Sponsor Content Created With SK hynix

On the cutting edge: How SK hynix's history prepared it for the AI revolution

Get ready for the next step in a data-intensive world.

HBM (High Bandwidth Memory) is vital for the future of AI. In our data-intensive world, being equipped with the right tools is the difference between finding the answers you need and being left in the dust. SK hynix is a company that has been preparing for this moment for a long time. So long, in fact, SK hynix engineers joked that HBM stood for "Hynix Best Memory." From co-developing the world's first HBM to its one-team spirit, we'll take a look at how it laid the groundwork for success in the AI era.

A bold beginning

With roots stretching back to the early 1980s when it was known as Hyundai Electronics, SK hynix's history in the memory field starts with the construction of its first semiconductor fabrication factory in 1983. Battling against semiconductor titans, SK hynix could fairly be categorized as an underdog.

After some initial struggles against inhospitable headwinds, the company doubled down on its passion, investing in top-notch R&D infrastructure. This move would soon pay dividends, cascading into a series of breakthroughs that advanced its proprietary technology and would lead to the company posting a profit only five years after its inception. A recession in the early '90s threatened to stall that momentum, but SK hynix doubled down again, reinvesting in its company and pushing all its chips in on mass production of 16MB and 64MB DRAMs. This gamble paid off when the semiconductor industry experienced a tremendous upswing in 1995.

Foresight and follow-through

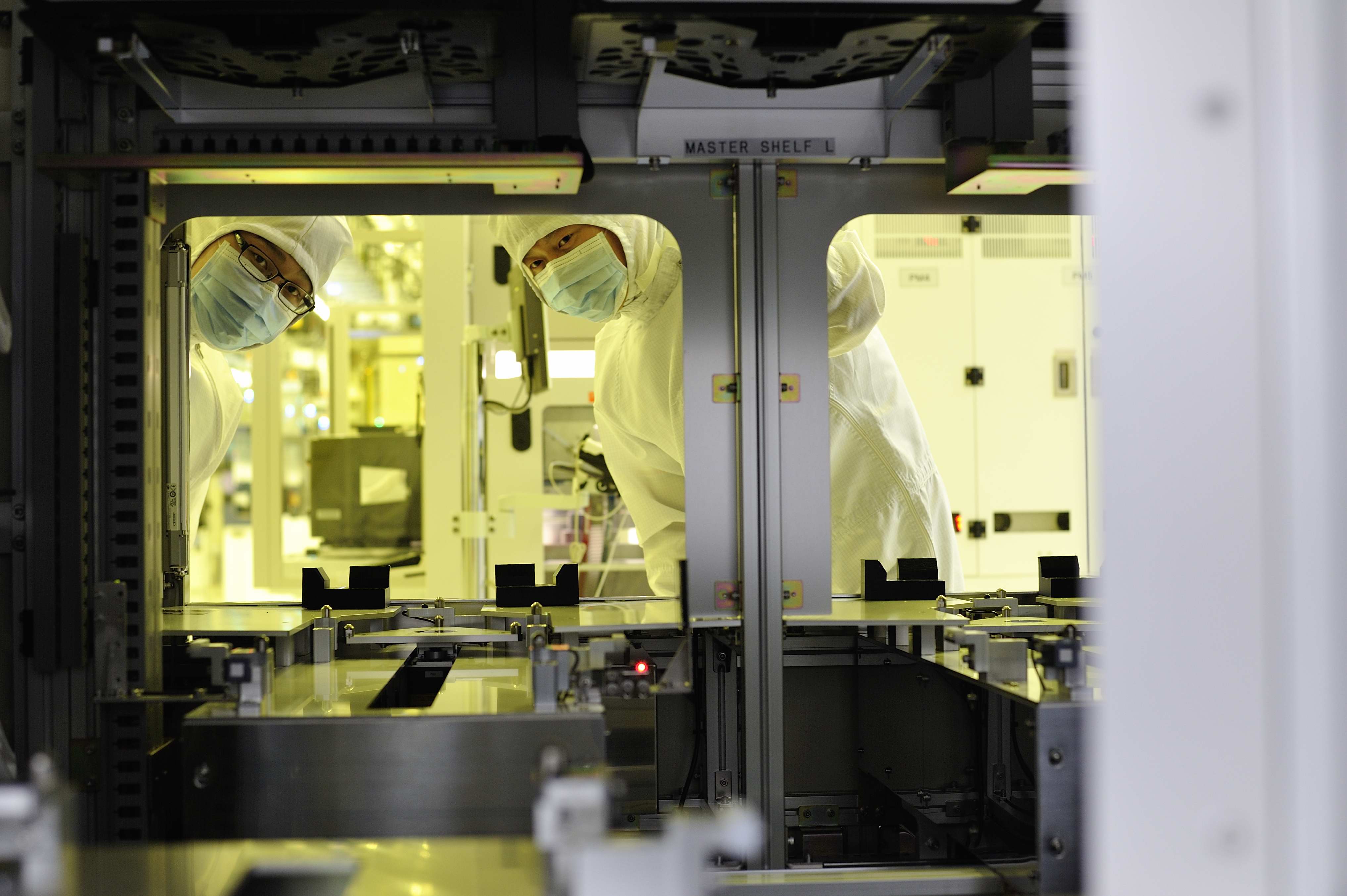

By the mid-2000s, SK hynix (At the time, the company was known as Hynix) had faced multiple economic challenges and responded to each one with redoubled efforts to right the ship, focusing on its flair for creativity and collective energy, with workers and management working in lockstep. That's when TSV (through-silicon via) technology started to come to the forefront. This feature drills thousands of microholes in DRAM chips to connect the holes of upper and lower chips with electrodes. Some saw this advancement as a first step to the implementation of HBM, though the high infrastructure requirements scared most companies off.

Not SK hynix. In the early stages, there was considerable debate over whether to push forward, as heavy investment in related equipment was deemed essential. Yet amid growing uncertainty and concerns over significant losses, SK Group Chairman Chey Tae-won continued to make strategic investments, driven by his conviction that advanced semiconductor sectors, including artificial intelligence, would only become more important. The company saw the path forward and dedicated itself to the development of HBM far before most other manufacturers, beginning in 2009. It began to find the right investors and partnerships to expand its R&D and factories and make sure they were ready for the future. Along the way, its corporate culture codified "one-team spirit" as its core tenet, removing barriers between employees and inviting collaboration throughout the company. This foresight also allowed them to be ahead of the game on other products like LPDDR5, GDDR7 and NAND Flash.

As the demand for high-powered GPUs continued to rise, SK hynix was prepared to meet it. Its commitment to the HBM-supported future was stalwart, sure that the high-performance computing (HPC) ecosystem was right around the corner. That moment finally arrived in 2020. As the AI era revealed itself, demand for HPC technology was at a fever pitch. Who was ready with years of technical expertise? SK hynix.

One-team future

After years of being the underdog, SK hynix grabbed the top spot in the HBM market. But it did not get to that position by being satisfied. The company is driven by constant innovation, setting benchmark after benchmark. It set a goal that some thought was unachievable: to improve performance by 50% with each generation while maintaining the same power consumption. Without the one-team spirit, that would have been impossible. It requires collaboration from so many departments, working with one clear goal in mind.

Still, they met each goal, culminating in this year's release of HBM4, a feat achieved while shortening the development timeline despite the product's complexity. The benchmarks are best-in-class. Power usage is 40% more efficient and hynix anticipates it will improve AI service performance by up to 69%. With more than 10Gbps(Gigabit per second) operating speed, you'll have the ability to process over 400 Full HD movies, each with a capacity of 5GB, in just one second. It's hard to fathom speed like that.

SK hynix is more than the sum of its parts. It's a true testament to one-team spirit, finding ways to join hands across departments to accomplish a goal. That spirit is spreading, with new plants popping up around the world. Between the M15X in Cheongju, the Yongin Semiconductor Cluster in Korea and an advanced packaging facility in Indiana, SK hynix is making sure their supply chain is ready for whatever comes next.

As mass production of the HBM4 gets underway this year, SK hynix is ready to show you the path to an AI-enabled future. Where will that lead you? We don't know yet, but SK hynix is the guide you'll want.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Jacob York is a Branded Content Editor and Writer for Future, focusing on the Games and Tech verticals. Jacob's previous writing experience encompasses everything from award winning plays to websites about tree removal services. The tree removal website also won an award.

In his spare time, he enjoys learning how to bake, spending time at a theme park with his wife, and doing "product research" by diving into a video game. A creative through and through, Jacob would like to take a moment to remind you to support your local Equity hiring theatre.