Extreme Overclocking

Graphics Card Preparation

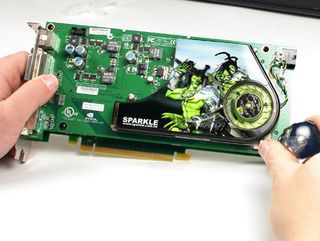

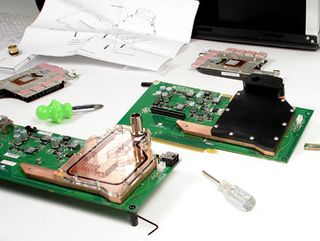

Once all of the components were together, it was time to rip apart the factory shipped graphics coolers and retrofit them with precision water blocks. The Sparkle SF-PX78GX2 is designed around the Nvidia specification for the GeForce 7950GX2. It has its core clocked at 500 MHz and the GDDR3 memory at 600 MHz (1.2 GHz DDR). There are only a few screws that hold the twin PCBs (Printed Circuit Boards) together. Once the two sections of the card were apart, it was time to take the coolers off and clean the surface of the processor and memory modules.

We used Artic Silver Ceramique on the graphic components, to make for better conductive mating between the block and the components. While we could have used Artic Silver 5, using a compound comprised of 99.9% silver is not wise, as a leak could be fatal. Even though the coolant is non-conductive, once you introduce electrically conductive particles you can make the fluid conductive. The small transistors exposed next to graphics processors need to be protected from leaks, so using a non-conductive paste ensures that we don't short out the system if a leak does occur.

With both water blocks in place, the PCBs needed to be sealed together using a rubber gasket between the blocks. This gasket ensures a water-tight seal between the two blocks where the coolant from the bottom PBC flows into the top block. When fully assembled, the water-ready Sparkle GeForce 7950GX2 was 1.4 lbs heavier, at a total of 2.7 lbs (1.2 kg).

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Current page: Graphics Card Preparation

Prev Page The Right Equipment Next Page Installation Of Water SystemMost Popular