Thermal Paste Comparison, Part One: Applying Grease And More

If you find yourself fighting a stubbornly-low overclock, there's a chance that your thermal solution isn't working as effectively as it should. We're testing a number of thermal pastes that might help. But first, let's go over the basics of CPU cooling.

The Differences Between AMD And Intel Heat Spreaders

Convex and Concave Heat Spreaders

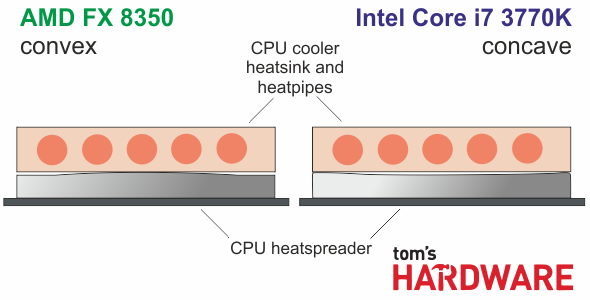

To make matters worse, heat spreaders are not merely rough, but due to the way they're manufactured, they aren't level, either. The following diagram exaggerates the problem for the purpose of illustration:

AMD’s heat spreaders are slightly higher in the center and Intel’s have higher edges. From my perspective, AMD's approach is better-suited for cooling. Due to the mounting pressure of the CPU cooler, the thermal compound is thinnest where most of the heat needs to be transferred. Thus, Intel CPUs deserve perhaps a touch more thermal paste, and you should take care that no air gaps form in the center.

How Thermal Paste Spreads under Pressure

The following animation illustrates how thermal paste escapes to the sides when pressure is applied. Later, we’ll discuss the relationship between a paste’s fluidity (how "liquid" it is, the opposite of viscosity) and the maximum mounting pressure in detail. For now, let’s just say that a paste with low viscosity is more suitable for low-pressure mounting methods, like Intel’s push pin method, than a "hard" paste.

The technical specifications of a thermal paste’s thermal resistance do not necessarily predict its real-world performance for a specific combination of CPU, paste, and cooler. A good heat sink can be crippled by a mismatched thermal compound. A good match between cooler and paste can achieve more than just blindly choosing an expensive thermal compound.

Current page: The Differences Between AMD And Intel Heat Spreaders

Prev Page Interaction Of The Heat Spreader And Heat Sink Next Page Choosing The Right Paste: More Than A Matter Of PriceGet Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

alidan please tell me yo are also going to do the solder the heatsink to the cpu method? i forget what its called, but that is what i want to use for my next computer and would love to see how it stacks up.Reply -

The Von Matrices In the second section about advanced cooling methods, are you planning on discussing delidding CPUs and replacing thermal paste? If you do it might be worth mentioning that the delidding won't improve temperatures because of improved thermal paste conductivity but because of reducing the thickness of the paste. See http://forums.anandtech.com/showpost.php?p=34053183&postcount=566Reply -

stickmansam Huh, I do turn my heatsinks sometimes for optimal alignment so the heat pipes are perpendicular to the die. Depends if I got the room in the case and what ram is being used. Also heatsink dependentReply -

slatts1024 One of the best articles I've read on Tom's in years and that's saying something. Looking forward to part 2.Reply -

Shankovich Loving that DHT-based design overlay picture on the first page. I've been telling my friends for a while to just get coolers with plated covers because the pipes miss the hotspot on intel CPU's, but no I'm full of bs apparently. This video is awesome btw, shows how spreads happen http://www.youtube.com/watch?v=EyXLu1Ms-q4Reply -

nukemaster How many volts does this "7 volt" unregulated power supply put out?Reply

Just curious. I have some 8/9/12 volt regulators that would eliminate the guessing games for resistor fan adapters(voltage depends on the fans current draw).

I have seen unregulated 6 volt power supplies range from 8-over 12 volts at low loads.

For a rather low price you can use a regulator to get whatever voltage you want :)

ohh yeah and...

I can't wait for the next part of this to be release -

jimmysmitty From what I have seen it depends on the materials. AS5 was great for a while but thee are better ones out than that now such as Noctuas or Zalmans.Reply

I also enjoyed using the IC Diamond thermal paste as it proved to cool very well but since it has a diamond based substance it can scuff the heat spreader.