Tech Industry

Latest about Tech Industry

-

-

Cadence releases new AI supercomputer — uses Nvidia RTX Pro 6000 GPUs to improve simulation run time

By Jowi Morales Published

-

Former SK hynix employee transferred advanced chip packaging technologies to Huawei

By Anton Shilov Published

-

Startup trains AI models with gaming GPU setup under $100K

By Ash Hill Published

-

Nvidia celebrates dumping of Biden-era AI chip export rules — simpler new policy promised

By Anton Shilov Published

-

Baidu developing AI-driven animal to human translator – Dr Doolittle plans revealed in patent application

By Mark Tyson Published

-

Musk’s Colossus is fully operational with 200,000 GPUs backed by Tesla batteries

By Jowi Morales Published

-

After projecting losses of $1.5 billion, AMD CEO Lisa Su calls for a balance between export controls and national security

By Anton Shilov Published

-

Explore Tech Industry

Artificial Intelligence

-

-

Startup trains AI models with gaming GPU setup under $100K

By Ash Hill Published

-

Nvidia celebrates dumping of Biden-era AI chip export rules — simpler new policy promised

By Anton Shilov Published

-

Baidu developing AI-driven animal to human translator – Dr Doolittle plans revealed in patent application

By Mark Tyson Published

-

Musk’s Colossus is fully operational with 200,000 GPUs backed by Tesla batteries

By Jowi Morales Published

-

After projecting losses of $1.5 billion, AMD CEO Lisa Su calls for a balance between export controls and national security

By Anton Shilov Published

-

Clippy resurrected as AI assistant — project turns infamous Microsoft mascot into LLM interface

By Dallin Grimm Published

-

AI taught to analyze Windows crash dumps, released to open source

By Mark Tyson Published

-

Nvidia warns U.S. AI hardware export rules could backfire, empowering Huawei to define global standards

By Anton Shilov Published

-

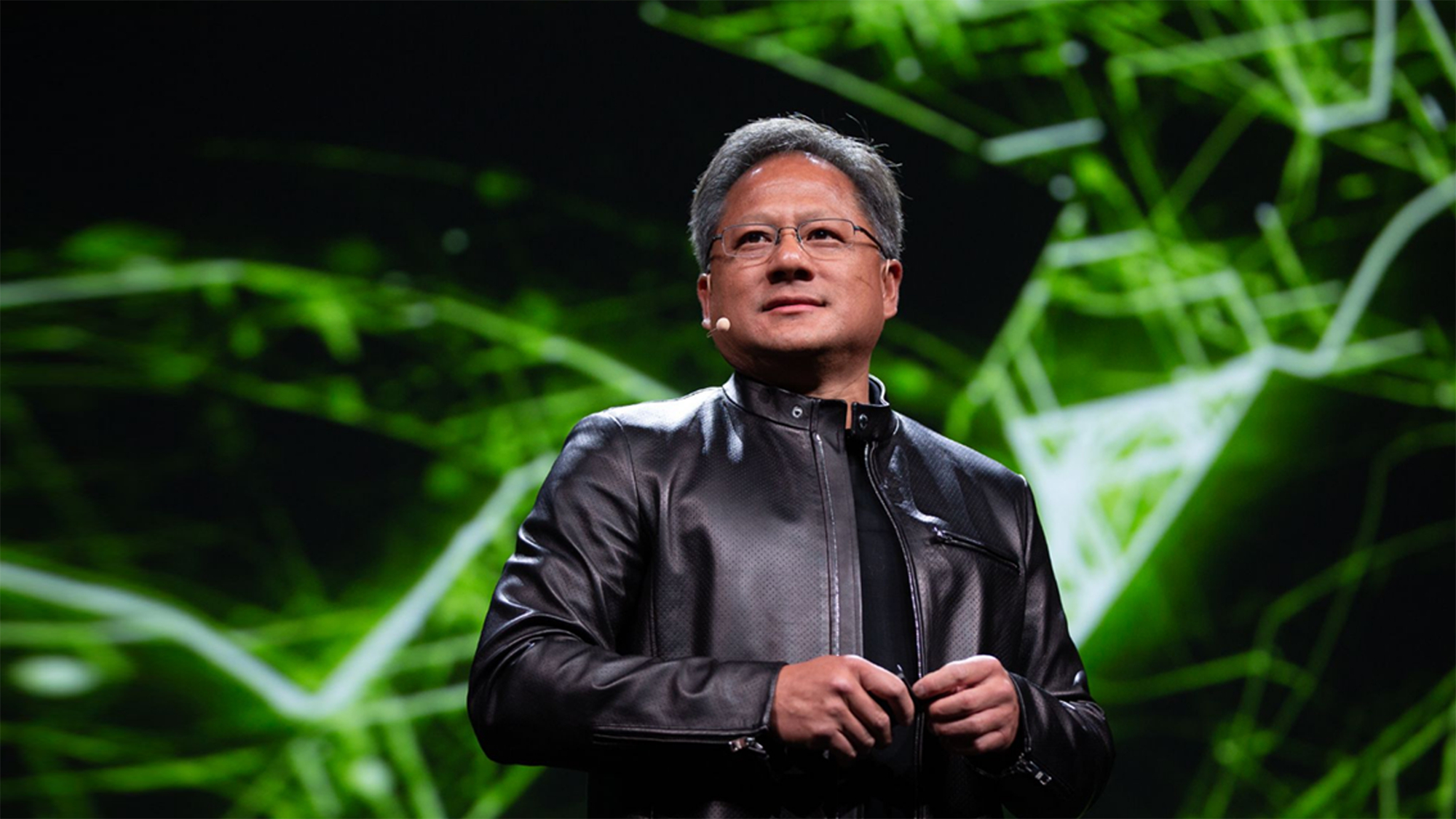

Nvidia's CEO says China is not far behind the U.S. in AI capabilities

By Anton Shilov Published

-

Big Tech

-

-

UK company allegedly paid $4m in bribes to secure Microsoft data center construction contract

By Jowi Morales Published

-

Trump administration brands Amazon's tariff transparency plan a 'hostile and political act'

By Mark Tyson Published

-

Nvidia gaming GPUs an afterthought as AI generates mountains of cash — RTX 50-series shortages mentioned, not explained

By Jowi Morales Published

-

Apple says it will spend $500 billion in US over next four years as it faces down Trump tariffs

By Andrew E. Freedman Published

-

Data hoarders race to preserve data disappearing U.S. gov websites

By Jowi Morales Published

-

Intel CEO Pat Gelsinger visits Elon Musk’s Memphis data center, touts Xeon deployment

By Jowi Morales Published

-

'Jensanity' continues in Taiwan, Mini-Jensen Huang cosplayer sports massive Nvidia GPU for Halloween

By Jowi Morales Published

-

Server dealer keeps hitting at Elon Musk for $61 million bill

By Jowi Morales Published

-

Nvidia’s stock surge mints new employee millionaires, but many can’t yet enjoy their wealth

By Jeff Butts Published

-

Cryptocurrency

-

-

Energy use in a Kuwaiti city fell by over 50% after authorities cracked down on crypto mining

By Jowi Morales Published

-

Bitcoin miners front-running tariffs by scrambling to ship thousands of machines before penalties hit

By Jowi Morales Published

-

Man who lost $780 million in Bitcoin in a landfill now wants to buy the entire dump before city closes the site

By Mark Tyson Published

-

Court ruling halts man's $750M bitcoin recovery effort from landfill

By Mark Tyson Published

-

Bitcoin crosses $100,000 milestone as incoming U.S. administration looks increasingly crypto-friendly

By Kunal Khullar Published

-

Bitcoin launderer hands over $400 million as he heads to prison

By Roshan Ashraf Shaikh Published

-

Bitcoin skyrockets to an all-time high of over $84,000

By Aaron Klotz Published

-

Man who lost half-billion dollar Bitcoin HDD sues local authority for $500 million for not letting him dig through landfill

By Mark Tyson Published

-

Twelve people sentenced for cryptocurrency heists and laundering

By Roshan Ashraf Shaikh Published

-

Cyber Security

-

-

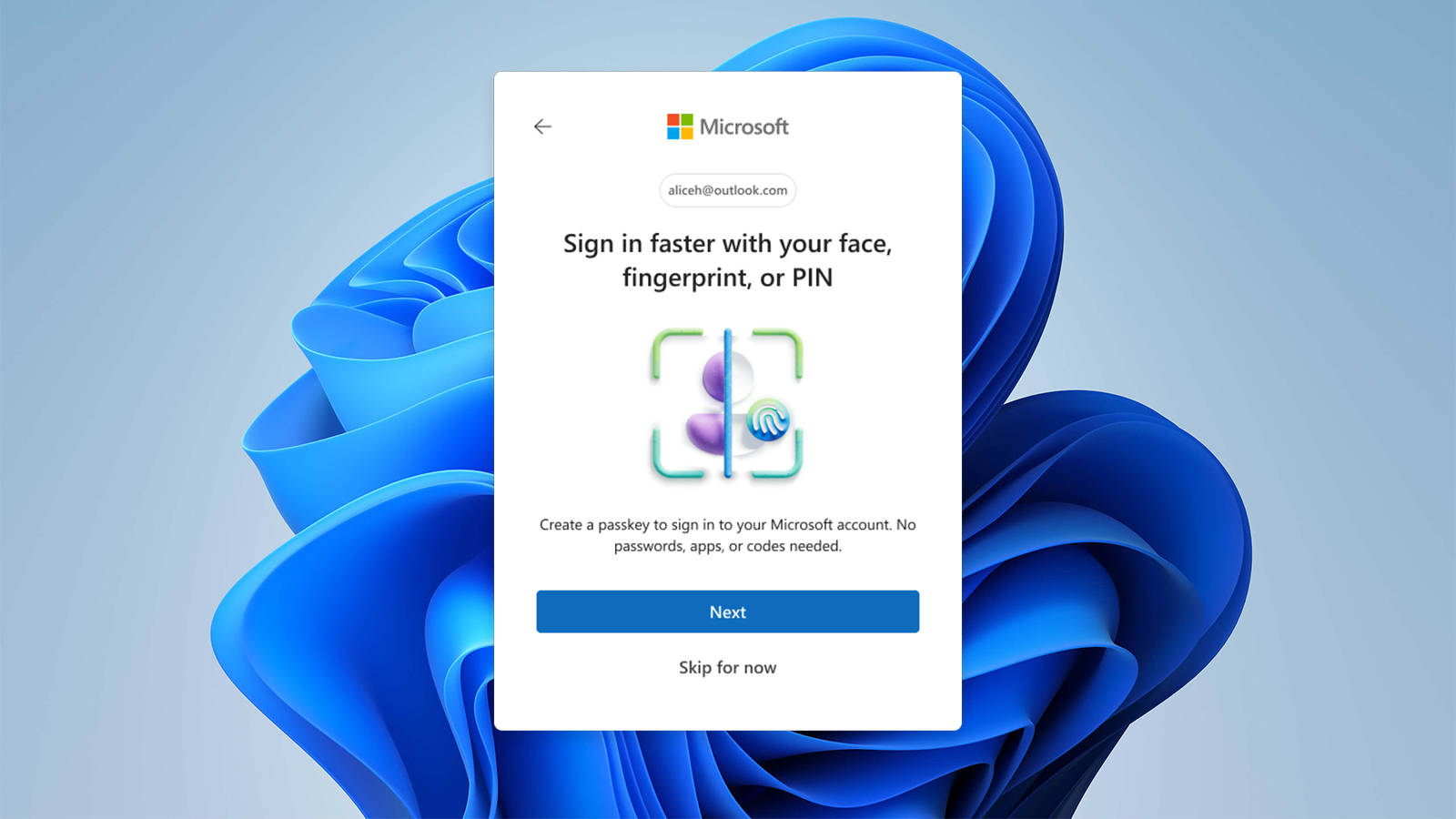

Microsoft makes passkeys the default authentication method for all new accounts

By Jowi Morales Published

-

Crosswalks in Silicon Valley hacked to play satirical messages from Musk and Zuckerberg sound-a-likes

By Mark Tyson Published

-

Akira ransomware can be cracked with 16 RTX 4090 GPUs in around ten hours — new counterattack breaks encryption

By Dallin Grimm Published

-

Apartment complexes broken into with phone in minutes

By Dallin Grimm Published

-

FBI identifies North Korea as source of $1.5 billion ByBit hack

By Jowi Morales Published

-

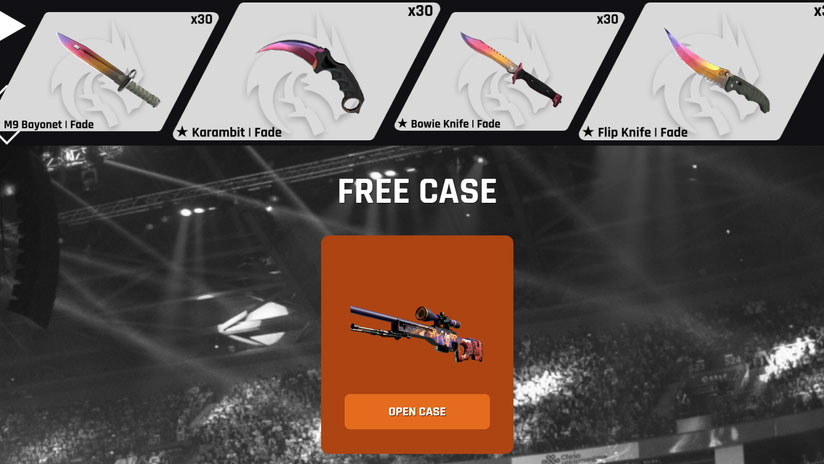

CS2 fans targeted by Streamjackers — viewers shown fishy links, QR codes

By Mark Tyson Published

-

Security researcher finds vulnerability in internet-connected bed

By Christopher Harper Published

-

Intel roasts AMD and Nvidia in its latest product security report, claiming AMD has vulnerabilities with no fix planned, Nvidia has only high-severity security bugs [Updated]

By Jowi Morales Published

-

Backdoor uncovered in China-made patient monitors

By Roshan Ashraf Shaikh Published

-

Manufacturing

-

-

Former SK hynix employee transferred advanced chip packaging technologies to Huawei

By Anton Shilov Published

-

ASML accelerates 50-football-fields-size mega expansion plans in the Netherlands

By Mark Tyson Published

-

Apple expects to source over 19 billion chips from U.S. factories this year

By Anton Shilov Published

-

TSMC SVP Kevin Zhang opens up on process technology development & evolving demands: Interview

By Anton Shilov Published

-

TSMC starts construction its 1.6nm and 2nm-capable U.S. fab: Fab 21 phase 3

By Anton Shilov Published

-

Taiwan puts new restrictions on exports of TSMC's most advanced process technologies

By Anton Shilov Published

-

China reportedly waives tariffs on some US chip imports

By Jowi Morales Published

-

Startup aims to 3D print chips and cut production costs by 90% — nanoprinter operates at wafer scale

By Anton Shilov Published

-

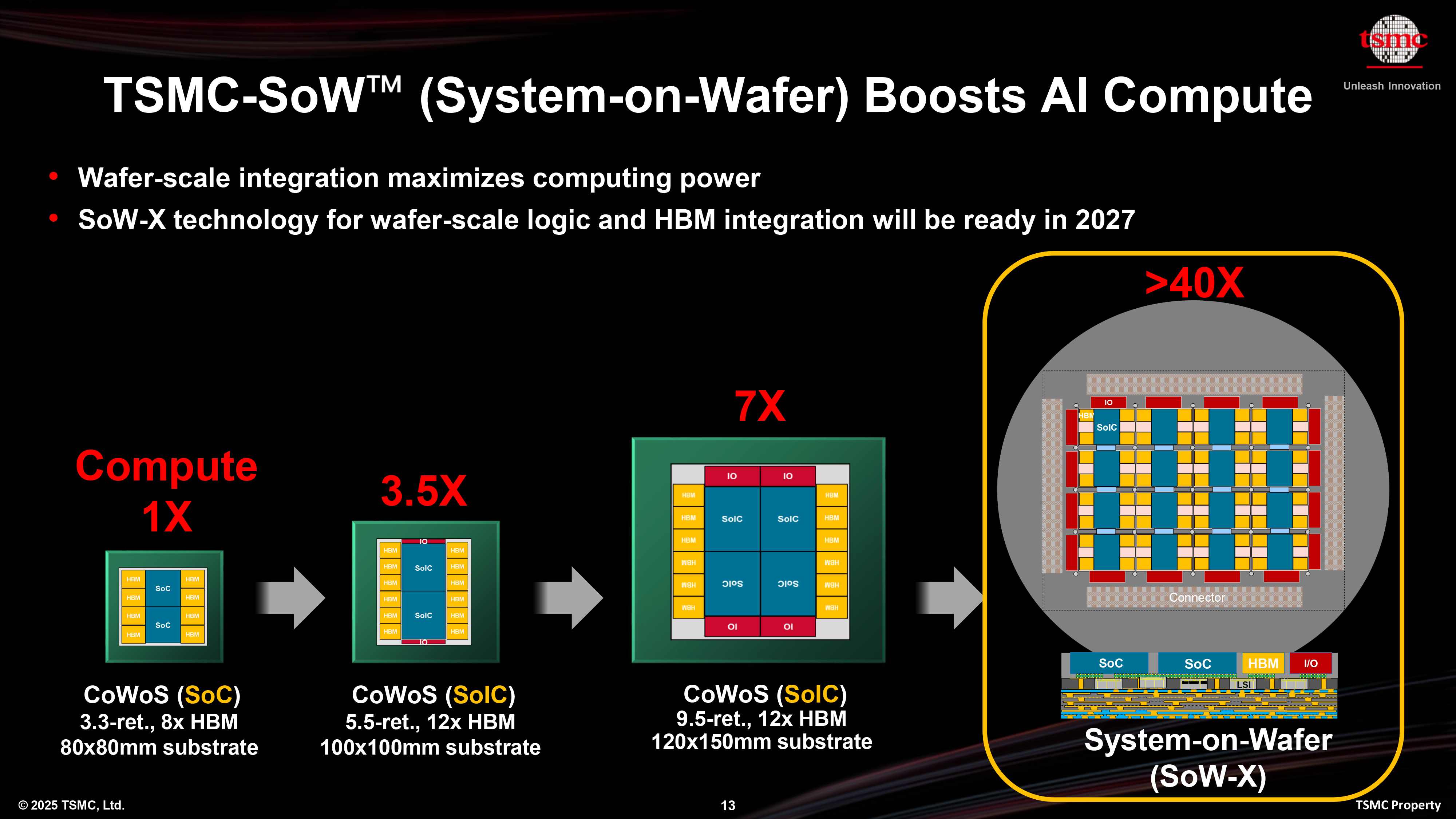

TSMC mulls massive 1000W-class multi-chiplet processors with 40X the performance of standard models

By Anton Shilov Published

-

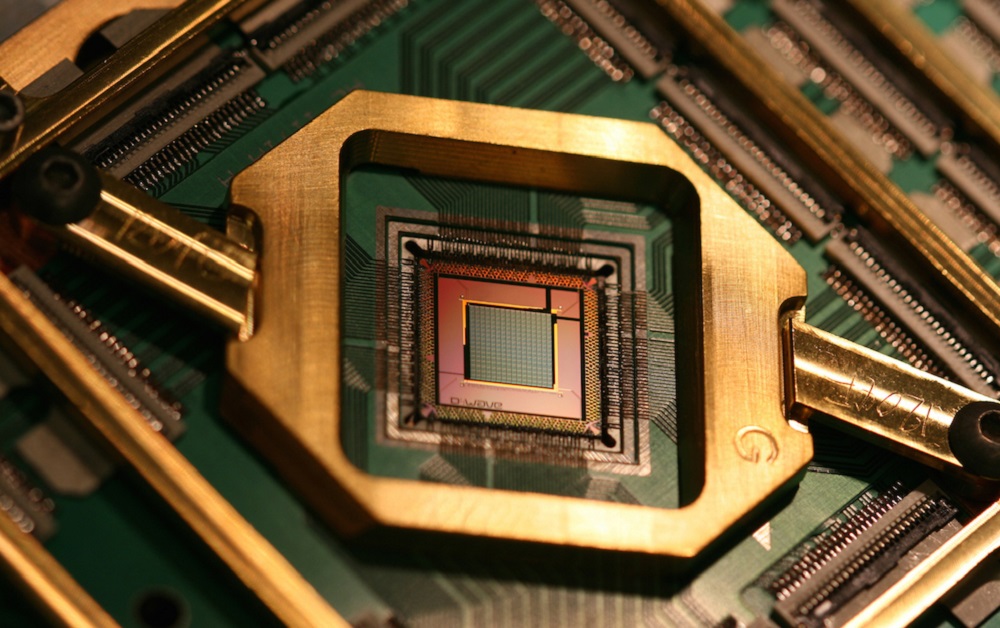

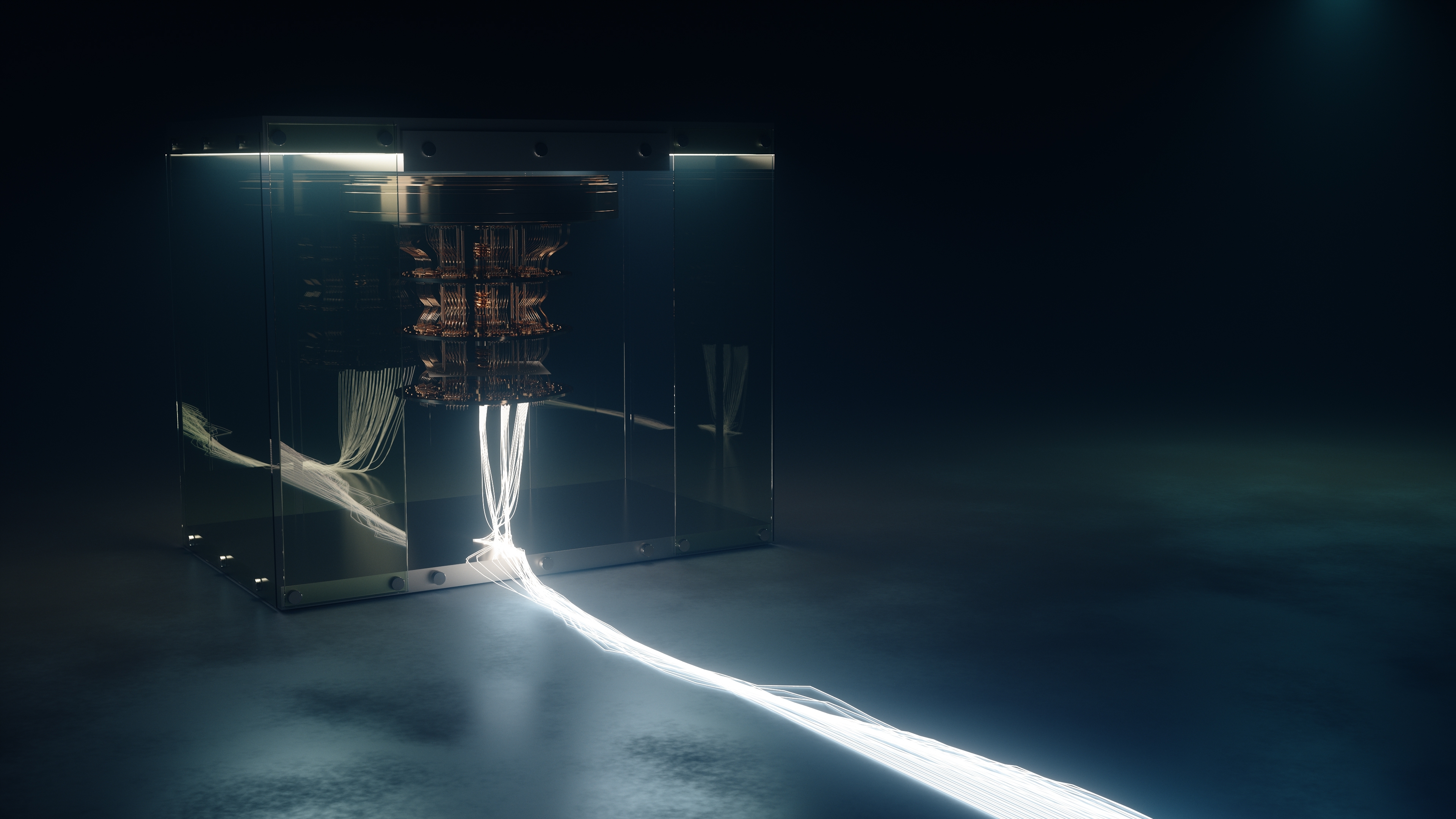

Quantum Computing

-

-

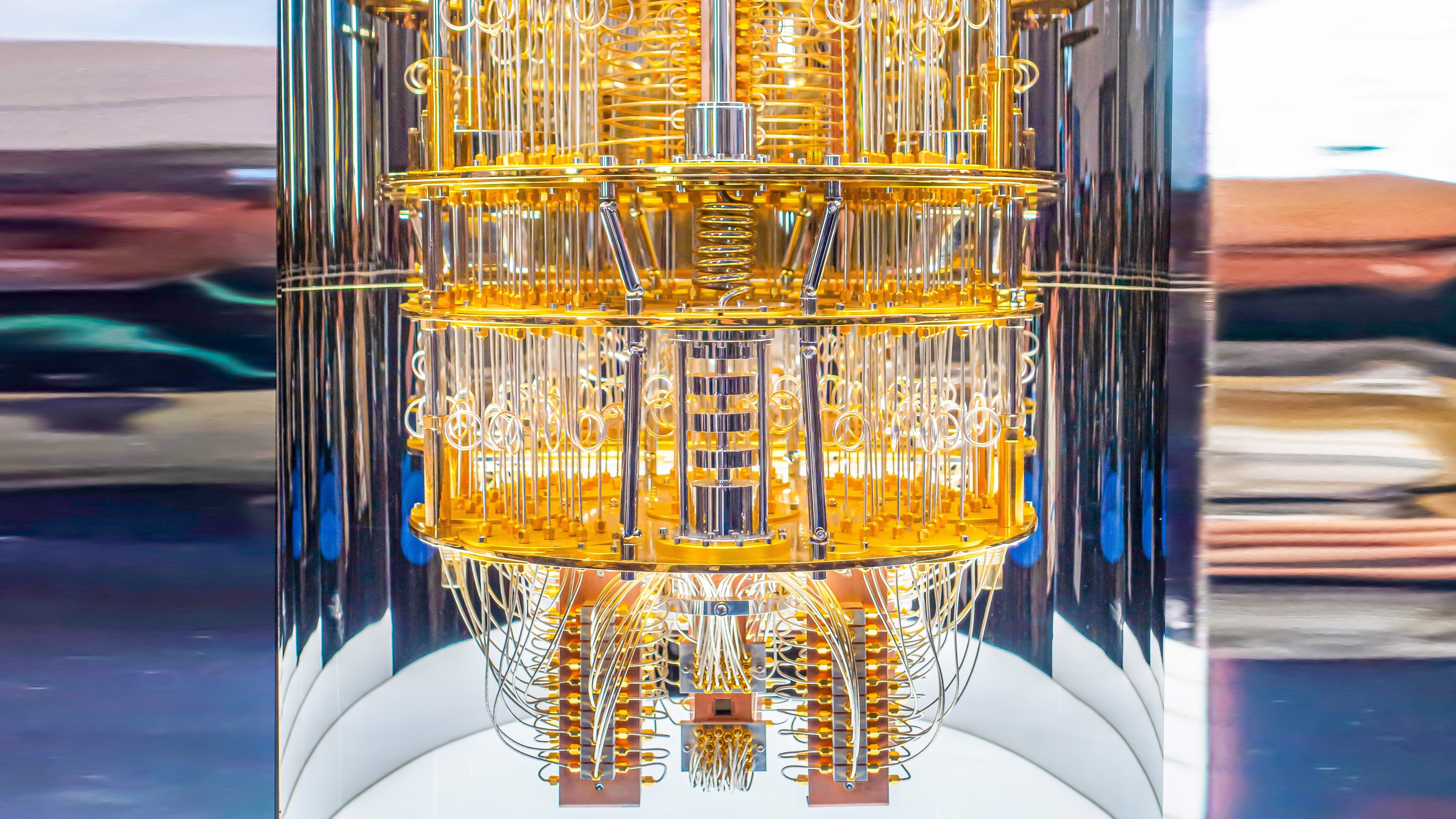

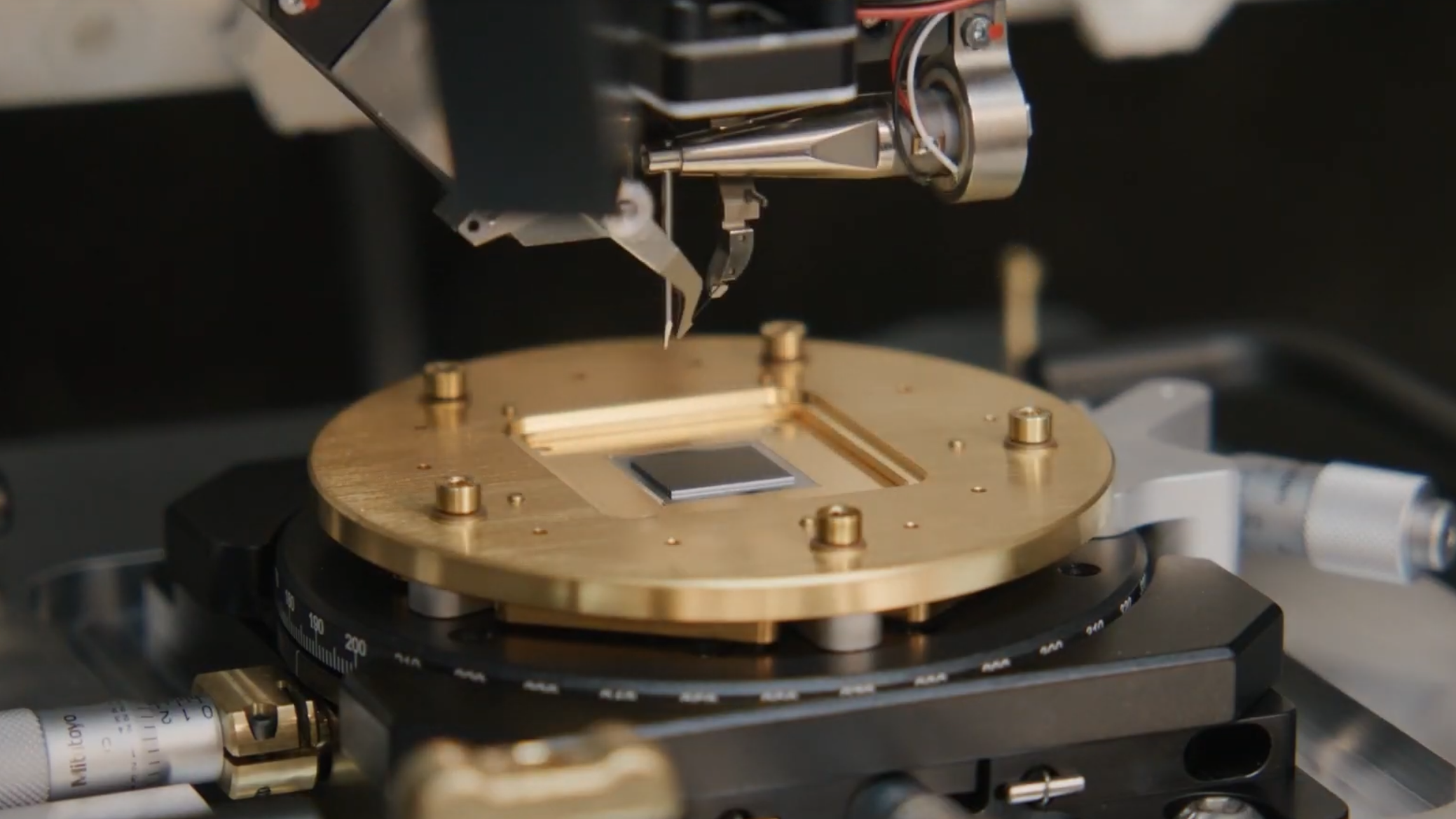

QNodeOS claims to be the first operating system for quantum networks, paving the way for future quantum applications

By Hassam Nasir Published

-

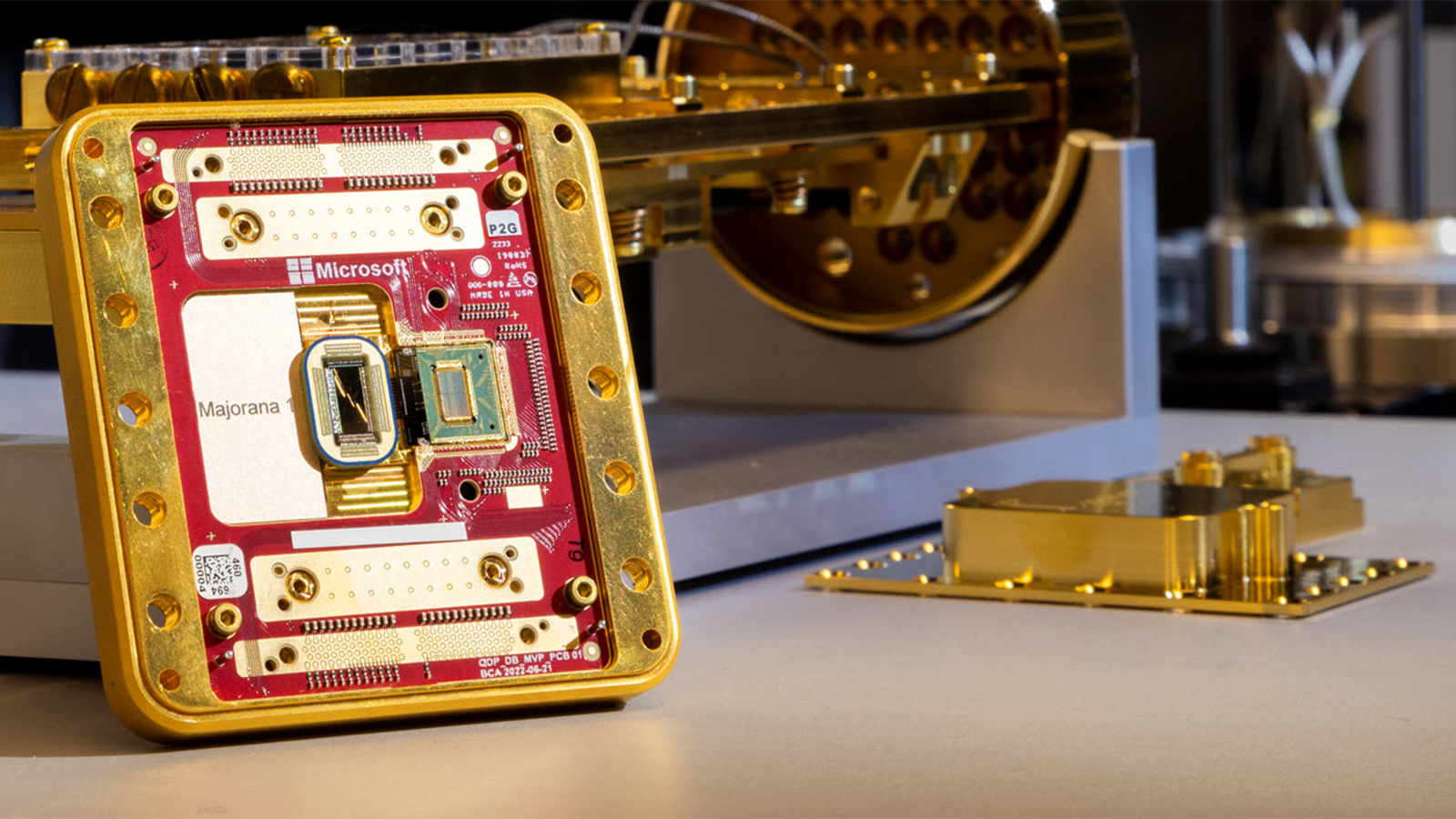

Microsoft's latest Quantum computing claims have been named 'unreliable' by scientists

By Jowi Morales Published

-

Amazon's Ocelot quantum chip uses 'cat qubits' to 'reduce error correction by up to 90%'

By Christopher Harper Published

-

Quantum computing stocks dropped over 40% after Nvidia CEO prediction

By Aaron Klotz Published

-

China's 504-qubit quantum computer chip marks a new domestic record

By Anton Shilov Published

-

Google claims its new Willow quantum chip can swiftly solve a problem that would take a standard supercomputer 10 septillion years

By Mark Tyson Published

-

Chinese scientists use quantum computers to crack military-grade encryption

By Mark Tyson Published

-

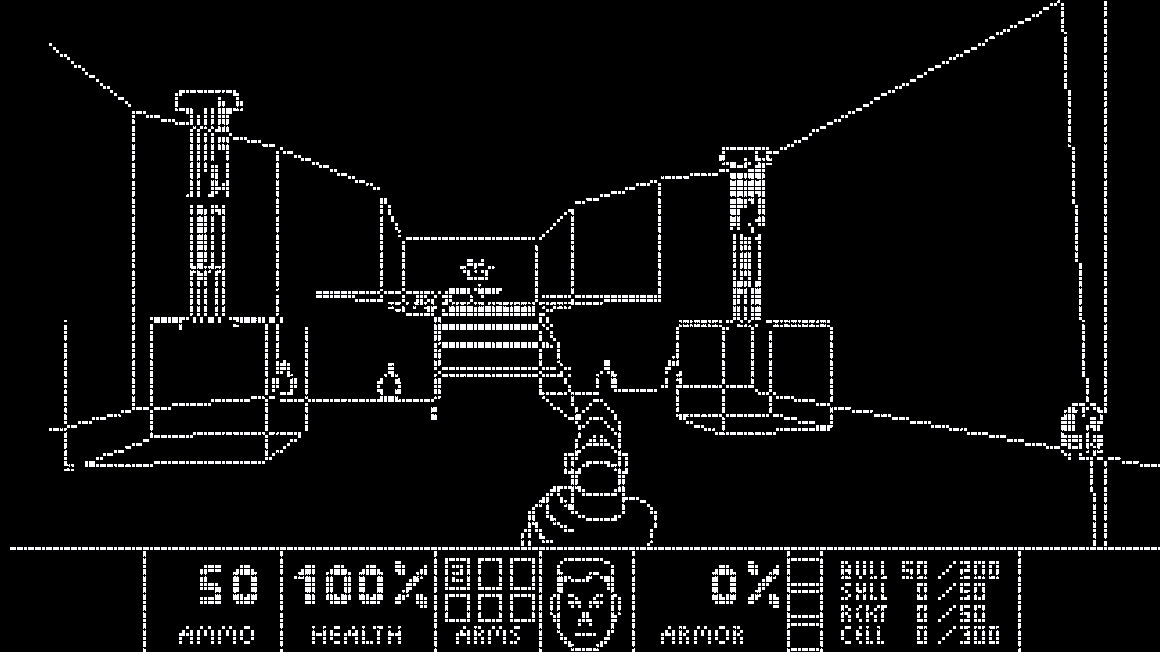

DOOM can now run on a quantum computer with Quandoom port

By Mark Tyson Published

-

Diamond-based quantum accelerators to be integrated into Oak Ridge National Laboratory's HPC

By Mark Tyson Published

-

Supercomputers

-

-

Cadence releases new AI supercomputer — uses Nvidia RTX Pro 6000 GPUs to improve simulation run time

By Jowi Morales Published

-

Elon Musk’s Nvidia-powered Colossus supercomputer faces pollution allegations from under‐reported power generators

By Jowi Morales Published

-

AMD sets new supercomputer record, runs CFD simulation over 25x faster on Instinct MI250X GPUs

By Jowi Morales Published

-

Aurora supercomputer is now fully operational, available to researchers

By Anton Shilov Published

-

China releases Top 100 supercomputer list for 2024: No ExaFLOPS systems mentioned, obfuscation continues

By Anton Shilov Published

-

Summit supercomputer gets virtual farewell on Zoom

By Jowi Morales Published

-

NEC supercomputer combines Intel Xeon and AMD Instinct accelerators to nearly triple performance

By Anton Shilov Published

-

Russian government to issue grants enabling companies and researchers to rent supercomputers

By Anton Shilov Published

-

Isambard 2, the world's first Arm-based supercomputer, retires after six years of service

By Jowi Morales Published

-

Superconductors

-

-

New research shows naturally occurring mineral is an 'unconventional superconductor' when purified

By Christopher Harper Published

-

New research reignites the possibility of LK-99 room-temperature superconductivity

By Francisco Pires Published

-

U.S. Govt and researchers seemingly discover new type of superconductivity in an exotic, crystal-like material

By Francisco Pires Published

-

Nature Retracts Controversial Room Temperature Superconductor Paper (But Not LK-99)

By Francisco Pires Published

-

What is a Superconductor?

By Francisco Pires Published

-

MIT's Superconducting Qubit Breakthrough Boosts Quantum Performance

By Francisco Pires Published

-

LK-99 Research Continues, Paper Says Superconductivity Could be Possible

By Francisco Pires Published

-

Is LK-99 a Superconductor After All? New Research and Updated Patent Say So

By Francisco Pires Published

-

Science Journal Says LK-99 Superconductor Dream is Over

By Francisco Pires Published

-

More about Tech Industry

-

-

After projecting losses of $1.5 billion, AMD CEO Lisa Su calls for a balance between export controls and national security

By Anton Shilov Published

-

ASML accelerates 50-football-fields-size mega expansion plans in the Netherlands

By Mark Tyson Published

-

Clippy resurrected as AI assistant — project turns infamous Microsoft mascot into LLM interface

By Dallin Grimm Published

-