The Secret Sauces of THG's LCD Tests

The Mechanism

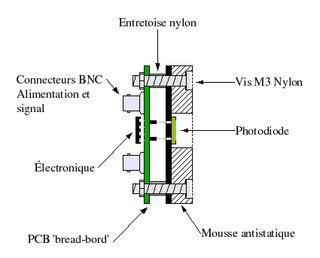

Getting the mechanical components right is a crucial point for the success of this method: we've got to avoid any noise from external light sources, which could distort the measurements of the screen itself. This unwanted nuisance is most often the result of ambient lighting at 50Hz AC. We get around this by placing the photodiode at the bottom of an opaque cavity, which we then literally stick to the screen for the duration of our tests: this is also the method employed by LaCie itself, by the way, for its Blue-Eye optical probe.

Then, we have to maintain a constant distance between the probe and the panel: that's because the intensity of the luminosity diminishes rapidly with distance. We use here anti-static foam (of the sort normally used for mounting electronic components): it's resistant to compression and offers the enormous additional benefit of not scratching the screen during testing. Thanks to the rigidity of this material we can be assured of maintaining parallelism with the panel's surface.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Most Popular