Micron says New York chipmaking fabs still on track according to its latest timelines — accelerates second fab in Idaho and reallocates CHIPS Act funding (Updated)

No delays after all

UPDATE 11/11/2025: Micron has provided Tom's Hardware with the latest version of its Environmental Impact Statement (EIS) that details the plans for the company's fab complex in New York. As it appears, there are no delays compared to the timelines that Micron announced in mid-2025. As expected, construction of the first fab will start in late 2026, will be completed in 2028, and the fab will come online in circa 2030. We have updated this story in accordance with the latest version of the EIS

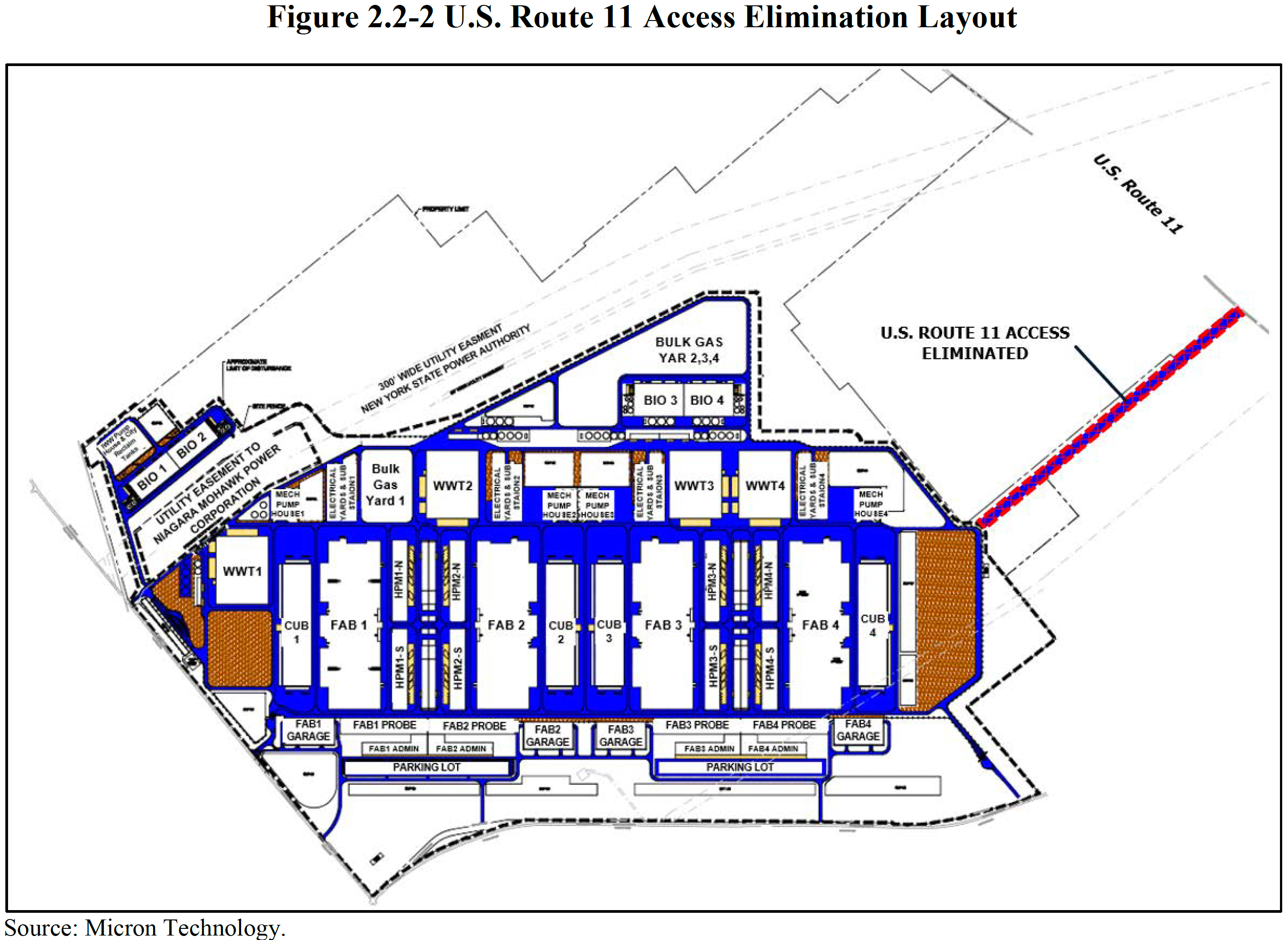

Micron has published the final draft Environmental Impact Statement (EIS) for its fabs near Clay, New York, which reveals the final schedules for construction of four fabs starting late 2025 through 2041. Meanwhile, a report from Syracuse indicates that the company is accelerating its Idaho fabs and reallocating CHIPS Act funding to that facility.

"Micron remains focused on bringing leading-edge memory manufacturing to New York, and we appreciate the strong partnership with federal, state, and local authorities," a Micron statement supplied to Tom's Hardware reads.

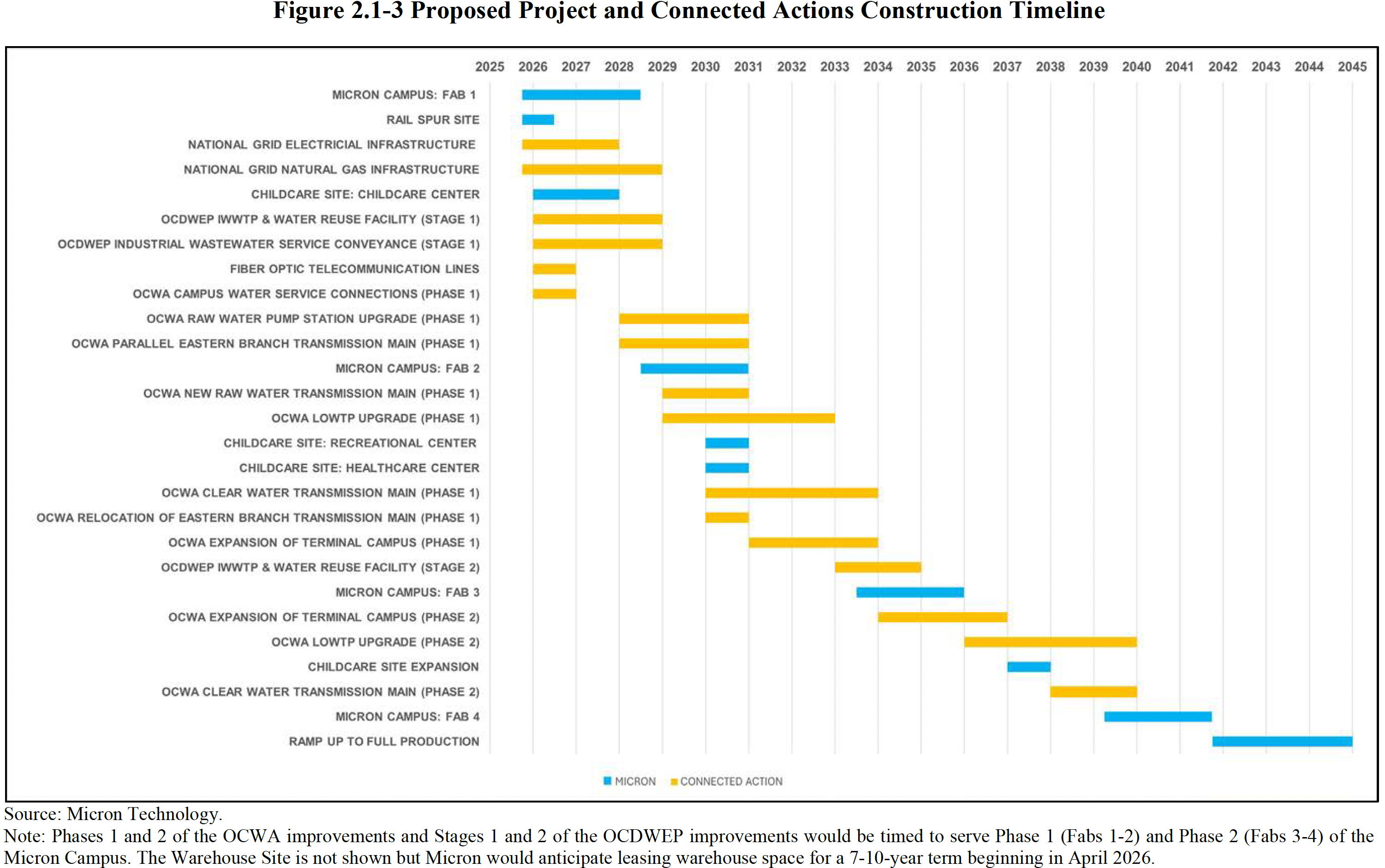

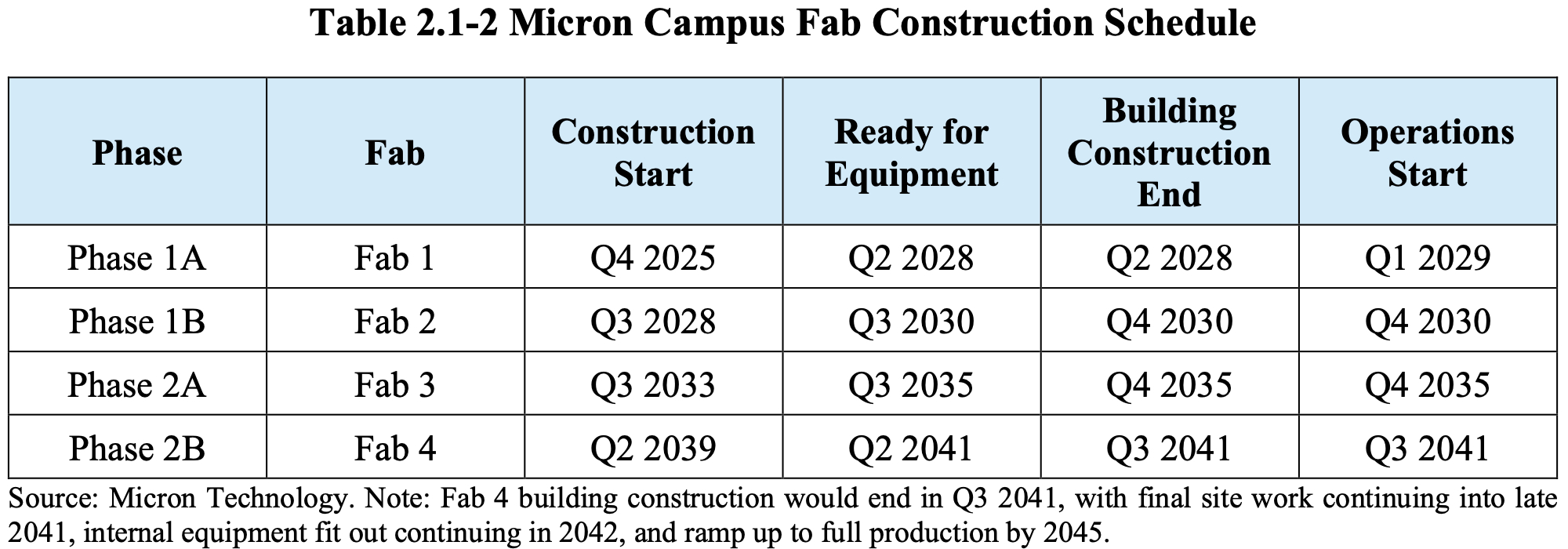

According to Micron's official draft EIS document released back in June and the latest draft EIS published in November, the construction phase for the first fab (Fab 1) would start from late 2026 (after a year of preparations that start in late 2025, according to the company's U.S. expansion plan unveiled on July 1, 2025) and will last till the second half of 2028, or early 2029. It usually takes 12 to 24 months to fully equip a fab, depending on various factors; hence, it is reasonable to expect the first fab to start DRAM production sometime in 2030, five years later than initially expected. Yet, Micron believes it can partly equip its Fab 1 in three quarters and begin operations in Q1 2029.

The same environmental documentation pins Fab 2's construction start to the second half of 2028, Fab 3's construction start to the second half of 2033, and Fab 4's construction start to the first half of 2039. This way, the Micron Clay campus will be fully built and ramped to full production by 2045, which is five years behind schedule.

"Micron would mobilize for initial site preparation for the Proposed Project beginning in the fourth quarter of 2025, with the first two DRAM manufacturing facilities (Fabs 1 and 2) estimated to be operational by 2029 and 2030, respectively, and the remaining fabs (Fabs 3 and 4) estimated to be operational by 2035 and 2041," a statement by Micron from the EIS submitted in June reads.

Micron reportedly acknowledged an amendment to its $6.1 billion CHIPS Act funding agreement with the U.S. Department of Commerce, as the company is reportedly bringing forward its ID2 facility in Idaho. The two Idaho facilities — one existing and one newly planned — will be completed ahead of those in Clay, which means that there is a strategic reshuffling of project priorities in place.

As part of the alleged realignment, Micron redirected about $1.2 billion of its federal grant from New York to Idaho, reducing Clay's share from $4.6 billion to $3.4 billion. The company reportedly indicated that the update was consistent with evolving project requirements under the federal agreement. Local authorities, including Onondaga County Executive Ryan McMahon, reportedly attributed the delay of Micron's New York campus to widespread labor shortages and the longer construction cycles that have become.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The realignment of the projects in America probably does not affect Micron's ultimate goal to produce 40% of its DRAM output in the U.S. as the company prioritizes one project after another, not delaying new fabs altogether. Meanwhile, prioritization of the fab ID2 will have a positive effect on Micron's output of HBM memory in the U.S., as the company also intends to build an advanced packaging facility for HBM and other types of memory that require stacking and advanced packaging in Idaho.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.