Liquid Cooled HDD Study Touts Greater Reliability, Lower TCO

Putting spinning rust in liquid might seem risky, but sealed helium drives were used.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Immersion cooling specialist Iceotope has published a study sharing its findings in the wake of a series of tests completed at one of Meta’s (Facebook) data centers. The study looked carefully at the pros and cons of precision single-phase immersion cooling in businesses that use high-density data storage servers. Iceotope asserts that its results were “conclusive” in demonstrating this cooling methodology is a superior solution when compared to air cooling, as well as other forms of liquid cooling such as cold plates, tank immersion, or two-phase immersion.

HDDs are still in high demand in data centers, with Seagate saying that 90% of cloud storage uses this mechanical magnetic storage technology. At the same time, consumer demand for higher bitrate content, and the generation of storage-hungry new content (photos, videos, etc) will continue to ramp up for the foreseeable future. Thus it is important for companies like Meta, who partnered with Iceotope for this study, to optimize storage facilities with regard to reliability, efficiency, and total cost of ownership (TCO).

In the tests, a standard air-cooled commercial storage system with 72 HDDs and supporting components was re-engineered to work with Iceotope’s precision single-phase immersion cooling. Specifically, the modified system used a dedicated dielectric loop connected to a liquid-to-liquid heat exchanger and pump. Single-phase cooling is much simpler than dual-phase - where the coolant boils from liquid to gas, travels into a condenser and then flows back into the system (hence dual-phase). Instead with single-phase, the coolant just flows around the hotter and cooler areas of the loop, doing its job without any phase change.

Four main observations were made by the Iceotope testing team. Firstly, the 72 HDDs showed very little variance in temperature (just 3° C) wherever they were located in the server array. It is important to highlight that the storage array used hermetically sealed helium-filled HDDs. Secondly, the liquid could climb in temperature to an easily manageable 40°C with no impact on reliability. Thirdly, the power consumption of the cooling system was <5% of the system total. Lastly, it was noticed that the single-phase precision cooling was virtually silent and vibration free.

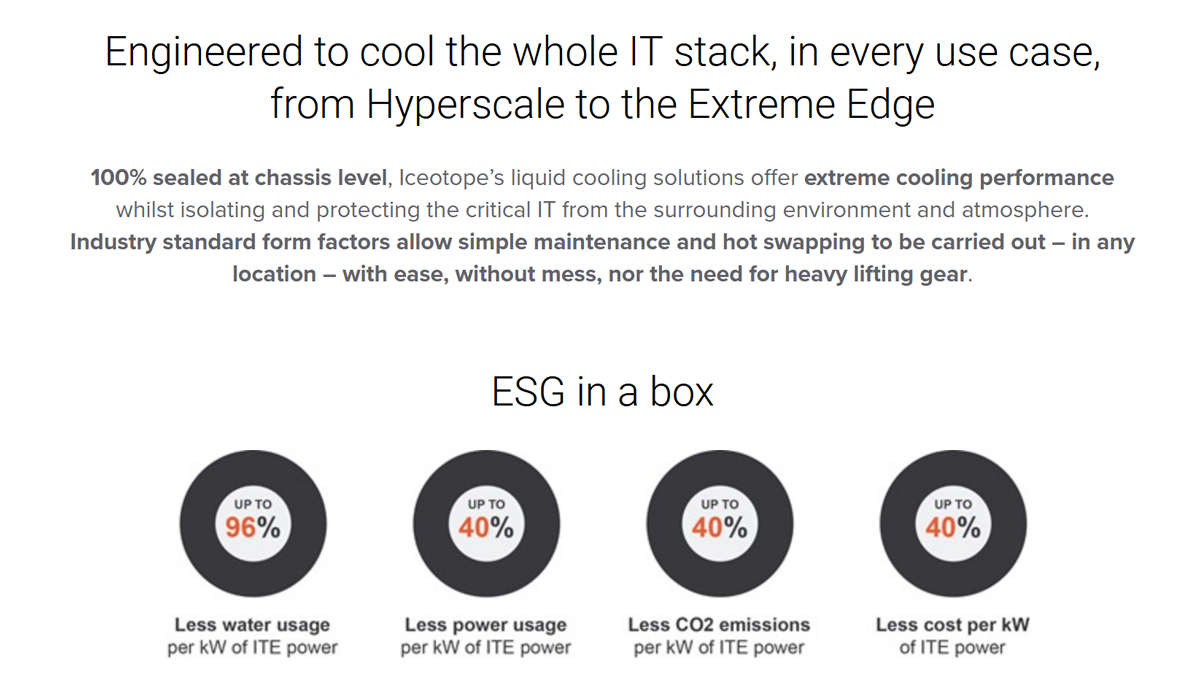

Overall, these benefits can lead to improved TCO figures and greater reliability of the storage hardware. Thanks to the demonstrable benefits, Iceotope’s solution can also be beneficial to a company’s environmental, social and governance (ESG) regulatory evaluations.

But of course, this is a study undertaken by a company that sells this service. So take it with a few grains of salt. And let huge companies like Meta incur conversion and cooling costs for at least a few years before deciding it's worth it to liquid-cool the media collection currently sitting on your NAS drive.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

InvalidError Immersion cooling for HDDs sounds a bit overkill when drives only dissipate 10-15W each with most of that heat sunk into the cast aluminum frame. You could probably achieve most of the benefits by simply using the drives' mounting holes and some thermal paste to attach coolant channels to the side walls which could do double-duty as drive rails.Reply -

thestryker I'd imagine pretty much any improving the quality of air cooling would end up decreasing density which is problematic for datacenter. The biggest question I have regarding this is simplicity of swapping a failed drive, or lack thereof.Reply

The fact that they ended up seeing better reliability by keeping more consistent temps is interesting and something I'm going to keep in mind when I put together my replacement server. -

tmwrnj ReplyInvalidError said:Immersion cooling for HDDs sounds a bit overkill when drives only dissipate 10-15W each with most of that heat sunk into the cast aluminum frame. You could probably achieve most of the benefits by simply using the drives' mounting holes and some thermal paste to attach coolant channels to the side walls which could do double-duty as drive rails.

Unfortunately, that approach doesn't scale.

If you've got 60 drives per 4u chassis, that modest 10-15W per drive works out at 7,200W to 10,800W per rack. You can try to conduct that heat into the rack hardware, but it isn't going to go anywhere without a bunch of forced air. When you do blow that heat out of the rack then it has to go somewhere, which in a data center means the HVAC system. You're then using a whole bunch of energy to exhaust that air from the building or chill it and recirculate it.

Immersion cooling for HDDs sounds like overkill, but it's a potentially rational approach when you're putting tens of thousands of HDDs in the same room. The efficiency and reliability benefits might be outweighed by capital and maintenance costs, but it's a question worth serious consideration for customers like Meta. -

InvalidError Reply

What part of integrating liquid cooling into drive rails requires forced air?tmwrnj said:You can try to conduct that heat into the rack hardware, but it isn't going to go anywhere without a bunch of forced air. -

richardvday Reply

You're still reducing density is I believe what was meant. It most definitely would reduce the density depending on how thick they needed to be.InvalidError said:What part of integrating liquid cooling into drive rails requires forced air? -

InvalidError Reply

it is ~15W tops, cooling channels would need to be about as small as they can possibly be made without compromising structural integrity or becoming a clogging problem. If you go with immersion, you still need space between drives for coolant flow along with something to hold them in place, so I'd imagine the density would be quite similar.richardvday said:You're still reducing density is I believe what was meant. It most definitely would reduce the density depending on how thick they needed to be.

Except that according to BlackBlaze, their HDD failure rates go up when temperature is under 25C, so HDDs don't like being too cold either.richardvday said:Surprise ! Reducing heat leads to longer product life who would have thought 😂