Tom's Hardware Verdict

The UniFormation GKtwo offers a pro-level experience with a heated resin vat, a quick-change build platform and other features at the cost of a higher price than the competition.

Pros

- +

Integrated resin vat heater

- +

Large build volume

- +

High resolution

- +

Quick-change resin vat and build platform

Cons

- -

Complicated build platform leveling process

- -

Expensive relative to similar printers

Why you can trust Tom's Hardware

The UniFormation GKtwo is a desktop resin 3D printer that offers an eye-popping 29.6 micron XY resolution thanks to the high resolution 8K masking LCD. The large build volume of 432 in^3 (8.97" x 5.04" x 9.64") can easily fit multiple small parts or larger individual components, and the integrated heating element allows users to print in a colder environment without worrying about resin viscosity. The build platform and resin vat can be quickly changed without tools, but the complicated build platform leveling process is significantly less user-friendly than the typical two-bolt style used on printers like the Elegoo Saturn 8K.

Available on the UniFormation site for $899.99, the GKtwo is not an inexpensive resin 3D printer and the price may put off potential customers who are able to find similar resolution for less money. Combined with the complicated build platform leveling, this prevents the GKtwo from making the list of the best resin 3D printers. However, anyone interested in printing in a cold-weather environment will appreciate the integrated heating element. Likewise, the quick-change resin vat and build platform are major quality-of-life improvements for anyone switching materials frequently.

UniFormation GKtwo Specifications

| Machine Footprint | 13.7" x 12.4" x 18" (350mm x 315mm x 455mm) |

| Build Volume | 8.97" x 5.04" x 9.64" (228mm x 128mm x 245mm) |

| Resin | Standard, Water-Washable, and ABS-like UV Resin |

| Normal Exposure Time | 3 seconds |

| UV Light | 40 UV LED COB Matrix |

| Masking LCD Resolution | 7680 x 4320 px (8K) |

| Masking LCD Size | 10.3-inch |

| Interface | 5-inch LCD Touchscreen |

| Connectivity | USB Thumb Drive |

| XY Resolution | .0296mm |

Included in the Box of UniFormation GKtwo

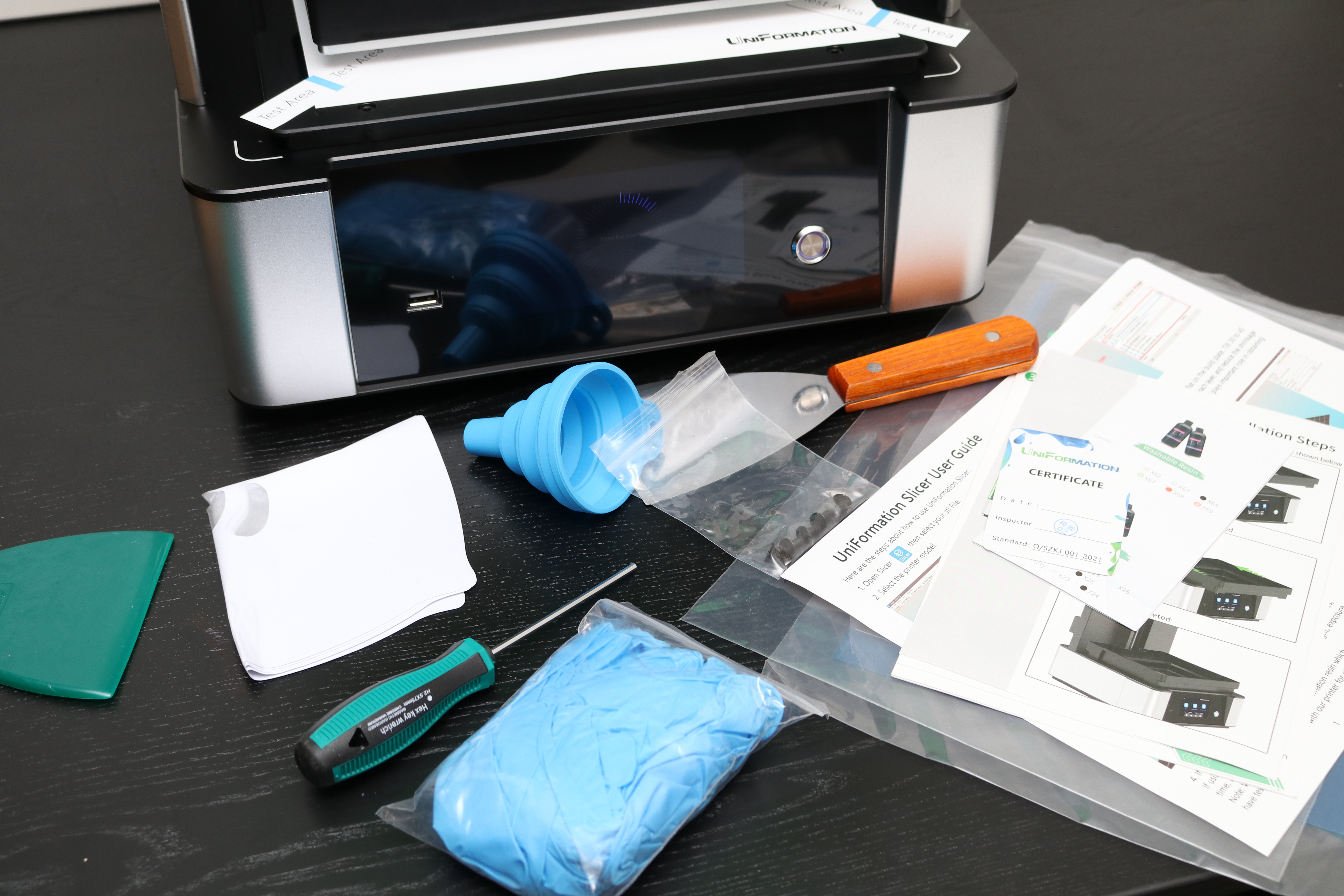

Like most resin 3D printers in this price range, the UniFormation GKtwo includes everything you need to get started right away; just add resin and you’re good to go. The printer includes a scraper, silicone funnel, gloves, paper filters, and other higher-value accessories such as an LCD screen protector and replaceable film for the resin vat. Build platform calibration aids and a USB thumb drive with slicer software are also included.

In addition to the printed quick start guides, UniFormation has also included nine videos on the USB thumb drive that provide detailed instructions for performing various tasks such as filtering resin, testing the UV exposure, and calibrating the build platform. Considering how critical some of these processes are to print success, this is a helpful inclusion for visual learners who prefer to watch an instructor instead of reading a guide.

Design of UniFormation GKtwo

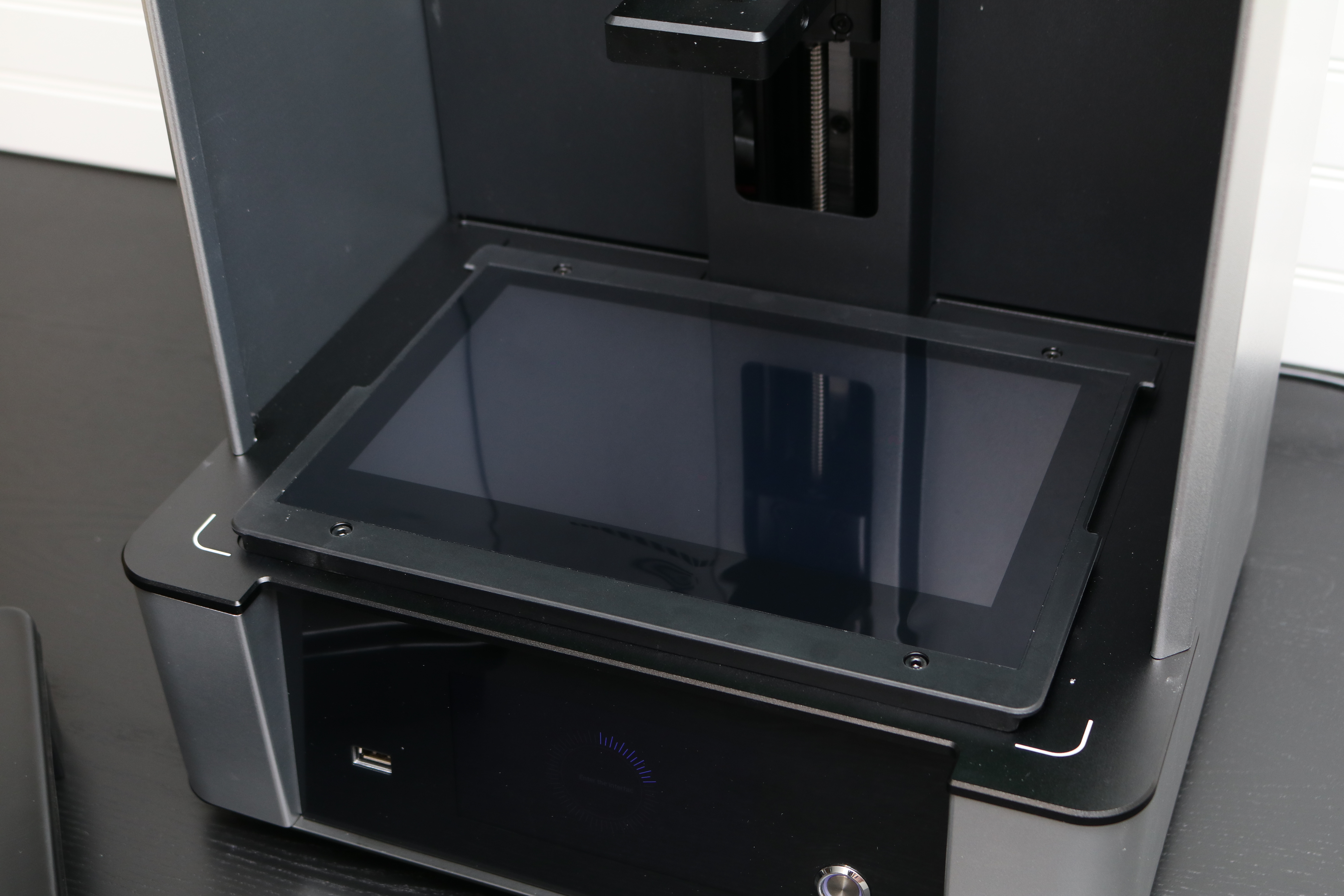

The UniFormation GKtwo has a large 5-inch touchscreen LCD interface located on the front of the machine, a single power button to toggle the printer on and off, and a USB port for inserting a USB thumb drive. The printer enclosure feels sturdy and robust, and the feet are adjustable for ensuring the resin sits level in the vat.

The Z-axis uses a single lead-screw for movement, and the build platform uses a quick-release hinge to secure the platform in place. The COB UV LED light source is located underneath the masking LCD, which is covered by a replaceable screen protector.

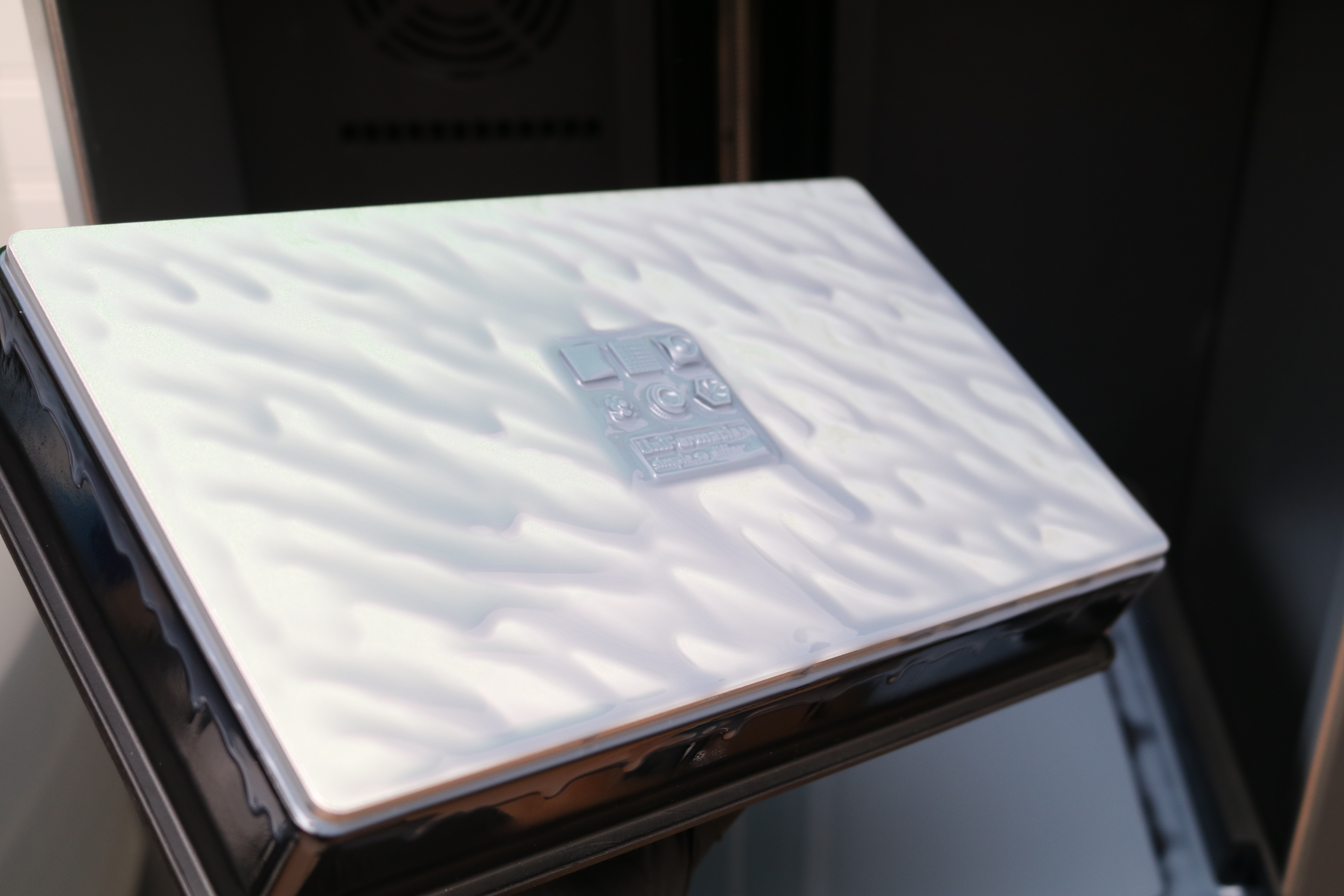

Unlike most resin 3D printers, the lid on the GKtwo doesn’t lift up and off the printer. Instead, it features a hinged design that flips upwards allowing the user to access the platform and vat. While this is ideal for users that keep their printer on a table, it does mean that you will need extra space above the printer so the lid can be fully lifted back between prints. I found this feature to be very helpful during printing, as I wasn’t constantly looking for an open space on my desk to place the lid after removing it.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The Gktwo includes a lid for the resin vat, a helpful feature that allows users to effectively swap between materials without requiring a lengthy cleaning process. Typically, the resin vat needs to be cleaned thoroughly when switching between materials to prevent cross-contamination. By including a cover, UniFormation has made it simple to swap out vats so users can put aside material not actively being used without worrying about light hitting the resin or dust settling in the resin. This, coupled with the screwless quick release mechanism that holds the vat in place makes changing vats a very fast process.

The included air filter attaches to the rear of the GKtwo and uses integrated magnets to hold itself in place. The GKtwo has a large fan mounted inside the printing area that pushes air through the attached charcoal air filter. The air filter reduced the amount of odor during printing, but it’s worth noting that UniFormation recommends changing the charcoal filter every 15 days if the printer is being used regularly. The filter is sold in packs of six for $59.99, so it should be considered a consumable from a wear-and-tear perspective.

The build platform of the GKtwo is rectangular, and lacks the typical angled or trapezoidal shape seen on other resin 3D printers. The result is a platform that is very easy to clean, as the resin naturally falls off the side during printing and you only need to wipe around the edges to clean the platform fully. This is a massive time-savings when compared to printers like the Anycubic Photon Mono X which use difficult-to-clean hardware to attach the build platform to the Z-stage gantry.

While it may not seem like a major feature, the ability to fully clean the platform in only a few minutes with no resin lurking in an upward-facing bolt meant that resin color changes were lightning-fast. Part removal didn’t require significant clean-up time, and the overall cleaning process was greatly simplified. The platform has a small gutter running along the perimeter that catches resin as it drips, so one continuous wipe is enough to clear the sides and a second wipe is enough to fully clean the platform.

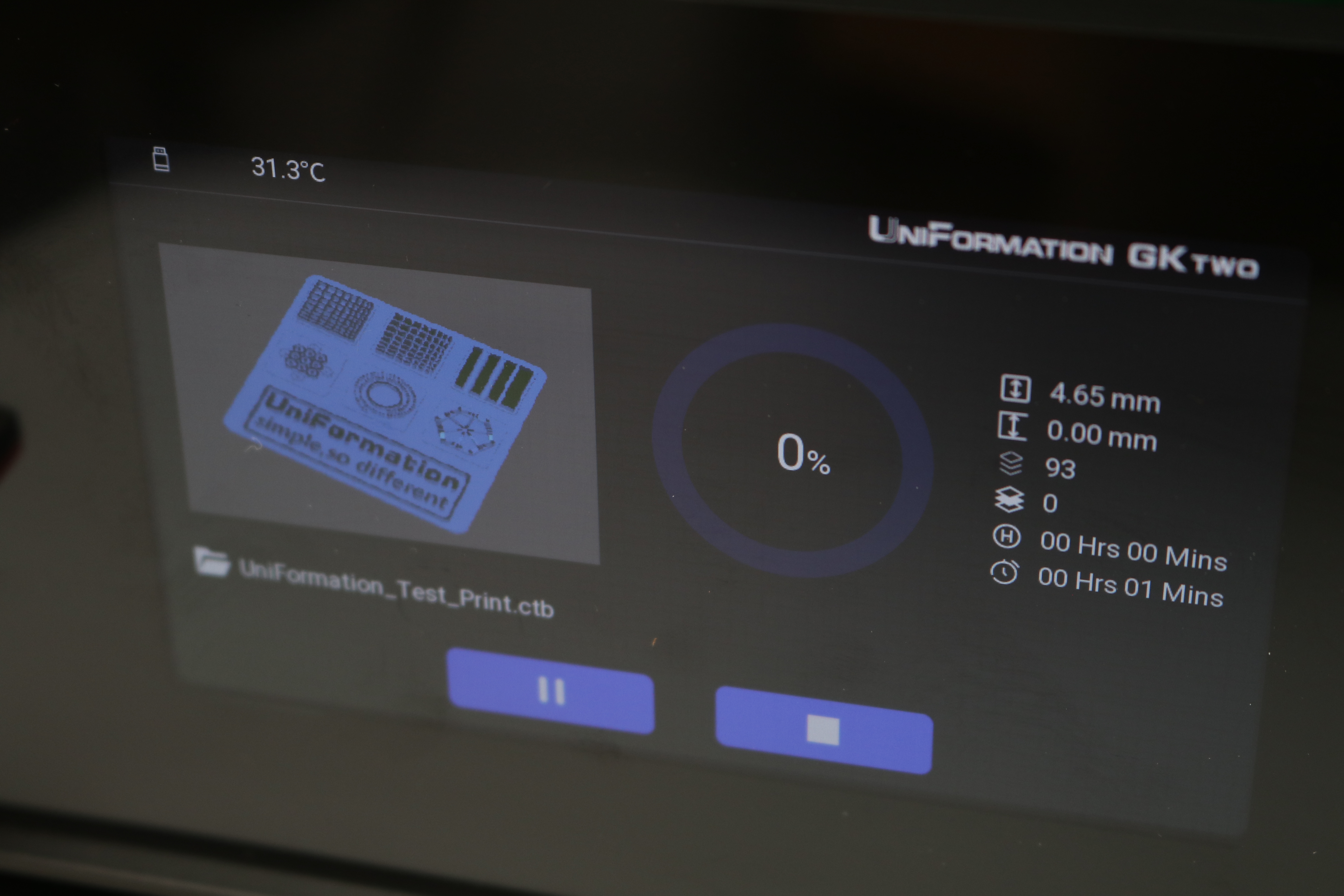

The GKtwo has an integrated heater to increase the temperature of the resin, a feature that those who live in cold climates will greatly appreciate. Resin tends to print best when warm, so heating the resin allows users to print in a cold environment while maintaining a raised local temperature. I set the heater to 30°C during printing, and the printer displayed the status of the heater at the top left of the LCD during the print.

Leveling the Build Platform on UniFormation GKtwo

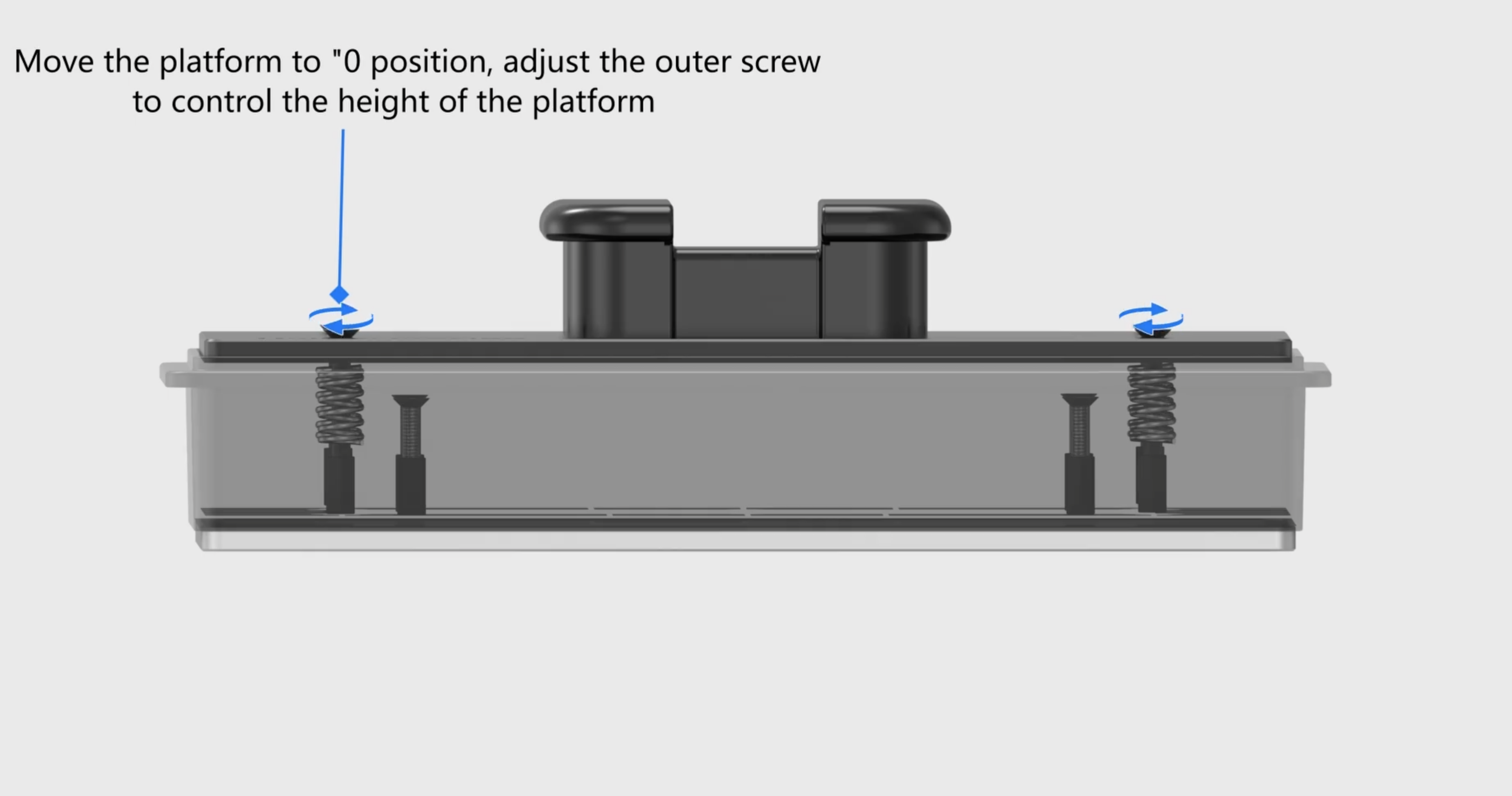

The UniFormation Gktwo has a unique platform leveling process that is unlike the typical two or four-bolt leveling system used by other resin 3D printers. The build platform surface is actually a component in the build platform assembly which needs to be manually offset using an eight bolt leveling system. This process involves homing the built platform to Z0, tightening the four spring-loaded bolts to calibrate the bed, and then tightening the remaining four bolts that hold the platform in position. Once these have all been tightened, the platform can be checked at all four corners using the included strips of paper to test the offset.

I only needed to level the platform once during testing, but the process took significantly longer than the two-bolt process of the Elegoo Saturn 8K or the automatic leveling of the Anycubic Photon Mono M5s. Advanced users who are familiar with the spring-loaded manual bed leveling on filament desktop 3D printers will intuitively grasp the leveling mechanism on the GKtwo, but beginners will likely struggle with the complicated eight-bolt process. UniFormation has included a video demonstration on the USB thumb drive of this process, which I recommend watching carefully before attempting the calibration.

Printing Safety with UniFormation GKtwo

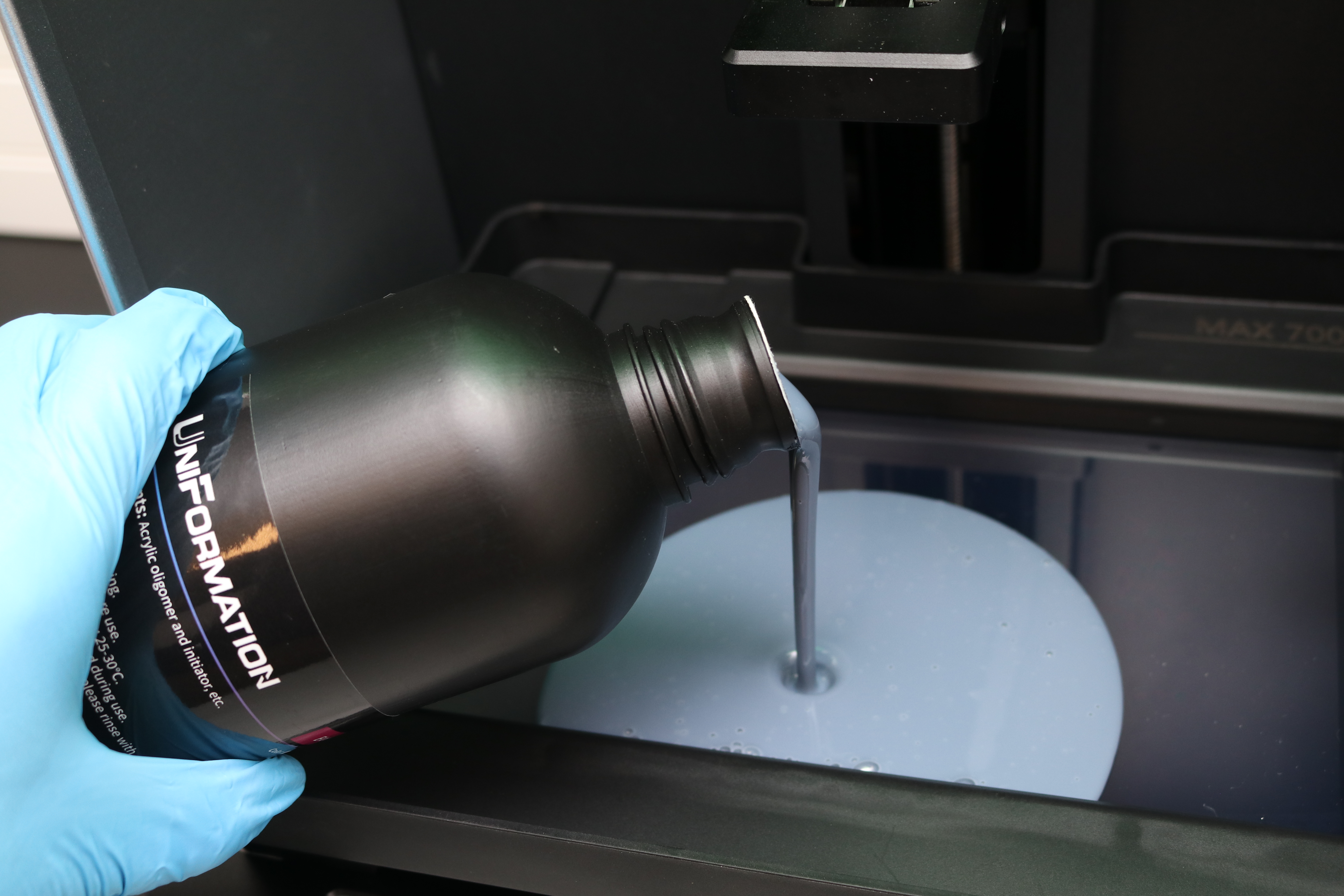

The UniFormation GKtwo uses UV resin, a material that you need to handle safely when in an uncured state to avoid injury. The resin can be harmful when making contact with skin, so make sure to wear gloves when pouring, cleaning up, or handling uncured resin. I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

Make sure you use the GKtwo in a well-ventilated room to minimize the danger from inhaling fumes. Any spills or uncured resin stuck to a surface should be cleaned using 99% Isopropyl Alcohol and the container for the resin should be kept closed and secured when not actively pouring material.

UniFormation included two bottles of X13 and X10 resin, which is labeled as “Biodegradable” and ”PLA-Based”. When I asked UniFormation for more information about this particular claim, I received the following response from a representative: “...but It also needs to be decomposed gradually over many years under certain conditions (temperature and humidity). The rate of complete natural degradation is relatively slow. If you want it to degrade quickly, you have to rely on specialized facilities, it can be returned to water and carbon dioxide, but the time is long, so there is one more tips, material compostable needs more time, so we did not suggest.”

Printing the Included Test Prints on the UniFormation GKtwo

UniFormation has taken a slightly unorthodox approach to test prints which may come as a surprise to seasoned 3D printing veterans. Instead of including multiple test prints on the included USB thumb drive or integrated memory, the GKtwo includes a PDF that links to a Google Drive folder populated with pre-supported models. These models have been provided by artists such as Wicked, Collective Studio, Villain Design & Prints and repositories such as STLFlix. Included in the folder are high-resolution pictures showing the model after printing, assembly, and painting for inspiration, along with discount codes for subscription services.

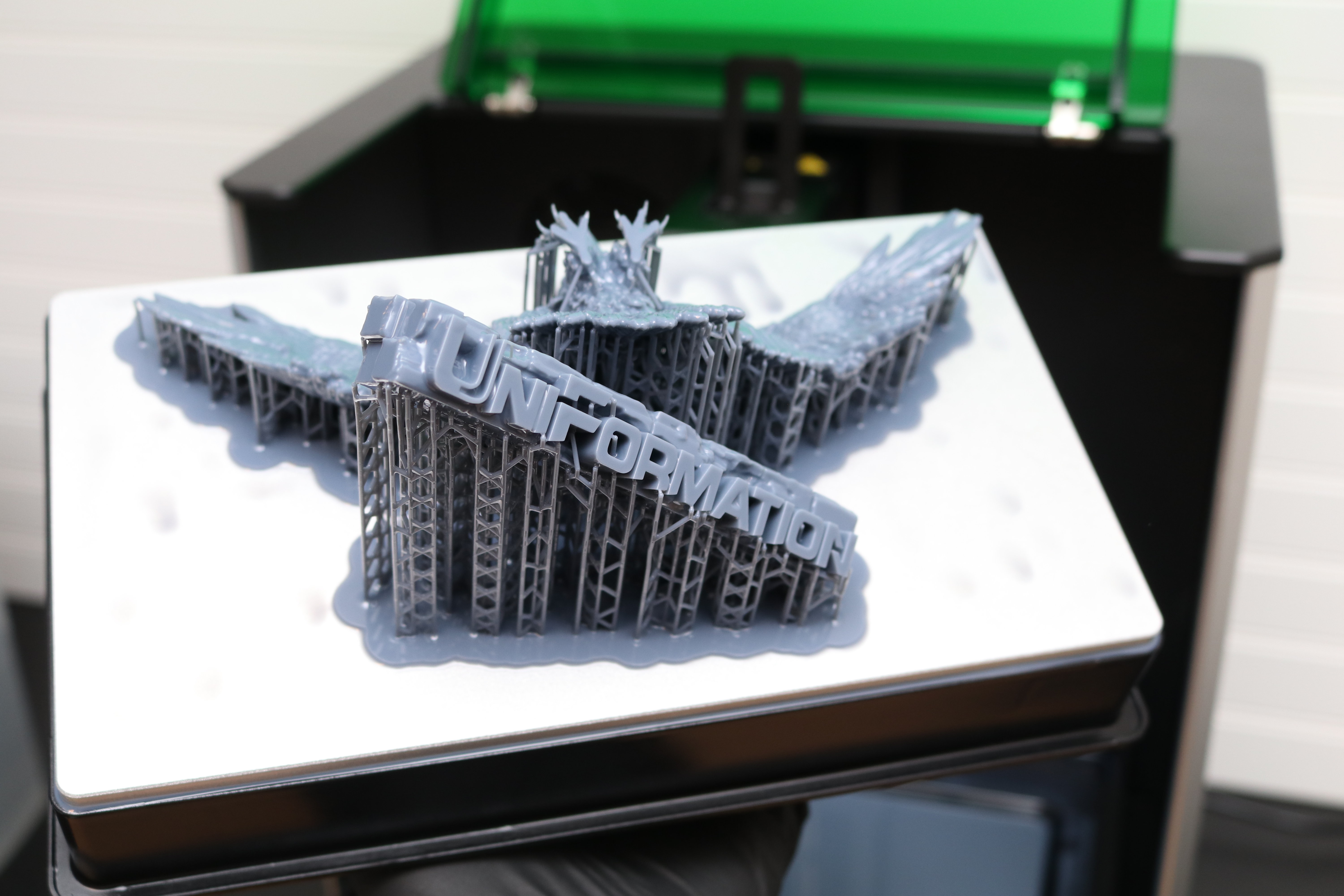

Among the demo prints is a file called “SUMMON THE EAGLE” by STLFlix, which also features the UniFormation logo embossed on a textured brick wall. This model is included in both unsupported and pre-supported formats, and is an impressively detailed and ambitious test print for a resin 3D printer. The wide wingspan of the eagle means that this print occupies a large amount of area on the build platform, allowing it to double as a calibration test to ensure proper calibration.

The 8K resolution of the GKtwo results in each feather on the wings being clearly defined, and the embossed logo is razor-sharp and clear around the edges. While larger than a typical test print and requiring more resin than a simple calibration plate or cube, this model offers an impressive glimpse into what the GKtwo is capable of. However, this print takes around 3 hours and uses 135 grams of resin, which may be more than some users are comfortable using for a test.

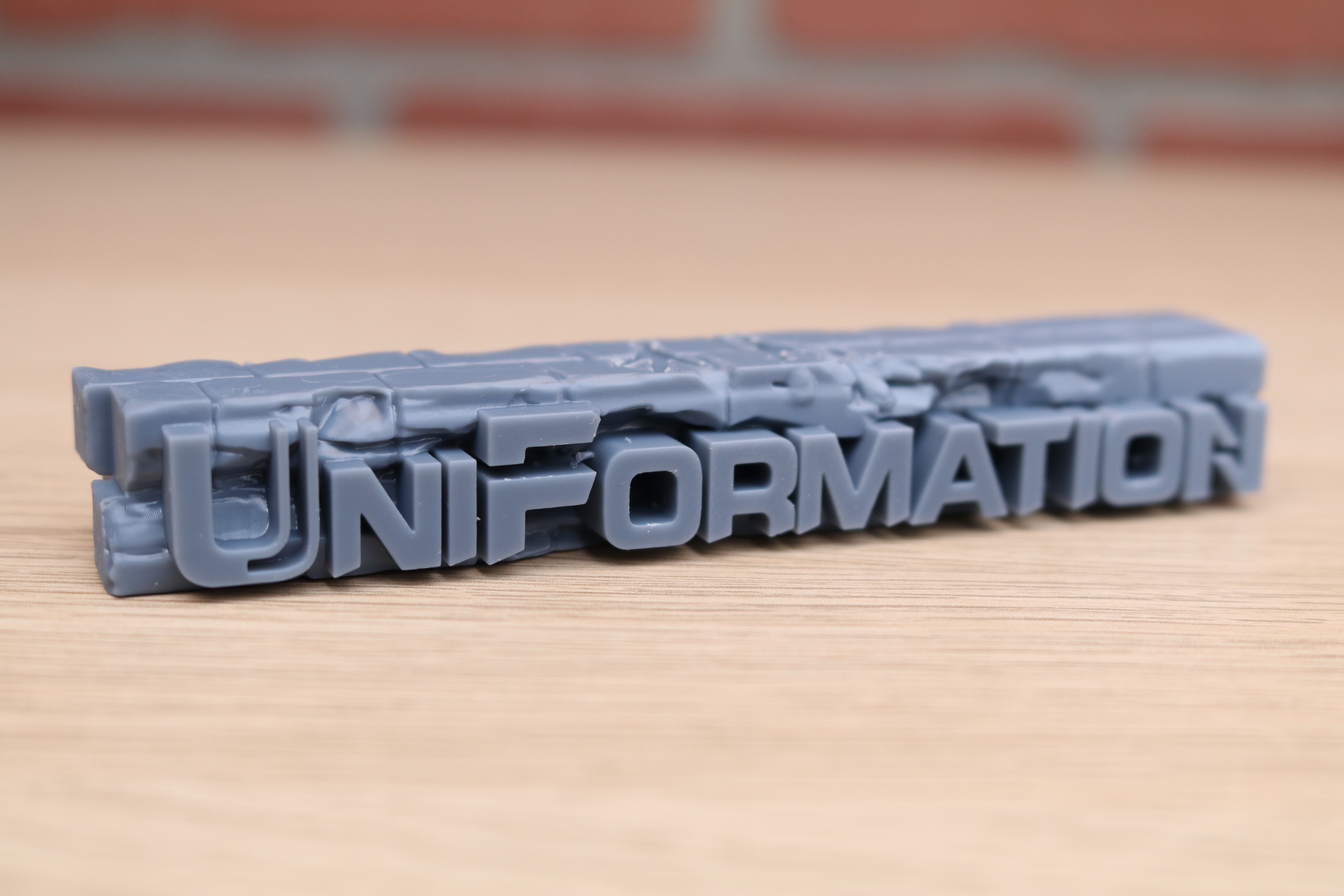

For those only interested in a fast print to determine if the printer is functional and calibrated, the dryly-named ‘UniFormation-Exposure Test File20230213.stl’ offers a more pragmatic example of the high-resolution capabilities of the GKtwo.

This test print includes multiple fine features such as thin posts, small holes, and shallow curves to show off both XY resolution. The UniFormation slogan “simple, so different” is embossed at the bottom of the print and this, plus the fine features on the plate, allows users to determine if the printer is ready to go in around 20 minutes and only uses a few grams of resin.

Printing with the UniFormation GKtwo

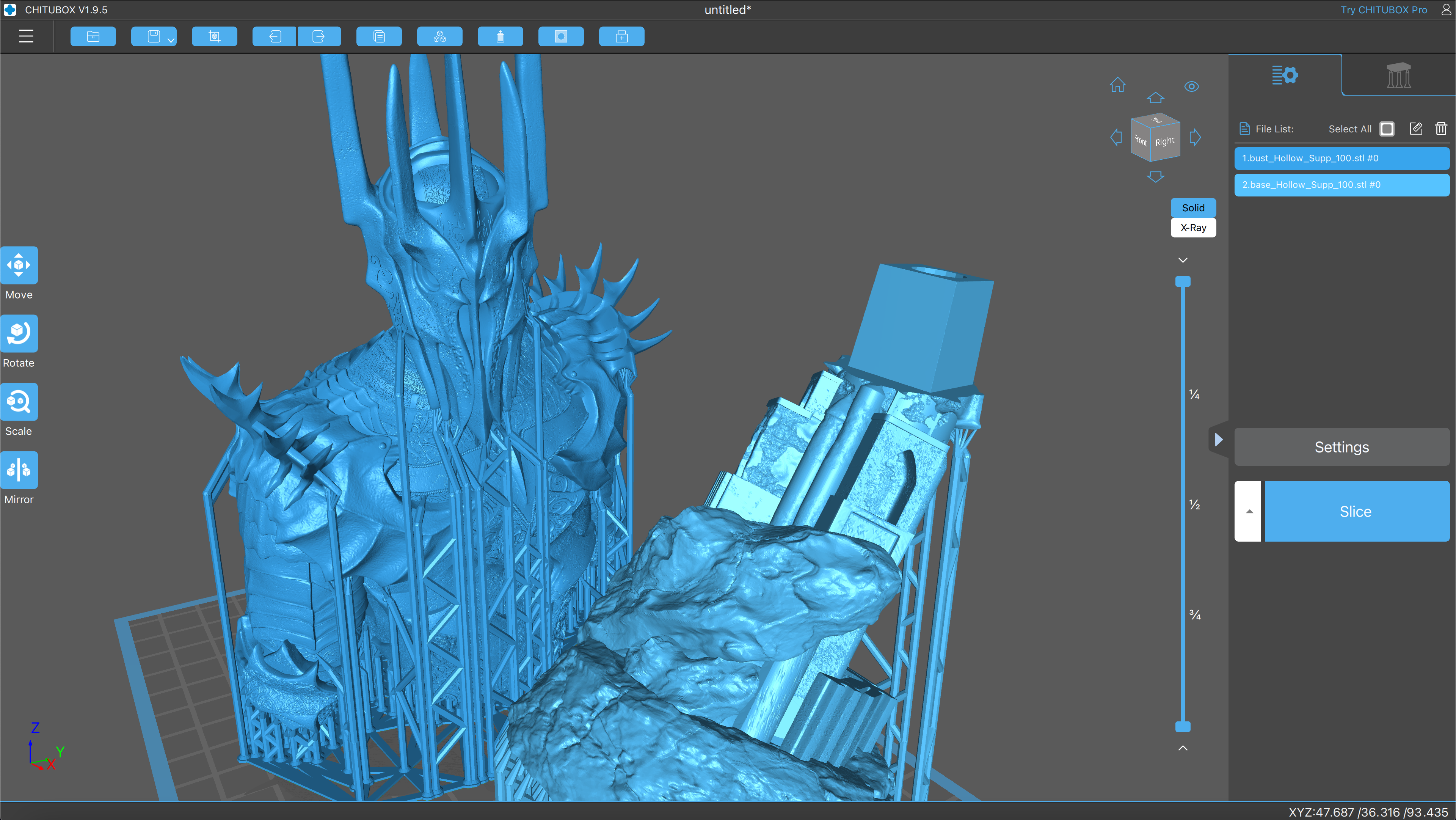

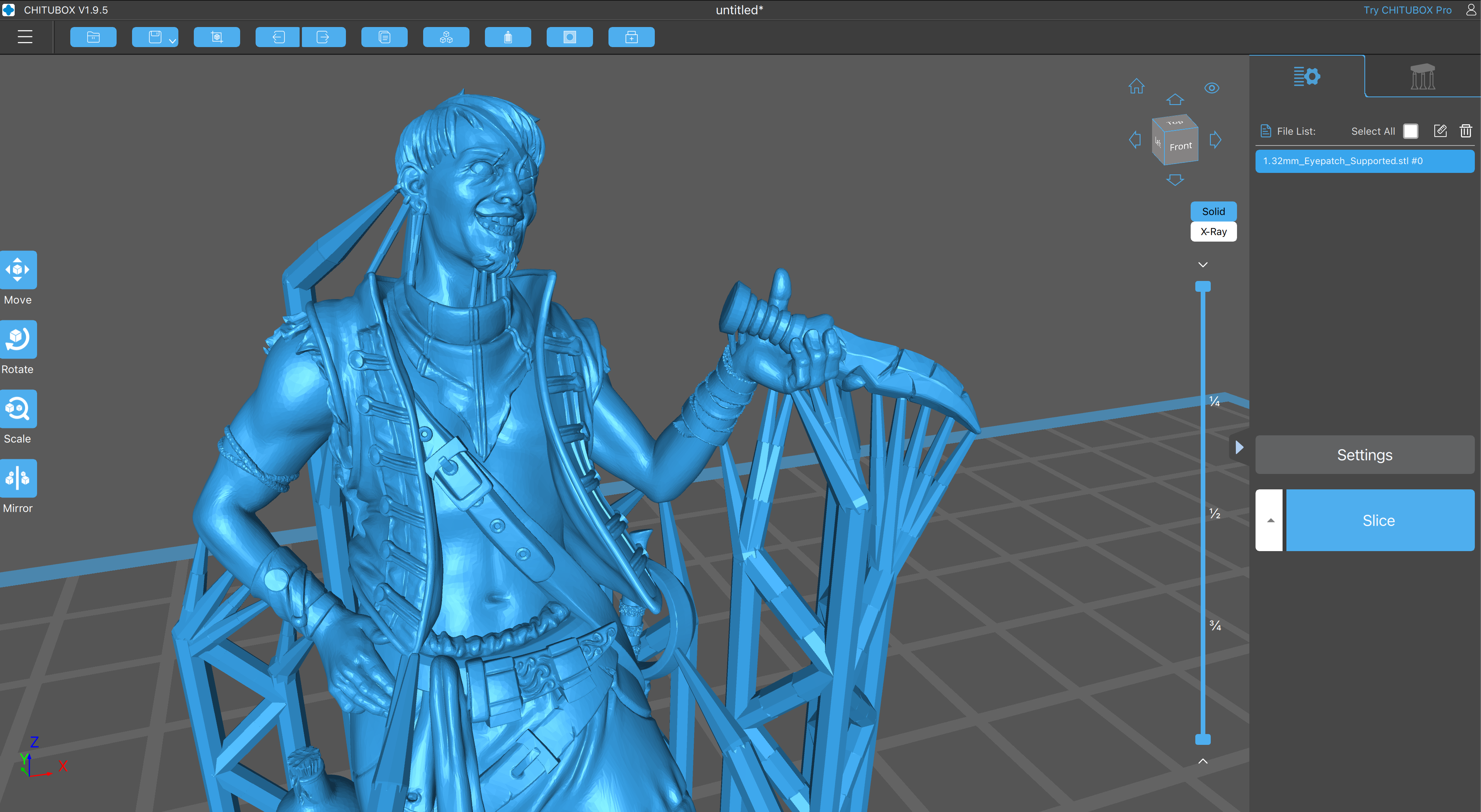

The UniFormation GKtwo includes two slicers on the USB thumb drive, Chitubox and Slicer (more on the latter in a bit). Both versions are Windows-only, so Mac users will need to download the software directly from the UniFormation site. Chitubox 1.9.5 includes a profile for the GKtwo 3D printer, as well as multiple print profiles for various resin types and layer heights. Chitubox tends to be my default slicer for resin 3D printers, as it can easily handle complex triangle meshes and large file sizes when adding supports, vent holes, or performing hollowing operations.

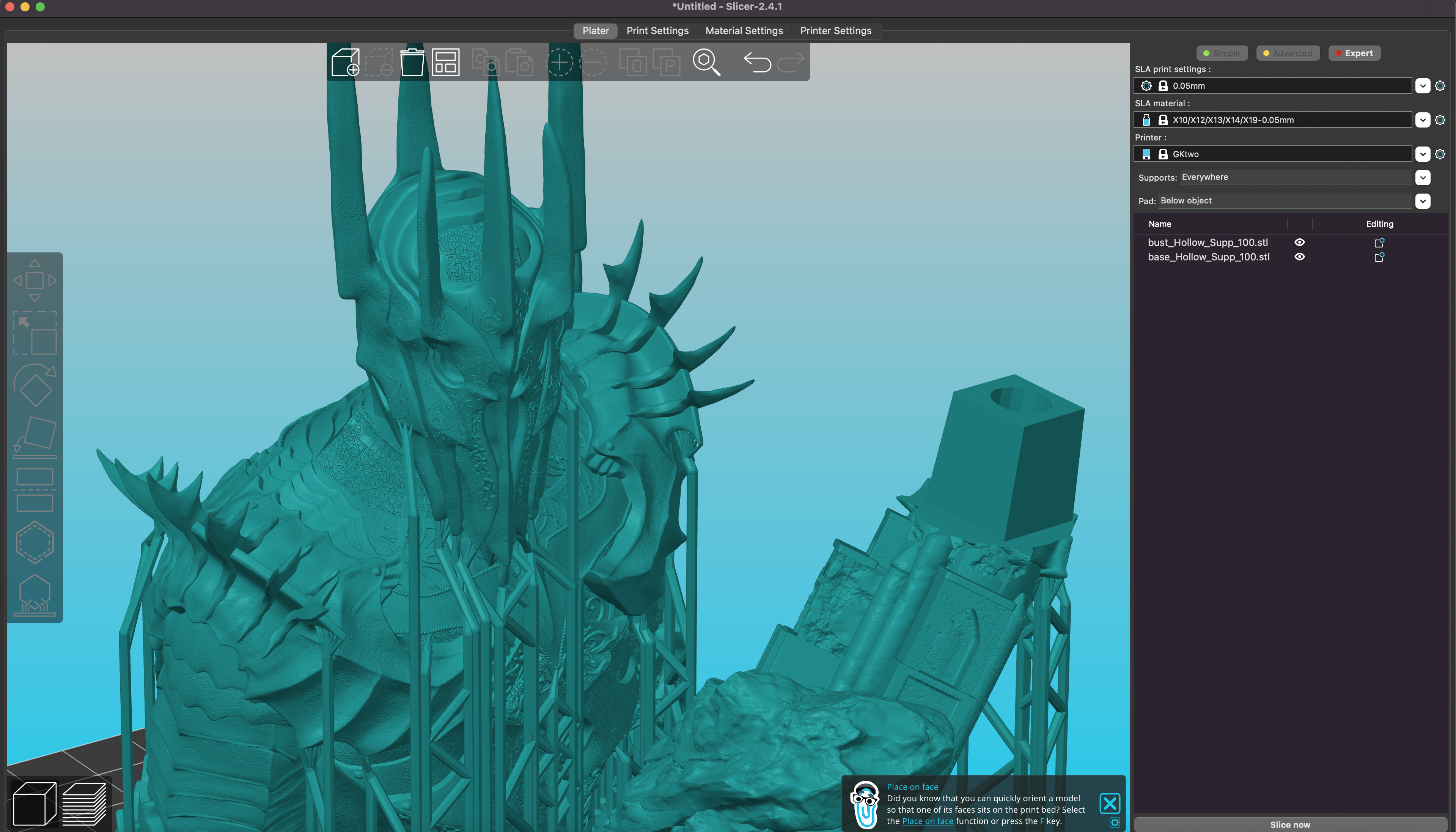

Interestingly enough, UniFormation is the first company I’ve seen that includes a fork of PrusaSlicer with a resin 3D printer, and this slicer even includes the little Jo Prusa Clippy mascot at the bottom of the interface.

PrusaSlicer is compatible with the Prusa SL1S resin 3D printer (one of the best resin 3D printers), but hasn’t received the same level of adoption as Chitubox, Lychee, and others in the resin 3D printing space. Just like the Windows-only Chitubox, UniFormation didn’t include a macOS version of Slicer and I had to download it from the site.

This slicer is simply called “Slicer”, but it lacks the “Help” dropdown as well as the “About” selection, meaning that there is no attribution to Slic3r or Prusa Research readily accessible. Without attribution or more robust documentation, users will likely struggle to start with Slicer as opposed to the more widely-used Chitubox.

I asked a representative for information regarding attribution, and received the following response: “...our slicer is in compliance with the open source licenses, The reason here u can not search the information, is that we created it by our China company name rather than the brand before, cause there u did not see anything by uniformation. for u can check by this link and can be proved. https://github.com/juxin-technology”

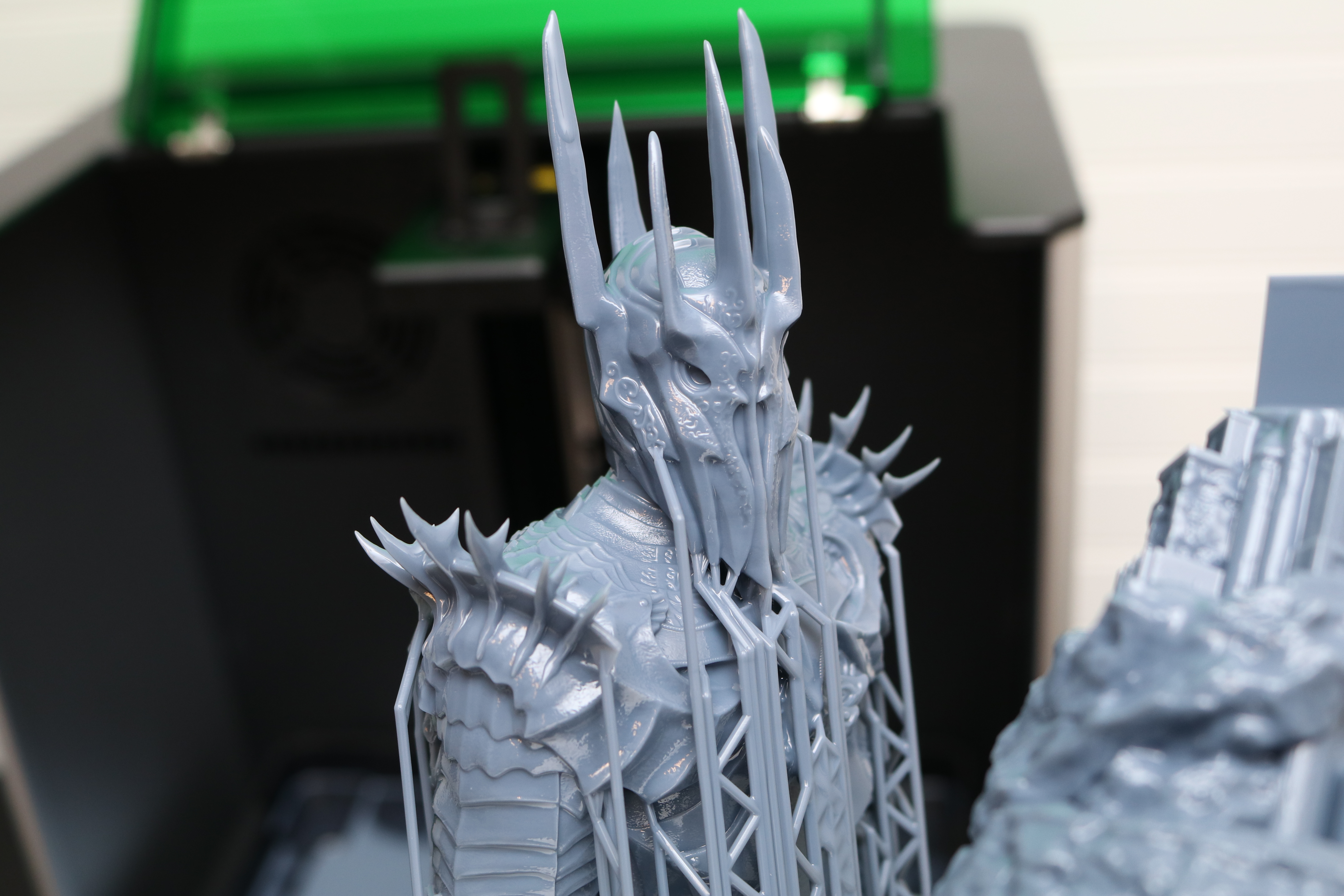

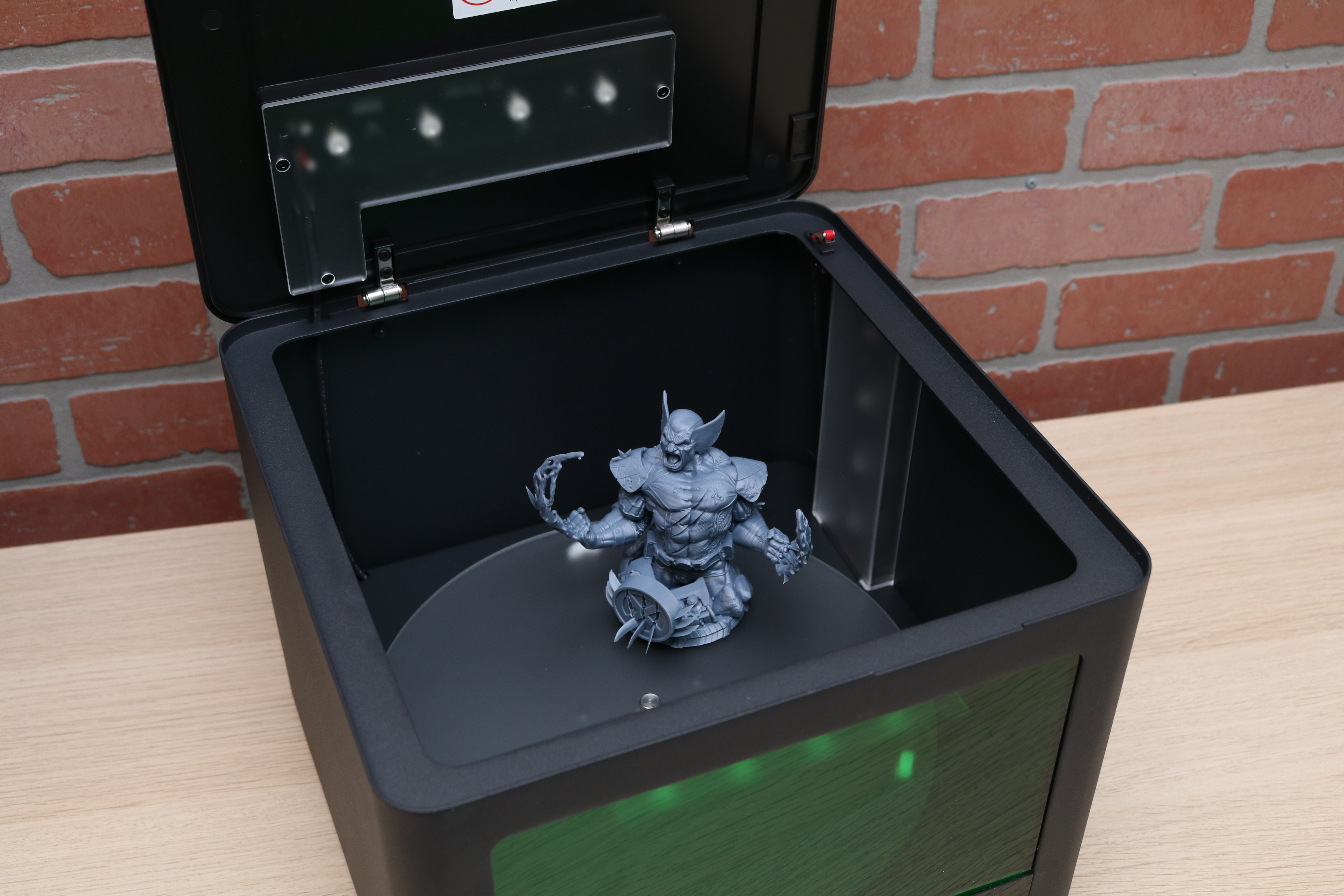

The bust of Sauron by artist Fotis Mint has supports already generated and doesn’t require any software post-processing or other preparation before printing. The model was sliced using the default Chitubox settings for a 50 micron layer height, which are all provided by UniFormation. Also provided are 30 micron layer height and 100 micron layer height profiles, for higher and lower resolution printing, respectively.

The 8K resolution of the masking LCD really shines with this model, and the overall level of detail is undeniably impressive. The fabric texture, embossing on the armor, and rocky sculpture on the base all resolved nicely, with no apparent pixelation or stepping, even on shallow curves. The weathered spikes on the crown have a very organic appearance of corroded metal, but the point at the very top is still sharp enough to come to what feels like a single-pixel point.

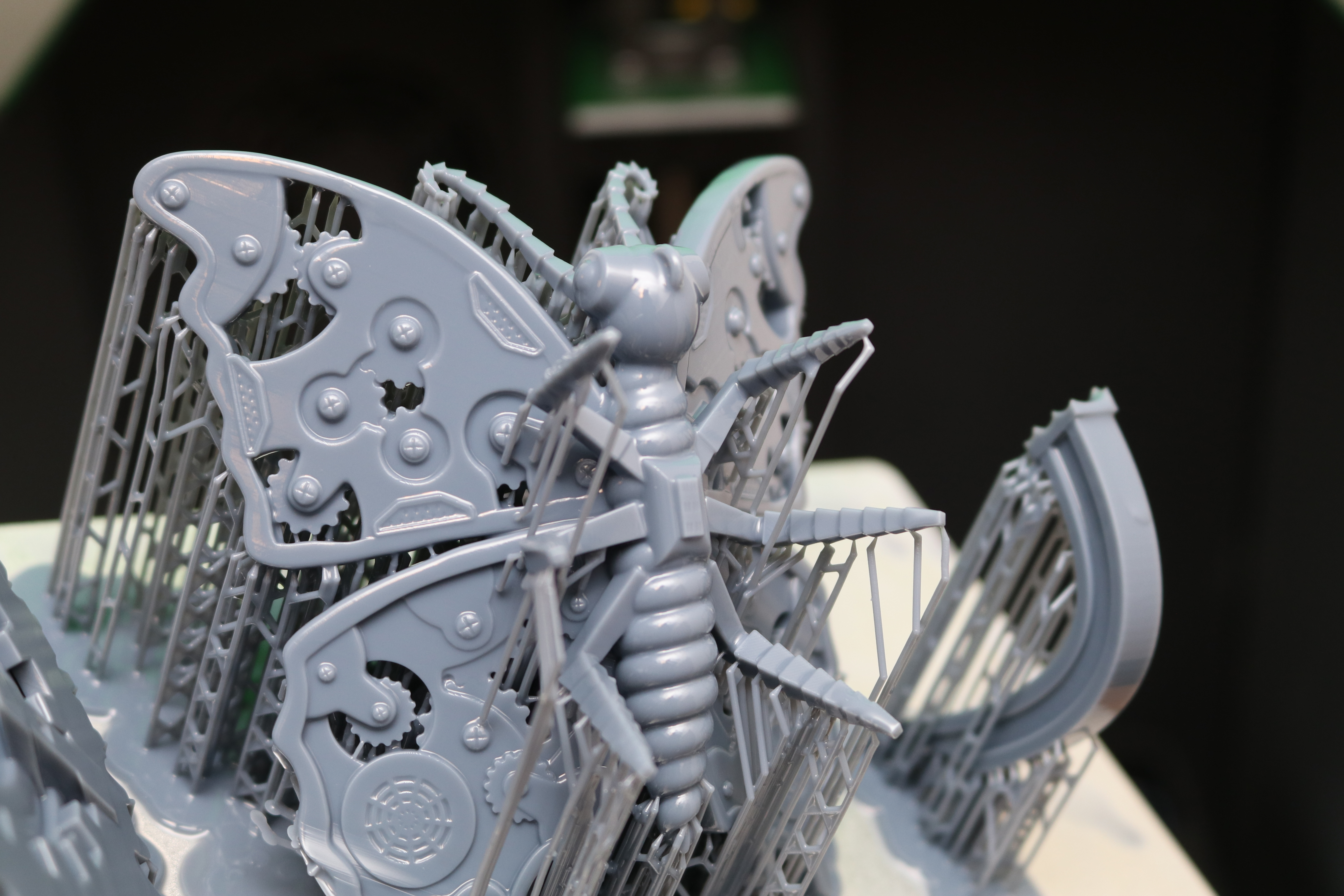

Other pre-sliced models like the Steampunk Butterfly by Romwba3D have a similarly impressive appearance with no defects present after printing. While the build platform leveling is tedious, it performed well during testing. Larger parts with thick walls, such as this Steampunk Butterfly, printed without delaminating from the platform.

Printing using the X10 white resin resulted in smooth, even models that had a similar level of detail. The equal parts impressive and terrifying Teeth Cup by DaveMakesStuff printed with a smooth surface without compromising on the level of detail present.

Curing Models with the D265 Curing Station

UniFormation also sent the $149.99 D265 curing station along with the Gktwo, a refreshingly well-designed piece of hardware that worked exceptionally well. The D265 uses four integrated LED strips and a total of 16 405nm UV LED lights to cure parts on a rotating turntable. The LED lights are positioned on both sides as well as the top and the bottom of the unit and provide full, uniform UV coverage for curing parts. The rotating turntable base is transparent and has a frosted textured surface which prevents models from sticking during curing.

Just like the GKtwo, the D265 has a flip-up hinged lid which minimizes the footprint needed during use. The timer can be set in increments of minutes and seconds, and using the default setting of 10 minutes resulted in models that felt dry and fully cured after processing. Curing stations can sometimes feel like an afterthought from OEMs, but inexpensive D265 is well-designed and provides functionality as well as clean industrial design.

Printing 32mm miniatures on the UniFormation GKtwo

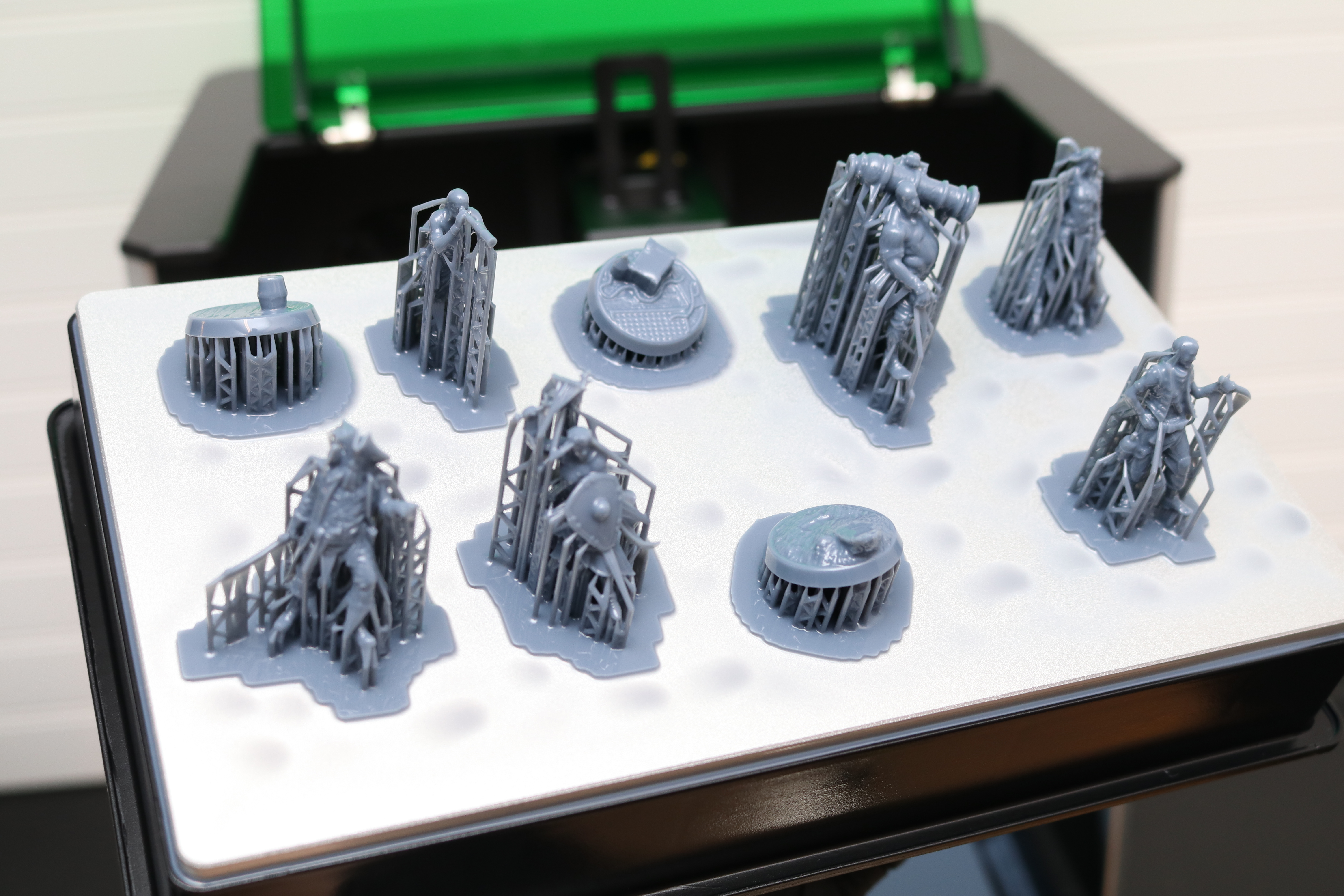

The UniFormation GKtwo has an XY resolution of 29.6 microns, which is another way of saying that the GKtwo is capable of printing very, very, very fine details. Combined with the wide build platform and fast 3 second per-layer curing time, the GKtwo is ideal for printing lots of small parts in a single build.

When printing 32mm miniatures, every micron counts for resolving details and textures at such a small scale. Printing 32mm miniatures from Loot Studios is a great way to test a printer's ability to print fine details. I filled a tray with the pirate-themed ‘Ship Ahoy!’ 32mm miniature collection from Loot Studios and used the UniFormation-supplied default settings in Chitubox for X13 resin:

- 0.050mm Layer Height

- 3 second Per-Layer Exposure Time

- 30 second Bottom Exposure Time

- 120mm/min Lift Speed

- 2mm Lift Distance

- 220mm/min Retract Speed

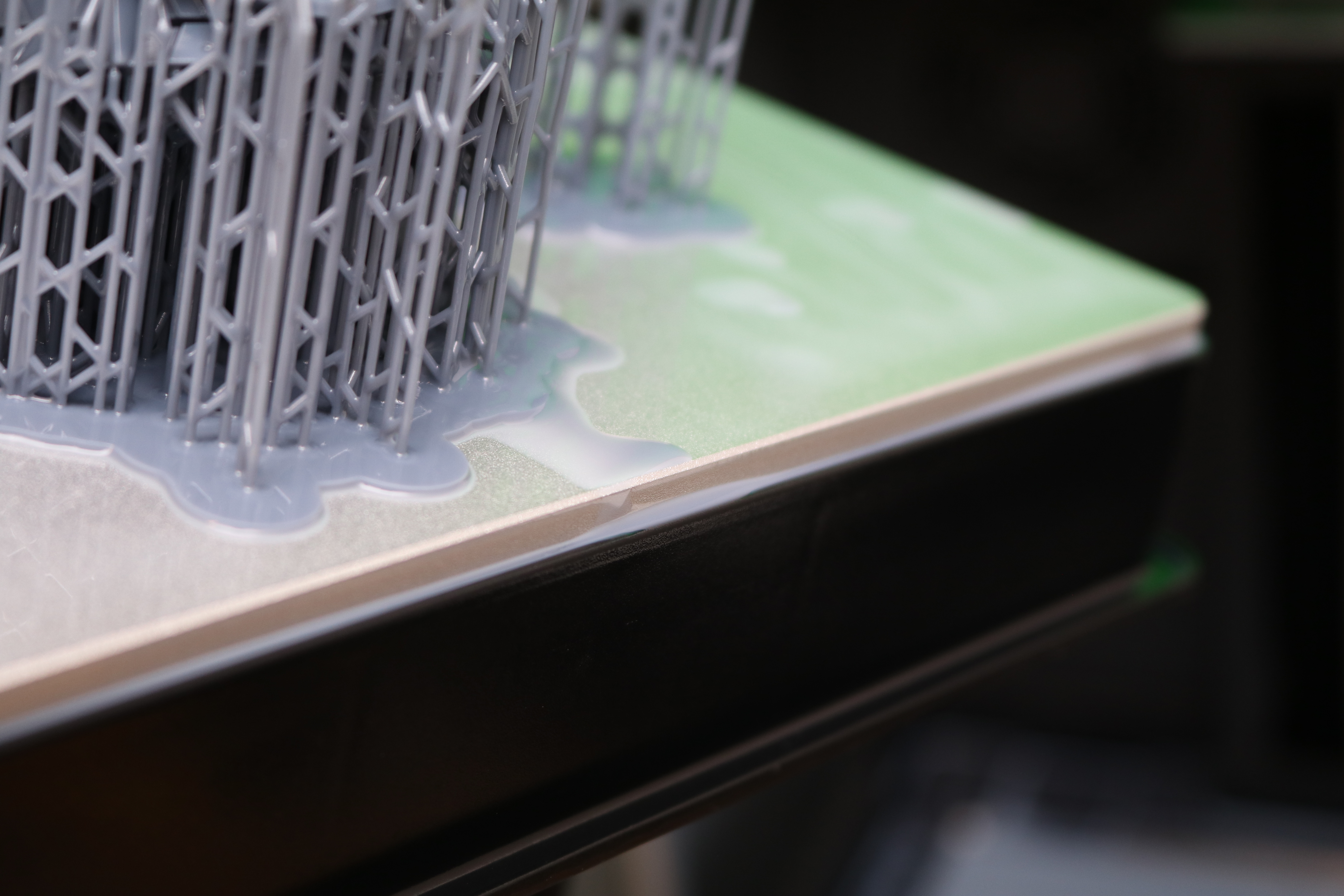

Printing in under 2 hours, the models printed flawlessly even when spread across the full area of the build platform. The miniatures, printed with the X13 resin, are easily removed from the textured build platform and the supports only required a minimal amount of effort to remove. The parts were gently washed in IPA and dried before curing for 10 minutes in the D265 curing station.

The details are crisp, and even tiny features like the transitions in the monocular held by the pirate are readily discernible and could be further post-processed or painted. The parrot on the shoulder of the pirate captain has visible feathers, an impressive feat for a miniature printed at this scale. The wood paneling on the 32mm base is also readily apparent, and small inclusions like the rope on another 32mm base resolved nicely.

Comparison of UniFormation GKtwo vs. Anycubic Photon Mono M5s

The GKtwo features impressive XY resolution and a large build volume, but it’s easy to forget how quickly the desktop resin 3D printing market is evolving. For instance, the Anycubic Photon Mono M5s (one of the best resin 3D printers) offers even finer layer resolution, automatic build platform leveling, and a “High Speed” mode which cuts the per-layer print time in half. When comparing just the spec sheets of both printers, it may be difficult to understand why the GKtwo is priced nearly $400 dollars higher than the Photon Mono M5s.

| Header Cell - Column 0 | UniFormation GKtwo | Anycubic Photon Mono M5s |

|---|---|---|

| Masking LCD Resolution (px) | 7680 x 4320 (8K) | 11,520 x 5120 (12K) |

| XY Resolution (mm) | 0.029 | .019 x 0.024 |

| Build Dimensions (in.) | 9.0 x 5.0 x 9.6 | 8.6 x 4.8 x 7.9 |

| Build Volume (in^3) | 432 | 326.112 |

| Masking LCD Size (in.) | 10.3 | 10.1 |

| Platform leveling | 8-bolt manual | Automatic |

| Resin Vat Heating | Integrated | None |

| Price (retail) | $899 | $579.00 |

| Price (sale) as of 9/6/23 | $899 | $499.99 |

The product launch video on YouTube opens with the GKtwo emerging from a solid block of ice in a frozen tundra, driving home the cold-weather capabilities of this printer. In addition, the flip-up lid and quick release resin vat are ideal for printers lined up on a surface in a production facility, as opposed to the removable lid on the Photon Mono M5s which needs to be placed somewhere while the printer is being actively used.

If you plan on operating the printer in a cold environment and need a machine that can quickly get up to temperature between prints, the GKtwo may make sense for your application. If you’re just looking for the highest resolution possible or a slightly lower price, other printers like the Anycubic Photon Mono M5s may be worth investigating.

Bottom Line

The UniFormation Gktwo offers impressive 8K resolution and a solid feature set for the prosumer, but the $899 price tag is difficult to justify for most users. The quick-change resin vat and build platform, flip-up lid, and integrated heater all combine to provide a more polished experience for anyone who is seeking to maximize printer uptime. Unfortunately, the build platform calibration process is highly manual, and at this price point it would be reasonable to expect a higher level of automation on such a critical part of the printing process.

Other 8K printers like the Elegoo Saturn 8K are available for under $300, which makes the GKtwo a hard sell if you’re only looking for high resolution. If you’re interested in more automation and sensors and are less interested in resolution, a printer like the Prusa SL1S provides automatic build platform calibration and an automatic resin weight check before printing at the expense of a lower XY resolution.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

-

Jhiltdog Not sure if the reviewer has ever used a resin printer before but the gktwo is by far the easiest to level. It’s literally four screws you turn very slightly, takes 5 seconds. And to compare this to the anycubic plastico m5s is silly. The m5 is rectangular pixels (need a review on that alone!). I own and reviewed over 50 resin printers in the past 6 years. Gktwo is right up there with the bestReply