PSU Repair: A Case Study

When your PSU won't start, most enthusiasts don't go beyond a paperclip or multimeter check. Today, we'll do a comprehensive repair of Antec's old SL300.

The Test Plan

Now that I have enough data to work with, and knowing how my areas of interest operate, I can put together a list of things that need to get looked at and things that I need to keep in mind.

The first and most important point is that the primary side of the 5VSB and PWM sections are referenced to -170V or whatever the low-side capacitor happens to be charged at. Without a proper differential probe, this means I will only be able to make rough DC measurements. But for most of what I want to look at on the primary side, that should still be good enough: if there is trouble to be found, it won't be subtle.

In flyback converters with multiple outputs, energy gets dumped into outputs following the path of least impedance. When capacitors start to go bad, dropping capacitance and increasing ESR, more energy gets dumped into other outputs, ripple voltages and currents increase across all outputs, and regulation gets worse. This tends to wear them out fairly evenly until they start failing altogether. Since the 5VSB caps are definitely in poor shape, all other outputs from that flyback transformer become suspects.

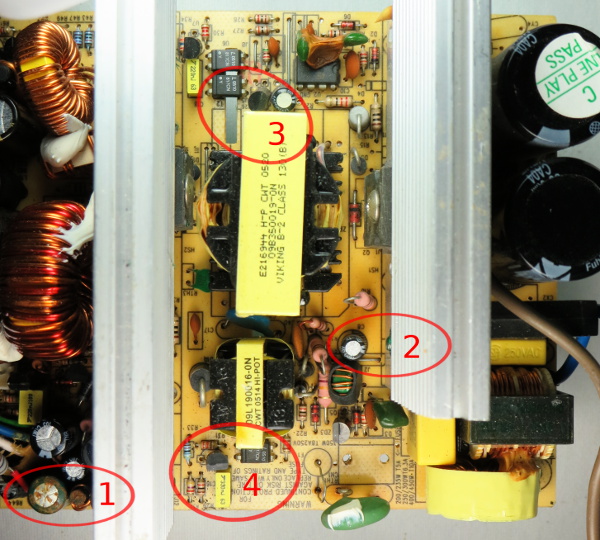

With that in mind, what are my targets?

- The 5VSB output caps are definitely busted, so I will be swapping those out and see how much it helps. I doubt they'll do anything about the out-of-spec 5VSB voltage, but this should at least eliminate most of the switching noise.

- Voltage on the 5VSB's auxiliary output needs further investigation to see if the 47µF capacitor is still doing its job and what its actual operating voltage is. Changing this capacitor for a larger one should reduce the dips caused by the PWM section starting to draw current from the auxiliary output and make it less susceptible to whatever happens on the 5VSB output.

- Check voltage on the PWM chip's VCC pin to see if there might be an issue either with its bypass capacitor or the power it receives from the auxiliary output through the photocoupler and booster transistor that might not come from the the auxiliary supply itself.

- Check signals around the 5VSB's TL431 to see if incorrect voltage might be caused by a flaky IC, resistor or leaky capacitor

Those would be my four main suspects, and I am 90% confident I will not need to go beyond the third. Before digesting my PCB assessment, I considered investigating the PS_ON# path and the TL431 on the 3.3V output, but decided to toss those ideas in the improbable bin. Same goes for everything related to the main converter feedback loop, since outputs look perfectly fine when the converter manages to start.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

-

Nuckles_56 An interesting read, it was interesting following the process you used to troubleshoot the problemReply -

Crashman I used to do this for a living :)Reply

Don't tell my boss, I've managed to convince him that I'm only an expert at running benchmarks and writing about the results :) -

epsiloneri Disclaimers won't help. The people who will likely hurt themselves trying this are the same who lack the reading comprehension and self awareness to understand those disclaimers are directed at them. I admire you courage in publishing this.Reply

-

beetlejuicegr the truth is the paper clip and multimeter is all i can go in to psus. after all i haven't studied electricity or circuits or whatever.Reply

However i do hate to throw stuff earlier than it should, like you. -

C12Friedman I like this article and I fully agree with the conclusion. I've repaired a few PSU's but, for the most part I scavenge them anymore since I can't put them in a new system (nor would I want to) IMO they aren't really worth anything other than for on a test bench.Reply -

Mr A Daniel, I know next to nothing about electronics, and yet I could not stop reading this article. Fascinating! Thanks very much!Reply -

Urzu1000 This was a great article! It was informative, as well as interesting. Personally, I've only had one PSU fail on me so far. My brother-in-law's self-built computer had a really low-end Thermaltake PSU. 800W Bronze, and oh man, did that thing go out in a blaze of glory. Very loud popping, and smoke, and funny smells. When I ripped it out of the computer, there were burns inside the case. Miraculously, the other components remained unharmed, so I slapped in a new PSU (750W Gold Seasonic) and fired it up.Reply

Still working good, but I get black soot on my hands every time I open up that case. It's a black case, so it's hard to clean it off properly. -

Interesting article. I would have simply replaced the entire unit. You saw how to fix the failure, but how many units were damaged that you didn't see? A ticking time bomb that will eventually send some spike to your much more valuable hardware than a 10 year old PSU. Wasteful, yes. I get it. I don't like to waste either. And if it's on marginal hardware, fine. But on primary systems I'm not willing to take the risk. I'd rather throw away a 200$ part that has a 0.05$ repair solution, than risk frying 800$+ hardware.Reply

-

kalmquist "Antec's manufacturer (Channelwell in this case) got the live and neutral wires backwards, which means that in the “off” position, the neutral line gets opened and everything on the primary side becomes live instead of neutral."Reply

That's really bad--I doubt it is even legal to sell a power supply wired like that. I've never bought a CWT (Channelwell) power supply, and based on this I wouldn't buy one, except perhaps for a high end model where you might gamble that the company would exercise a bit more care.