TFT Guide - Part 1 - Flat Panel Displays

Manufacturing And Yields

The construction and manufacturing of active matrix TFTs is just as complicated as the way in which they work. Many different materials and very thin layers of glass are used, and that on a diagonal surface of up to 30 inch! The rejection rates for production are correspondingly high. Extremely thin transistors are applied to the devices which control its color display elements during later operation. Above all, the spacing between the layers must be absolutely correct. As in the wafer and chip manufacturing business, the production of TFTs is related to a specific yield. Although manufacturers have very different opinions on this topic, it remains a fact that smaller models are easier to manufacture and their rejection rate is lower. The manufacturers are therefore all confronted with the common problem of either producing larger TFTs for flat panel displays or smaller ones for notebooks and other application fields. Larger models mean higher profits but at the price of lower yields whereas the quantities for notebooks are much higher, with a higher yield. Currently - in the second quarter of 1999 - both fields are in short supply - notebooks are apparently being produced and then stocked while the manufacturers are constantly waiting for TFTs in order to be able to finish and supply the machines and the demand for 15" flat panel displays (and larger devices) can not be completely met.

Current Price Situation And Price Trends

Prices range between twice to three times those of CRTs. This means that a 15.1 inch LC display (corresponding to a 17" tube display) cost around $850 and $1,300. An 18.1 inch TFT (corresponding to a 21" tube display) will cost between $2,800 and $3,500.

A short-term negative trend became apparent in the first part of 1999 where prices rose slightly. Many flat panel manufacturers increased their prices for 15" panels from $500 to $600. This development stands in contrast to the general trend of the IT market but the high demand makes this pricing policy currently possible.

It's somewhat curious that without the burden of the poor financial situation of the manufacturers, 15" panels could literally cost about $80. In theory, flat panel displays could then cost less than CRTs. However, drastic changes aren't likely to occur until capacities are reduced or the primary demand for displays shifts away from notebook production.

What Is A TFT? - Getting To Know The Technology

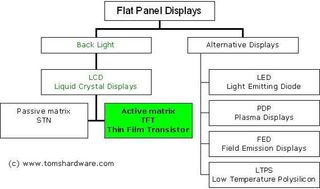

Modern display technologies are currently classified as either cathode ray tube monitors (CRTs) or flat panel displays. Tube devices are large and take up a lot of space, flat panel displays - i.e. devices without a tube - as the name states, are flat and space-saving. The flat panel display category itself encompasses a number of very different technologies such as LCDs (Liquid Crystal Displays), plasma displays, LEDs (Light Emitting Diode) and various other devices. Within these technologies, one can distinguish between flat panel displays that emit light and those that use back light that passes through them.

We will discuss those flat panel displays that - from the current point of view - seem to be the most purposeful; so-called TFT-LCDs. These devices belong to the group of displays that use back light passing through them. STN and DSTN (passive matrix LCDs) are also used, but nowadays only in very low-priced notebooks.

Figure 1: Overview of the different flat panel display technologies. Active matrix LCD's have prevailed on the market.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

-

viktor3600 Hi!Reply

I am marjan ,and I have nokia 6303c with this type of display (I think) and I work in service for SYSMEX in my country and one day I spray my nokia with WURTH spray for contact ,next day on my nokia screen has shown lots of big black dots .What should I do to remove this dots .

Please send me an answere to my E-mail :marjanarsov@hotmail.com

Most Popular