Popular Overclocker Delids Core i9-11900K with Impressive Results

But delidding the 11900K is incredibly risky.

A week ago, German overclocker der8auer published a video showcasing his findings on delidding a Core i9-11900K, Intel's new flagship Rocket Lake CPU. It's not one of the best CPUs, based on our testing, but it's still a formidable opponent in the right workloads. der8auer found that delidding Rocket Lake yielded very impressive temperature results; however, the process is so difficult that it might not be worth the effort.

The problem with the 11900K is its more complex PCB layout of components. Next to the IHS are a bunch of tiny SMD (surface mounted device) capacitors that are incredibly delicate. The capacitors are so close to the IHS that you can easily hit one of them while removing the IHS, which would likely render the CPU nonfunctional.

This is unlike the earlier 9th and 10th Gen chips that don't have any SMDs anywhere near the IHS, allowing for a (relatively) safe delidding process if you have the right tools. But der8auer is a professional overclocker and skilled at delidding, so he took the chance on his 11900K.

Not only do the SMDs pose problems, but what's even worse is the amount of pressure you need to apply to the 11900K during the delidding. der8auer had to upgrade his CPU delidding tool with a torque wrench to get the IHS to move at all, where past CPUs only needed an Allen wrench. You can see the strain of trying to twist the tool while keeping the delidding box stable in the above video.

Needless to say, this adds significant risk to the delidding process. Even with the torque wrench, the IHS didn't want to come off, so der8auer had to resort to warming the CPU up in an oven first. In the end, he was able to successfully remove the IHS, though he mentions several times that he would not recommend most people attempt to do so.

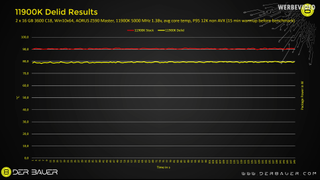

The good news is that the end results are quite impressive. der8uer noted a 10C–12C reduction in temperatures, purely from scraping off the solder on the IHS and replacing it with liquid metal.

This is very impressive on a chip that already has solder. Using solder (as opposed to some form of thermal paste) between the CPU die and the IHS is already a good solution for thermal dissipation. Upgrading to liquid metal normally only results in about a 5C reduction in temperatures, not 10-12C.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

It's rather unfortunate that the delidding process is so incredibly risky on Rocket Lake CPUs. We'd love to see more delidded 11900K testing to see if der8auer's results are typical, but the likelihood of damaging the CPU is so great that it's not worth the risk for the vast majority of users — even for an impressive 10C drop in temperatures.

Aaron Klotz is a freelance writer for Tom’s Hardware US, covering news topics related to computer hardware such as CPUs, and graphics cards.

-

Thomas Wells Comment in the last paragraph "It's rather unfortunate that the delidding process is so incredibly risky on Comet Lake CPU" should read Rocket Lake CPU perhaps?Reply -

TechyInAZ ReplyThomas Wells said:Comment in the last paragraph "It's rather unfortunate that the delidding process is so incredibly risky on Comet Lake CPU" should read Rocket Lake CPU perhaps?

Thank you for the input! We'll fix that typo ASAP. -

InvalidError Reply

If that was really the intent, Intel could have easily placed them a millimeter or so closer to the IHS perimeter. Even better would be to put some UNDER the IHS, I'm sure it could fit 0201s under there, mill SMD pockets under the IHS if necessary for clearance and wiggle room.hotaru.hino said:I wonder if Intel is putting SMT caps where they are to deter delidding. 🙃 -

zodiacfml bad idea for 99% of users, doesn't need it considering the solder TIM and huge die size. better off buying a beefy coolerReply -

Co BIY I thought the goal of delidding was to directly connect the die to the cooler and bypass the IHS ?Reply

Very surprised that liquid metal made any improvement over TIM. I understand why it would be an improvement over paste. -

InvalidError Reply

The problem with STIM is that the distance between IHS and the die is larger than it needs to be with paste to allow for mechanical compliance between the different temperatures and thermal expansion coefficients across the die, STIM and IHS. If the STIM layer was thinner, de-lidding would also have a much higher chance of ripping chunks of the die off the substrate.Co BIY said:I thought the goal of delidding was to directly connect the die to the cooler and bypass the IHS ?

Very surprised that liquid metal made any improvement over TIM. I understand why it would be an improvement over paste. -

escksu What the heck is a professional overclocker?? Overclocking is not even a profession.....Reply -

InvalidError Reply

It becomes one when you are prolific enough that motherboard manufacturers hire you push their motherboards beyond reasonable limits. Almost anything can become a profession when you manage to gain name recognition for it.escksu said:What the heck is a professional overclocker?? Overclocking is not even a profession.....

Most Popular