A Look Into The Hard Drive's Future

More Features: Vibration Control, Height Adjustment

It is obvious that the width of the so-called data tracks—the concentric circles upon which data is recorded—must become smaller in order to increase data density. This, however, makes it important to avoid vibrations, which while they don’t cause damage, can influence performance if the drive has to keep readjusting the heads all the time in order to stay on the correct track.

This isn’t an issue for desktop hard drives, but enterprise applications with dozens or hundreds of drives operating in rack-mount servers may very well suffer from fluctuating performance. Hitachi says that it uses a technology called Rotational Vibration Safeguard to counter the effects of vibration. Two sensors on the hard drive (see image) are used to properly detect vibration and have the drive adjust to the new conditions. In addition, robust hard drives may be equipped with wider tracks and with an increased number of servo tracks, which drives use for navigating the surface. Most automotive hard drives are designed in this manner.

Flying Height of HDD Heads and Height Adjustment

Adjusting the flying height of the heads is another important tool to provide reliable hard drives that are capable of operating at various altitudes. Height adjustment is performed by adding a heatable element at the front part of the heads. Heating increases surface area, which results in the heads being lifted up a bit, so they move further away from the magnetic surface. This makes is possible to utilize hard drives at altitudes of 3000 m (10,000 ft) and more (5000 m for the Endurastar series). If this feature were missing, the heads could get too close to the surface due to decreased air pressure, and probably cause a crash and data loss. The nominal distance between the heads and the surface is only 12 nm—in contrast, a human hair has a diameter of approximately 40,000 nm.

The Return of 5,400 RPM 3.5” Drives

Finally, 5,400 RPM hard drives are coming back to the 3.5” space! Western Digital was the first manufacturer to offer a 3.5” drive that spins at “> 5,400 RPM” for efficiency reasons: the Caviar GP (Green Power) is one of the most efficient 3.5” drives.

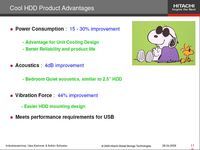

5,400 RPM initially died out because 7,200 RPM spindle speed offered much better performance with only a little trade-off in performance. Since technology has moved on, today’s 5,400 RPM drives will aim to be quiet while delivering sufficient performance for consumer applications. Hitachi says that a 5,400 RPM drive delivers a 15-30% improvement in power consumption, acoustics that are comparable to 2.5” hard drives, and half of the vibration.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Current page: More Features: Vibration Control, Height Adjustment

Prev Page Future Capacities and Recording Improvements Next Page ConclusionMost Popular