Build Your Own (Physical) 3D Models

Liquid Plastic Fills To Fill The Mold, Continued

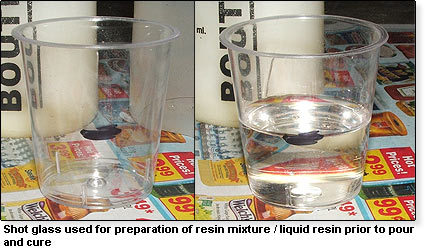

Once the resin has been poured into the mold, it is ready to remove in approximately ten minutes. While this time is suitable for removal of the part, full cure can take an additional 24-48 hours to complete. Utilizing a silicone mold for a model of this type is superior to other types of two part molds such as urethane. Molds made from urethane require a special release agent, which prevents the resin from bonding to it. Nearly nothing will stick to silicone, including paint. If the base of your model requires a different color than the resin, you can actually paint the mold, pour the resin and the paint will become attached to its surface.

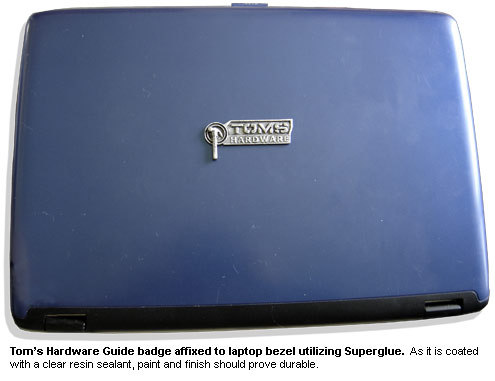

To match the original badge on my Toshiba notebook and provide a little contrast, I've decided to paint the finished product silver with a protective and clear resin coat. A black undercoat over the white model will increase the contrast of additional paint layers. I've followed this coat with a silver base, a "wet wash" of black, and finally drybrushed the logo with the original silver base paint. The resin seal was applied by spray in a small paint booth, free of dust, to provide a smooth finish. As the resin is a plastic I've simply used superglue to attach it to my laptop bezel, which bonded instantly.

Conclusion

The great thing about making a 3D model is that it can be rescaled to any size in the physical realm, limited only by the axis dimensions of the machine it is being created on. Thus, small models can be turned into bigger ones, or vice versa. This reuse is very practical, especially for client branding purposes - the same development cycle can be integrated into nearly any end product, whether it is a 3D animation, paperweight, keychain or door sign.

Working with 3D is a cool hobby and can open the door to entrepreneurial pursuits or a great career in many fields other than game creation. Modern graphic processors like the ATI X1000 or GeForce 7 models are revolutionizing manufacturing and visualization technology.

At Tom's Hardware Guide we tend to pay a lot of attention to the "flash whiz bang" of new technology related to gaming and eye popping speed tests. It's inspiring to see the industry advance outside of the game market, and see how graphics engines are being applied to achieve practical results in areas once dominated by more traditional methods.

Join our discussion on this topic

Speak out in the Toms's Hardware reader survey!

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Liquid Plastic Fills To Fill The Mold, Continued

Prev Page Peeling Back The Rubber - There Is The Mold