Tom's Hardware Visits PCPartner In Dongguan, China

Have you ever wondered where your graphics card came from? There's a good chance it’s made by PCPartner in China. Zotac, PCPartner’s in-house brand, invited us on a tour of its factory in Dongguan, China, right after Computex, and we couldn't pass it up.

PCPartner. PC...Who?

When a company like Zotac asks us if we’d like to take a tour of its factory, it’s hard to say no. After all, we’re geeks at heart and want to know where our hardware comes from. Besides, you could say we were in the neighborhood anyway, what with Computex and all.

So why did the bus that picked us up at our hotel unload us at PCPartner? Simple. PCPartner is one of those huge companies that’s a big industry player but that you never hear of. Oh, and it also happens to be the organization that owns Zotac.

And What About Zotac?

The brand Zotac was born about four years ago and the logic behind that move was simple. Since PCPartner was manufacturing components for big-name firms like HP, Dell, Acer, and Fujitsu anyway, the company already had the know-how, equipment, experience, and most important, an excellent relationship with Nvidia. That’s a good position from which to launch an Nvidia-only brand of graphics cards. Eventually, Zotac’s product line grew to include mainboards that also cater to the AMD, Intel, and VIA crowds and use those companies’ chipsets. Additionally, Zotac is known for its mini-ITX products and ZBOX line of HTPCs. But when it comes to graphics cards, Zotac is still an Nvidia-only vendor.

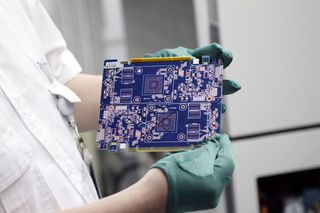

In The Beginning, There Was A PCB

PCPartner wanted to demonstrate how graphics cards are made by leading us along several production lines to explain the process. Since PCPartner also manufactures products for other companies, our guide was very careful to only show us the production lines cranking out Zotac gear, allowing us to take photos of those locations exclusively, so as not to give away company secrets of its partners. That was a shame, really, since we spotted some interesting hardware that hasn't even been announced yet. Put it this way: PCPartner also manufactures for Sapphire and AMD, and we saw more than one reference board that will be coming out in a few months.

At any rate, this is where the manufacturing process begins. Here we see a blank PCB that will be turned into two graphics cards just as it is about to be fed into the first machine.

Stack And Load

Time is money, and that’s especially true when it comes to creating hardware with cutting-edge equipment. To maximize efficiency, the company needs to ensure that wait times are as short as possible. That’s why the first machine is fed from a stack of raw PCBs like the one we saw on the previous page.

Solder On The Go

The manufacturing technique used to assemble these cards is called SMT, which stands for surface-mount technology. Again, this machine shows that efficiency is the prime directive in a plant like this one. In this step, soldering paste is applied to the areas of the board where components will be mounted to simplify and speed up the assembly process.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

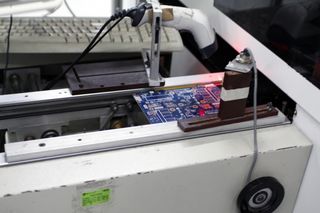

Checkpoint Scan

To track the progress of a card throughout the manufacturing process, and to facilitate quality control, the PCBs are scanned after every step in the production process. Each PCB has its own unique barcode to identify it. If a problem is found with a card, it’s very simple to go back and figure where it occurred. As an added benefit, PCPartner knows exactly how long a certain card needs from the time the blank PCB is loaded into the first machine to the time it is put into its retail package and prepared for shipping.

Keeping Component Feeds "Reel Simple"

What looks like reels of film are actually component feeds with small parts like resistors. Compared to tablet-fed production lines, feeds like this save on space and simplify reloading. Each reel is coded with an RFID to prevent incorrect loading. If the ID doesn’t match the feed, the machine generates an error message and stops until the error is corrected.

Feeding The Machine

Pulling back to a bigger perspective reveals the entire machine, feeders and all. This model belongs to the newest generation and can work on six boards in parallel.

Pick And Place At A Fast Pace

And here’s a close-up. Individual components are mounted using the “pick and place” method. As the name implies, a small robotic arm picks up the parts and places them in their respective locations, while an optical sensor checks their orientation and that they are seated correctly.

Tracking Progress, Part II

As the twin cards leave the SMT machine, they are scanned once more. The first components surface-mounted components are now visible on the PCB.

Bringing The Heat

Remember the soldering paste that was applied in step one? It needs to be heated in order to set, and that’s exactly what happens here. Think of this machine as a long oven with various temperature zones. The cards pass through them, the solder heats up, sets, and cools down, at which point the parts on the board are firmly in place. If you look at the monitor, you can see the individual temperature zones.

-

soccerdocks Get rid of the "read more" button and just make the text appear all the time and I'll consider actually reading this article.Reply -

jestersage It's pretty fair wage over here (not exactly in Dongguan) especially if you are single. For comparison, thing of $2 Big Macs. I figure those on campus can write off rent, electricity and water (yes, we pay for tap) from their monthly bills as well.Reply -

steelbox "We were told that if PCPartner didn’t let them work overtime, most would actually quit and look for other employment."Reply

Right... let me correct that.

"We were told that if the employee didn’t accept working overtime, most would actually be fired and forced to look for other employment."

Most Popular