China Dispatch: Adventures in Case Manufacturing

Let's Start At The Beginning, Continued

Once the prototype case is complete, it is time to test the thermal qualities of that case. Chenbro uses a thermal test chamber for this process. Why use a thermal test chamber? In order to get an accurate reading, you must be able to monitor and control the ambient temperature and also prevent the room temperature from interfering with the test results. Chenbro follows Intel's established guidelines for the thermal testing of each case; whether it is a server, workstation, or desktop case. Each Chenbro case is tested to exceed Intel's minimum thermal specifications.

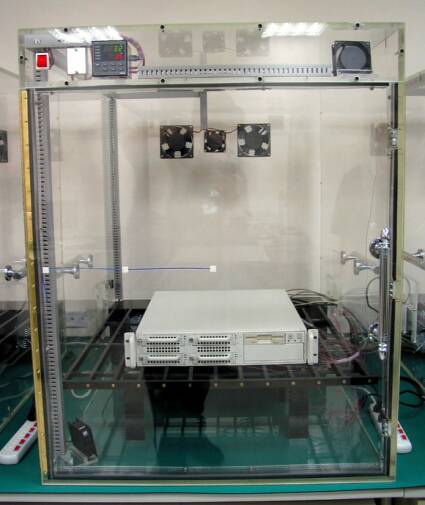

Here is one of the four thermal test chambers used by Chenbro in its testing lab. All four of the chambers are connected to the monitor station, and it is possible to test up to four systems at a time. Chenbro not only tests each case that they produce, they also purchase and test cases from other manufacturers for comparison study.

The computer monitoring station is connected to the thermal test chambers. Using software provided by Intel, Chenbro can test its cases using the Intel-established and recognized thermal specifications guidelines. This station can monitor as many as sixteen thermal test points within the case to establish the thermal management performance of a design.

It is very important to follow Intel's thermal testing guidelines prior to submission to Intel for validation and qualification. Although this is an expensive manufacturing process, it is an added stamp of quality assurance for the purchaser that their particular case has passed Intel's thermal test qualifications. All of Chenbro's products not only pass, but also exceed by far, the specifications set by Intel. Choosing to purchase a case design that has been qualified by Intel is certainly is a clear indication that the thermal performance of the case should be good, but the Intel tests are only set to embrace a baseline configuration, so those who are into extreme overclocking could be disappointed. The good news is that this is still an excellent starting point if you are concerned about the thermal performance of a certain case.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Let's Start At The Beginning, Continued

Prev Page Let's Start At The Beginning, Continued Next Page Let's Start At The Beginning, Continued-

zhijunli Please visit more factories before you say "why others don't think that an inexpensive detail such as this is important."Reply -

Those guys been working with vendors that can supply vacuum deposited, electroplated, printed and spray painted plastic parts. This is old news..Reply

http://www.pa-international.com.au/index.php?option=com_content&view=article&id=127&Itemid=172