China Dispatch: Adventures in Case Manufacturing

Plastic Injection Process, Contiued

The plastic is melted down by the injection machine and then injected into the mold. When the mold is separated, you then have the finished product. In this picture, you can see the side panel window for the Xpider/Gaming Bomb as the machine is releasing it.

An employee inspects and packs the finished side panel window for the Xpider/Gaming bomb prior to final assembly.

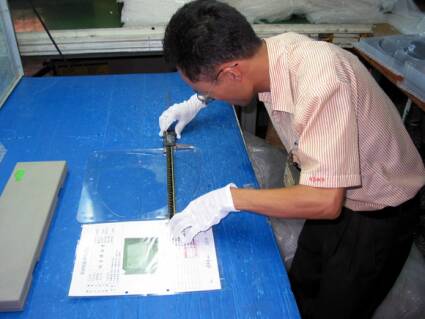

Time for another Q.A. check; this time they are checking the quality of the side panel window. Here measurements are taken to make sure that the window is produced exactly to specification. Any variation in the case would cause the window not to fit the cut out area of the side panel.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Plastic Injection Process, Contiued

Prev Page Plastic Injection Process Next Page Plastic Painting Process-

zhijunli Please visit more factories before you say "why others don't think that an inexpensive detail such as this is important."Reply -

Those guys been working with vendors that can supply vacuum deposited, electroplated, printed and spray painted plastic parts. This is old news..Reply

http://www.pa-international.com.au/index.php?option=com_content&view=article&id=127&Itemid=172