China Dispatch: Adventures in Case Manufacturing

Plastics Sub Assembly Process, Continued

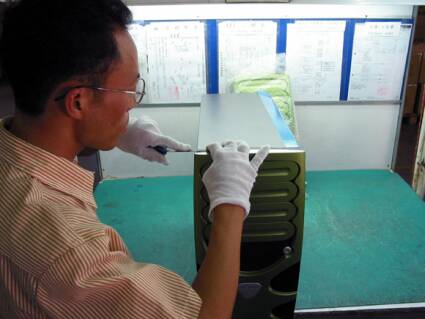

You might notice these in many of the pictures that we have taken. These Standard Operating Procedure (SOP) sheets are hanging above each station to remind workers of the correct process and detail for the job that they perform. These reference sheets serve as a guide for consistency and to spell out the quality expectations for the finished product.

Once again, Q.A. inspects and measures the tolerances of the bezel by testing it in a real case. It is important for the plastics to fit well. Tolerances are everything here, and measurements are taken to insure that the fit of the bezel is to specification when it is attached to the case.

The bezels are now packed and stored for later use in the final assembly process. Notice the bubble wrap that is used to protect the bezel from possible damage prior to final installation.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Plastics Sub Assembly Process, Continued

Prev Page Plastics Sub Assembly Process Next Page Final Assembly Process-

zhijunli Please visit more factories before you say "why others don't think that an inexpensive detail such as this is important."Reply -

Those guys been working with vendors that can supply vacuum deposited, electroplated, printed and spray painted plastic parts. This is old news..Reply

http://www.pa-international.com.au/index.php?option=com_content&view=article&id=127&Itemid=172