THG Unveils New LCD Benchmarking Method

The Mechanics

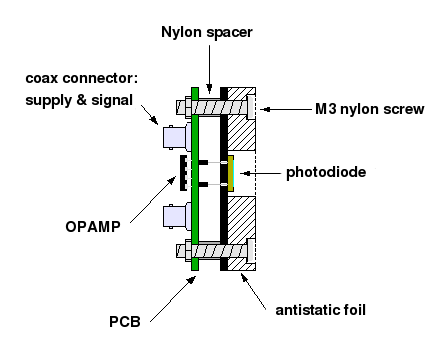

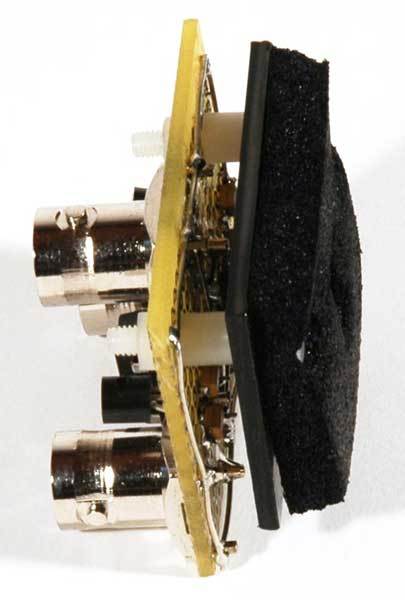

The mechanical construction is a crucial point for the success of this method. Any parasite light sources could falsify the brightness measurements of the monitor itself. This kind of interference is exacerbated by the fact that the ambient lighting is often alternating (50 or 60 Hz). So we placed the photodiode at the bottom of an opaque cavity which we then attach to the screen for the measurements. This is the same approach used by LaCie with its Blue-Eye calibration sensor.

Then, a constant distance has to be maintained between the sensor and the panel. This is because light intensity decreases quickly with distance. We use an antistatic foam normally used for storing electronic components. It's almost uncompressible and has the enormous advantage of not scratching the screen during measurements. The broad contact surface combined with the rigidity of the material guarantees the part will not compress under pressure. We also make sure that parallelism with the panel is good.

The Stimulation Software

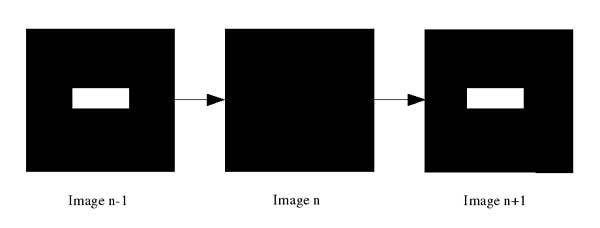

We can now measure the response of one or several pixels. But in order to do it, we have to stimulate the monitor with an appropriate and perfectly reproducible video sequence. The stimulation software we use adapts to all display resolutions and adjusts to the refresh frequencies supported by the monitor. Then, it projects a blinking line in the middle of the display, using the monitor's vertical refresh frequency for its blink frequency.

The software also includes the following adjustments:

- Choice of the display mode (resolution, nominal frequency).

- Separate channel adjustments (8 bits per RGB channel for displaying any color in 24 bits).

- Frequency (sub-multiple of the nominal frequency).

- Possibility of fixed image (no blink at all).

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: The Mechanics

Prev Page How It Works Next Page The System In Use - Example: CRT Monitor