China Dispatch: Adventures in Case Manufacturing

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Let's Start At The Beginning, Continued

The first step in the process is the design. Chenbro uses a computer aided design process for every part in the case. Important reasons for this are that a computer aided design process makes it easier to feed the data into the NCD machine to make the prototype, and the use of computer aided design makes the overall concept to pre-prototype process move more quickly and be more exact. Using the NCD process to produce the parts for the case is called "soft tooling," as the NCD machine relies upon the precision of a laser to cut the parts for the case.

Here we see one of the many design engineering stations within the design department at Chenbro. While these engineers were working on another project, we asked whether we could see the design bezel from the Xpider/Gaming Bomb, and they were more than happy to show it to us.

As you will learn later on, Chenbro uses "hard tooling" to assure better and more consistent product quality, which entails a die stamping process. Hard tooling is an expensive investment due to the number of unique dies required to make each case design. Chenbro invests over $3 million US dollars per year for hard tooling dies to produce cases. Cases that are produced using hard tooling are always preferable over cases produced with a soft tooling process. While there are cases that are created every day using the soft tooling process, it is VERY difficult to get consistent quality using soft tooling, due to the variance in the NCD process from case to case. Another disadvantage of the soft tooling process is that the "run" or production rate per month is quite low, which translates into reduced production and higher prices for the end purchaser. While a manufacturer might be able to produce 1,000 cases per month using the NCD process, that same manufacturer could produce 5,000+ cases per month using the hard tooling (metal stamping) process. And, with the hard tooling process there are fewer production mistakes and required re-runs due to poor quality and/or process defects.

A close-up example of the slot cover area of a case that was created using hard tooling. As you can see, hard tooling provides a much cleaner edge.

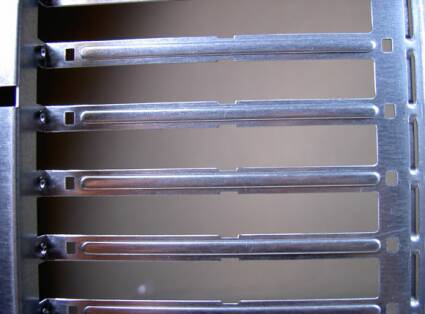

A close-up example of the slot cover area of a case that was created using soft tooling. The edges on the soft tooling are significantly more rough than the hard tooling example, above.

Another example of the differences between hard tooling vs. soft tooling. Notice the cleaner edge on the hard tooled case when compared with the soft-tooled case below.

As we can see in this close-up, the surface of the soft tooling is less polished looking than that of the hard tooled case, above.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Let's Start At The Beginning, Continued

Prev Page Let's Start At The Beginning: The Design, Prototype, And Testing Process Next Page Let's Start At The Beginning, Continued-

zhijunli Please visit more factories before you say "why others don't think that an inexpensive detail such as this is important."Reply -

Those guys been working with vendors that can supply vacuum deposited, electroplated, printed and spray painted plastic parts. This is old news..Reply

http://www.pa-international.com.au/index.php?option=com_content&view=article&id=127&Itemid=172