'Next-gen 3D printing' enables printing with two different materials at once — faster, lighter, and more precise multiplexing nozzle tech demoed by U.S. gov't scientists

Department of Energy’s Oak Ridge National Laboratory (ORNL) scientists assert the innovation will unlock ‘new possibilities for aerospace, automotive, energy, and beyond.’

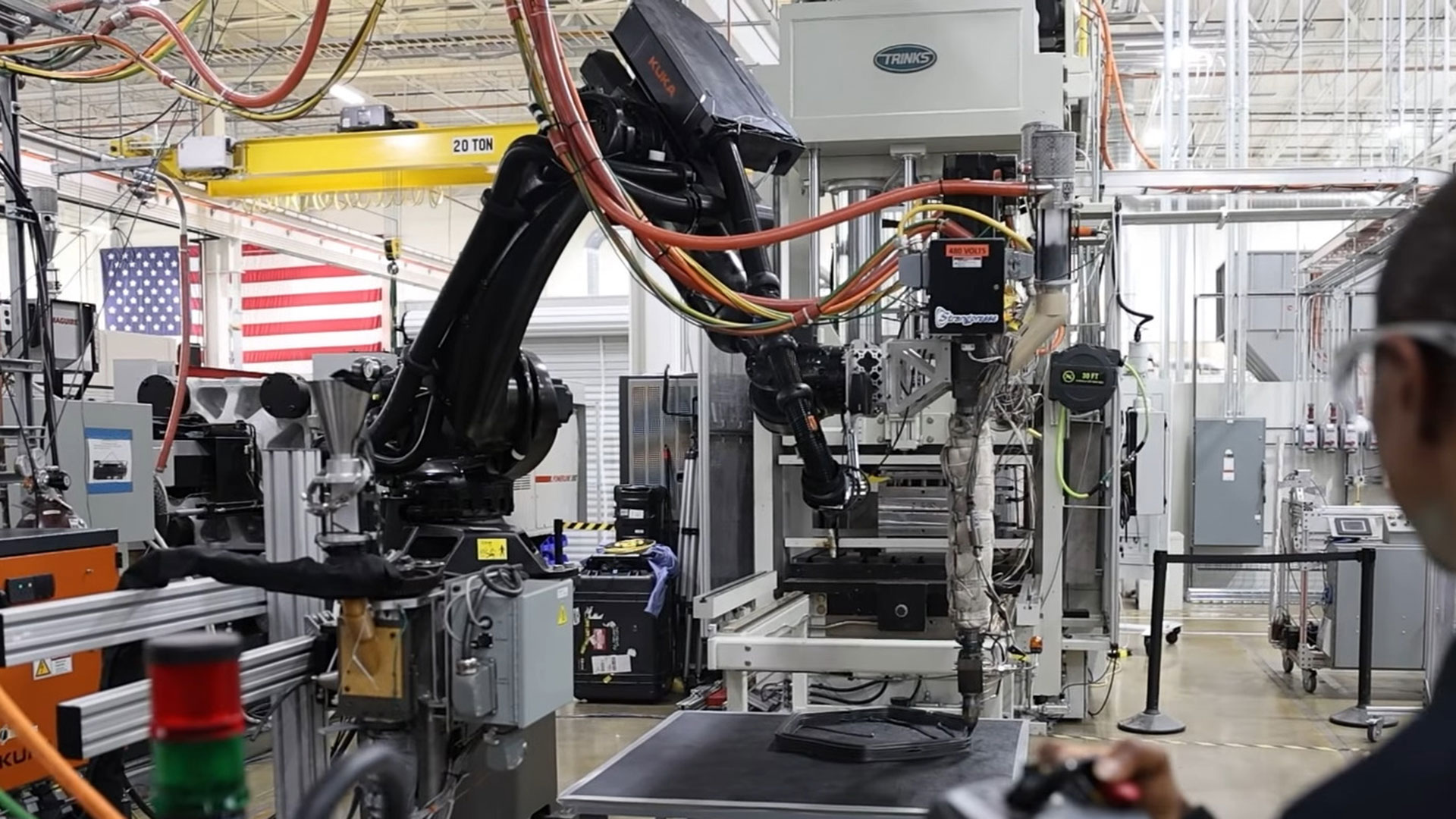

Scientists from the Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL) have demonstrated what they describe as a “next-generation 3D printing system.” The key innovation here is a multiplexed nozzle, which can deliver scalable 3D printing to industry while minimizing the typical tradeoffs in output size, weight, and complexity. Crucially, the tech also enables printing with different materials at the same time.

Compared with many industries, 3D printing is still in its infancy, and as such, pathways to optimization can be quite radical, and make significant differences to the technology. ORNL’s innovations here target larger extruders with higher throughput that are usually used to construct larger objects in a reasonable time. They think their innovation is going to make a big difference, and are hence labeling it as next-gen.

This revamped method for 3D printing at scale addresses weak points in the process as things go large. “Extruders can continually be made larger, but their weight requires stiffer and more expensive gantry systems or robots to carry and control them,” noted ORNL in 2023, when it first took the wraps off this technological advance. “Larger extruders also suffer from unreliable flow control at low speeds (<10% of maximum throughput), which can be an issue for small builds and low speed printing operations.”

So, how does it work?

At its heart, the next-gen 3D printing system relies on multiple extruders combined to multiplex the output into a single stream of molten polymer. Due to this change, it is claimed that typical large-scale issues such as weight penalties and unreliability at lower speeds are minimized.

For example, the extrusion rate can be slowed where required by turning off one of the multiplexed nozzles. Also, multiple materials can be fed through at a controlled rate, at once. The ORNL suggests this also opens up more complex ‘ribbon’ and ‘core and sheath’ bead designs straight from the nozzle.

During the freshly published demonstration video, we are informed that “more extruders can be added for higher throughput without sacrificing quality or control.” No upper limit is mentioned for multiplexing nozzles.

It is hoped that the ‘next-gen 3D printing’ tech from the ORNL will be used soon in applications used by additive manufacturers, the marine industry, and the aerospace industry. Some of the benefits may also trickle down to the consumer 3D printer space, in time, giving us capabilities beyond the best dual-nozzle mechanical switching systems we have tested, like the Bambu Lab H2D.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button!

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

edzieba There have been plenty of multiplexing printheads demoed before. The big issue is that molten polymers are surprisingly difficult to get to flow in a non-laminar manner, so trying to get multiple outputs to mix at point of extrusion is far harder than expected. e.g. using a bulk undyed filament and inserting a tiny sliver of a saturated dye-carrier does not really work for dynamically coloured prints (you just get a little string of colour in the extrudate) and if conditions aren't just right you end up with the outputs from each extruder separating again as they exit the combined nozzle!Reply