EKWB Fluid Gaming A240 Liquid Cooling Kit Review

Why you can trust Tom's Hardware

Test Methods, Results & Conclusion

Test Bench Hardware

Our test bed for open loop cooling testing uses an i7-5960X with its two hottest cores disabled running at 4.2 GHz with 1.2V Vcore. The fans and pump are connected directly to the motherboard's headers. The fans and radiator are connected in a push configuration and are left outside the open case test bed. Temperature is measured under load of Prime95 v27.9, small FFTs, 12 threads. Temperatures are not measured until the loop heats up and reaches equilibrium.

For consistency’s sake, the exact same fans and pump used on the Slim 240 review were also used for the A240.

Comparison Products

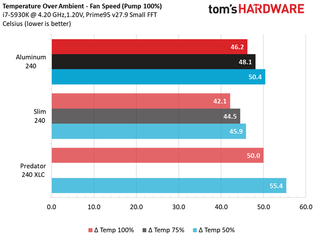

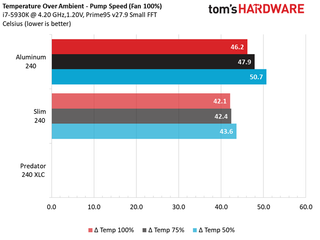

Temperature

We've started adding 75% fan speeds to our liquid loop testing to give you a more complete picture of the thermal curve of these coolers. As expected, switching to aluminum lowers the cooling capacity. At full fan speed, the A240 is a little behind the Slim 240 at 50% fans. It's still comparable to many AIO closed loop coolers, but we tend to expect custom loops to perform better.

Switching to focus on pump performance, it appears aluminum is a little more sensitive to flow rate than copper is. But since this uses the same SPC 60A pump, there's really no reason not to leave it at 100% speed with its low power draw and almost imperceptible noise level.

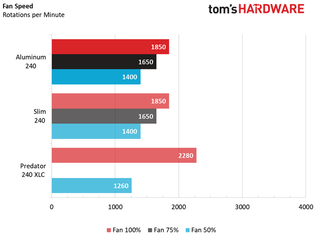

Tachometer

Fans and pumps typically have a slight speed variance in parts, even across fans of the same model line. In the interest of removing variables, we used the same fans and pumps as last time, meaning not just the same models, but the exact same parts as in the Slim 240 review. As such, the speeds were the exact same.

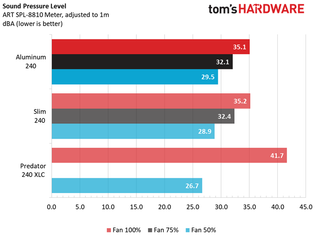

Noise

Just because we used the same fans and pumps doesn't mean the A240 should have the exact same noise level as the Slim 240. Different metals vibrate in different ways, so an aluminum radiator won't necessarily sound the same as a copper one. We can see the Slim 240 is measurably quieter at low fan speeds. Above 75%, they're indistinguishable.

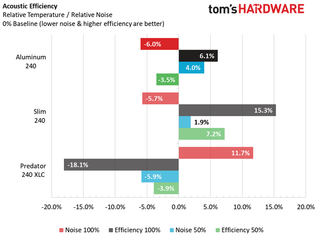

Acoustic Efficiency

With such similar noise levels, acoustic efficiency comes down to cooling performance. The Slim 240 takes the lead here convincingly. However, both these kits still outclass the Predator.

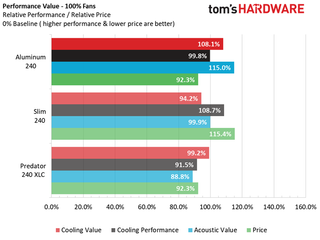

Performance Value

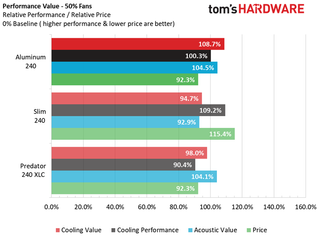

The A240 costs the same as the Predator but maintains lower temperatures at all speeds. Also, despite the Slim 240 cooling 10% better, its 15% higher price put it below the value curve, leaving the A240 as king of the value mountain in this matchup.

At 50% fan speed, the Predator makes up a lot of ground in the acoustic department, as its fans can spin down lower than the Slim or A240. The A240 actually increases its cooling value and maintains value above the Predator in every measurable way.

Final Word

Contrary to what we’ve been told, aluminum doesn’t need to be a dirty word in liquid cooling. Yes, it has its downsides. But as we've seen, those downsides aren’t as drastic as we’ve been led to believe.

Aaluminum doesn’t have the thermal conductivity of copper and doesn’t keep your CPU quite as cool. On our test bed, that amounts to about 4°C. That’s not insignificant, but it’s not usually a deal breaker either. It’s enough to make or break a heavy overclock right at the edge of thermal throttling, certainly. Those at moderate overclocks or lower will be largely unaffected.

The performance alone is enough to warrant an Approved award at this price point. When factoring in the expandability and customization an open loop offers over a sealed AIO cooler, this becomes some of the best cooling value in the liquid space. You could almost make the argument the A240 renders most other expandable AIOs obsolete. As an added benefit, you know you’re getting a single-metal cooling solution that won’t develop corrosion problems on its own. That’s not something you can say about every AIO out there.

The initial worry about the Fluid Gaming line was lack of expansion options, since buying a Fluid kit meant you were locked into aluminum only parts. That’s no longer a concern, as EK offers replacement parts for the CPU block, aluminum compression fittings, GPU block add-ons, and expansion kits for adding radiators. Plenty of other companies also offer aluminum radiators in various sizes, so you’re not tied to EK-only parts.

Sealed AIO coolers still offer the best total performance under $100. But if you’re already looking in the $140 range, we recommend spending the extra $20 to get the Fluid Gaming A240 kit along with the improved customization and expandability that comes with it.

MORE: Best CPU Cooling

MORE: How To Choose A CPU Cooler

MORE: All Cooling Content

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

-

Malik 722 what about the regular all-in-one solutions from the other brands which use cooper plate for heat transfer are they safe.Reply -

WyomingKnott Yes they are safe. They just have to be made with all copper parts. Heck, you could make one with silver for all the metal parts and it would be "safe," but it would be a waste of money.Reply -

lightofhonor I have the A240R for Vega cards. Works great, though can't cool both if both are OC and full load.Reply -

Lutfij It might be a cheaper alternative to get your feet wet for custom level watercooling but expansion options can and will be limited since not everyone makes aluminum waterblocks for every card on the market. Even EKWB have shut down their thinkcell programme since they couldn't keep track of the immense level of suggestions for various request/demands with a vast sea of SKU's for CPU's, motherboard's chipsets as well as monoblocks and lastly GPU's.Reply

FYI, corrosion inhibitors only slow down the process of galvanic corrosion or the liquid inside an AIO aren't actually water based but a special fluid concocted at Asetek's factory. -

Olle P The initial part about galvanic corrosion is somewhat flawed:1. To get galvanic corrosion there must be a direct metallic path between the two different metals in contact with the fluid. An aluminium radiator paired with a copper water block is no problem unless they're in direct electrical contact through the mountings.Reply

2. Galvanic corrosion is typically a very slow process. The only clear example of galvanic corrosion I've been able to find in water cooling is the CPU block provided with Zalman Reserator 1. It had a gold plated base mated to an aluminium housing, doubling the galvanic potential compared to copper.

Over the last few months I've been running a test to see the effects of galvanic corrosion. A piece of aluminium and a piece of brass in a plastic cup with mineral water (the top notch local tap water). The metal pieces are connected by a wire and I add more water every few days due to evaporation.

This far there's absolutely no sign of corrosion!

It would be horrible to use in a cooling loop though, because there's a lot of calcium being produced that would clog any cooling block. In fact: Most of the pictures found of what users seem to think is the result of galvanic corrosion in water cooling seems to be other substances (from the fluid) causing deposits.