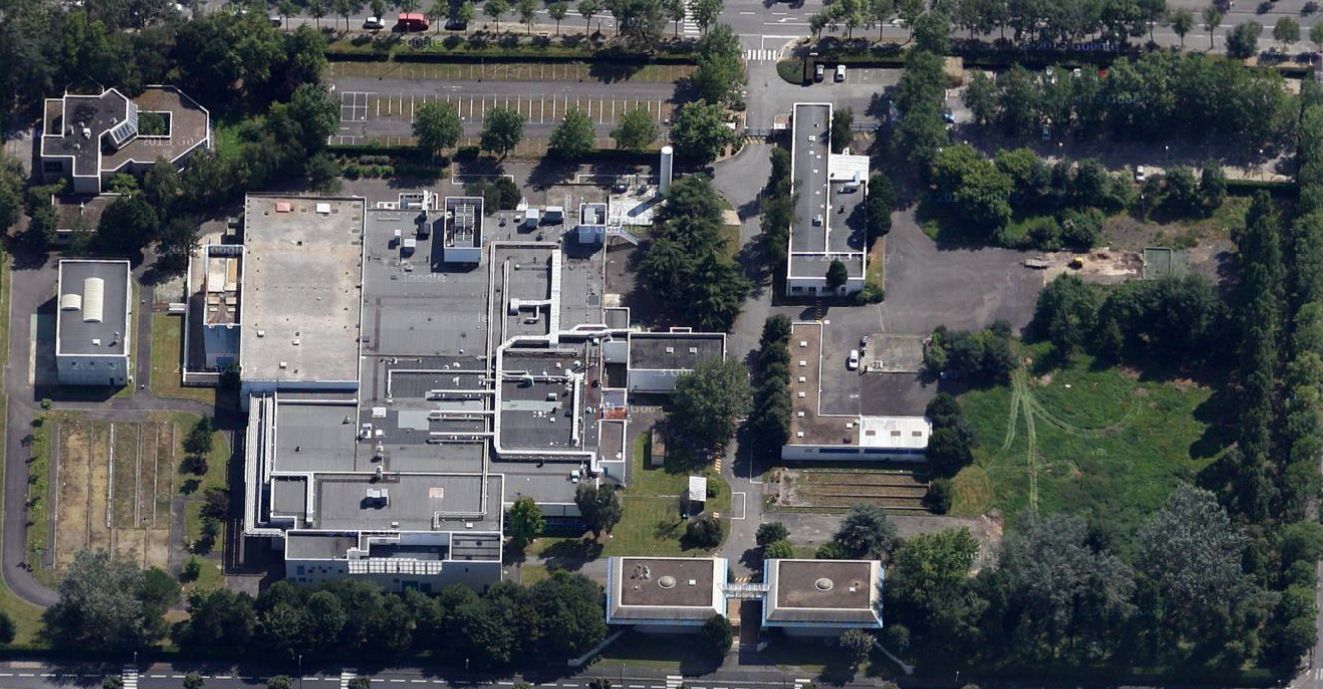

Tom's Hardware Visits STMicroelectronics In Rennes, France

History Of The Rennes Site

Once upon a time, life was painful indeed. In 2003, the Rennes plant’s front-end activity (wafer etching) was moved to Singapore. In the collective memory (and also according to Wikipedia), that meant the closure of the Rennes site. But as our photos show, the information propagated by the media at the time, announcing a complete shutdown of the plant, was false. The plant is still open, and its back end (hermetic die assembly, now its core business), is not new, nor is it the result of a repurposing after the move to Singapore. So it’s important to go back over the site’s history.

The Rennes site dates back to 1960s. Initially built by Fairchild, it was bought by SGS (Società Generale Semiconduttori) Microelettronica, an Italian semiconductor group that merged with France’s Thomson Semiconducteurs in 1987 to become SGS-Thomson. In 1998, Thomson SA withdrew from the company, which then became STMicroelectronics.

From the start, the Rennes site had a front-end activity that included the entire process of fabricating die on a wafer (implantation, diffusion, epitaxy, photolithography, metallization, and testing). In the 2000s, the fab was producing 150 mm (six-inch) wafers. The front end accounted for 90 to 95 percent of activity at the site. It was moved to Singapore in 2003-2004 under the impetus of an “economic rationalization.”

But the Rennes plant had also had back-end activity since its inception, and the assembly of chips for the aerospace market is not a recent operation at all; SGS began doing this in 1977. So, the activity has always existed. It wasn't a matter of “transforming” or repurposing it. But there was significant growth due to the increasing success of the back-end operation.

The 2003 Facelift

When the front end was moved offshore, the back end employed 44 people and accounted for five to 10 percent of the site’s business. In 10 years, STMicroelectronics multiplied that volume by a factor of eight, and now employs around 100 people.

The company owes its growth to heavy marketing and technological investments that increased its products’ presence on the aerospace market. Another key strategic move was its acquisition of European and American qualifications, making Rennes the only STMicroelectronics site able to product chips that can be sold on any aerospace market in the world.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

To optimize management of this growing business line, in 2006, Rennes was attached to the company’s site in Tours. It employs mostly production operators, but the company has also strengthened the technical teams. Today, there are two teams on the site, with a small additional weekend group needed for running the reliability tests, which last approximately 1000 hours (and up to 2000 and even 4000 hours for certain components). A night shift is being put in place to handle the increase in business.

The explosion of activity at the site is also related to some notable achievements. The French fab’s most recent exploit is the inclusion of chips from Rennes in the Mars rover Curiosity (and we were assured that the memory chips that were corrupted by cosmic radiation weren’t from their facility). The Rennes site is now indissociable with space.

Current page: History Of The Rennes Site

Prev Page Tom's Hardware Visits STMicroelectronics Next Page The Beginnings And Development Of The Rennes Back End-

Scionyde "The poor overall economic picture and pessimistic approach newspapers like to take in speaking of the electronics industry in France would lead you to think that that scenario is utopian at best."Reply

Maybe I'm missing something obvious, but isn't 'utopian' the exact opposite of the word you were intending to use there? -

vancedecker This is really cool. A totally unexpected article in the swamp of cell phone reviews and press releases, on other sites...Reply -

army_ant7 @ScionydeReply

I'm thinking that "utopian" was used in a way to mean something highly unachievable, unlikely, or unfeasible. I'm not sure how that would apply though and I can't speak for the author. I'm not sure if this helps explain that... -

vaughn2k "Once the die is mounted in its case, the wires must be soldered to connect the chip and the pins. This operation can seem archaic compared with the processors used in PCs or smartphones, whose dies are connected via direct contact with bumps on their epoxy carriers." - The wire is not soldered to the pins but welded using an ultrasonic force + power - or Ultrasonic wirebonding. The head of the tool where the wire (either it is an Al or Au wire) comes out, generates this combination of ulrasonic energy to be able to connect the die pad and pins. If an Au wire is used, the process adds a thermal property, which is also called thermosonic bonding. CPU and smart phone chips (and virtually all chips) uses the same process. However, most assembly uses Au wire or Cu wire, instead of Al wire. Another process that is used o intorconnect chips to substrate is called flip-chip bonding, or soldering or ILB (inner lead bonding), and then going into the process of underfilling, to protect these interconnects.Reply -

vaughn2k "The testing also checks for the presence of particles inside the packages" - It is called PIND test (Particle Impact Noise Detection). It is in MIL-STD 883E method 2020.8 -- ;)Reply -

WyomingKnott What double-post? I don't see one.Reply

More practically, you should be able to delete your own post by going to the forum version of the comments. Click on the blue icon with quotation marks, full-edit the duplicate post, and there should be a delete button. -

Hey, and what about Goodram? Isn't it the last european based manufacturer of ram, flash, ssd etc? Can you please make a small trip there as well?Reply