Ultra Durable 3: Extra Copper, Benchmarked

Ultra Durable 3: How It Works

Lots of Copper

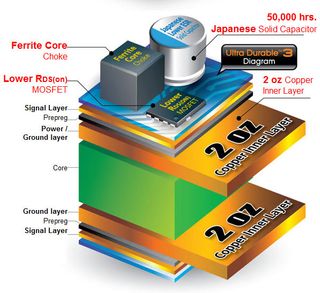

As mentioned earlier, Ultra Durable 3 is a marketing buzzword, which covers several different features and motherboard details. The most important technical detail is the use of an increased amount of copper within the printed circuit board. Every circuit board, whether we’re talking about a graphics card, a memory module or a motherboard, consists of multiple layers. Mainstream motherboards consist of four layers of copper, two of them for signals, one power and a power/ground layer, while complex products can have even more layers. With Ultra Durable 3, Gigabyte decided to turn the layers—which have thus far been considered a necessity—into a motherboard feature, by using more copper to influence the electrical and thermal behavior of the printed circuit board.

Gigabyte says that it uses 2 ounces instead of 1 ounce of copper for each of the inner layers. One ounce equals 28.35 g, which means that an Ultra Durable 3 motherboard comes with almost 57 g of additional copper for the two inner layers. The exact amount has not been disclosed, and probably varies from one motherboard product to the next.

Copper is an excellent electric conductor, but it also has great thermal conductive properties, which is why it is used in heat sinks. A greater profile for signal paths translates into less electrical resistance—this may result to less heat dissipation. The Gigabyte micro-site on Ultra Durable 3 says that resistance (impedance) could be cut in half, and even talks about power savings thanks to the reduced electrical resistance. You’ll find our test results on the following pages of this article.

In addition, the large amount of copper distributed almost across the entire area of the inner layers helps to dissipate heat away from motherboard spots such as voltage regulators or chipset components. We believe that this may have a noticeable impact on operating temperatures, while we aren’t entirely sure about the influence on electrical characteristics. In theory it sounds nice, and spectacular numbers such as support for DDR2-1366+ and DDR3-2200+ memory sound great, but high-quality components certainly account for the lion’s share of the progress that Gigabyte is so proud of.

High Quality Components

As I mentioned, Ultra Durable 3 is a feature mix that consists of more than increasing the copper profile for the key PCB layers. Gigabyte found it equally important to continue building on high quality components, such as low-resistance MOSFETs, solid Japan-made capacitors, ferrite core chokes instead of iron core components, and well-dimensioned heat sinks that include a heat pipe solution. MOSFETs are metal oxide field effect transistors, which are used as efficient voltage regulators. Depending on the power load, these components may become hot, so they benefit from direct cooling by the heat sinks and indirect cooling through the increased amount of copper in the PCB.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Gigabyte has been aggressive in deploying flexible, high-capacity voltage regulators based on up to 12 phases, and in using power-saving mechanisms to dynamically and adaptively switch phases on and off to provide maximum efficiency. This feature is called Dynamic Energy Saver (DES). While it does a nice job for high performance processors, its effect is limited if you use a processor that is already efficient.

The approach of improving a motherboard on a component level—without working on more complex features—sounds promising. Let’s see if Ultra Durable 3 really makes a difference.

Current page: Ultra Durable 3: How It Works

Prev Page Can Supplementary Copper Improve A Motherboard? Next Page Gigabyte EP45-UD3P Ultra Durable 3Most Popular