PSU Repair: A Case Study

When your PSU won't start, most enthusiasts don't go beyond a paperclip or multimeter check. Today, we'll do a comprehensive repair of Antec's old SL300.

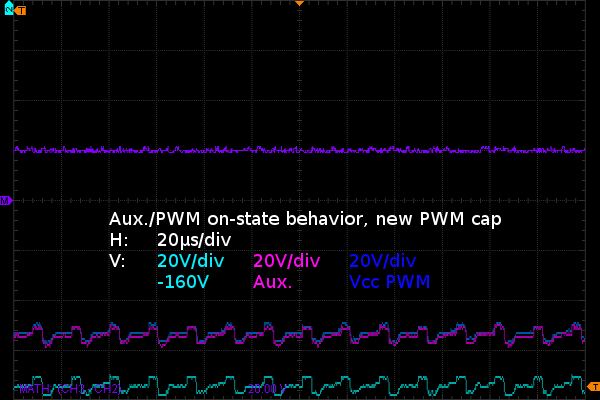

PWM Bypass Capacitor Results

Considering the tremendous improvements from replacing the busted auxiliary cap, I am starting to have doubts about how much more replacing the controller's bypass cap might achieve: the controller seems perfectly happy drawing current from the auxiliary supply cap through its photocoupler and transistor.

Then again, the way there is effectively no ripple on the auxiliary supply while the main outputs are live using the new 100µF cap tells me the new capacitor is grossly over-sized and that the controller's 22µF cap should have been more than enough to keep it running. The fact that it did not, at least not without the help of several kicks in the pants to get it started, may indicate it is either busted or severely degraded, just like the auxiliary output's was.

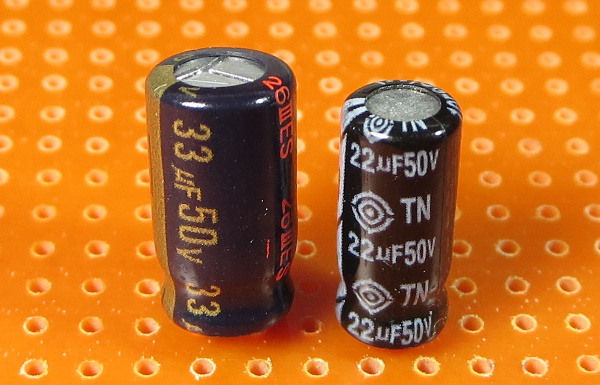

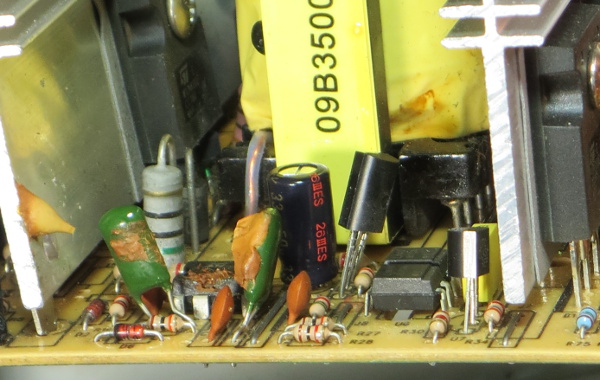

I just so happened to have 33µF 50V FC-series caps in stock, which should be a great fit for the 22µF 50V cap on the board.

The sizes look quite similar and I have matching lead spacing, but it is not quite a perfect fit. I still had to nudge a transistor sideways to slip the 1.3mm-wider capacitor in. I call that close enough and not worth ordering replacements specifically for it, although I might still end up doing so if it helps me pad an order to get free shipping.

Unlike the previously-replaced caps, which had capacitance an order of magnitude off or worse, this one actually measured in at 18µF, not that far from its nominal 22µF.

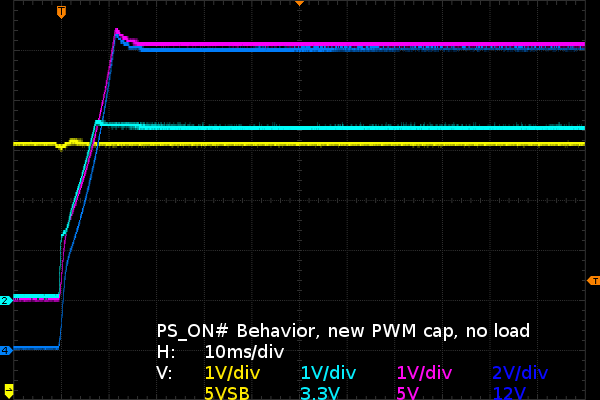

It might be difficult to tell anything has actually changed from the PS_ON# behavior. There is only one tiny detail to give it away: a small dip on the 5VSB output just before the main converter starts operating. This would be the PWM's bypass capacitor charging up, momentarily dragging the auxiliary and 5VSB outputs down slightly.

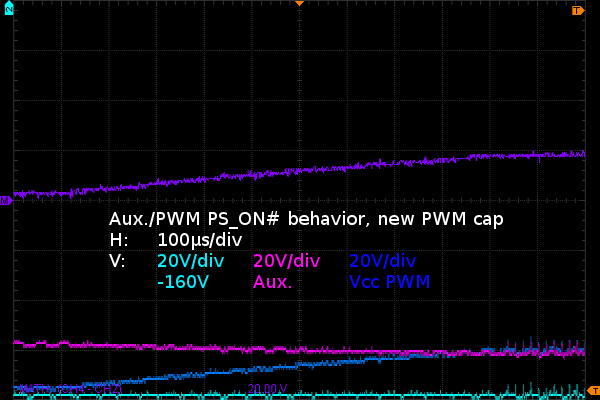

On the primary side, there is only one obvious change: whereas the old cap “charged up” to the auxiliary supply's voltage in a matter of maybe 10µs during the PS_ON# sequence, the new capacitor takes almost a whole millisecond to do the same, a hundred times longer, to reach its 20V operating point. While the old cap's nominal capacitance may have been marginally good, its series resistance must have been horrible for it to have effectively no effect on circuit operation.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

During the steady on-state, I cannot honestly say I see any difference on my primary-side signals from the new bypass capacitor. The signals look slightly cleaner but at the resolution these screen captures were made at, differences are at the noise floor.

Current page: PWM Bypass Capacitor Results

Prev Page Auxiliary Output Capacitor Replacement Next Page Capacitor Postmortem