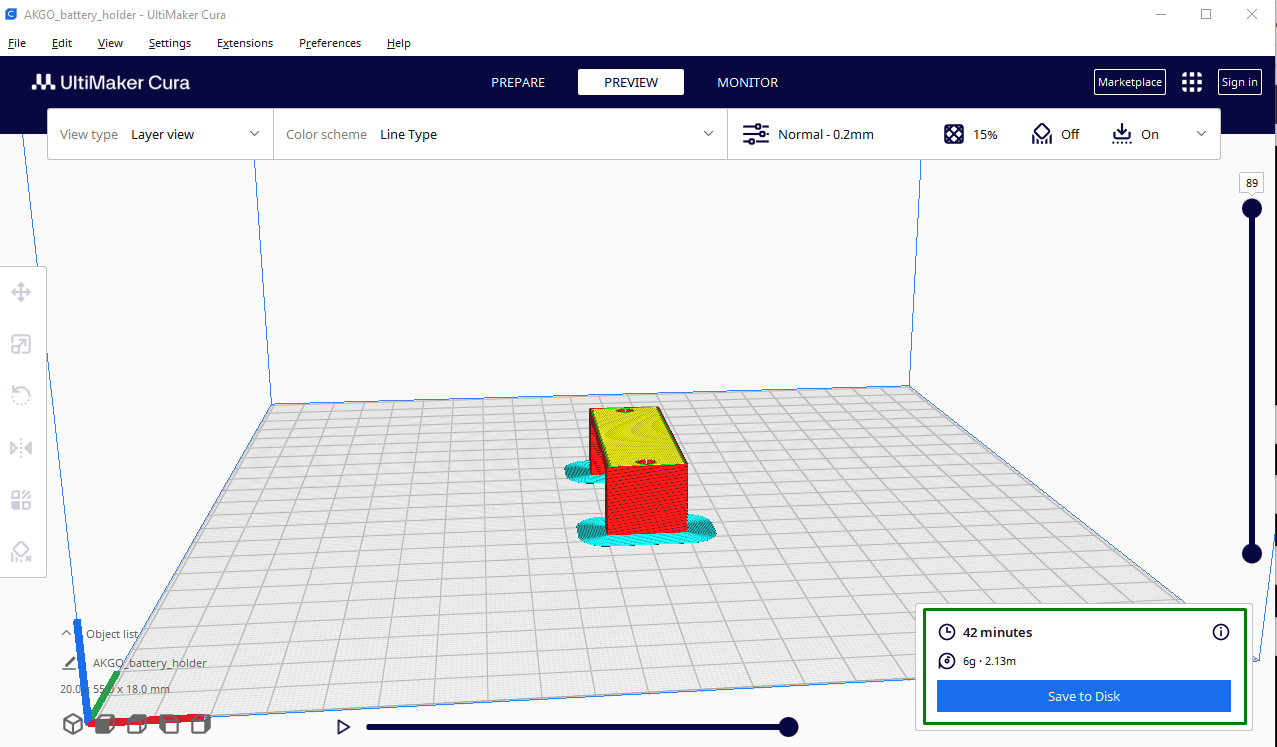

You can determine the cost of the material you will use by first knowing the volume of your 3D object. You can do this in any 3D modeling software. Afterward, you need to slice your file and preview it to see the size of the material you need. For example, if you are using Cura, you will see the size of the material below the interface.

In the above picture, that file will use 2.13m long or 6g of the material.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

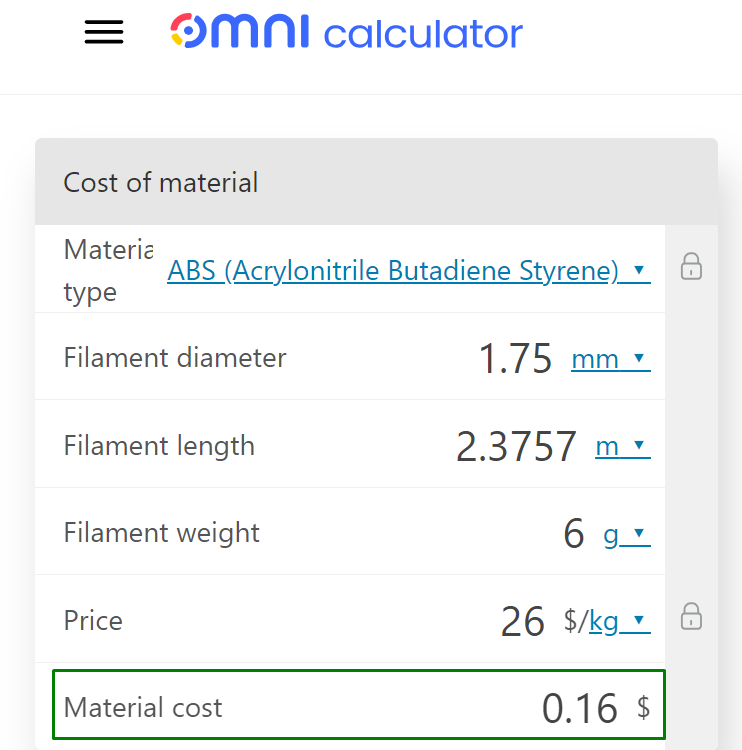

If you find that your file will use a lot of material, you can adjust the parameters like infill density and layer resolution and see how they impact the size of the material. Once you find the size of the material, you then need to know the diameter of the filament you are using and the price per kilogram or pounds. The one I am using has a diameter of 1.75mm and costs $26/kg. To get the cost of 3D printing material, we shall then use a 3D printing cost calculator like Omnicalculator to get the approximate cost.

After applying the values, I got the cost of the material to print that section of the design to be $0.16.

Labor Costs

The labor costs include the time and effort required in all the stages of your project. That is the time taken to design the model, prepare it for 3D printing, the actual 3D printing process, and post-processing activities labour.

Designing the 3D model takes a lot of time, especially if the project you are working on is complex and needs someone skilled in 3D modeling.

The designer should also ensure that the model is optimized for 3D printing. If you are not the one designing, you need to hire someone skilled, and this can add more cost to your project, unlike when you are doing it yourself.

The time it takes to 3D print your designs depends on the type of 3D printer you are using and the complexity and size of your print. When you slice your design, your 3D printer slicer will be able to show you the approximate time for 3D printing.

After 3D printing, you will need to do post-processing activities like removing supports, sanding, and even advanced techniques like electroplating and coating, which can be expensive compared to other activities. If you are charging someone and would like to approximate the cost, you will need to multiply the total time taken from the design stage to post-processing with your hourly rate.

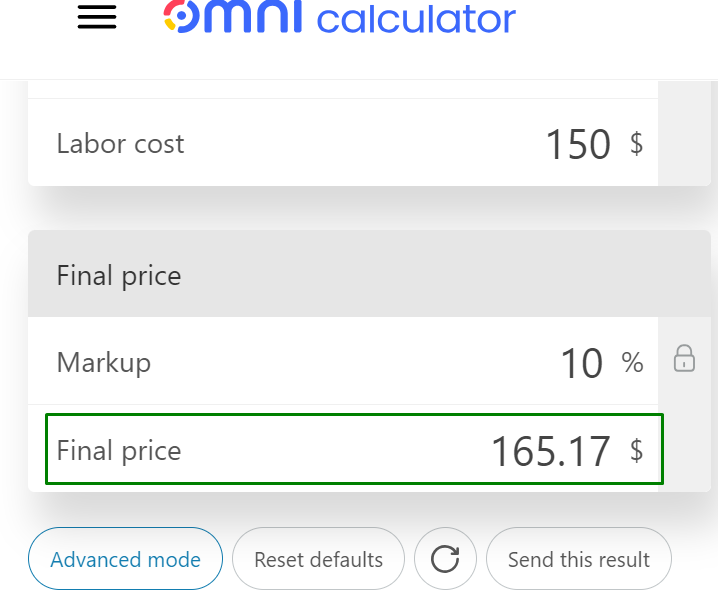

You can then combine the amount you will get with the material cost and get the approximate 3D printing cost. Instead of doing it manually, you can use the Omni calculator. For example, I can approximate the time to design and 3D print my file to be 10 hours, and I charge approximately $15 an hour. So, the total labor cost will be $150.When you use the calculator, it adds all the totals together with a 10% markup and displays the final cost (labor and material cost), as shown below.

You can also use the Prusa3D 3D printing calculator in addition to the Omni calculator.

3D Printer Capabilities

The type of 3D printer you are using greatly impacts the cost of 3D printing. Those with advanced features and a large build volume can accommodate larger files and help reduce the overall cost, unlike smaller 3D printers, which require splitting the file to fit on the bed, which adds more cost.

Even though the initial cost of purchasing large 3D printers is high, and they can sometimes use a lot of power, the overall operational cost is reduced. Additionally, the reliability of a 3D printer plays a crucial role. The one that breaks down frequently can increase the 3D printing cost as you will need to take time to maintain it.

Unreliable 3D printers can also cause the print to fail before you complete your project, which means you will have to start over again and use more material and time. 3D printers with automatic features like automatic bed leveling also help reduce the work of manually adjusting the printers before 3D printing, especially when working with several 3D printers.

The speed of the 3D printer also directly affects the cost. A higher speed reduces the time required to complete the project and labor costs as one doesn’t have to wait long for the project to be completed. If your 3D printer can handle a higher speed without compromising on the quality of the print it will be beneficial.

Operational Costs

Operational costs include elements like the power consumption of the printer. The electricity cost varies depending on the 3D printer you are using and the size of the project. Most 3D printers don’t use a lot of electricity, and you might not even notice it on the bill unless you are running several of them.

If you know how much power it consumes in kilowatts per hour, you will have to multiply it by the total 3D printing time, and you will be able to know the electricity cost.

Also, if you are 3D printing frequently, you need to take into account the maintenance costs of your 3D printer. This involves replacing worn-out parts like hotends, extruders, and the bed, lubrication, and even cleaning. But the good thing is that these costs don’t count in every 3D printing job, as you need them only once in a while.

Having looked at the factors that influence 3D printing costs, it’s also important to look at the methods available for calculating the total cost of 3D printing. We have already looked at Omni calculator which is helpful in estimating the budget when labor and material costs only are considered. Let’s see other estimation calculators that you can use to approximate the cost.

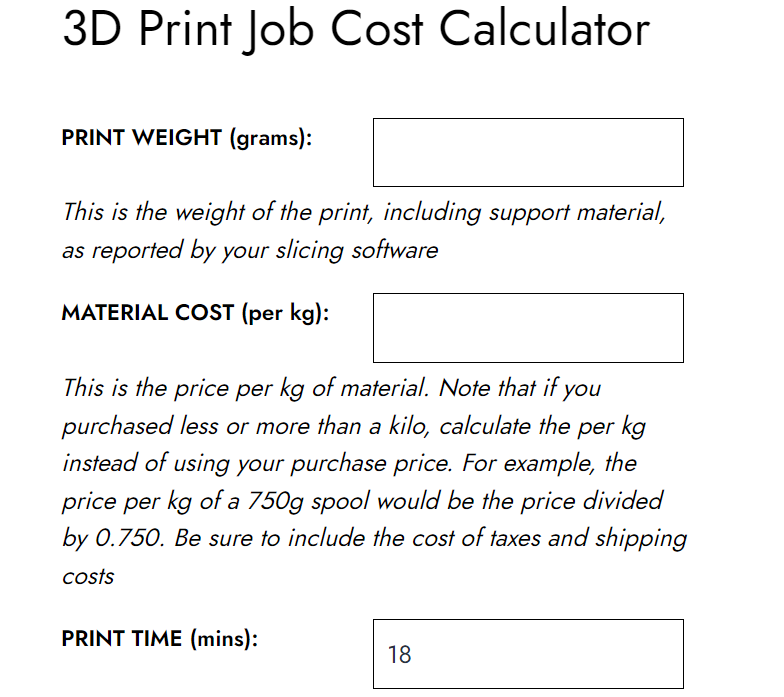

3D Print Job Cost Calculator by Fabbaloo

The Fabbaloo calculator integrates the basic 3D printing factors that determine cost and it works with both filament and resin filaments. Unlike the Omni calculator, which includes only material and labor costs, this calculator includes more details like the cost of the 3D printer, electricity cost, and the amount of power the printer consumes.

It also includes markup cost, post-processing time, and fail ratio. Once you fill all the boxes, you can click on Calculate to see the estimated cost. You can also Prusa3D 3D printing price calculator if you need an alternative to the Fabbaloo calculator.

In addition to using a 3D printing calculator, you can also use an online 3D printing service to get an estimate of the cost. Below are some of the 3D printing services you can use.

Sculpteo

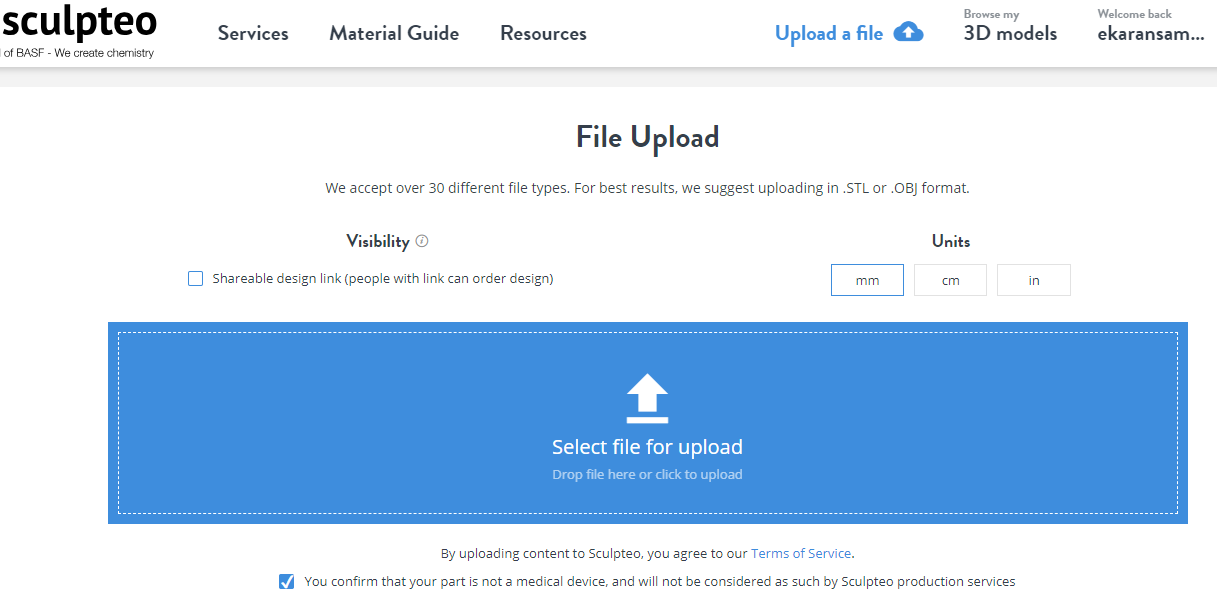

Sculpteo is an online 3D printing service provider with a platform that allows you to upload your 3D models and get instant quotes. Once you sign up, you will click on Get Your Instant Quote, and you will be redirected to the platform where you can upload your file.

You can add a single file or several of them. Once you do that, click on Next, and you will see the interface below.

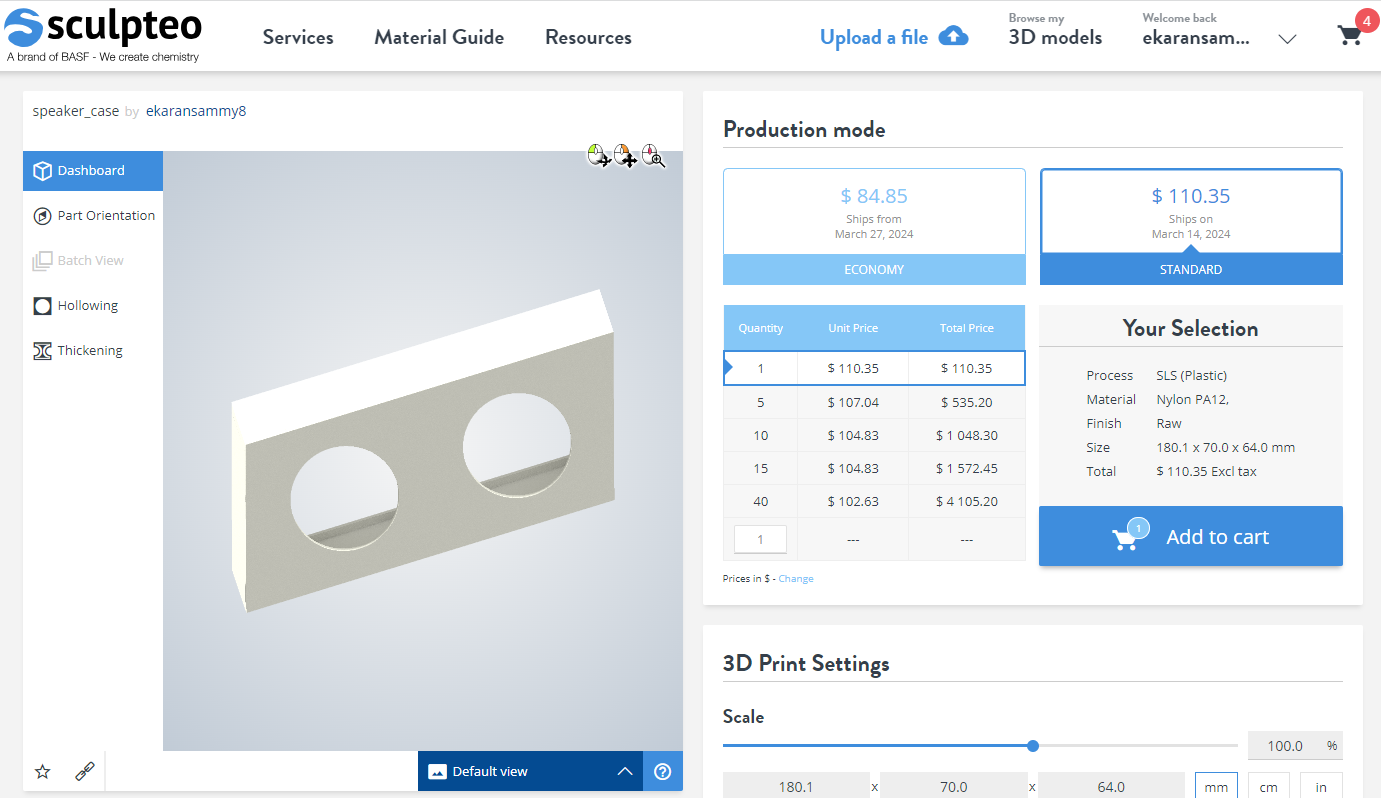

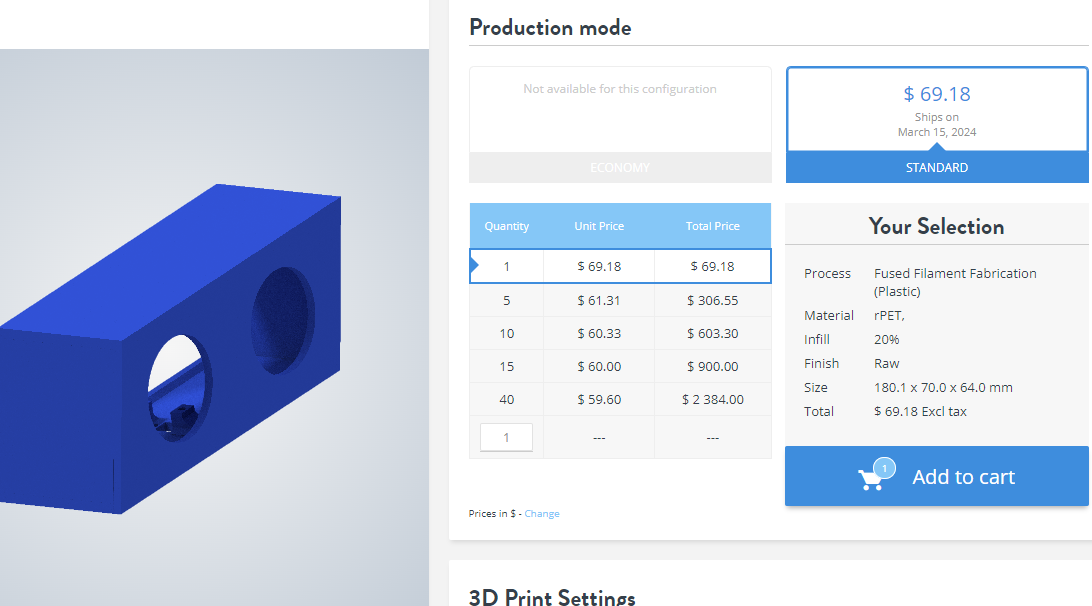

You can do basic editing, such as orienting your file, hollowing, thickening, and even scaling. Once you finish editing, you can choose the printing process, material, and other print settings. You will see the printing cost in real time, and then you can put it in the cart to order.

This is useful when you don’t own a 3D printer and would like a 3D printing service to handle your project or that of your client.

CraftCloud

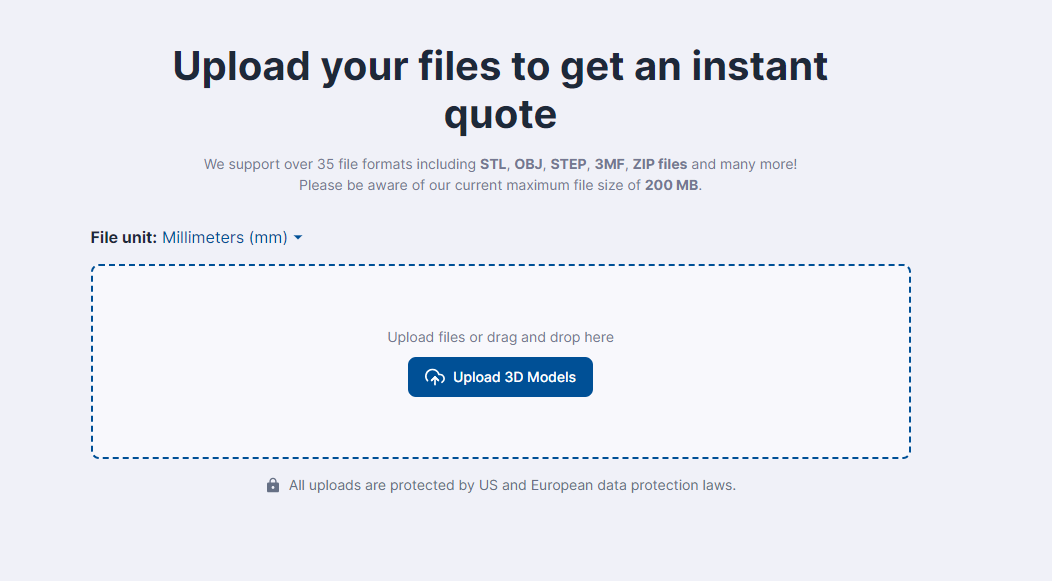

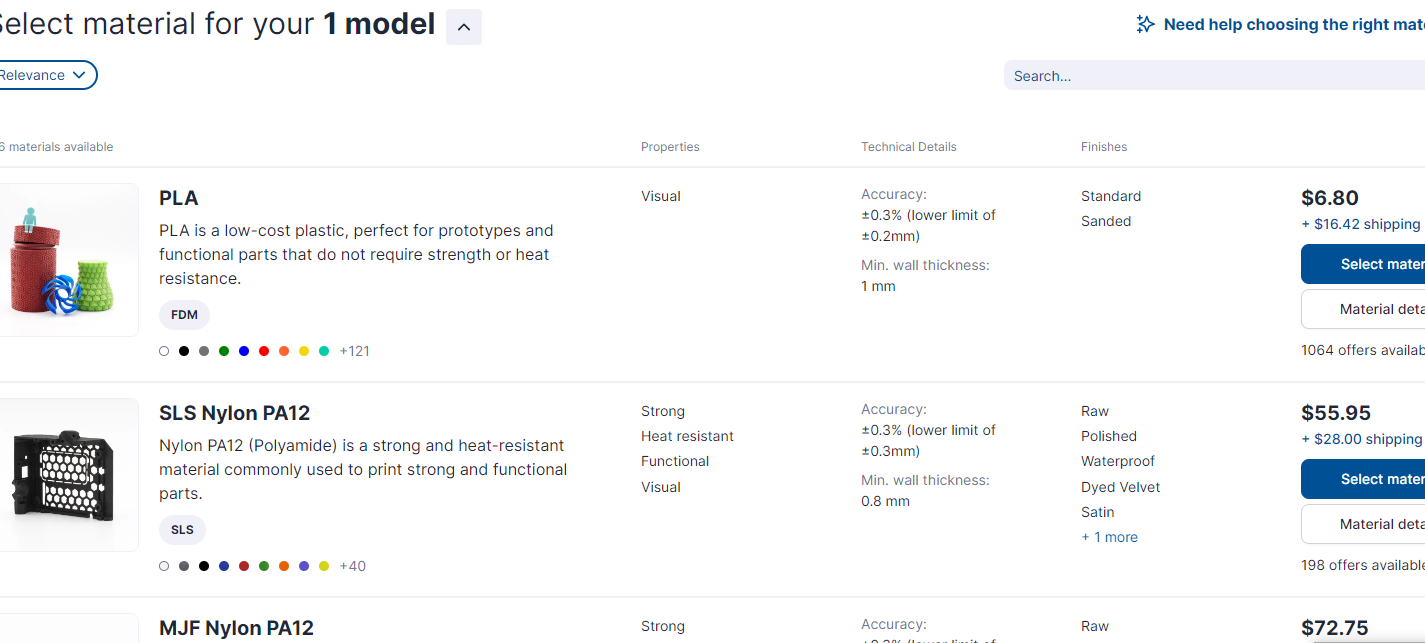

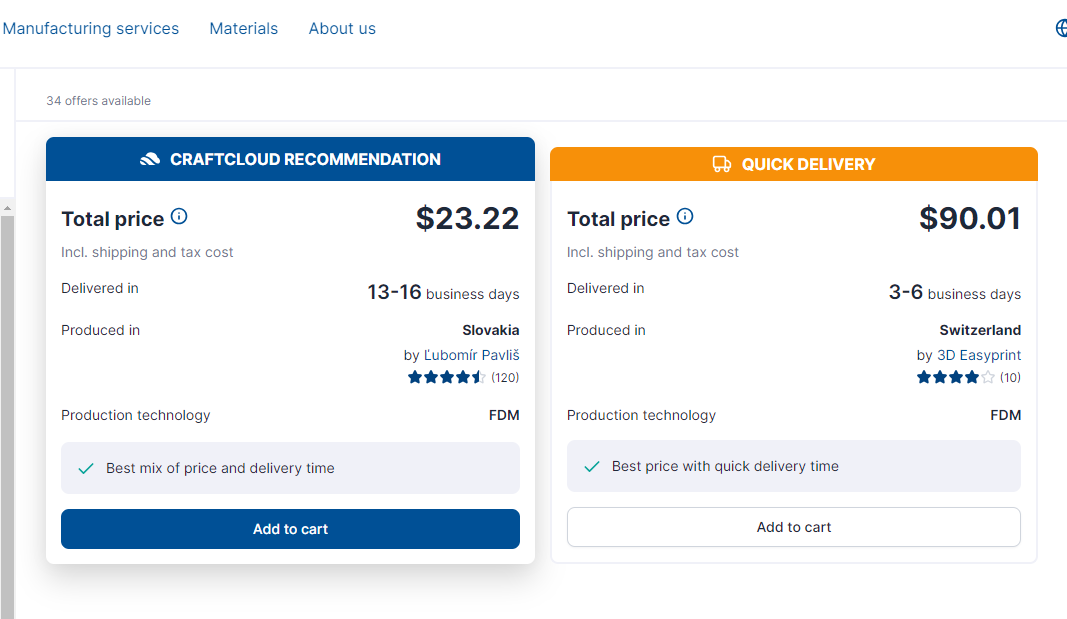

CraftCloud from All3DP is a 3D printing service similar to Sculpteo that we have just looked at. You can upload files in various formats, such as STL, STEP, OBJ, ZIP files, and 3MF.

Once you upload the file, you will see an option to see the various materials available and prices.

You can then select the finish and color and you will be able to see the approximate cost, time of delivery, as well as where your file will be 3D printed.

The above strategies should be able to give you an insight on estimating the cost of 3D printing, however, as you do your estimates remember that they could change because of various factors.

More 3D Printer Tutorials

- How to Use PrusaSlicer: A Beginners Guide

- 5 Ways Fix Z Banding in 3D Printing

- How to Use FreeCAD for 3D Printing

- How to Convert OBJ Files to STL Files for 3D Printing

- How to Clean and Cure Resin Prints

Sammy Ekaran is a freelancer writer for Tom's Hardware. He specializes in writing about 3D printing tutorials and guides. You can find more of his work on various publications, including Makeuseof, All3dp, and 3Dsourced.