Thermal Paste Comparison, Part One: Applying Grease And More

If you find yourself fighting a stubbornly-low overclock, there's a chance that your thermal solution isn't working as effectively as it should. We're testing a number of thermal pastes that might help. But first, let's go over the basics of CPU cooling.

Applying Thermal Paste, Part One

A Philosophical Debate: The Application Method

It’s tough to pick a technique for applying paste. Any method only works well if paste quantity and viscosity is absolutely correct for the particular application. In light of the hot spot discussion, however, we believe that smearing paste on the whole CPU is quite pointless and a thing of the past. Instead, we want to focus on the particularities of the CPU, its heat spreader, the heat sink, and the mounting method (in particular the mounting pressure).

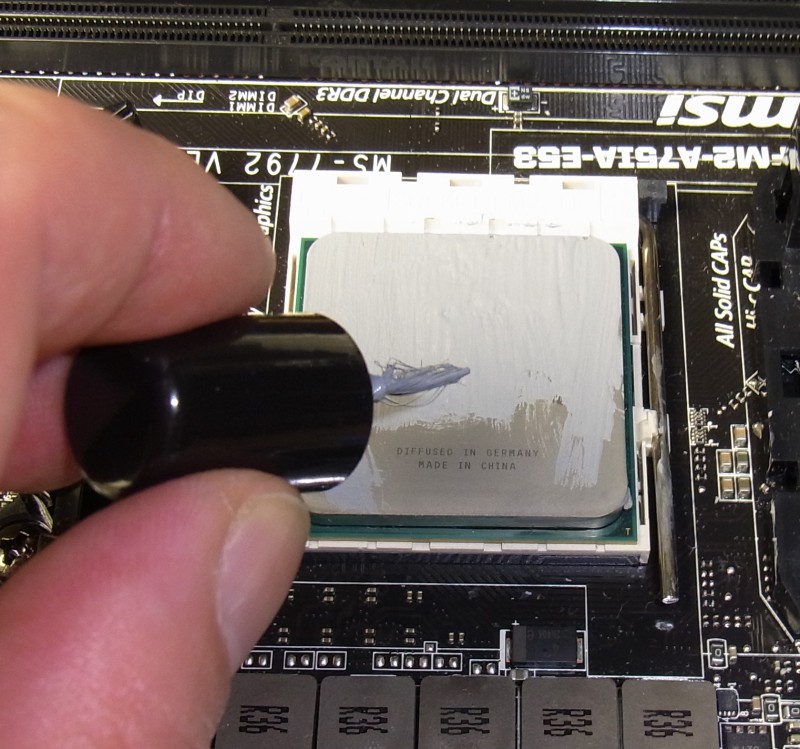

Brushes and Low-Viscosity Pastes

Liquid pastes like the Revoltec Thermal Grease Nano can be applied with a brush, and are consequently the easiest to use. However, low viscosity comes at the price of a high silicone content, which impacts thermal conductivity. These pastes typically fall to the bottom of our performance charts. When you try to apply semi-liquid pastes by brush, typically you wind up with too much, and that isn’t optimal, either.

Drop, Sausage, or Wall Painting?

In my opinion, spreading paste on the entire CPU is too tedious and runs the risk of applying too much material, or even causing air pockets. Furthermore, some pastes simply do not want to be smoothed. The more you try to even the surface out, the more it tears open.

Trying to spread a high-viscosity paste with a credit card is a fool’s errand. You'll waste a lot of time and won’t achieve a thin, smooth layer. Yes, you can try to put a latex glove on your hand and use your index finger. But even with this method, the risk of applying too much paste is significant, especially if you have no practice. The higher the viscosity, the less successful you can anticipate being trying to "paint the wall".

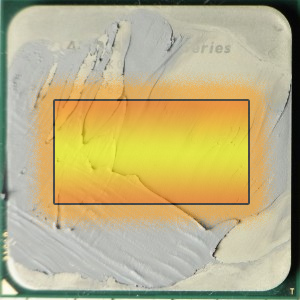

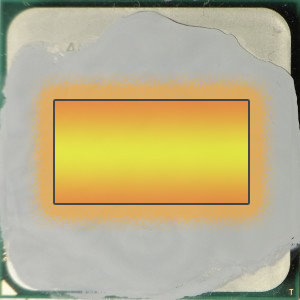

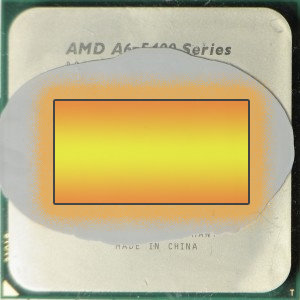

A Strip of Paste

When you imagine CPU die under the heat spreader, it may seem smart to put a strip of paste over that area. But don’t apply too much. Otherwise, the paste will ooze out on all sides. If your paste is electrically conductive, you can almost be assured of hardware damage.

When you apply the paste strip frugally, the result is better. Don’t worry too much about bare spots. The edges of the heat spreader don’t contribute much to thermal transfer anyway. If your cooler sports a back plate and applies lots of mounting pressure, the paste will spread further. As a rule of thumb, the lower the viscosity of the paste and the higher the heat sink's mounting pressure, the more your compound of choice will spread.

Current page: Applying Thermal Paste, Part One

Prev Page Choosing The Right Paste: More Than A Matter Of Price Next Page Applying Thermal Paste, Part TwoGet Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

alidan please tell me yo are also going to do the solder the heatsink to the cpu method? i forget what its called, but that is what i want to use for my next computer and would love to see how it stacks up.Reply -

The Von Matrices In the second section about advanced cooling methods, are you planning on discussing delidding CPUs and replacing thermal paste? If you do it might be worth mentioning that the delidding won't improve temperatures because of improved thermal paste conductivity but because of reducing the thickness of the paste. See http://forums.anandtech.com/showpost.php?p=34053183&postcount=566Reply -

stickmansam Huh, I do turn my heatsinks sometimes for optimal alignment so the heat pipes are perpendicular to the die. Depends if I got the room in the case and what ram is being used. Also heatsink dependentReply -

slatts1024 One of the best articles I've read on Tom's in years and that's saying something. Looking forward to part 2.Reply -

Shankovich Loving that DHT-based design overlay picture on the first page. I've been telling my friends for a while to just get coolers with plated covers because the pipes miss the hotspot on intel CPU's, but no I'm full of bs apparently. This video is awesome btw, shows how spreads happen http://www.youtube.com/watch?v=EyXLu1Ms-q4Reply -

nukemaster How many volts does this "7 volt" unregulated power supply put out?Reply

Just curious. I have some 8/9/12 volt regulators that would eliminate the guessing games for resistor fan adapters(voltage depends on the fans current draw).

I have seen unregulated 6 volt power supplies range from 8-over 12 volts at low loads.

For a rather low price you can use a regulator to get whatever voltage you want :)

ohh yeah and...

I can't wait for the next part of this to be release -

jimmysmitty From what I have seen it depends on the materials. AS5 was great for a while but thee are better ones out than that now such as Noctuas or Zalmans.Reply

I also enjoyed using the IC Diamond thermal paste as it proved to cool very well but since it has a diamond based substance it can scuff the heat spreader.