Motherboard and GPU Pricing Under Pressure Due to Copper Foil Shortage

But should you worry?

Prices are surging for the copper and copper-clad laminates (CCLs) used to make printed circuit boards (PCBs), which are then used for pretty much every type of electronics device. According to reports from DigiTimes, the cost of manufacturing devices like PC motherboards and graphics cards is rising due to a copper foil shortage, nad now the question is how much of that cost the manufacturers will pass on to the end user. According to some of our quick calculations, the impact of the copper foil shortages could be most felt in lower-end devices, while more expensive premium products might see less of an impact due to already-inflated pricing.

Costs Are Rising

It's no secret that chipmakers can't produce enough semiconductors due to the overwhelming demand for electronics, which is why chip pricing is high. But in addition to actual chips, all kinds of electronics use PCBs made of glass fiber and copper foil.

The price of copper went up from $7,755 per ton in December 2020 to $9,262 per ton today (September 28, 2021). The cost of copper foil surged 35% since Q4 2020 due to the rising prices of copper and energy carriers. As you would expect, the price for copper clad laminates (CCLs), a foundational component used for making PCBs, increased due to the costs associated with the prices of copper foil and energy. The trickle-down effect continues, and now price quotes for PCBs are increasing, too.

This will affect costs and possibly prices of all kinds of electronics, but PCs, motherboards, and graphics cards will experience more pricing pressure than other components because they tend to use large PCBs with a high layer count.

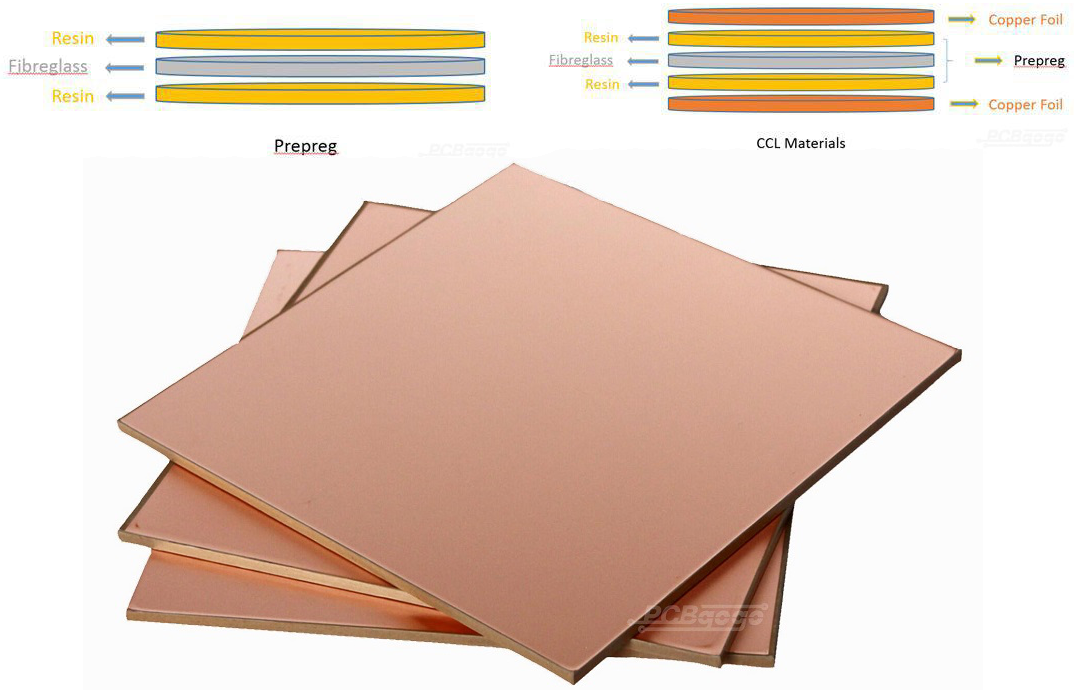

Every PCB is built using multiple CCLs, depending on the number of layers. Each CCL consists of several sheets of fiberglass plastic impregnated with epoxy resin that are stacked together and then covered with ~0.035-mm thick (or even thinner) copper foil on both sides. Traces on motherboards are formed by etching away unnecessary copper using processes like those used in microelectronics production (you can read more about the process here).

Each ATX-sized CCL (305x244 mm) uses around 23 grams of copper (we calculated it here), but a high-end motherboard uses a PCB with at least eight layers (i.e., eight CCLs), so it consumes at least 184 grams of copper (probably more, but we'll stick with this number). Therefore, before processing, a metric ton of copper is enough to build 5,434 eight-layer motherboards, which means that one ATX motherboard consumed $1.42 worth of copper in December and uses $1.70 worth of copper today. But that's before we add in the costs of turning the copper into a usable form, and before the impending price hikes.

While the cost of copper per motherboard did not increase significantly, the cost of copper foil and CCL production increased because of copper prices and rising energy carrier prices.

Right now, a roll of 0.0005-inch copper foil (width: 12 inches, length: 1200 inches) costs $423. Based on our estimates, such a roll is enough for ~62 ATX-sized CCLs, which means $6.8 per CCL or $54 of copper foil per eight-layer ATX PCB. Keep in mind that this is an estimate, and makers of CCLs for motherboards hardly use off-the-shelf copper foil. In addition, transportation fees are high since the demand for transport also increased due to the pandemic, leading to other secondary cost increases.

Overall, the costs of copper, copper foil, copper-clad laminates, PCBs, and manufacturing have increased quite meaningfully due to various factors. The price increases are not going to stop, though. Chinese CCL makers recently announced price hikes for their PCB customers, DigiTimes claims. Copper foil suppliers are also reportedly mulling increasing their processing fees to CCL makers in early 2022, which is why the latter are now negotiating with their customers to provide them reasonable offerings while ensuring decent profit margins.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Other Factors

In addition to the demand for PCs, other factors are driving up the prices of PCBs and CCLs. Copper prices are increasing not only because of high energy prices, but because demand for copper wires is growing as many applications switch from aluminum wires to copper wires. Transitioning to renewable energy sources requires brand new power generation equipment, which further hikes the demand for copper wires.

Meanwhile, as carriers transit to 5G networks, they acquire appropriate equipment, including base stations and networking systems that happen to use loads of copper wiring as well as high layer count PCBs that use many CCLs. Growing demand for such equipment naturally adds pressure on copper foil makers, CCLs and PCBs.

Should We Worry?

The price of copper hit a historical high in June, but since then, it went down and is now on the levels of 2010 ~ 2011, according to MacroTrends. But what impacts the costs of electronics is not the price of copper per se, but rather the price of copper foil, which is quite high these days.

While the cost of copper foil, CCLs, and PCBs is surging, its impact on pricing for graphics cards, motherboards, notebooks, and desktop PCs will vary.

A 10% price increase of one of the key components will be noticeable in the case of entry-level motherboards that are not sold with hefty profit margins and retail for $100 – $200. The same can be applied to inexpensive electronics that use relatively complex PCBs and relatively cheap active components (e.g., entry-level PCs). Hence, if you buy budget hardware, you may want to think about your purchase strategy.

The cost of active components (processor, memory, PMICs, etc.) still accounts for the lion's share of electronics build of material (BOM - the price to construct the product). Thus, even if copper foil pricing increases by 10%, it will hardly impact the price of a high-end motherboard that nowadays may retail for $350 – $900, since manufacturers might absorb the increase without passing it to the end-user. Something similar can be said about graphics cards and their retail prices: even if one ingredient gets a 10% price hike, a graphics card that uses it will hardly get significantly costlier at retail since it is already sold at an inflated price. So, if you buy expensive devices, you should probably not worry about the prices of copper, copper foil, CCLs, and PCBs.

But in addition to pricing, there is also the demand aspect. The world is deploying more electronics than ever, so until supply chains are ready to support this demand, there will be multiple factors that will affect the pricing and availability of electronics.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

artk2219 Sweet, another reason for even more expensive commodity items, awesome. Realistically its not a huge deal on a consumer level, but for OEM's with already tight profit margins, not the best news.Reply -

Krotow The message for general public - no consumer electronics for you in any form for next 100 years - give or take. Go back to countryside and start living as peasants.Reply -

hotaru251 Reply

insert Weird Al Yankovic's Amish Paradise song ;)Krotow said:The message for general public - no consumer electronics for you in any form for next 100 years - give or take. Go back to countryside and start living as peasants. -

thisisaname For me the TL;DR of this is no the copper price rise will not increase the price of good due to the small amount used. The price will be raised due increases in energy and transport costs.Reply -

spongiemaster Fed Ex adds buffet tables at airport terminals. Fatter pilots increasing jet fuel usage. Chip prices going up.Reply -

As Klaus Schwab said "You will have nothing and be happy".Reply

Here when something fails it ends up as landfill. There is no attempt to recycle anything except plastics.

No wonder there are shortages of all of these metals; silicon, gold, silver and so on. -

albundyhere ReplyKrotow said:The message for general public - no consumer electronics for you in any form for next 100 years - give or take. Go back to countryside and start living as peasants.

way ahead of you. bought a 2nd house with land right before covid hit, and been "working from home" ever since, haha. the family loves it out here. none of us ever want to go back to the city. what for? to get infected and live in misery? anyhoo, i'm not using as much tech as i used too...too busy enjoying the outdoors. peasant life is good when you've got money.